Patents

Literature

41results about How to "Meet preparation needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

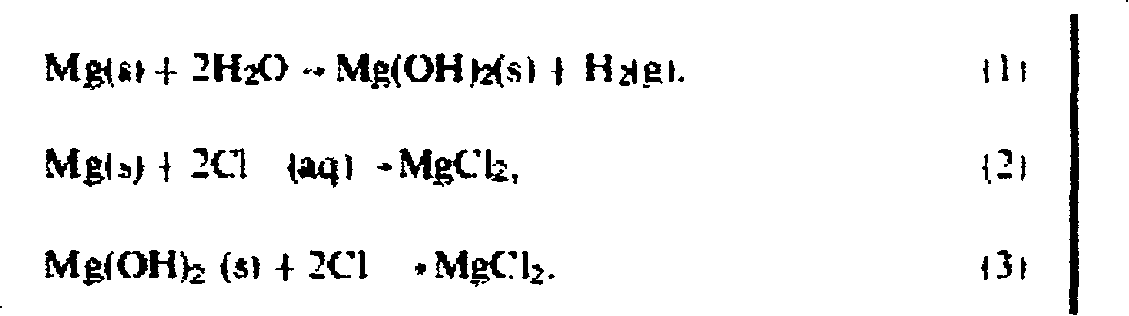

Biodegradable magnesium alloy blood vessel rack

The biodegradable magnesium alloy blood vessel rack consists of magnesium in 60-95 wt% and other metals, including RE, for the rest. Metal magnesium as the basic material has excellent tissue compatibility and blood compatibility, and the added other metal, including RE, elements raise and improve the comprehensive performance, especially mechanical strength, plasticity, degradability and biocompatibility. The magnesium alloy blood vessel rack has tensile strength of 200-300 MPa, elastic module of 10-50 GPa, elongation at break of 2-10%and degrading half life of 6-18 weeks. Most of the degraded metal ions are drained through renal tubules while small part being utilized by human body.

Owner:LIAONING YINYI BIOTECH CO LTD

Preparation method of nano calcium fluoride for self-lubricating tool material

InactiveCN102583486AHigh purityComplete crystal formCalcium/strontium/barium fluoridesNanotechnologyAlcoholSolvent

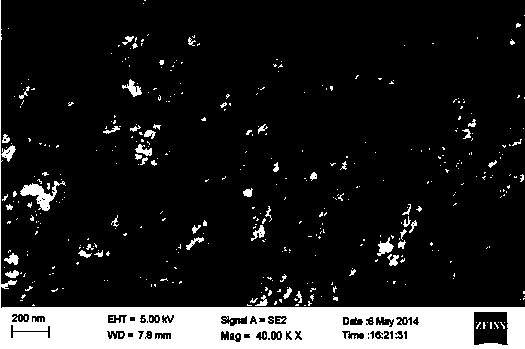

The invention relates to a preparation method of nano calcium fluoride for a self-lubricating tool material. According to the preparation method, an ultrasonic reduction method is adopted. The preparation method comprises the following steps of: preparing calcium nitrate and ammonium fluoride serving as raw materials into aqueous or alcohol solution respectively; adding PEG 6000-abslute ethyl alcohol composite solvent; performing ultrasonic dispersion; mixing the dispersed calcium nitrate solution and the ammonium fluoride solution under ultrasonic and stirring conditions; and reacting, aging, centrifuging, cleaning and drying to obtain nano calcium fluoride powder. The prepared nano calcium fluoride has the particle size of 15-50 nm and has high purity, complete crystal form, high crystallinity, uniform size distribution and high dispersion. The preparation method also has the advantages of simple technical process, convenience for operation and low equipment requirements.

Owner:QILU UNIV OF TECH

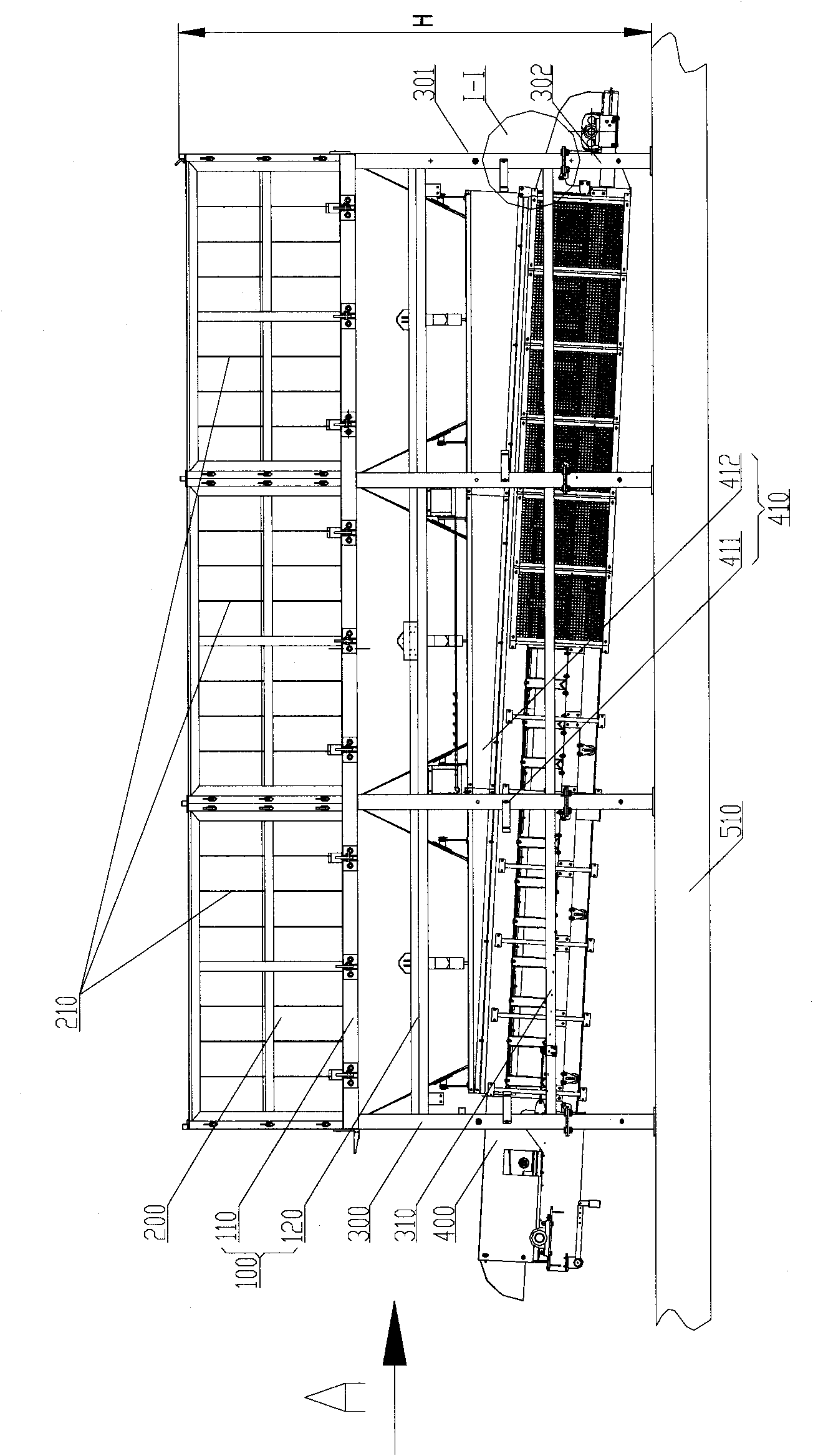

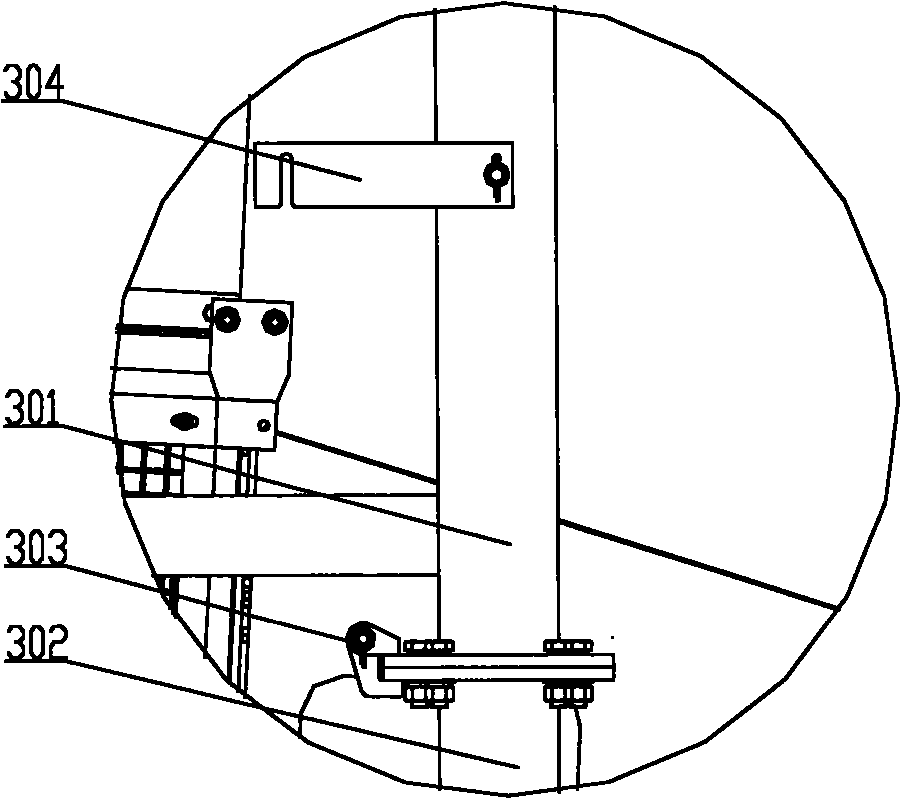

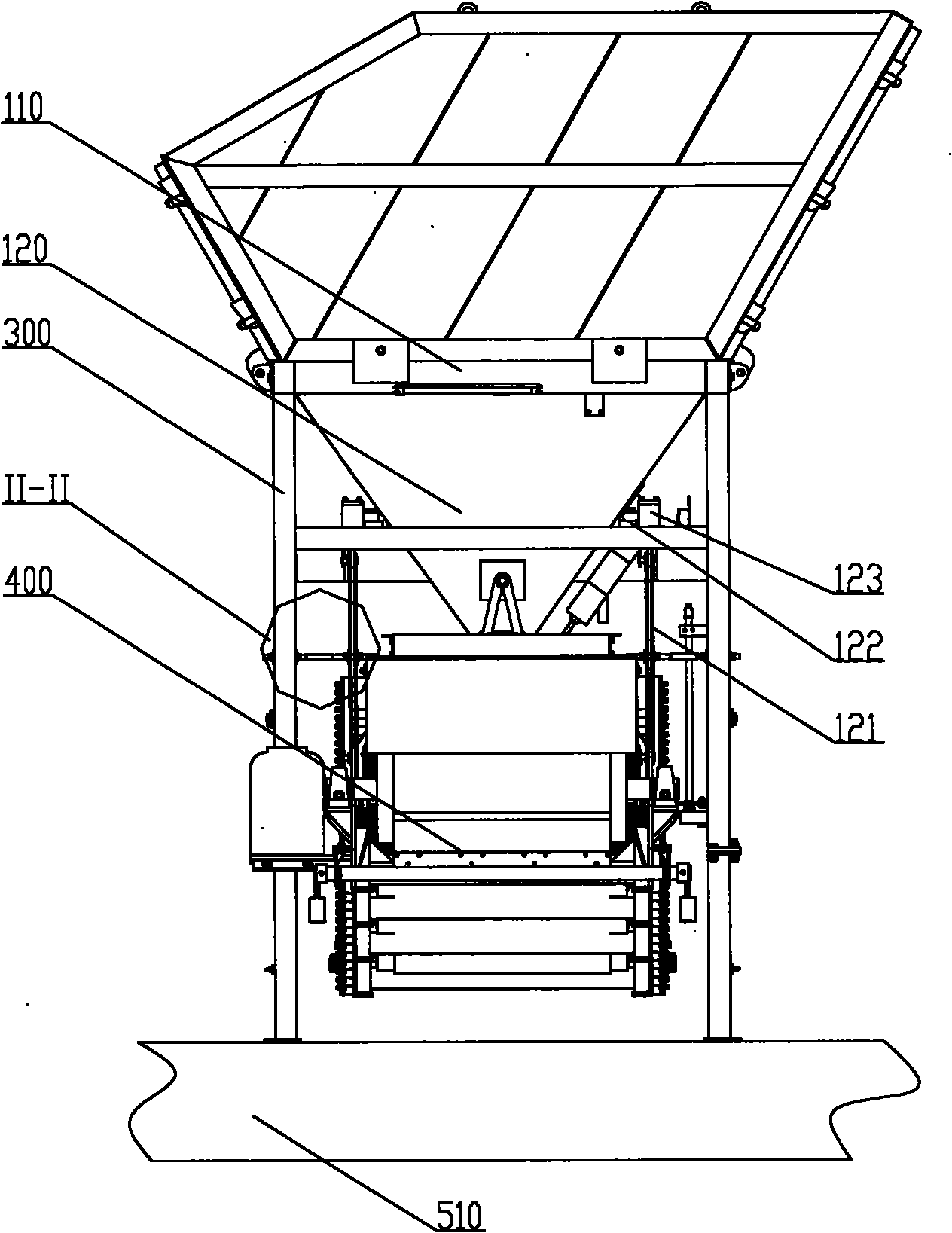

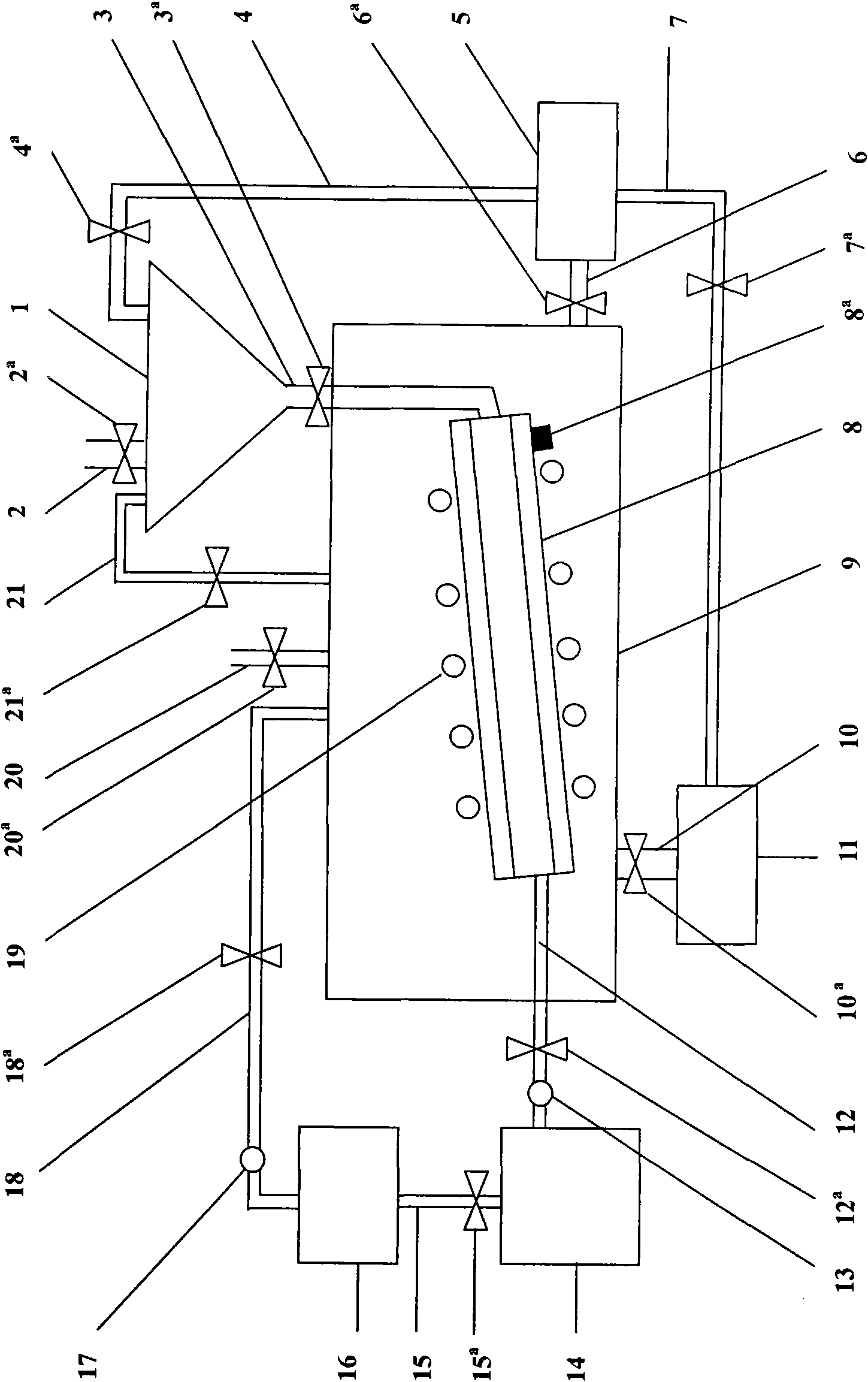

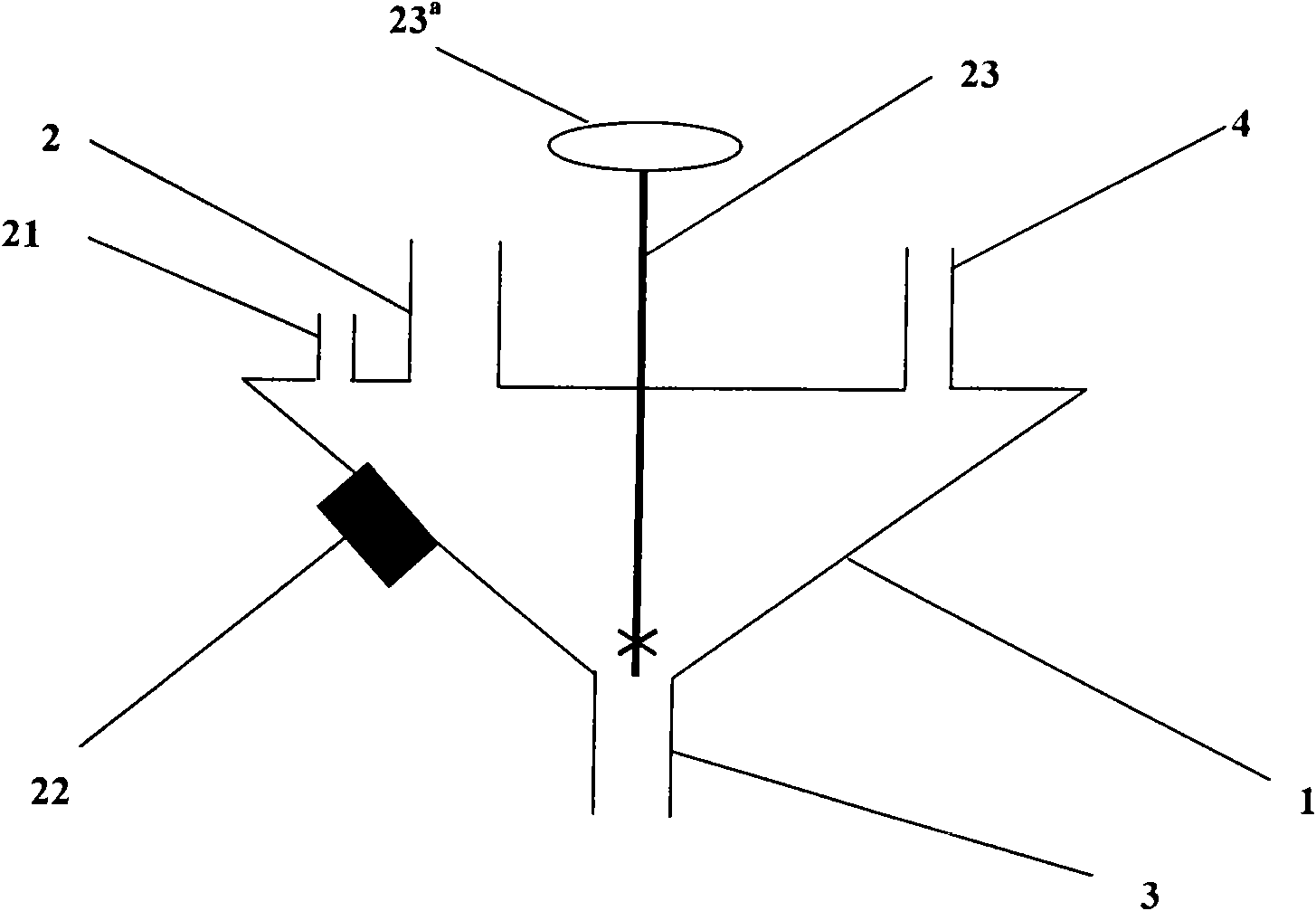

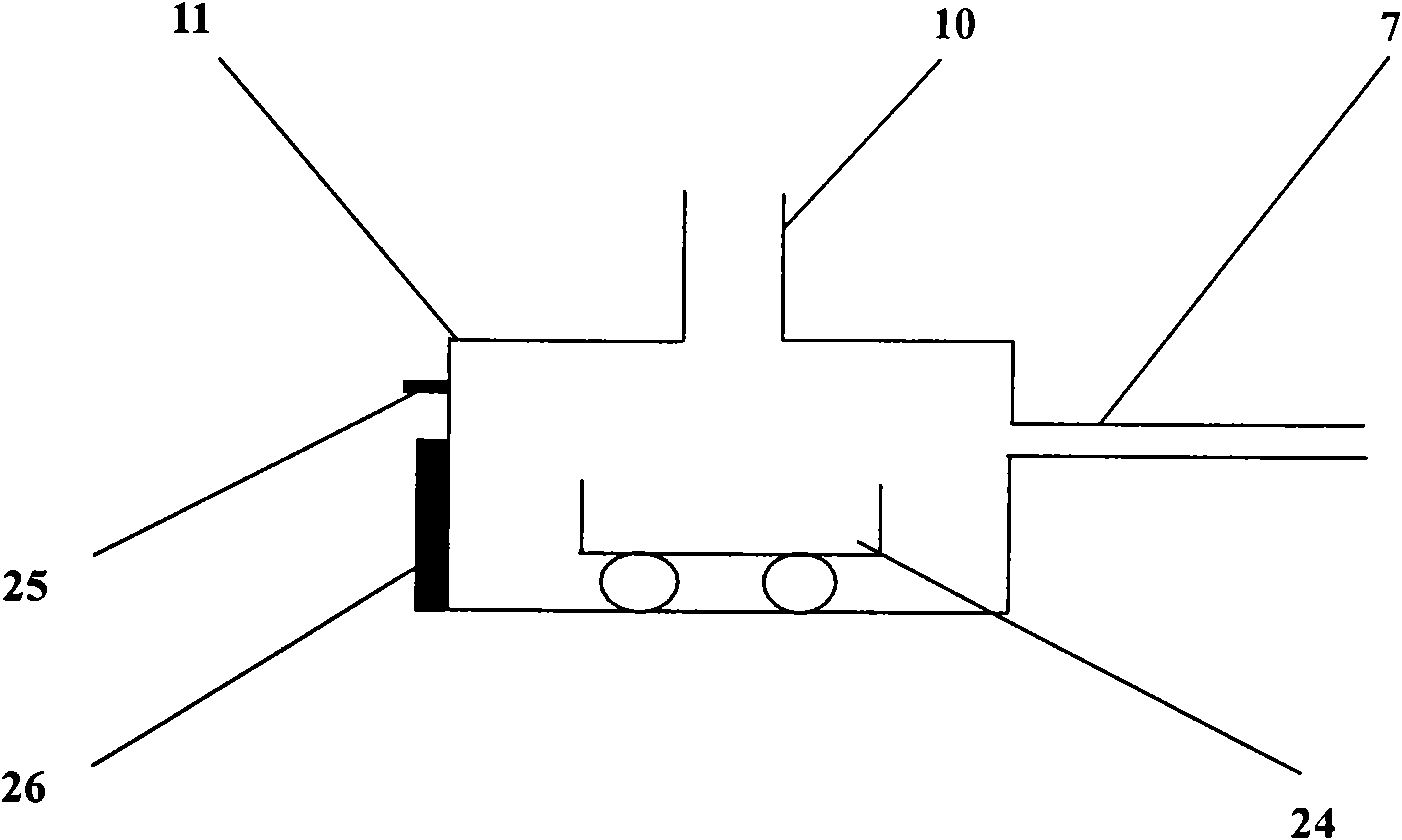

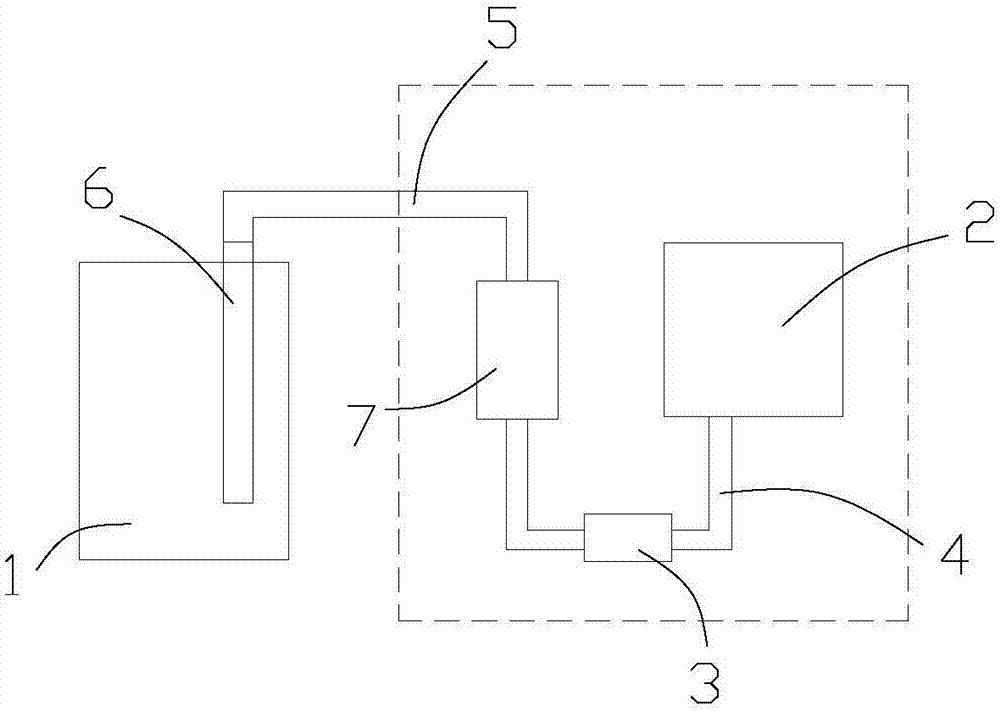

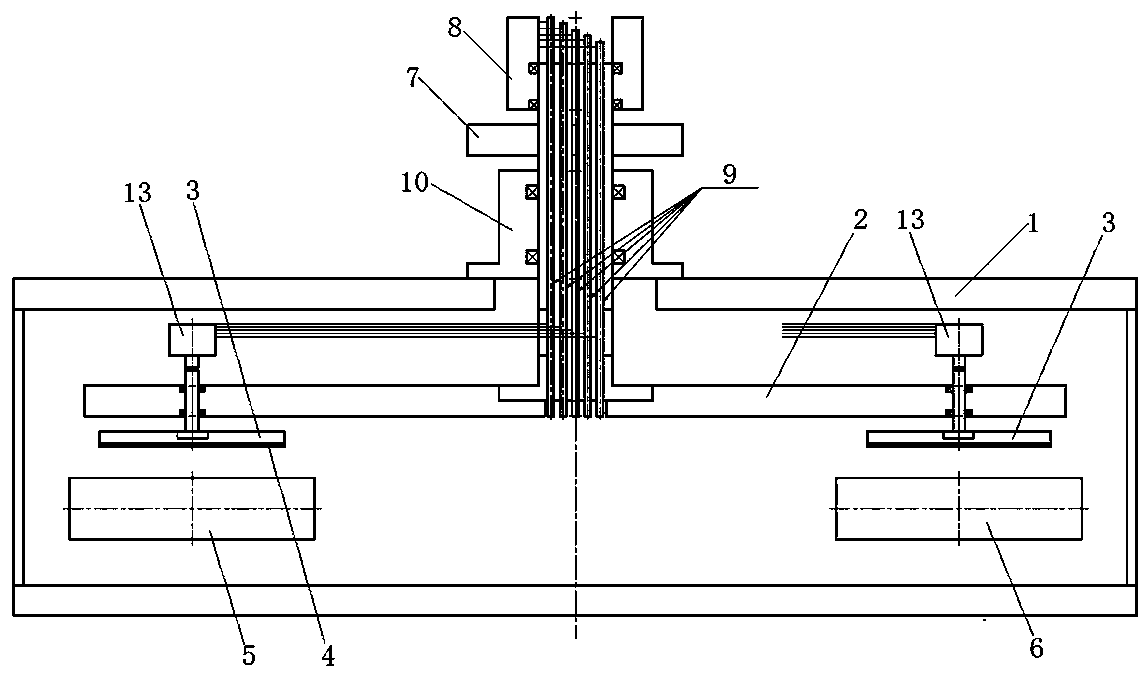

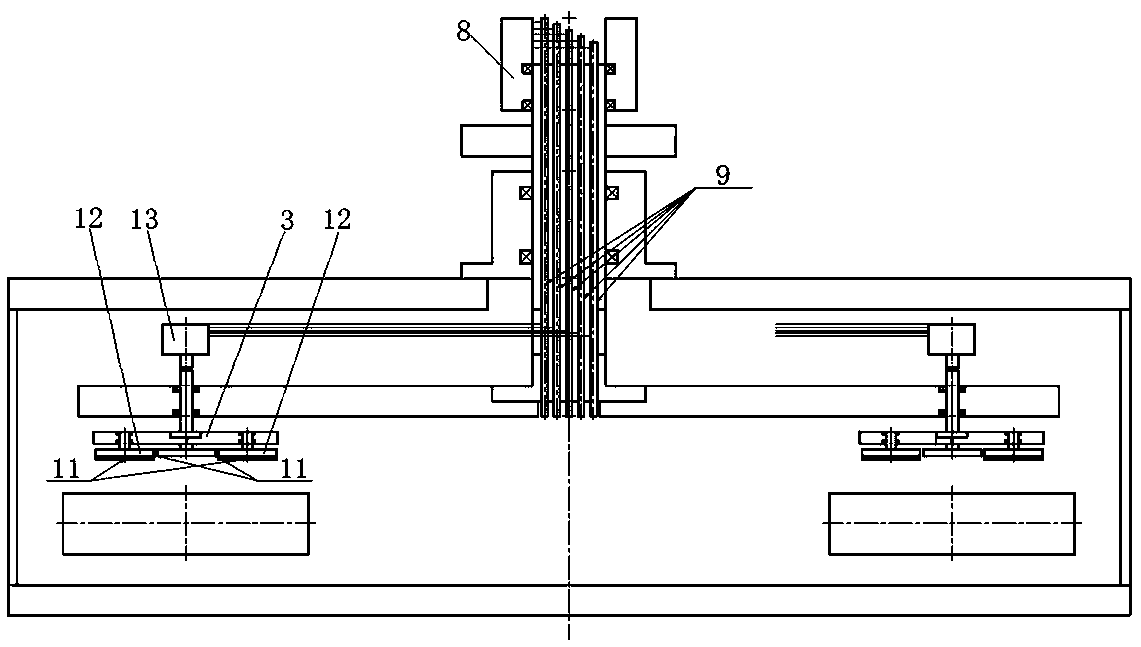

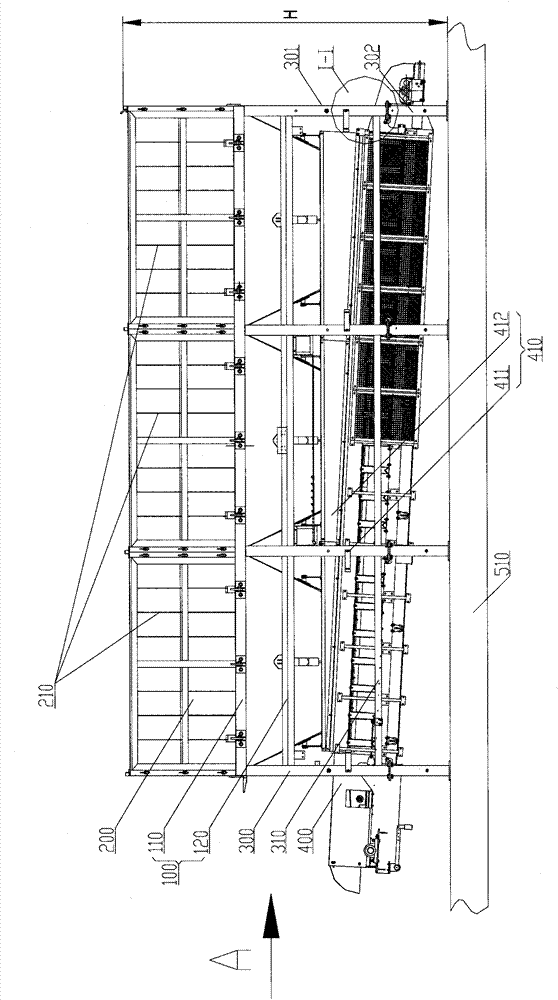

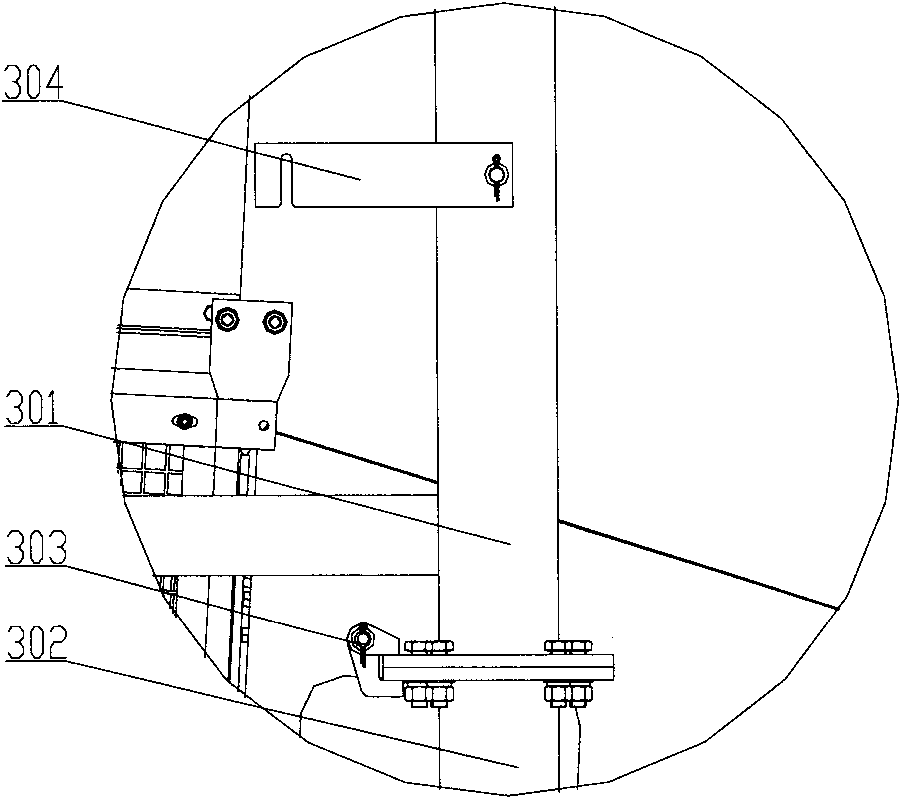

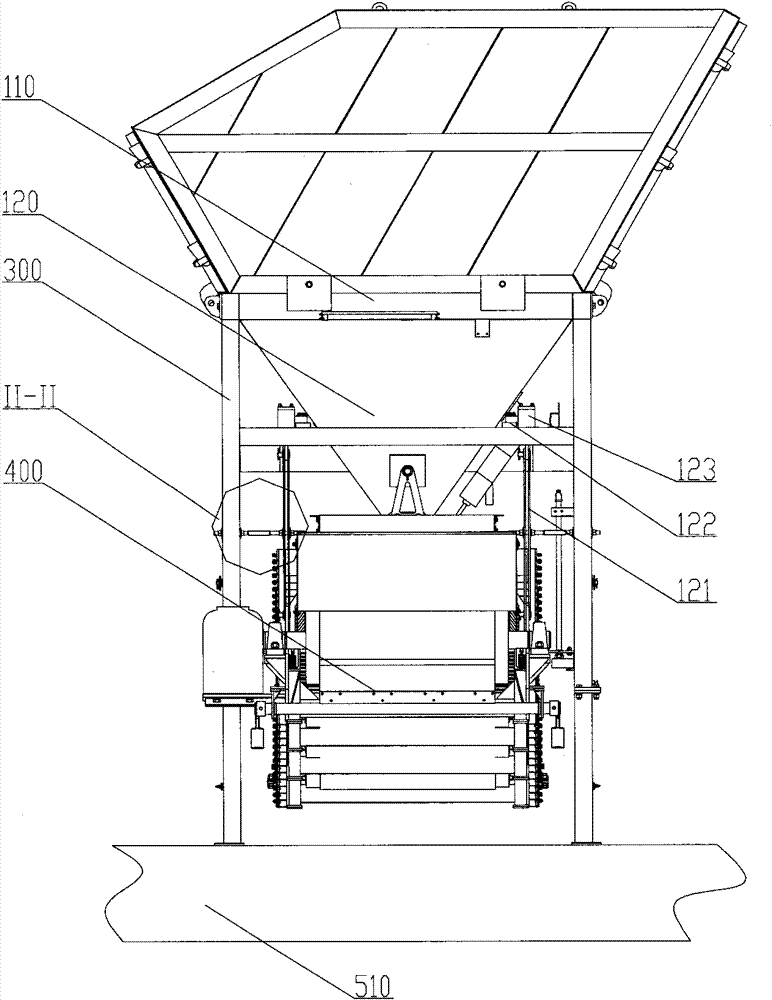

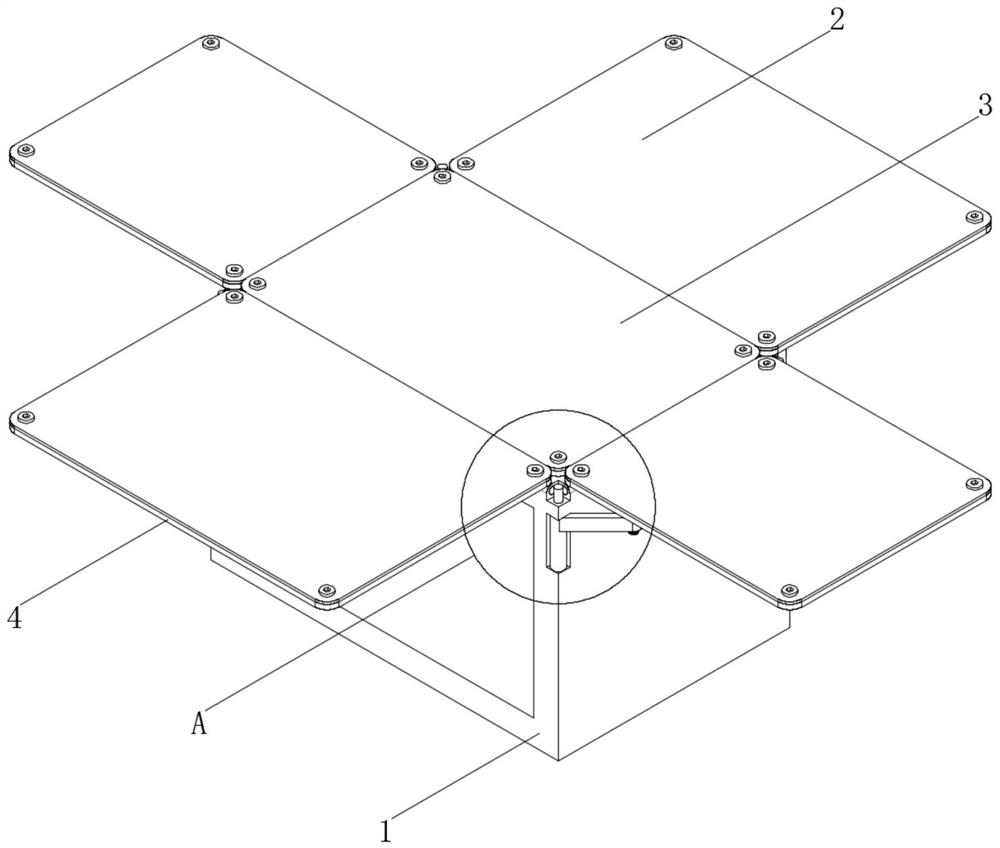

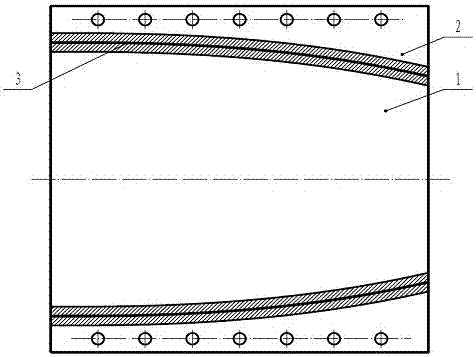

Mobile concrete mixing plant and batching machine thereof

ActiveCN101837612AGood transfer performanceReduced form factorSold ingredients supply apparatusMixing operation plantEngineeringBatch machine

The invention discloses a mobile concrete mixing plant and a batching machine thereof. The batching machine comprises a batching machine main body, a conveyor and a plurality of supporting legs, wherein the batching machine main body is supported on the preset base through the supporting legs. Compared with the prior art, the batching machine has a working state and a conveying state, wherein in the working state and the conveying state, the conveyor is suspended under the batching machine main body through suspending parts; when the working state is switched to be the conveying state, the vertical height of the supporting legs is reduced and the outline of the batching machine is reduced; in the conveying state, because the outline of the batching machine is smaller, the batching machinemain body does not need to be separated from the conveyor and materials do not need to be conveyed respectively before transfer and transportation and the batching machine has better transfer and transportation performance; and at the same time, in the working state, the batching machine has a bigger outline size so as to meet the requirement of the mobile concrete mixing plant on the preparationof concrete.

Owner:SANY HEAVY IND CO LTD (CN)

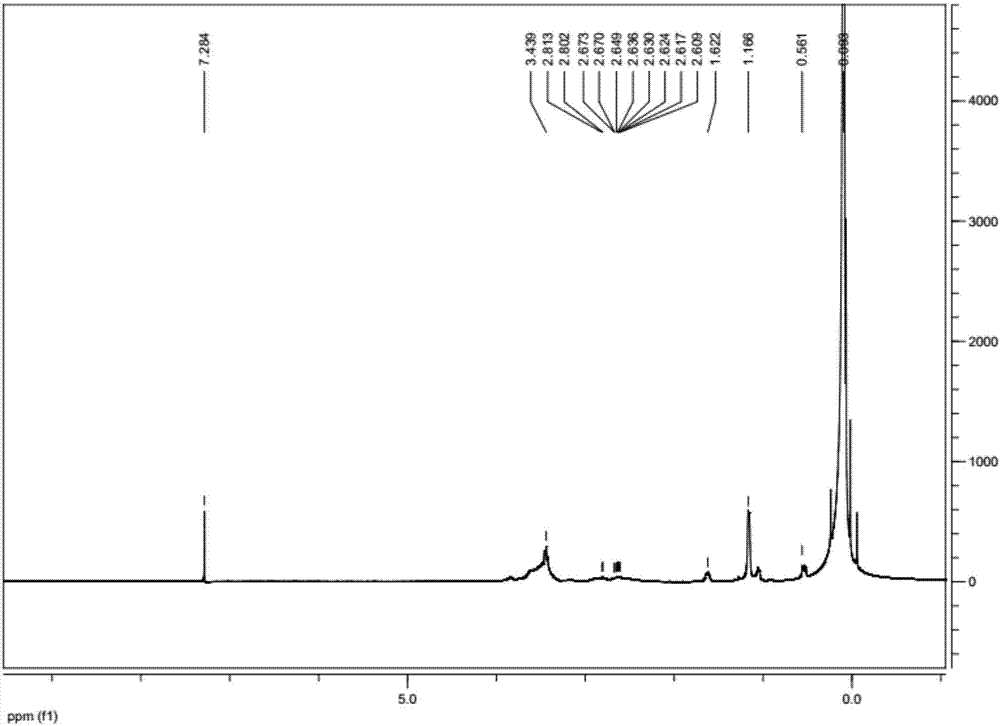

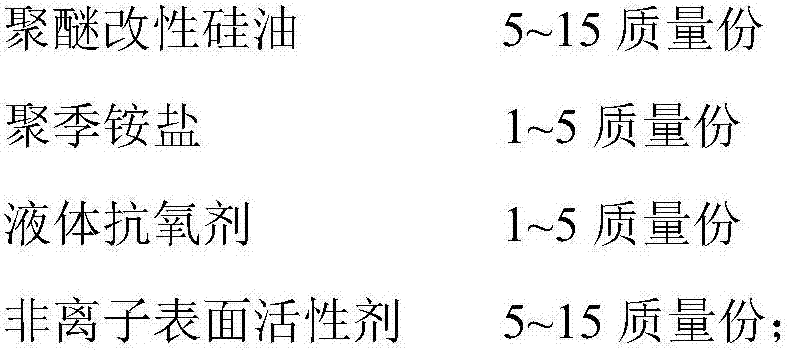

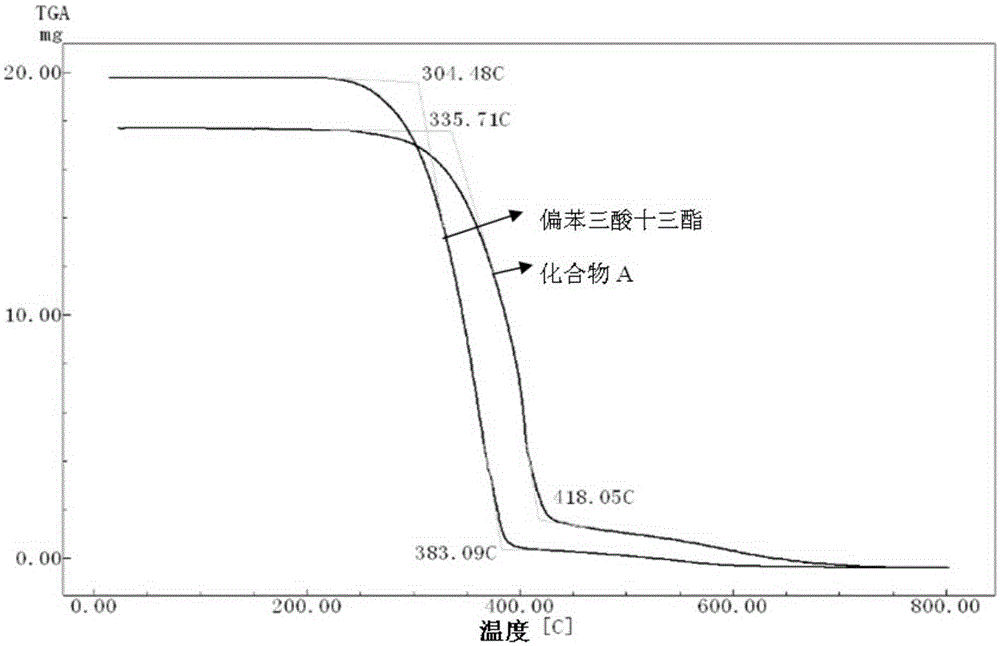

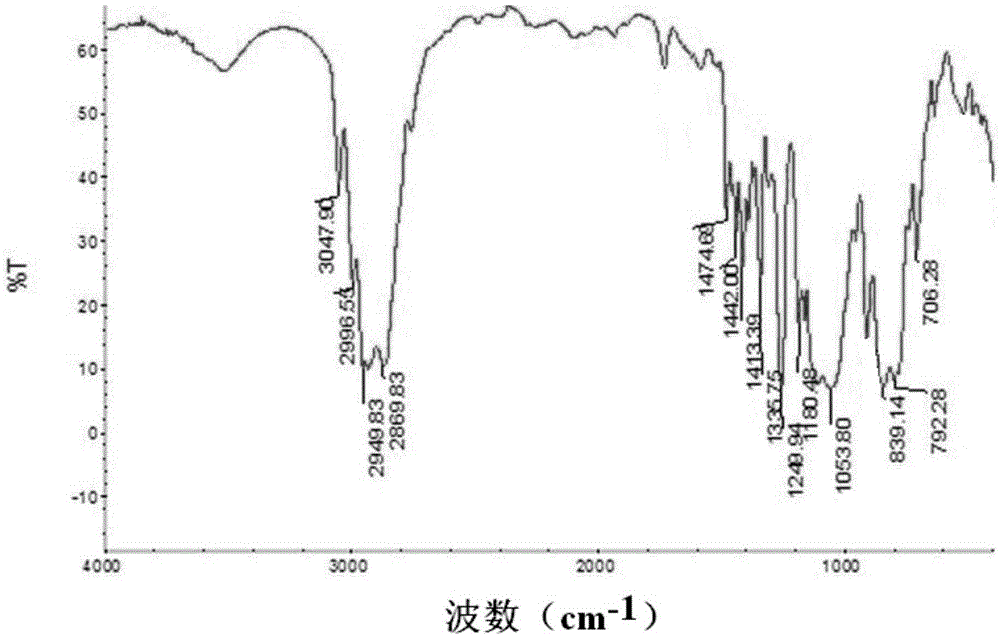

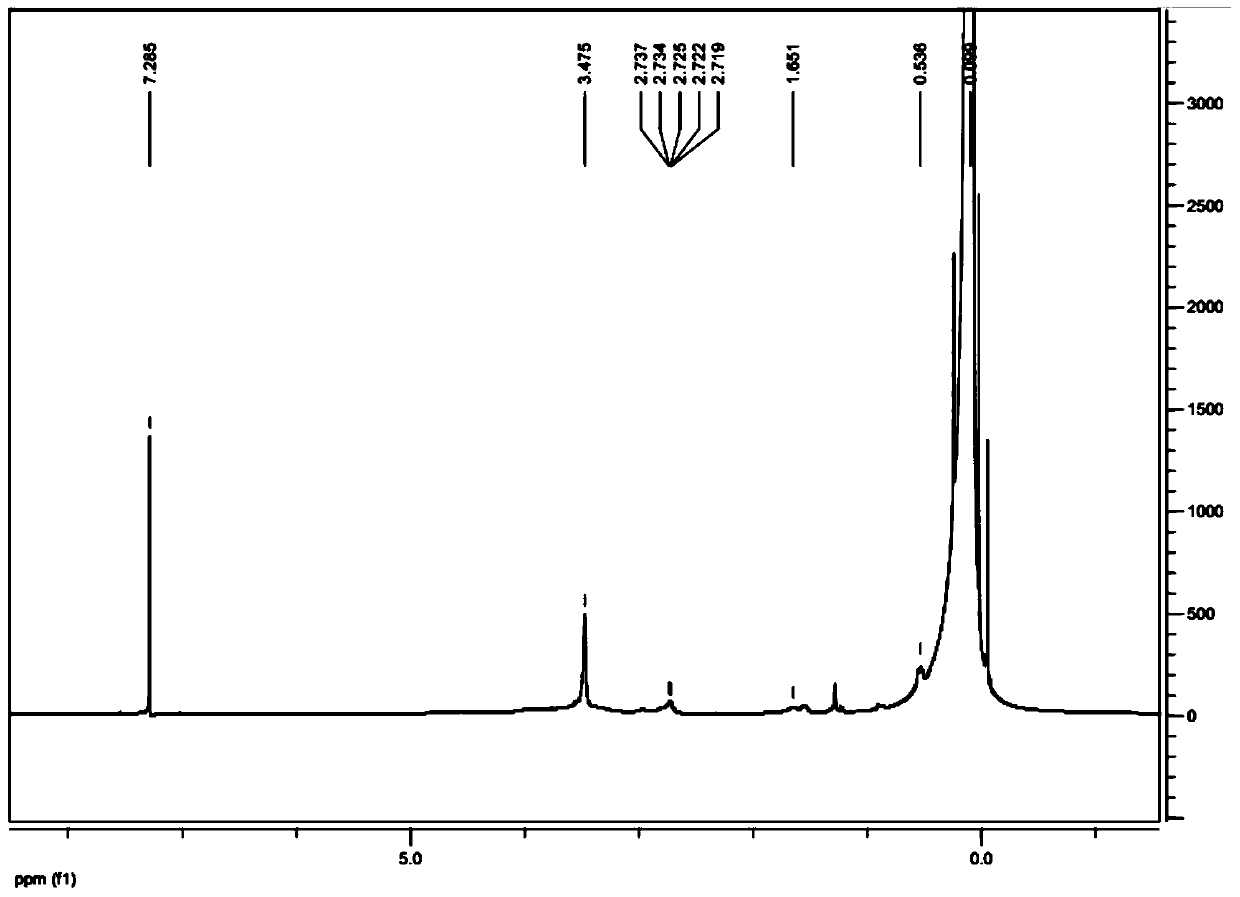

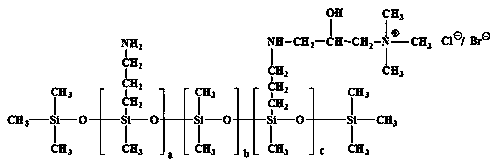

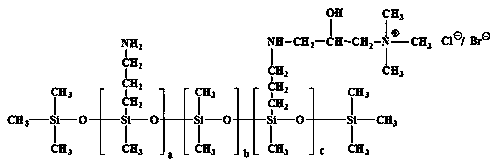

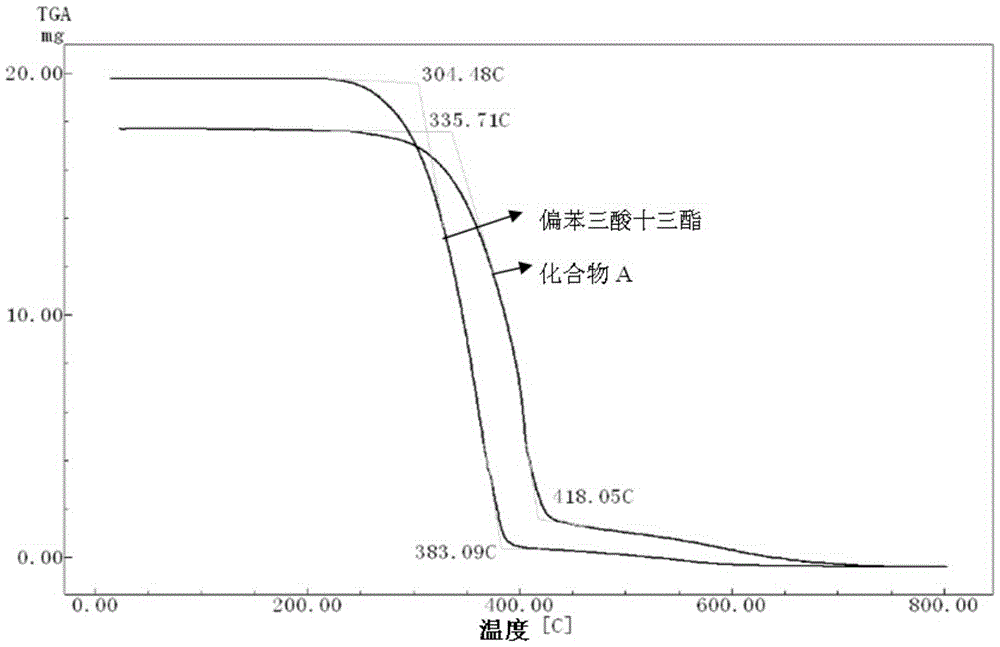

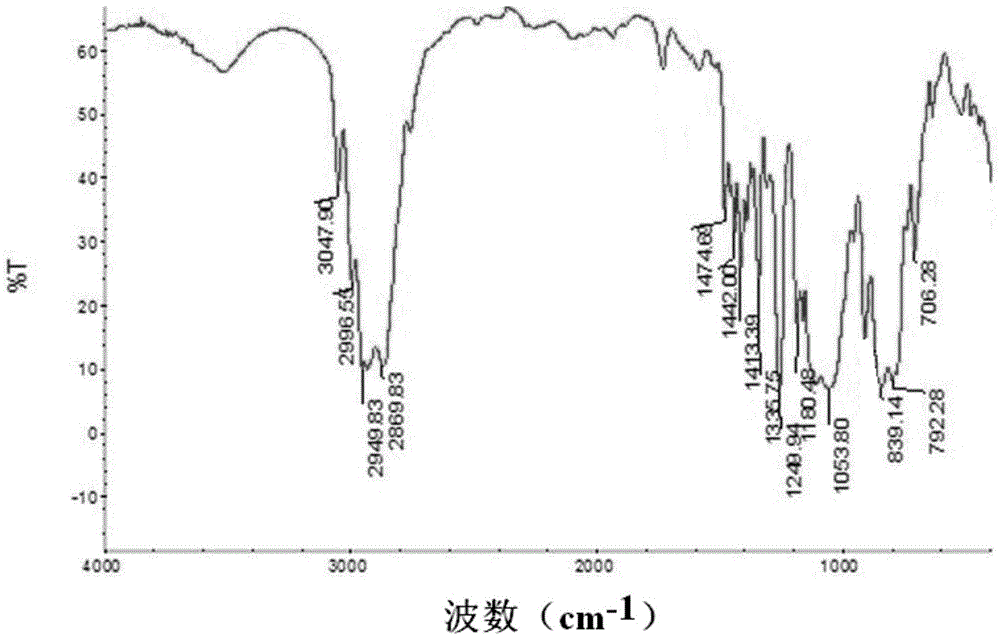

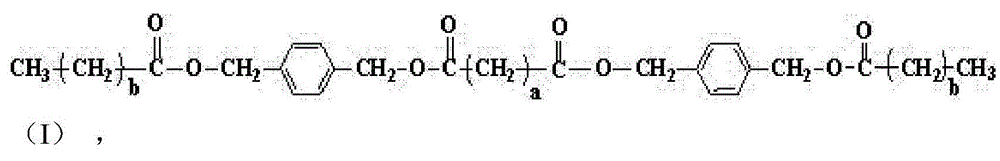

Carbon fiber oiling agent for dry spray wet spinning technology and preparation method thereof

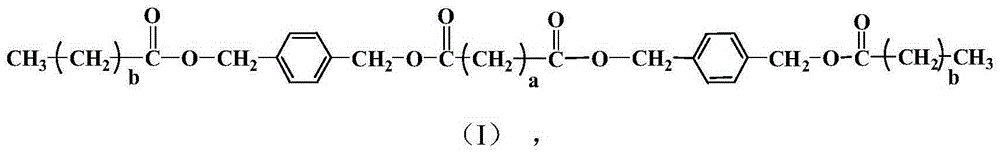

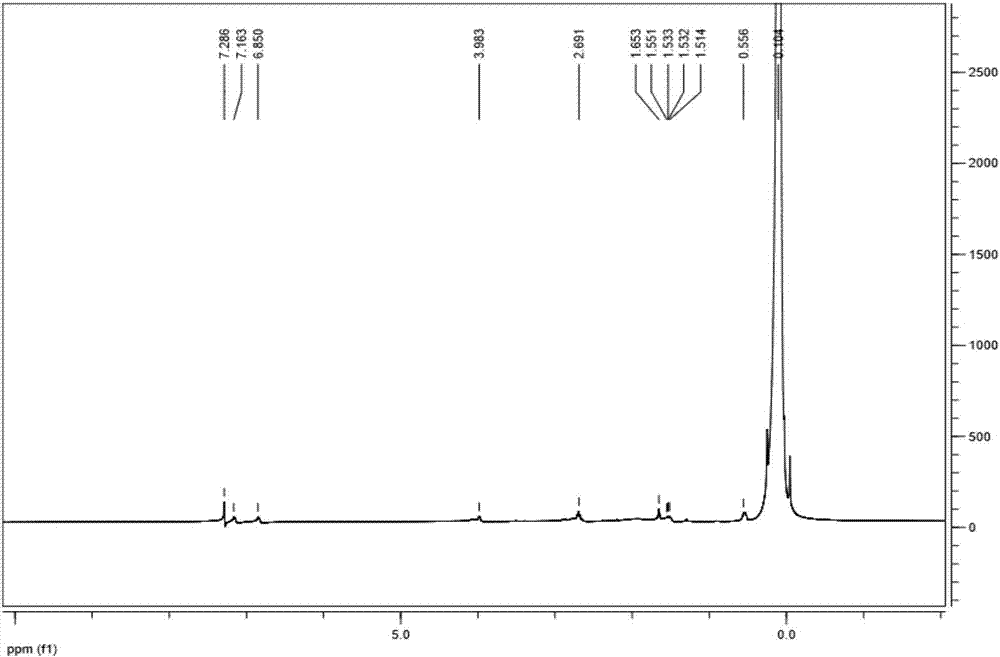

The invention relates to a carbon fiber oiling agent for a dry spray wet spinning technology and a preparation method thereof. The oiling agent comprises the following components in parts by weight: 65-75 parts of compound A shown as formula (I), 5-15 parts of polyether modified silicone, 1-5 parts of a polyquaternium anti-static agent, 1-5 parts of a liquid antioxidant and 5-15 parts of a surfactant. The invention solves the problems of roll banding, embrittlement under high temperature, and the like, of the oiling agent in the present dry spray wet spinning carbon fiber preparation process, meets the preparation requirement of the carbon fiber based on the dry spray wet spinning technology and increases the carbon fiber quality.

Owner:新元化学(山东)股份有限公司

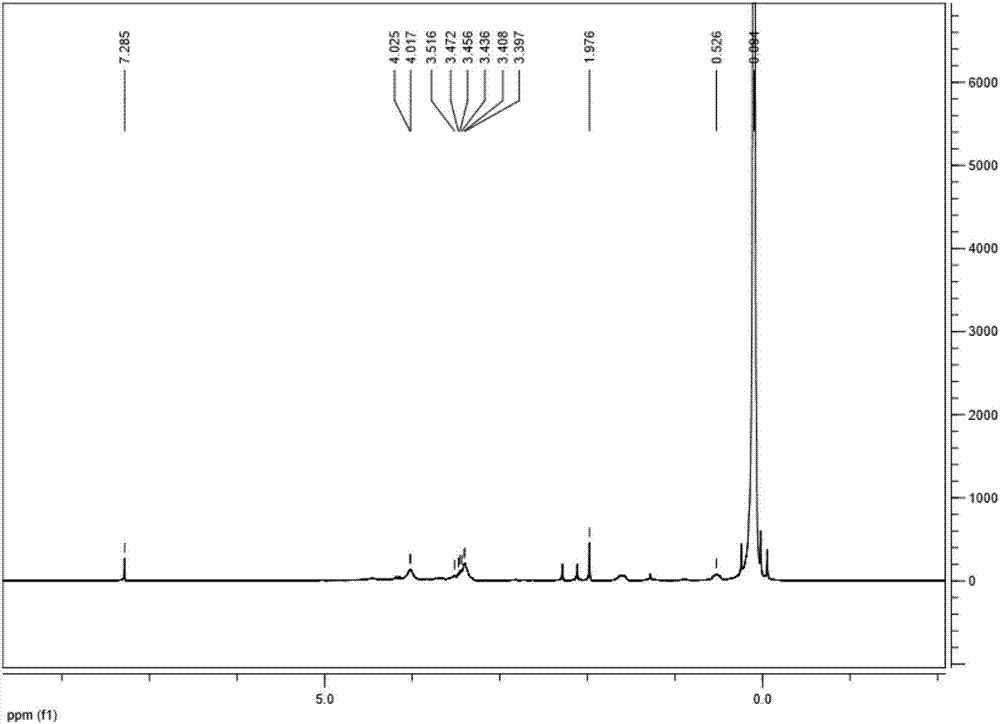

Carbon fiber oiling agent with non-silicon oiling agent and silicon-containing oiling agent compounded for use and preparation method of carbon fiber oiling agent

ActiveCN105297446AImprove heat resistanceGood heat resistance and lubricitySilicon organic compoundsPreparation from carboxylic acid halidesSide chainSurface-active agents

The invention relates to a carbon fiber oiling agent with a non-silicon oiling agent and a silicon-containing oiling agent compounded for use and a preparation method of the carbon fiber oiling agent. The carbon fiber oiling agent is obtained by compounding the non-silicon oiling agent and the silicon-containing oiling agent. The non-silicon oiling agent is prepared from, by mass, 100 parts of high heat-resisting compound A, 1-5 parts of antioxygen and 20-30 parts of surface active agent. The silicon-containing oiling agent is prepared from, by mass, 100 parts of side chain aminopropyl modified silicon oil, 3-10 parts of matter B and 20-30 parts of surface active agent. The carbon fiber oiling agent solves the problem of insufficient heat resistance of an existing oiling agent in the high-performance carbon fiber preparation process, and the non-silicon oiling agent and the silicon-containing oiling agent are matched for use, the preparation need of high-performance carbon fibers under different technological conditions can be met, so that the quality of the carbon fibers is improved.

Owner:新元化学(山东)股份有限公司

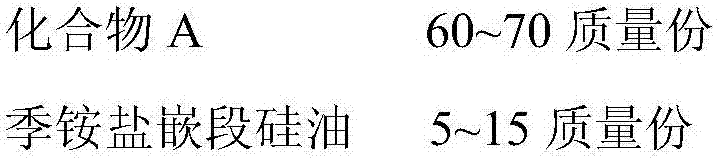

Large-tow carbon fiber oiling agent

ActiveCN107190514AMeet preparation needsImprove heat resistanceCarbon fibresHeat resistant fibresFiberCompound a

The invention relates to a large-tow carbon fiber oiling agent. The large-tow carbon fiber oiling agent is prepared from the following components in parts by mass: 60 to 70 parts of a compound A, 5 to 15 parts of quaternary ammonium salt block silicone oil, 1 to 5 parts of a liquid antioxidant and 10 to 20 parts of a surfactant. By adopting the large-tow carbon fiber oiling agent provided by the invention, the problems in a current large-tow carbon fiber preparation process that an oiling agent is stuck in a roller and has poor heat resistance, the anti-static electricity property is not lasting, and the like are solved; unification of properties including high attachment, high anti-static electricity property, low roller sticking property, high heat resistance and the like is realized by the single oiling agent; the requirements of preparation of large-tow carbon fibers are met, and the quality of the carbon fibers is improved.

Owner:新元化学(山东)股份有限公司

Preparation method of self-lubrication material nanometer calcium fluoride for ceramic cutting tool

InactiveCN104229853AHigh purityComplete crystal formMaterial nanotechnologyCalcium/strontium/barium fluoridesPolyethylene glycolCeramic knife

The invention relates to a preparation method of a self-lubrication material nanometer calcium fluoride for a ceramic cutting tool. The preparation method comprises the following steps: (1) weighing calcium nitrate and ammonium fluoride, respectively placing in a beaker, adding distilled water and anhydrous ethanol, to obtain a calcium nitrate liquid with content of calcium nitrate being 1mol / l, and an ammonium fluoride liquid with content of ammonium fluoride being 2.2-3.2mol / l; (2) weighing a certain amount of polyethylene glycol (PEG6000) dispersing agent with molecular weight of 6000, adding the ammonium fluoride liquid so that the mass fraction of the polyethylene glycol in the liquid is 1-2%; performing ultrasonic dispersion for 10-15min, thoroughly dissolving, to obtain a polyethylene glycol-ammonium fluoride complex liquid; and (3) placing the polyethylene glycol-ammonium fluoride complex liquid into a magnetic stirrer, setting the reaction temperature of 15-50DEG C, dropping the calcium nitrate liquid in the polyethylene glycol-ammonium fluoride complex liquid through a separating funnel, appropriately adjusting the speed to be close to flow-in speed (drop-in speed is 1-30ml / min), wherein the stirring frequency under which no liquid is splashed is the best. The prepared nanometer calcium fluoride powder is high in purity, complete in crystal form, high in crystal degree, uniform in size distribution, and good in dispersity.

Owner:QILU UNIV OF TECH

Preparation method of insoluble anode plate for wastewater reuse

InactiveCN106119899AUniform current distributionMeet preparation needsElectrodesMetal foilHydrometallurgy

The invention relates to a preparation method of an insoluble anode plate for wastewater reuse. The method is characterized in that a metal plate is selected as a matrix, at least one precious metal coating is prepared, and the matrix is coated with the precious metal coatings through the pretreatment procedure. Meanwhile, the adopted pretreatment procedure comprises a thermal treatment and etching process, and the matrix is of a sheet structure. Thus, a common anode screen can be partitioned into several sections to be processed, and the effects that current distribution of the anode screen is uniform in the electroplating process, and a cathode plate electroplating layer is made to be more uniform are ensured. The method is wide in application range, can meet the preparation demand of crack-free structure dimensionally stable anodes, and can also be applied to electroplating, wet metallurgy and metal foil preparation. The matrix is in the sheet shape, the dimension of the matrix can be designed flexibly according to the use demand, and the matrix can be customized based on actual treatment demands.

Owner:SUZHOU JIDAO ELECTRODE TECH

High-fluidity concrete and preparation method thereof

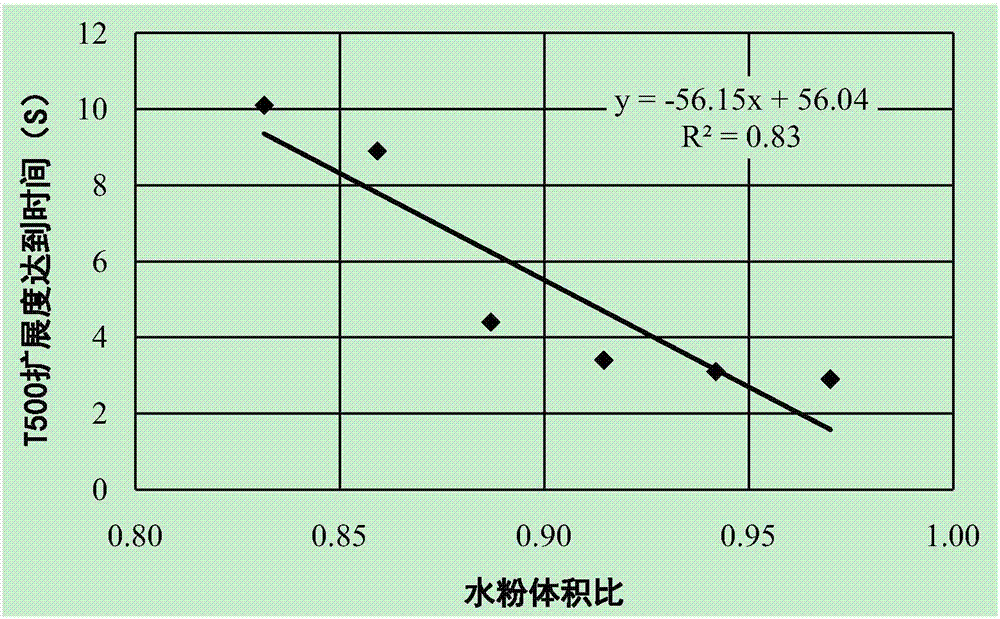

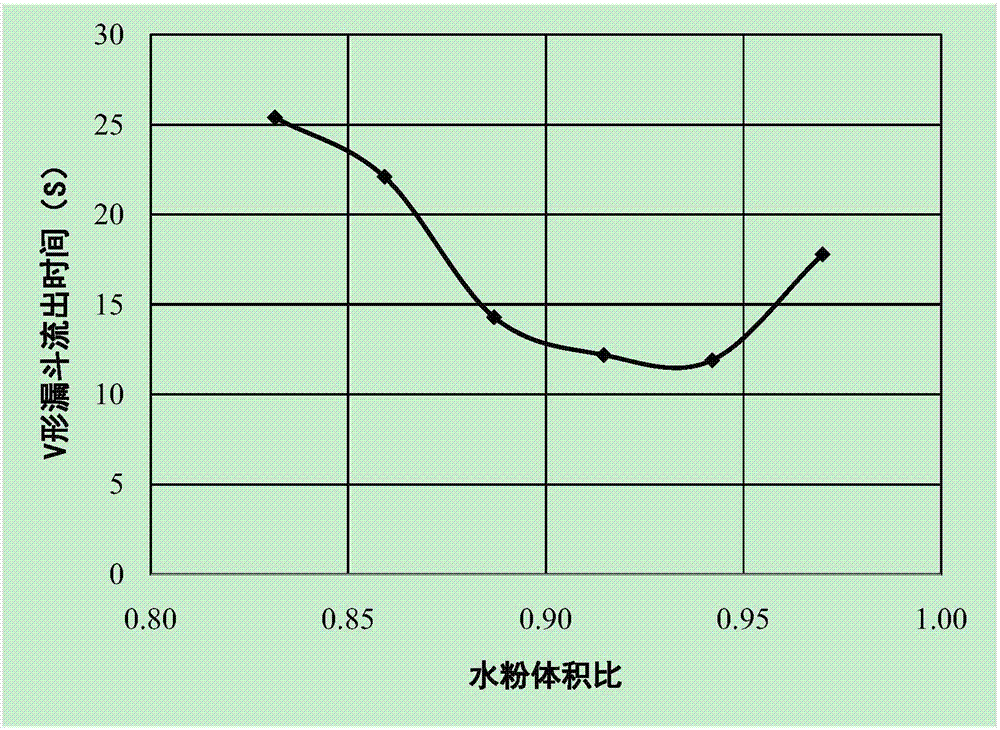

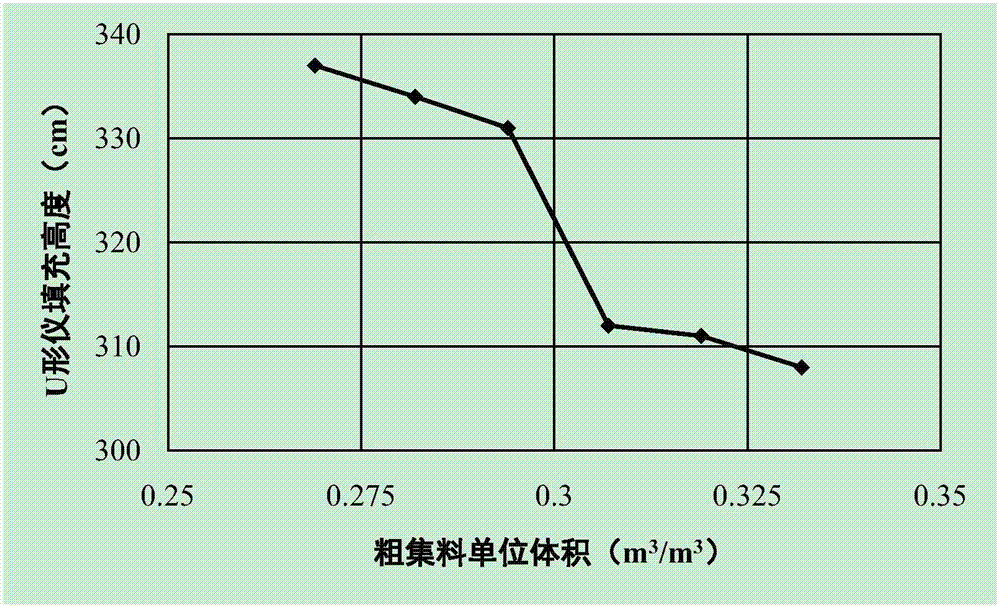

The invention relates to high-fluidity concrete. The high-fluidity concrete is prepared from coarse aggregates, fine aggregates, powder materials, additives and water, wherein the powder materials comprise cement, coal ash and mineral powder; the additives comprise a water reducing agent and a thickening agent; the usage amount of the coarse aggregates is 0.275 m<3> / m<3>-0.300 m<3> / m<3> in a unitabsolute volume ratio, the water consumption is 166.4 kg / m<3>-176.8 kg / m<3>, the water powder ratio is 0.83-0.97, the consumption of the powder materials is 510 kg / m<3>-540 kg / m<3>, the sand ratio is53-55%, and the mixing amount of the additives accounts for 0.95-1.1% of the consumption of the powder materials by weight. The performance index requirements for the high-fluidity concrete for filling a steel-shell immersed tube compartment are determined according to a concrete pouring construction technology of the steel-shell immersed tube compartment, and a high-fluidity concrete proportioning construction method for being suitable for a steel-shell immersed tube is formed through the research on the rules that the fluidity, the strength, the hydration heat and the shinkage of the concrete are affected by the change of various compositions.

Owner:CCCC FOURTH HARBOR ENG INST +1

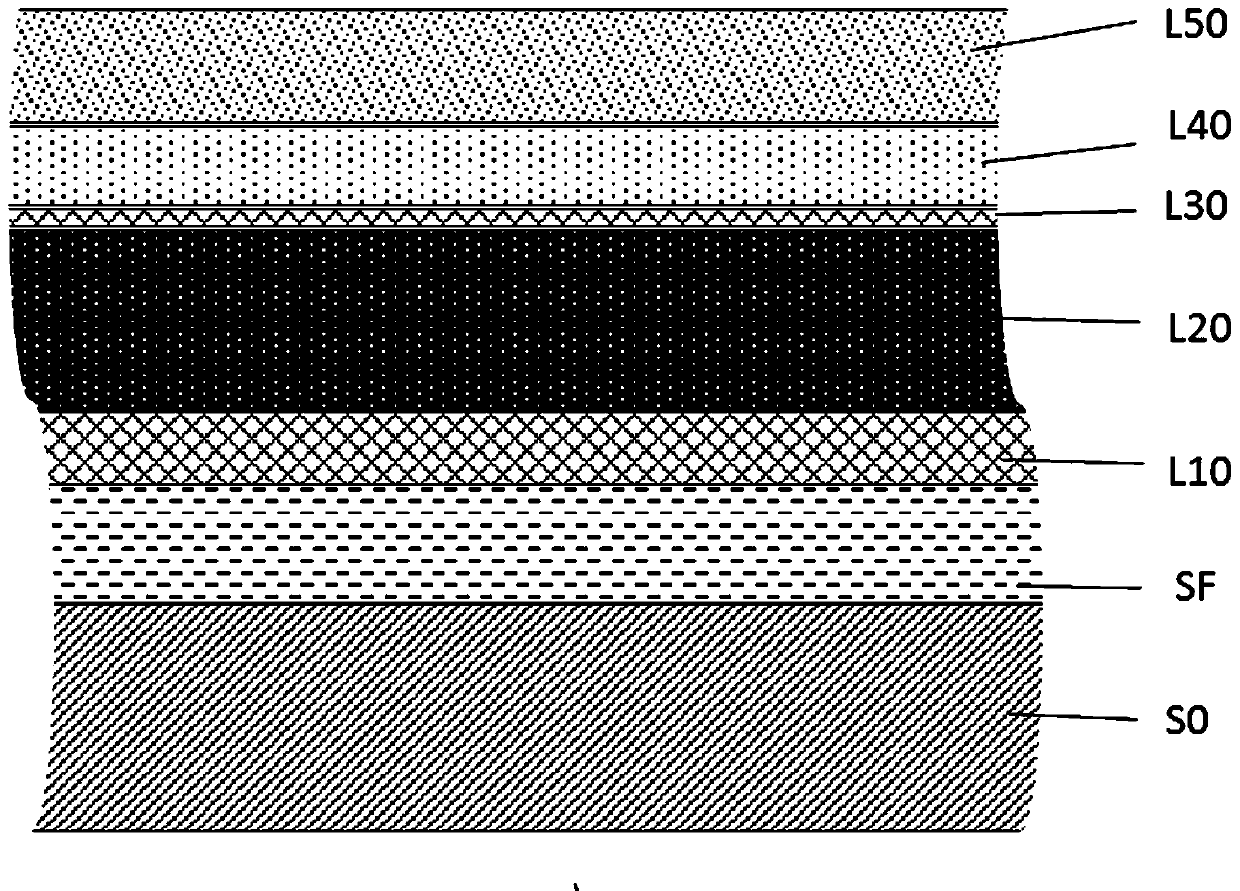

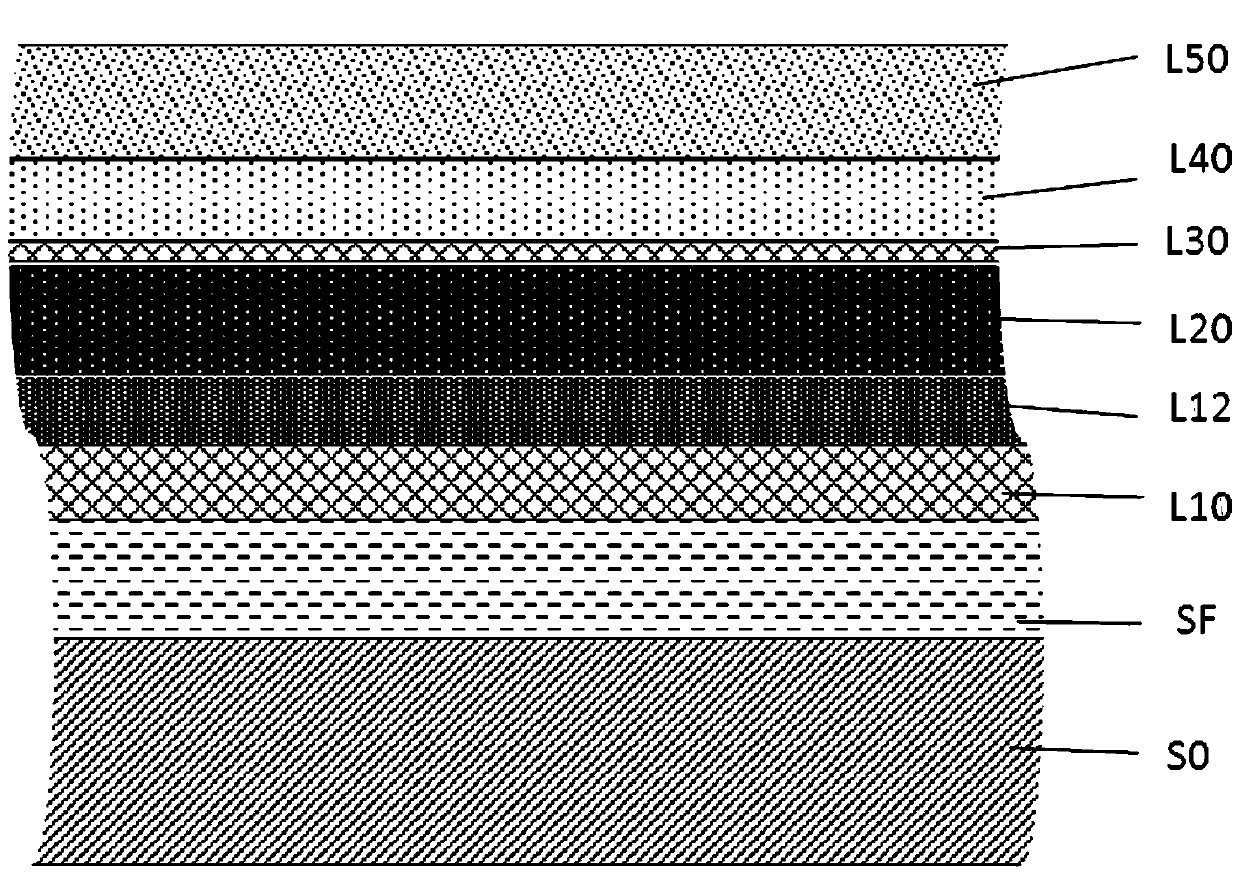

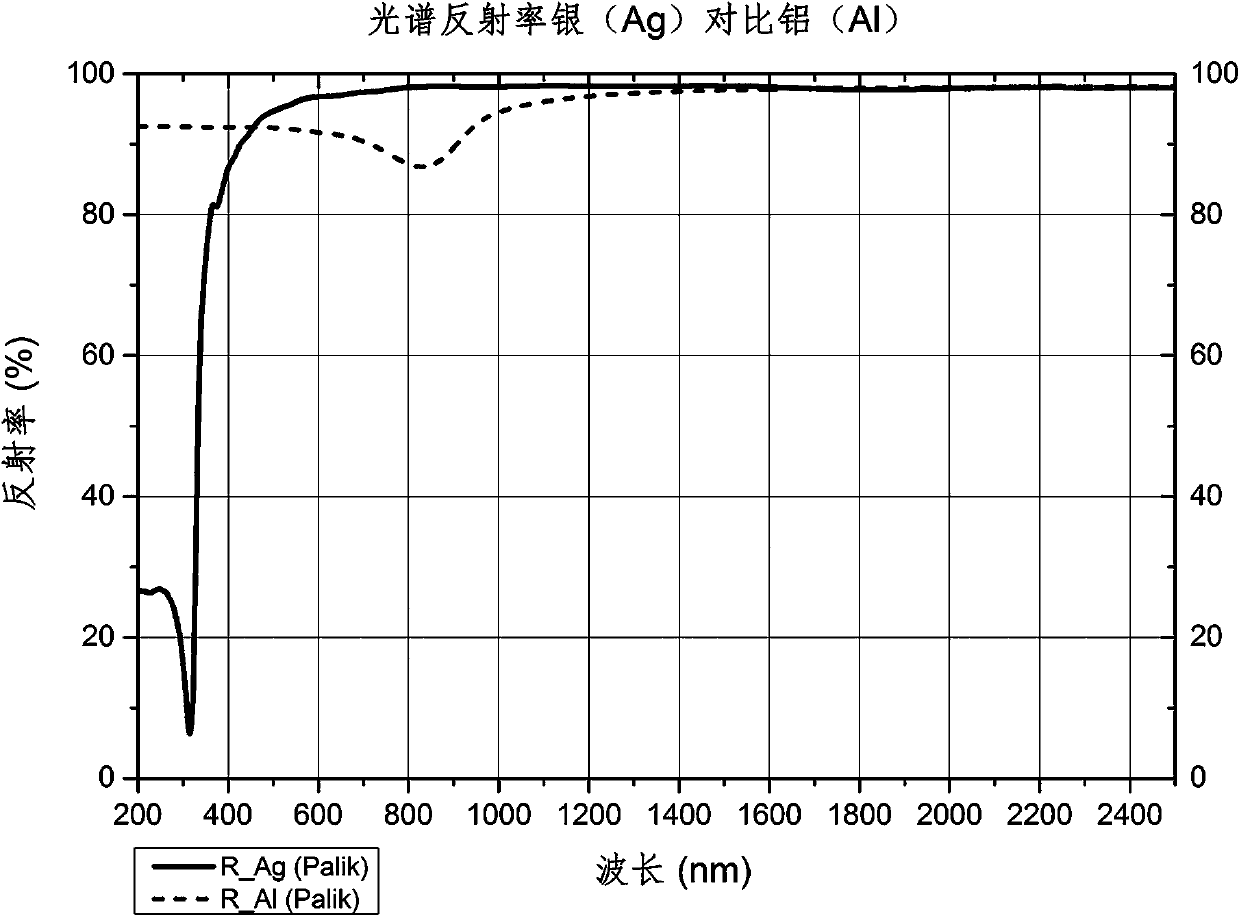

High-temperature-resistant and corrosion-resistant high-reflection mirror surface coating film system

The invention discloses a high-temperature-resistant and corrosion-resistant high-reflection mirror surface coating film system, and relates to the technical field of film plating. The system includesa metal substrate, wherein a first auxiliary film layer, a high-reflection silver film layer, a second auxiliary film layer, a low-refractive-index coating and a high-refractive-index coating are sequentially plated on the film plating surface of the metal substrate, and the first auxiliary film layer and the second auxiliary film layer are both metals plated by adopting a common sputtering process; and a silicon nitride (Me: Si) NX compound which is a multifunctional comprehensive auxiliary layer, can provide the adhesion promotion, diffusion barrier and anti-oxidation effects, so that the high-reflection mirror surface coating film system can have the advantages of high durability, high reliability and the like under the high-temperature and corrosive environment conditions. Preferably,the metals or metal alloys in the first auxiliary film layer and the second auxiliary film layer are the same. Preferably, a metal interface layer is further arranged between the first auxiliary filmlayer and the high-reflection silver film layer and is used for further restraining the transverse migration of silver atoms.

Owner:福建新越金属材料科技有限公司

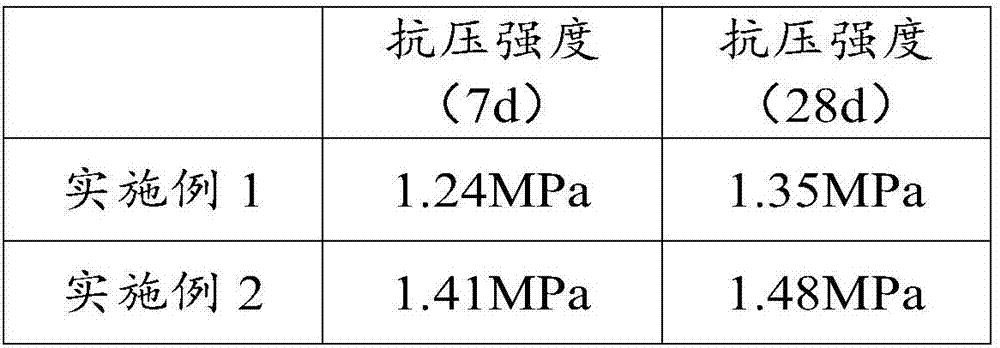

Soil solidifier as well as preparation method and application thereof

The invention provides a soil solidifier as well as a preparation method and an application thereof and relates to the technical field of materials. The soil solidifier is prepared from raw materials in percentage by weight as follows: 30%-50% of cement, 25%-45% of fly ash, 10%-25% of anhydrite and 5%-20% of an additive. The soil solidifier can modify sludge and spent clay into materials with high hardness and good water resistance and has better application prospects. The preparation method of the soil solidifier comprises the step of raw material mixing. The method adopts a simple preparation process and is high in controllability, low in preparation cost and suitable for large-scale production.

Owner:蔡小三

Continuous and dynamic reduction device and method of fluorescent powder

The invention relates to a device and a method for continuously and dynamically reducing and firing low-valent metal ion activated fluorescent powder under high-temperature and vacuum environment or controllable non-oxidizing atmosphere. The device comprises a sealable furnace body, a vacuumizing device, a controllable non-oxidizing gas generation device, a medium frequency induction heating device, a rotary kiln type reaction vessel, a continuous feeding device, a waste gas purification treatment device and a quenching device. The fluorescent powder manufactured by adopting the method and the device has the advantages of high brightness, narrow particle size distribution and good consistency. The method comprises the following steps of: (1) preparing materials; (2) generating vacuum or non-oxidizing gas environment in the furnace body; (3) carrying out medium frequency induction heating with the heating temperature of 1000 to 2000 DEG C; (4) enabling the materials to flow into the rotary kiln type reaction vessel continuously, dynamically roasting for 2 to 15h, automatically flowing into a certain medium of vacuum, non-oxidizing gas, water or oil for carrying out quenching treatment; and (5) treating the materials to obtain the product.

Owner:GRIREM ADVANCED MATERIALS CO LTD

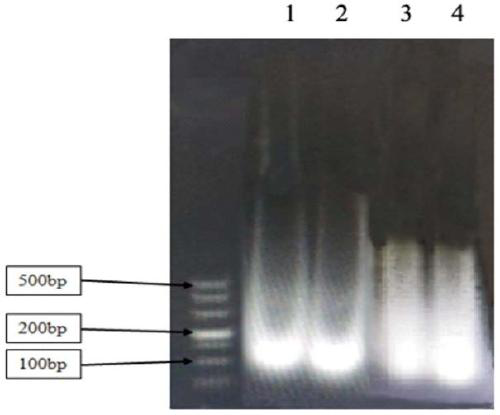

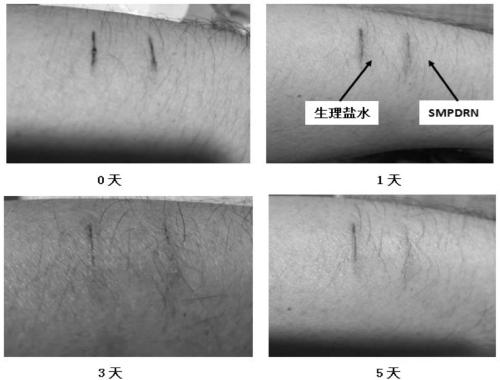

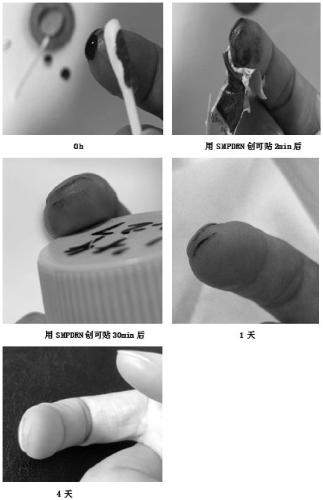

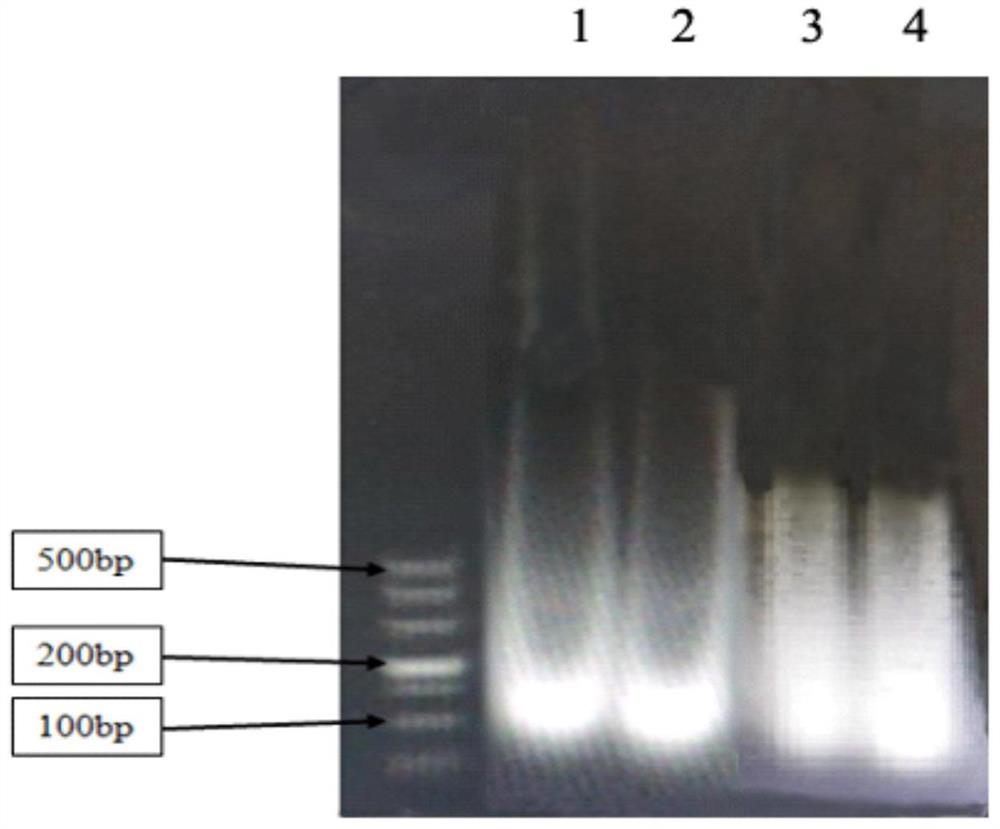

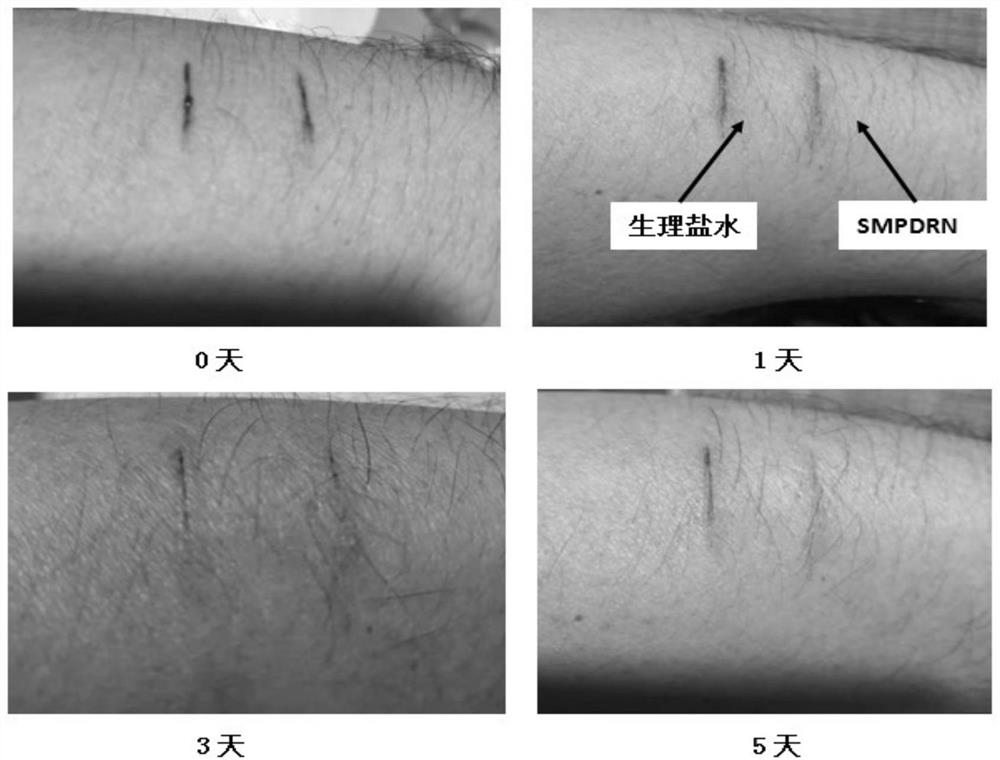

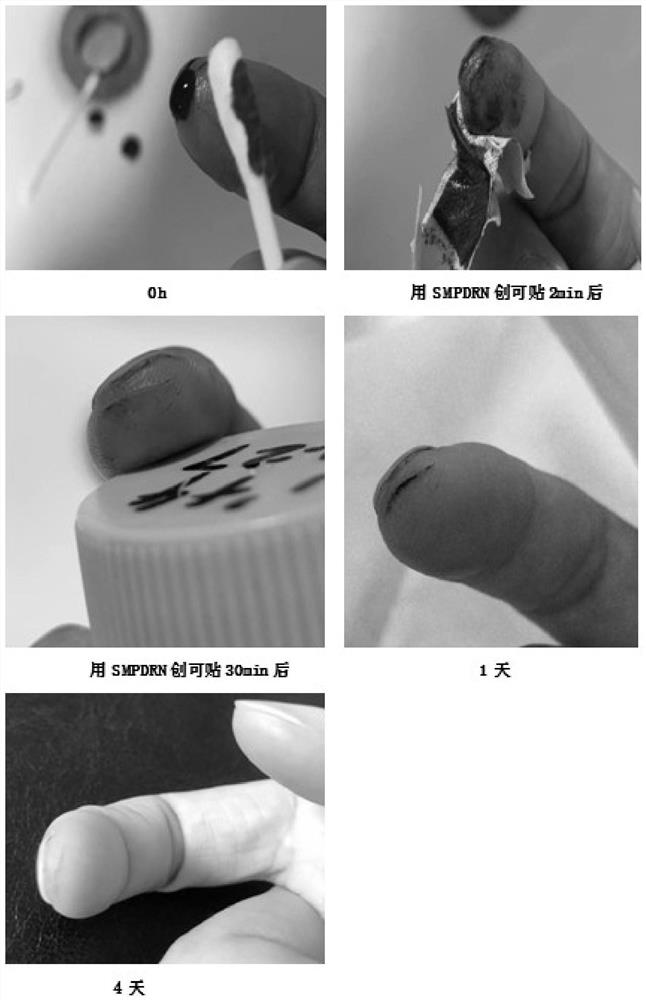

Dressing with functions of stopping bleeding and accelerating wound healing and preparation method thereof

ActiveCN111214694APromotes collagen synthesisPromote wound healingPharmaceutical delivery mechanismAbsorbent padsDeoxyriboseBiomedical engineering

The invention discloses a dressing with functions of stopping bleeding and accelerating wound healing. The dressing comprises micromolecule polydeoxyribonucleotides (SMPDRN) extracted from salmon. TheSMPDRN is extracted from salmon tissue, and the salmon tissue comprises sperms, semen and eggs of the salmon. Experiments prove that the dressing has effects of stopping bleeding, relieving pain, diminishing inflammation, promoting wound healing and the like. The SMPDRN used in the dressing is obtained by a preparation method provided by the invention, and has characteristics of a molecular weight concentrated in a high-efficiency area, relatively simple ingredients, high purity, simple process, stable ingredients and the like, so that preparation requirement of hemostatic dressing is met, the hemostatic dressing is stable in curative effect and ideal in safety, and difficulty of applying animal preparations to the preparation of hemostatic dressing is overcome. New applications of smallmolecular polydeoxyribonucleotides in medical field are developed.

Owner:恒昱生物制药(山东)有限公司

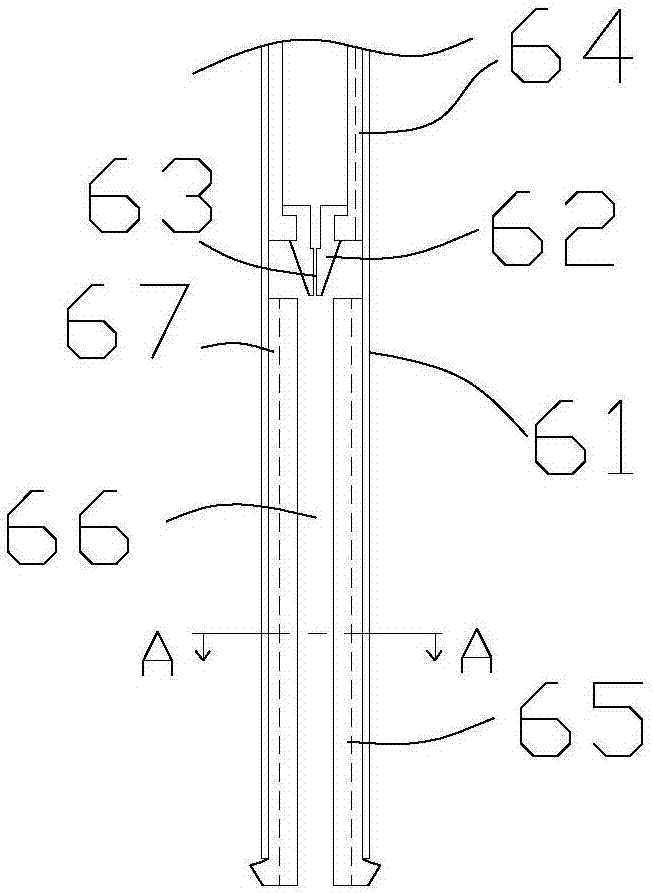

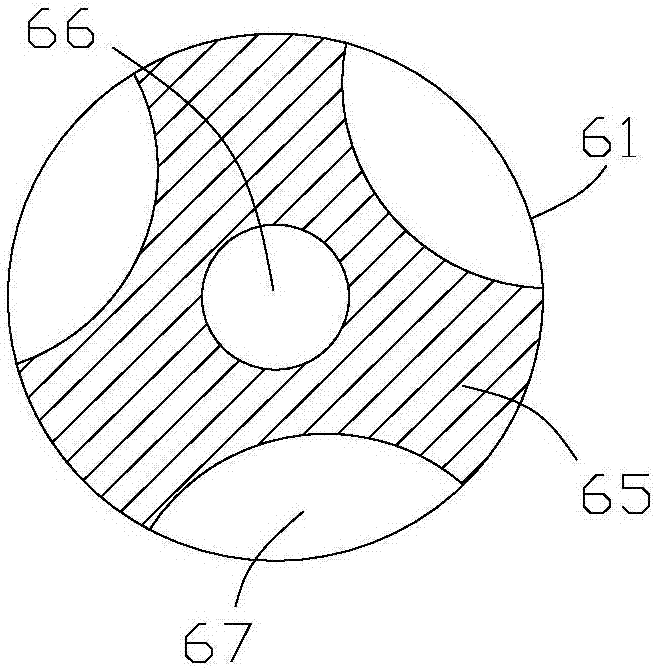

Frothy coffee maker and method for preparing frothy coffee

The invention discloses a frothy coffee maker and a method for preparing frothy coffee. The frothy coffee maker comprises a coffeepot and further comprises a water tank, a water pump, an input pipeline, an output pipeline, a liquid-vapor output rod and a heating assembly capable of operating by adopting different heating power. According to the coffee maker, the method for preparing frothy coffee comprises the following steps: controlling the water pump and the heating assembly to operate, sequentially outputting warm water and vapor through the liquid-vapor output rod, mixing, heating and extracting ground coffee, thereby obtaining the needed frothy coffee. The frothy coffee maker disclosed by the invention is simple in structure, the warm water, vapor or a vapor-air mixture can be output by changing the heating power of the heating assembly, the preparation needs of the frothy coffee are met, and the coffee maker is convenient to use and control. The preparation method disclosed by the invention is simple in process, the warm water, vapor or the vapor-air mixture of proper temperature and dosage can be obtained for preparing the frothy coffee by controlling the heating assembly and the water pump, the control is convenient, and the taste of the obtained coffee can be guaranteed.

Owner:WUHU ALDOC TECH CO LTD

A kind of large-tow carbon fiber oil agent for wet process and preparation method thereof

The invention relates to a large-tow carbon fiber oil agent used for wet processing and a preparation method thereof. The large-tow carbon fiber oil agent comprises the following modified oil components in parts by weight: 80 to 90 parts of compound A shown as formula (I), 1 to 3 parts of an antioxidant, 1 to 3 parts of polyether modified silicone and 5 to 15 parts of a non-ionic surface active agent. The large-tow carbon fiber oil agent meets the requirements that the oil agent is free of roller sticking after long-time use, lasting in antistatic property and good in high-temperature heat resistance, the carbon fiber is effectively protected, the requirement for the preparation of wet processing large-tow carbon fiber is met, and the quality of the carbon fiber is improved.

Owner:新元化学(山东)股份有限公司

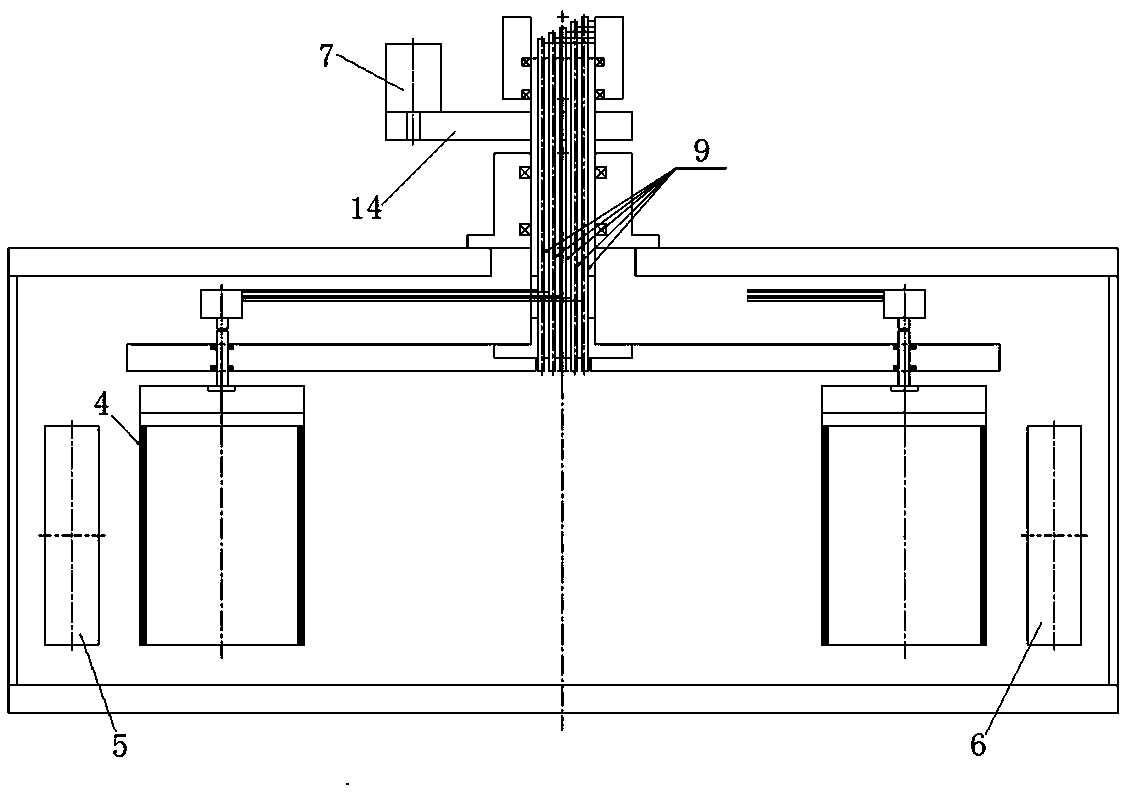

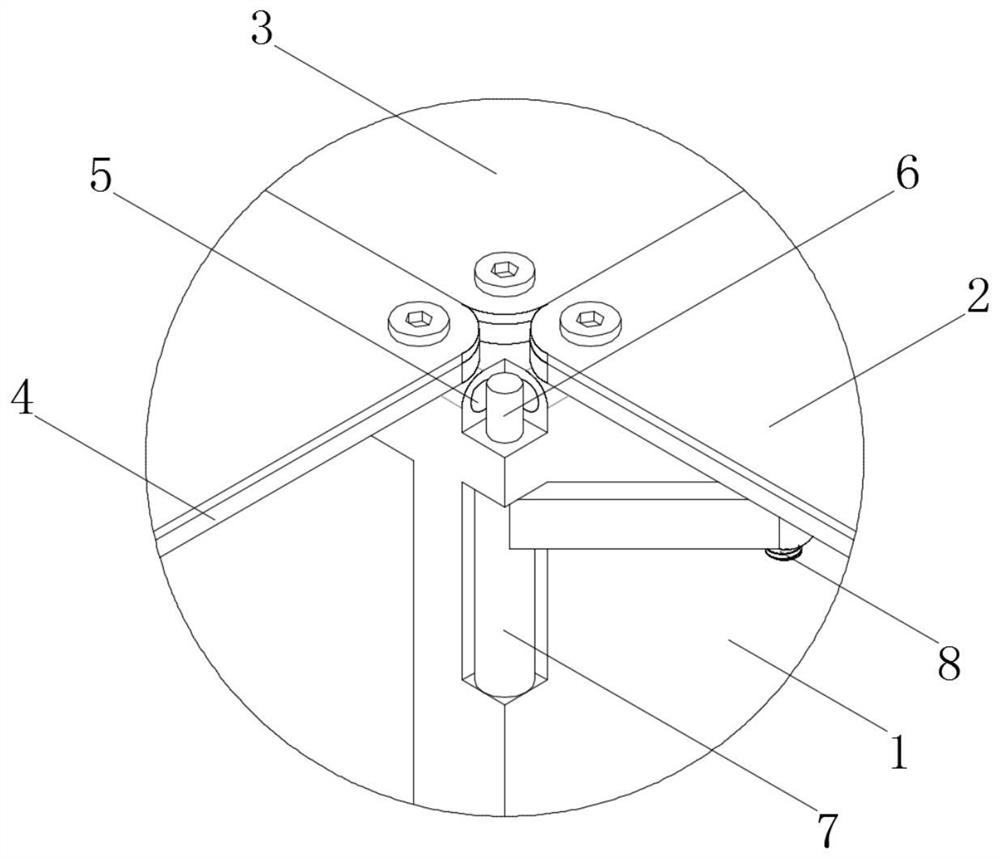

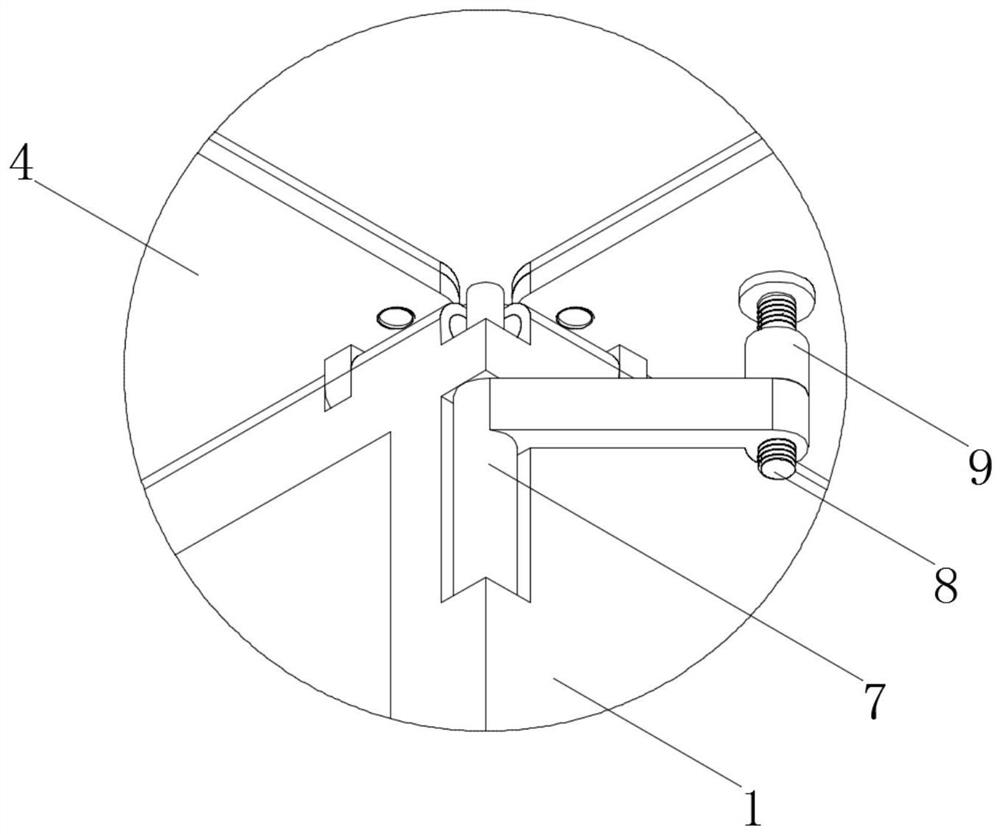

Sputtering film-forming device

PendingCN110408904AImprove film thickness uniformityMeet the requirements of high precision and low defectVacuum evaporation coatingSputtering coatingElectrical and Electronics engineeringCoating materials

The invention relates to the technical field of film preparation, in particular to a sputtering film-forming device which is characterized in that a substrate tray revolution turntable is in drive connection with a revolution motor arranged outside a vacuum film forming chamber and is driven by the revolution motor to rotate; a substrate tray autorotation turntable is in drive connection with an autorotation vacuum motor arranged in the vacuum film forming chamber; the autorotation vacuum motor is connected with a conductive sliding ring arranged outside the vacuum film forming chamber througha vacuum lead-in electrode; and the substrate tray autorotation turntable rotates under the driven of the autorotation vacuum motor. The sputtering film-forming device has the advantages that adjustment of a rotating speed ratio of revolution and autorotation of a substrate tray is realized, the uniformities of film thicknesses of different coating materials depositing on a substrate can be remarkably improved, and the preparation requirements of the film with high precision and low defects can be met; and dust generated by friction vibration of a transmission gear group when the transmissiongear group is adopted is reduced, so that generation of the defects of the substrate film is reduced.

Owner:OPTORUN SHANGHAI CO LTD

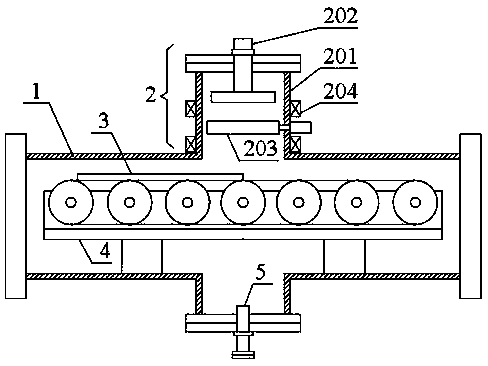

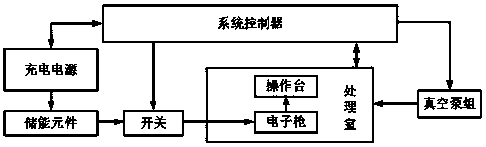

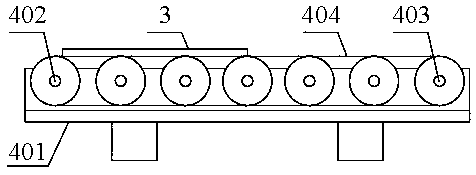

Material surface treatment device

The invention provides a material surface treatment device and belongs to the technical field of electronics. The treatment device comprises a treatment chamber, an electronic gun, an operating tableand an adjusting mechanism, whereinthe electronic gun, the operating table and the adjusting mechanism are arranged in the treatment chamber, and the treatment chamber forms a vacuum environment through an air suction and exhaust hole on one side. The treatment device utilizes electron beams to treat a surface of a material; and the device only consumes electric energy, can be repeatedly used, andis high in cost-benefit ratio. A treatment mode is short in action time, does not influence a treated object body, can remarkably improve surface smoothness of a treated material, is environment-friendly and harmless to a human body, and the device can be widely applied to the technical fields of aerospace, precision machining, power electronics, instruments and meters, material modification, preservative treatment, environmental protection technologies and the like.

Owner:陕西中控微脉智能科技有限公司

Method for preparing neodymium chloride hydrate through programmed temperature increasing method

ActiveCN106915759AMeet the synthesis requirementsMeet preparation needsRare earth metal chloridesThermal insulationRoom temperature

The invention relates to a method for preparing a neodymium chloride hydrate through a programmed temperature increasing method. The method comprises: loading a granular crystal NdC13.6H2O into a dehydration reaction kettle, starting the dehydration reaction kettle to stir, introducing nitrogen being subjected to low temperature steam preheating, starting a vacuum pump, vacuumizing, setting a temperature increasing program to start heating when the vacuum degree achieves 50 kpa, and naturally cooling the kettle temperature to 50 DEG C to obtain the neodymium chloride hydrate product, wherein the temperature increasing program comprises that the heating is performed for 2 h at the heating rate of 0.625 DEG C / min within the temperature range from room temperature to 100 DEG C and the thermal insulation time is 3 h at a temperature of 100 DEG C, the heating is performed for 2 h at the heating rate of 0.167 DEG C / min within the temperature range of 100-120 DEG C and the thermal insulation time is 6 h at a temperature of 120 DEG C, the heating is performed for 2 h at the heating rate of 0.167 DEG C / min within the temperature range of 120-140 DEG C and the thermal insulation time is 4 h at a temperature of 140 DEG C, and the heating is performed for 2 h at the heating rate of 0.15 DEG C / min within the temperature range of 140-158 DEG C and the thermal insulation time is 10 h at a temperature of 158 DEG C.

Owner:PETROCHINA CO LTD +1

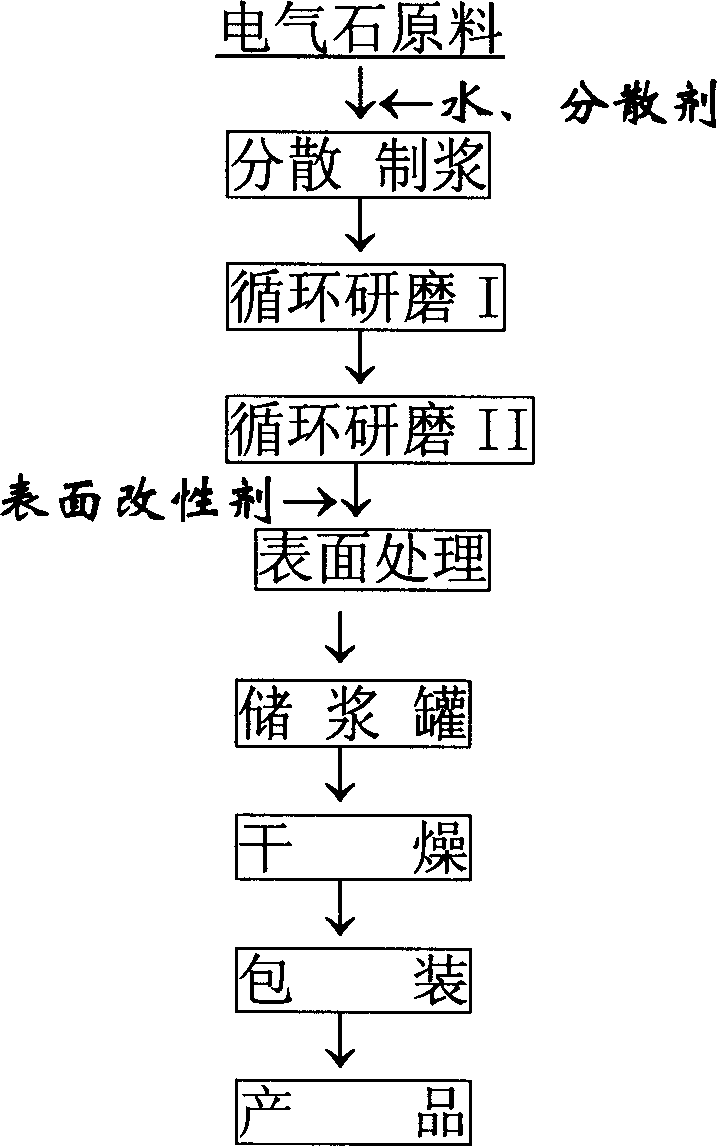

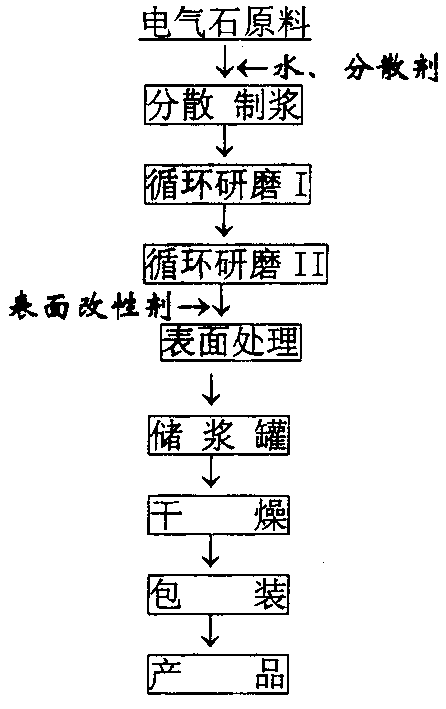

Preparing method for ultra-fine tourmaline powder material

The invention relates to a process for preparing ultra-fine tourmaline powder material, which comprises the steps of, decentralizing for grout making, wet-type super fine crushing, wet method surface preparation and drying. The invention realizes super fine grain size, better dispersity and surface activity.

Owner:浙江仁智股份有限公司

Dressing with functions of hemostasis and accelerated wound healing and preparation method thereof

ActiveCN111214694BHigh puritySimple processPharmaceutical delivery mechanismAbsorbent padsNucleotideCurative effect

The invention discloses a dressing with functions of stopping bleeding and accelerating wound healing, which comprises small molecule polydeoxyribonucleotide (SMPDRN) extracted from salmon. The SMPDRN is extracted from salmon tissues, and the salmon tissues include salmon testis, semen, and eggs. Experiments of the present invention have proved that the effects of hemostasis, pain relief, anti-inflammation, promotion of wound healing and the like can be achieved. The small molecule polydeoxyribonucleotide (SMPDRN) used in the present invention is obtained by the preparation method provided in the present invention, and has the characteristics of molecular weight concentrated in the high-efficiency region, relatively simple components, high purity, simple process, and stable components. It meets the needs of the preparation of hemostatic dressings, enables the hemostatic dressings to obtain stable curative effect and ideal safety, overcomes the difficulty of animal preparations in the preparation of hemostatic dressings, and develops small molecule polydeoxyribonucleotides in the field of medicine of new applications.

Owner:恒昱生物制药(山东)有限公司

Method for chemically removing trace cyclopentadiene from piperylene

ActiveCN107840777ASimple processReduce environmental pollutionDistillation purification/separationHydrocarbonsPiperyleneChemistry

The invention provides a method for chemically removing trace cyclopentadiene from piperylene. Trace cyclopentadiene refers to that the mass content of cyclopentadiene in piperylene is less than or equal to 1%. The method comprises the following steps: (1) adding n-butanol into potassium hydroxide at room temperature and carrying out stirring until potassium hydroxide is completely dissolved so asto obtain a solution A; (2) adding piperylene and cyclohexanone into the solution A at room temperature and carrying out stirring to obtain a mixed solution B; (3) subjecting the solution B to atmospheric distillation to obtain an effluent C and an in-bottle distillate D, wherein the effluent C is refined piperylene in which the content of cyclopentadiene may drop to 10 ppm or less; and (4) cyclically using the distillate D, and adding piperylene into the distillate D to realize reuse of the distillate D for removal of trace cyclopentadiene from piperylene, wherein in the step (1), the mass ratio of n-butanol to potassium hydroxide is 5-20: 1.

Owner:PETROCHINA CO LTD +1

Mobile concrete mixing plant and batching machine thereof

ActiveCN101837612BReduced form factorImprove transfer performanceSold ingredients supply apparatusMixing operation plantBatch machineEngineering

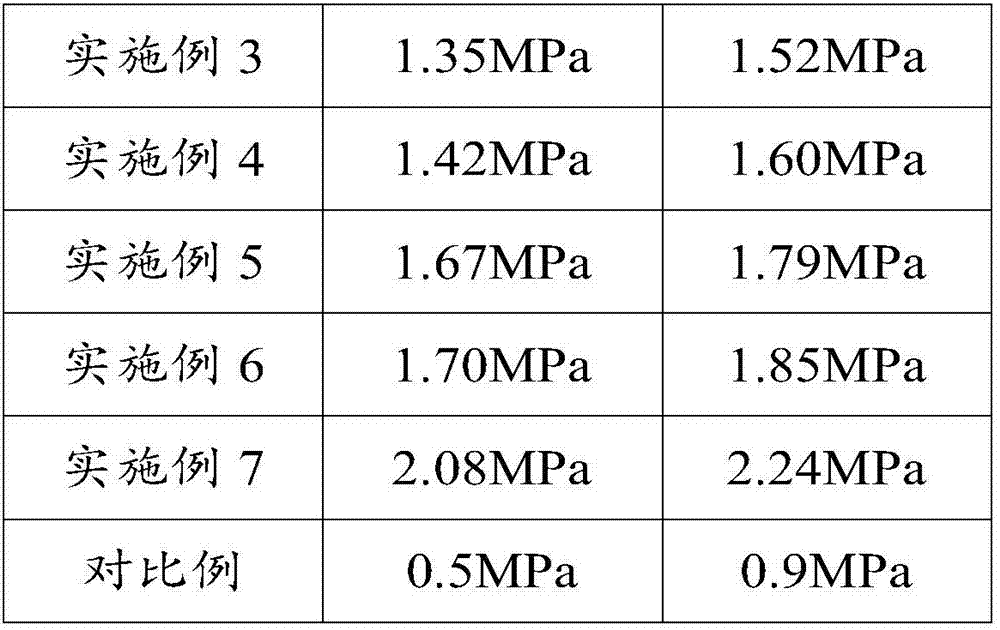

Disclosed are a mobile concrete mixing plant and a batching machine thereof. The batching machine is provided with a batching machine body (100) supported on a predetermined base (510) by supporting legs (300), a conveying machine (400) and multiple supporting legs (300). The conveying machine (400) is suspended below the batching machine body (100) via a suspension component. The batching machine has a working state and a conveying state. When the working state is switched to the conveying state, the vertical height of the supporting legs (300) is reduced and the outline of the batching machine is reduced so that before transferred and transported the batching machine body (100) does not need to be separated from the conveying machine (400) and materials do not need to be conveyed respectively thereby enabling the batching machine to possess better transfer and transportation performance. At the same time, the batching machine has a larger outline size in the working state so as to meet the requirement of the mobile concrete mixing plant on the preparation of concrete.

Owner:SANY HEAVY IND CO LTD (CN)

Environment-friendly hydrogen production purification equipment with photovoltaic auxiliary power supply

InactiveCN113929057AMeet preparation needsReduce usagePhotovoltaic supportsSolar heating energyMechanical engineeringHydrogen production

The invention discloses environment-friendly hydrogen production purification equipment with photovoltaic auxiliary power supply. The environment-friendly hydrogen production purification equipment comprises a main box body, and a movable solar panel and a fixed solar panel which are arranged above the main box body. A water tank and a storage battery are arranged in the main box body. The movable solar panel is arranged above a movable supporting plate and rotationally connected with the main box body through a horizontal shaft. A rotating strip is arranged in the vertical edge of the main box body, and a top bolt for jacking the movable supporting plate is arranged at the end, opposite to the main box body, of the rotating strip. The storage battery is electrically connected with the movable solar panel and the fixed solar panel through a charging module. The top of the water tank is covered with a box cover. Two electrodes are arranged in the box cover, cover pipes is arranged in the box cover, and the electrodes are located in the cover pipes. A box cavity is formed in the main box body, and a horizontal opening is formed in the arc-shaped face of the horizontal edge of the main box body. The environment-friendly hydrogen production purification equipment with photovoltaic auxiliary power supply is convenient to transport and hoist, can be used for preparing hydrogen under the condition of no external power supply, and is suitable for being widely popularized and used.

Owner:金源鸿

A kind of non-silicon oil agent/silicon-containing oil agent compounded carbon fiber oil agent and preparation method thereof

ActiveCN105297446BReduce loss rateImprove heat resistanceSilicon organic compoundsPreparation from carboxylic acid halidesFiberCompound a

Owner:新元化学(山东)股份有限公司

A kind of method for preparing neodymium chloride monohydrate by temperature-programmed method

ActiveCN106915759BMeet the synthesis requirementsMeet preparation needsRare earth metal chloridesThermal insulationCerium

The invention relates to a method for preparing a neodymium chloride hydrate through a programmed temperature increasing method. The method comprises: loading a granular crystal NdC13.6H2O into a dehydration reaction kettle, starting the dehydration reaction kettle to stir, introducing nitrogen being subjected to low temperature steam preheating, starting a vacuum pump, vacuumizing, setting a temperature increasing program to start heating when the vacuum degree achieves 50 kpa, and naturally cooling the kettle temperature to 50 DEG C to obtain the neodymium chloride hydrate product, wherein the temperature increasing program comprises that the heating is performed for 2 h at the heating rate of 0.625 DEG C / min within the temperature range from room temperature to 100 DEG C and the thermal insulation time is 3 h at a temperature of 100 DEG C, the heating is performed for 2 h at the heating rate of 0.167 DEG C / min within the temperature range of 100-120 DEG C and the thermal insulation time is 6 h at a temperature of 120 DEG C, the heating is performed for 2 h at the heating rate of 0.167 DEG C / min within the temperature range of 120-140 DEG C and the thermal insulation time is 4 h at a temperature of 140 DEG C, and the heating is performed for 2 h at the heating rate of 0.15 DEG C / min within the temperature range of 140-158 DEG C and the thermal insulation time is 10 h at a temperature of 158 DEG C.

Owner:PETROCHINA CO LTD +1

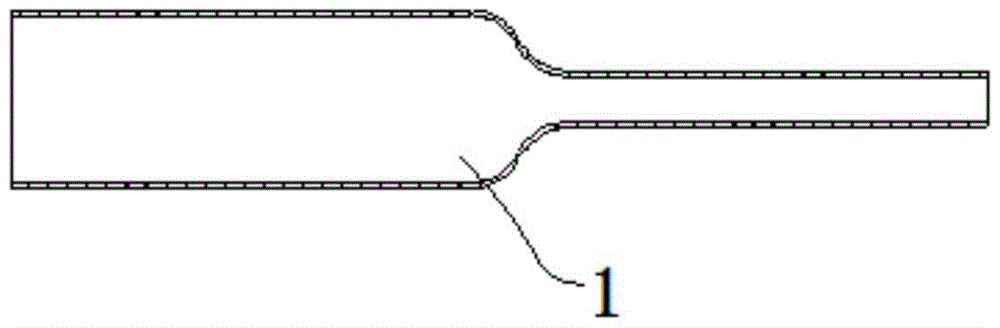

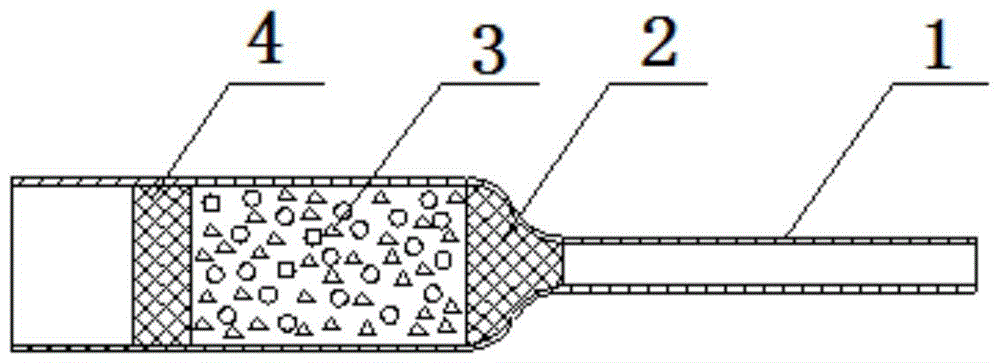

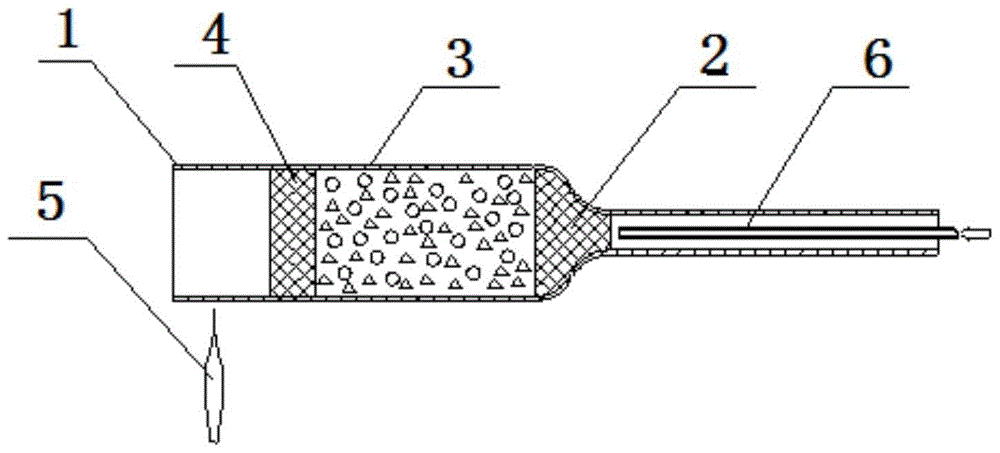

A kind of glass tube vacuum packaging method of traveling wave tube cathode

ActiveCN104157533BMeet preparation needsGuaranteed performanceCold cathode manufactureShielding gasEngineering

The invention discloses a glass tube vacuum packaging method for traveling wave tube cathode, comprising the following steps: (1) taking a glass tube with a large end and a small end, preheating and drying; (2) placing protective nets, cathode components or active substances in Into the big end of the glass tube, the cathode part or the active material are fixed on both sides by protective nets respectively; (3) The end face of the big end of the glass tube is closed under the protection of the protective gas; (4) The small end of the glass tube is sealed with a vacuum exhaust (5) seal off the glass tube on the vacuum exhaust stage to complete the vacuum packaging of the cathode component or active material by the glass tube; the present invention carries out vacuum packaging for the cathode component or active material, The cathode parts or active materials are isolated from the outside world, to prevent the cathode parts or active materials from being affected by external factors, to ensure the performance of the cathode parts or active materials, to further ensure the performance of the traveling wave tube, and to meet the preparation needs of the cathode of the traveling wave tube.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Formula and preparation method of tea for treating muscae volitantes

InactiveCN113230359AImprove drynessImprove blurSenses disorderDispersion deliveryOfficinalAdjunctive treatment

The invention discloses a formula and a preparation method of tea for treating muscae volitantes, and belongs to the technical field of medical teales. The formula is composed of the following components in parts by weight: 8-12 parts of root bark of delavay ardisia, 3-8 parts of flos buddlejae, 3-8 parts of fried semen cassiae, 3-8 parts of fructus lycii and 1-3 parts of ground bamboo. After being taken for a period of time, the prepared tea bag has the capability of improving muscae volitantes, epiphora induced by wind, dry eyes, blurred eyes and ghosting characters, has good rehabilitation after use, has the same soup color and taste as tea soup, is prepared from pure traditional Chinese medicines, and is relatively small in toxic and side effects, and thus the auxiliary treatment control of muscae volitantes can be realized. In addition, moisture removal preparation of the auxiliary materials is achieved through low-temperature freeze-drying in the preparation process, the overall medicinal activity is improved, and the preparation requirement is met.

Owner:田兴元

Biodegradable magnesium alloy blood vessel rack

ActiveCN100409904CGood biocompatibilityEnhance and improve comprehensive functionsStentsSurgeryHalf-lifeBiocompatibility Testing

The biodegradable magnesium alloy blood vessel rack consists of magnesium in 60-95 wt% and other metals, including RE, for the rest. Metal magnesium as the basic material has excellent tissue compatibility and blood compatibility, and the added other metal, including RE, elements raise and improve the comprehensive performance, especially mechanical strength, plasticity, degradability and biocompatibility. The magnesium alloy blood vessel rack has tensile strength of 200-300 MPa, elastic module of 10-50 GPa, elongation at break of 2-10%and degrading half life of 6-18 weeks. Most of the degraded metal ions are drained through renal tubules while small part being utilized by human body.

Owner:LIAONING YINYI BIOTECH CO LTD

A method for preparing a thin-walled cylindrical part with a curved surface of revolution

ActiveCN105537329BIncrease profitSolve technical difficulties such as precise moldingShaping toolsFurnace typesThermal treatmentTitanium alloy

The invention discloses a preparation method of a thin-walled tubular part with a revolution curved surface and aims at solving the problems that when a titanium alloy sheet tubular part is machined, machining and clamping are difficult to realize and the processing quality is difficult to guarantee; raw materials are low in utilization rate, long in processing period and high in cost; cold bending and forming difficultly meets the design requirement; and stamping and hot-bugling processing is rigorous in requirements on equipment and process, and is higher in cost. The invention provides a simple preparation method of the thin-walled tubular part with the revolution curved surface, in particular to a simple preparation method of a titanium alloy thin-walled tubular part with the revolution curved surface. According to the simple preparation method, the preparation demand of the titanium alloy thin-walled tubular part can be met. The method comprises the steps of preparing a fixed mold, cutting raw materials, as well as performing assembling and thermal treatment. The preparation method disclosed by the invention has the advantages of simplicity in operation, convenience in use, no need of expensive equipment, high utilization rate of the raw materials, short period, low production cost, high precision of products and better application prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method for spraying-free crucible

ActiveCN111040483AImprove compactnessImprove stabilityPolycrystalline material growthLiquid surface applicatorsIngot castingCrucible

The invention provides a preparation method for a spraying-free crucible. The preparation method comprises the following steps: S1, preparing a silicon nitride coating solution from silicon nitride, an alcohol-based silica sol, a ceramic adhesive and pure water according to a certain mass ratio, wherein the mass ratio of the silicon nitride to the alcohol-based silica sol is (1.5-2): 1, and the mass ratio of the silicon nitride to the ceramic adhesive is (14-10): 1, and the mass ratio of the silicon nitride to the water is 1: (1-3); and S2, brushing the silicon nitride coating solution onto the inner surface of a crucible, carrying out drying, then removing floating dust on the surface of the crucible, putting a drying agent, and carrying out packaging. The silicon nitride coating preparedaccording to a formula provided by the invention is good in compactness; spraying is replaced with a secondary brush coating preparation process, so the silicon nitride coating is more compact in strength, low in proportion of oxygen immersed into a silicon ingot and less in silicon nitride falling off; the effects of low hardness point and low-oxygen ingot casting are achieved; and the preparation method has the advantages of easy and convenient operation and high industrialization.

Owner:浙江润优新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com