Preparing method for ultra-fine tourmaline powder material

A technology of tourmaline powder and bulk material is applied in the field of preparation of ultra-fine tourmaline powder material, which can solve the problems of difficult to meet user requirements, no clear details, wide distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

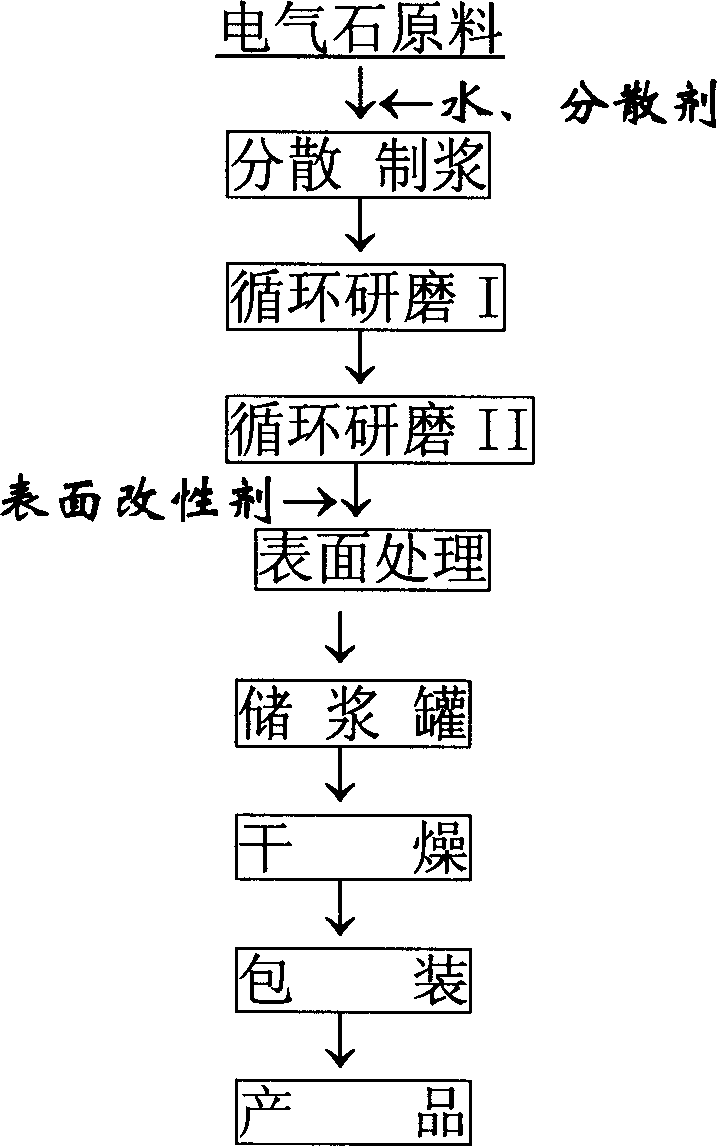

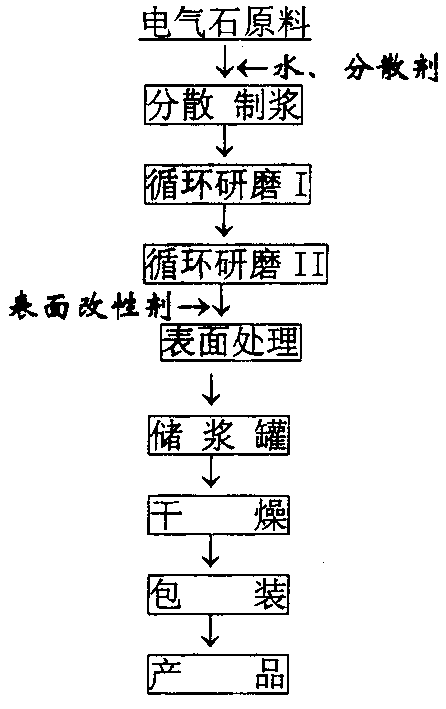

Method used

Image

Examples

Embodiment 1

[0026] Black tourmaline powder (fineness 200 mesh sieve remaining 2%, tourmaline content greater than 95%) 300kg, add 140kg water and 1.8kg sodium polyacrylate (dispersant), stir and disperse at high speed in a Φ800×1000mm dispersion tank for 15min., then pump into the first stage of the continuous two-stage GBP-80 grinding and peeling machine, and then pumped into the second stage of the grinding and peeling machine for 3.0 hours of circular grinding, and the ultrafine tourmaline slurry after grinding is pumped into the Φ800 In a temperature-controllable reaction tank of ×1000mm, the slurry concentration (mass percentage of tourmaline) is 65%, the temperature is raised to 75°C, 4.5kg of silane coupling agent is added, and the reaction is stirred at 75±5°C for 75min. Finally, the surface treated The slurry is fed into the XFG-400 multifunctional dryer for drying, the drying temperature is 197°C, and the outlet temperature of the dryer is 87°C.

Embodiment 2

[0028] Black tourmaline powder (fineness 200 mesh sieve remaining 2%, tourmaline content greater than 95%) 300kg, add 135kg water and 1.8kg triethanolamine (dispersant), stir and disperse at high speed in a Φ800×1000mm dispersing tank for 15min., then pump into The first stage mill in the continuous two-stage GBP-80 type grinding and peeling machine, after 3.0 hours of circular grinding, it is pumped into the second stage of grinding and peeling machine for 3.0 hours of circular grinding, and the ground ultrafine tourmaline slurry is pumped into Φ800× In a 1000mm temperature-controllable reaction tank, the slurry concentration (mass percentage of tourmaline) is 65%, the temperature is raised to 80°C, 3.6kg of silane coupling agent and 1.2kg of sodium stearate are added successively, and the reaction is stirred at 80±5°C for 80min , and finally put the surface-treated slurry into an XFG-400 multifunctional dryer for drying, the drying temperature is 208°C, and the outlet tempera...

Embodiment 3

[0030] Black tourmaline powder (fineness 200 mesh sieve remaining 2%, tourmaline content greater than 95%) 250kg, add 115kg water and 1.5kg sodium polyacrylate (dispersant), stir and disperse at high speed in a Φ800×1000mm dispersion tank for 15min., then pump into the first stage of the continuous two-stage GBP-80 grinding and peeling machine, and then pumped into the second stage of the grinding and peeling machine for 3.0 hours of circular grinding, and the ultrafine tourmaline slurry after grinding is pumped into the Φ800 In a ×1000mm temperature-controllable reaction tank, the slurry concentration (mass percentage of tourmaline) is 65%, the temperature is raised to 80°C, 4.0kg of silane coupling agent is added, and the reaction is stirred at 80±5°C for 70min, and finally the surface-treated The slurry is fed into an XFG-400 multifunctional dryer for drying, the drying temperature is 206°C, and the outlet temperature of the dryer is 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com