A kind of large-tow carbon fiber oil agent for wet process and preparation method thereof

A technology of wet process and large tow, which is applied in the field of large tow carbon fiber oil for wet process and its preparation. It can solve the problems of insufficient heat resistance, poor surface elasticity and brittleness of the oil film, and achieve the reduction of oil The effect of falling and protecting the low temperature carbonization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. Preparation of Compound A

[0033] Add 10Kg aminopropyl silicone oil (viscosity 150cp, ammonia value 0.16mmol / g), 5Kg isopropanol, 220gK to the reactor 2 CO 3 And 230g 3-chloro-2-hydroxypropyltrimethylammonium chloride (content 65%), stir, heat to 85℃~90℃, reflux for 4h, cool to room temperature, filter, evaporate the solvent under reduced pressure, and finally reduce the pressure The temperature is reduced to 133Pa, and the temperature is increased to 120°C to remove small molecules, and a colorless and transparent compound A-1 is obtained.

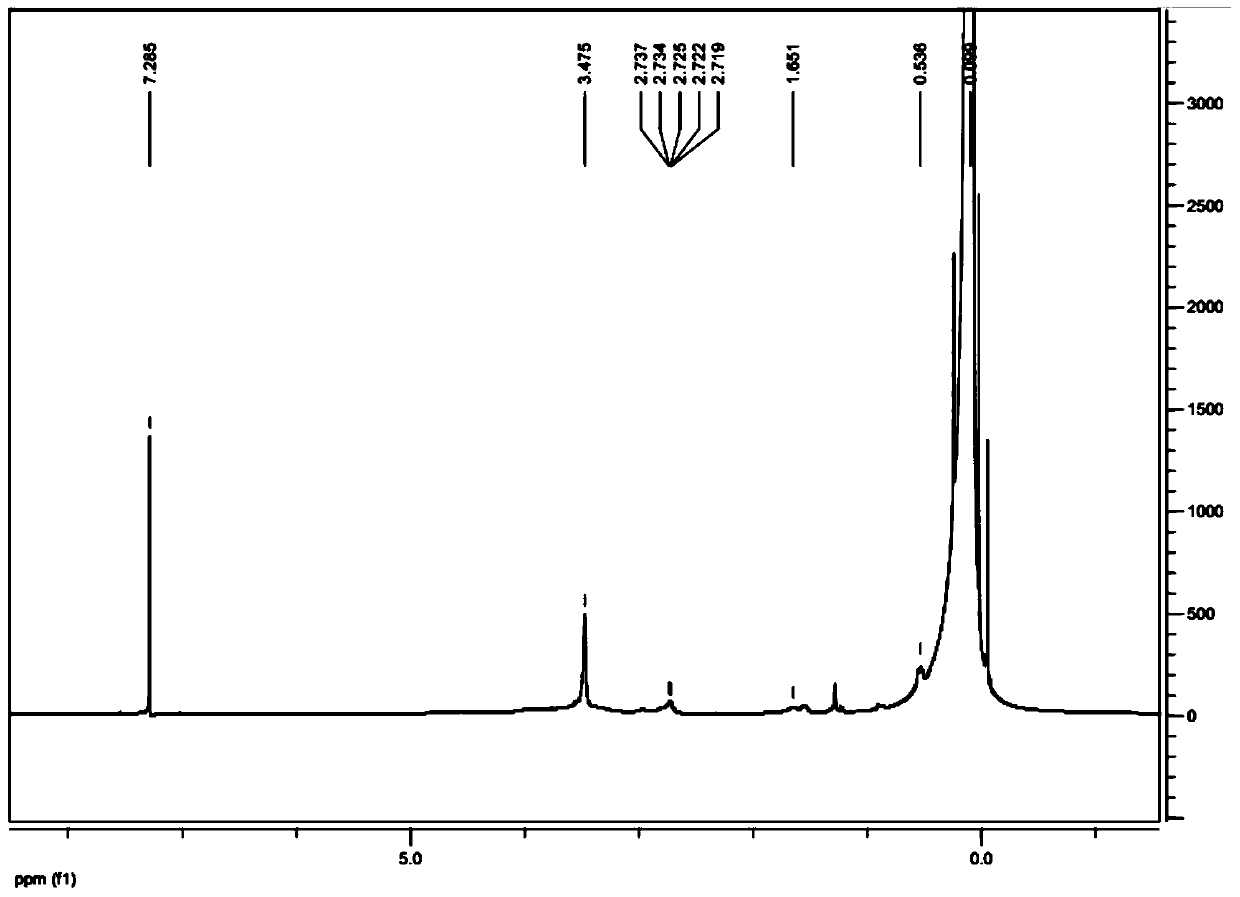

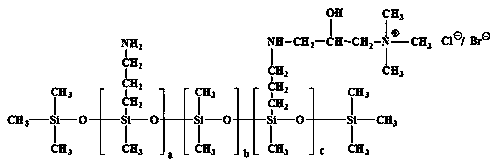

[0034] The hydrogen nuclear magnetic spectrum of compound A-1 is as figure 1 As shown, the solvent is CDCl 3 . Among them, chemical shift δ=0.099 is the proton peak of silylmethyl group, δ=0.536 is the proton peak of methylene group connected with silicon, δ=1.651 is the proton peak of methylene group connected with silylmethylene, δ=2.719~ 2.737 is the proton peak of the methylene group connected to the nitrogen atom of t...

Embodiment 2

[0035] Example 2. Preparation of Compound A

[0036] Add 10Kg aminopropyl silicone oil (viscosity 100cp, ammonia value 0.18mmol / g), 5Kg isopropanol, 220gK to the reactor 2 CO 3 And 175g 3-chloro-2-hydroxypropyltrimethylammonium chloride (content 65%), stir, heat to 85℃~90℃, reflux for 4h, cool to room temperature, filter, evaporate the solvent under reduced pressure, and finally reduce the pressure The temperature is reduced to 133Pa, and the temperature is increased to 120°C to remove small molecules, and a colorless and transparent compound A-2 is obtained.

Embodiment 3~5

[0038] The specific ratio and composition are shown in Table 1. The preparation steps are as follows:

[0039] After mixing the materials, stir dripping water, neutralize to neutrality with acetic acid after inversion, and finally obtain a stable emulsion with a particle size of 0.01μm~0.5μm through high-speed dispersion or high-pressure homogenization, which is a large tow for wet process Carbon fiber oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com