A kind of glass tube vacuum packaging method of traveling wave tube cathode

A technology of vacuum packaging and traveling wave tube, applied in cold cathode manufacturing, discharge tube/lamp manufacturing, electrode system manufacturing, etc., can solve the problems of prolonging cathode time, reducing the vacuum degree of the whole tube, and reducing the service life of the whole tube, etc. To achieve the effect of ensuring performance and meeting the needs of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0031] The glass tube vacuum packaging method of the traveling wave tube cathode comprises the following steps;

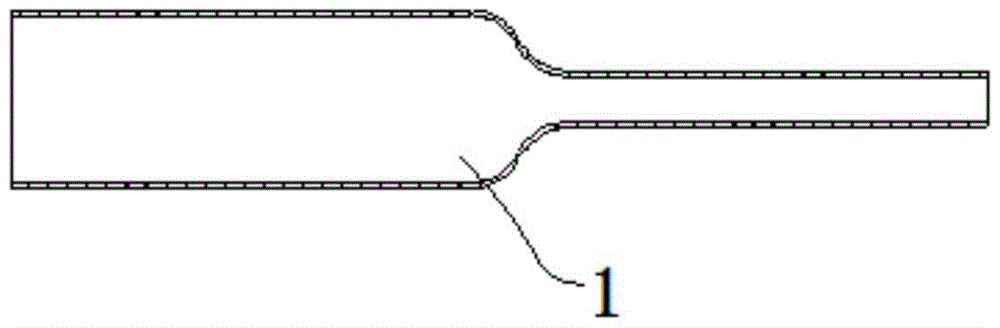

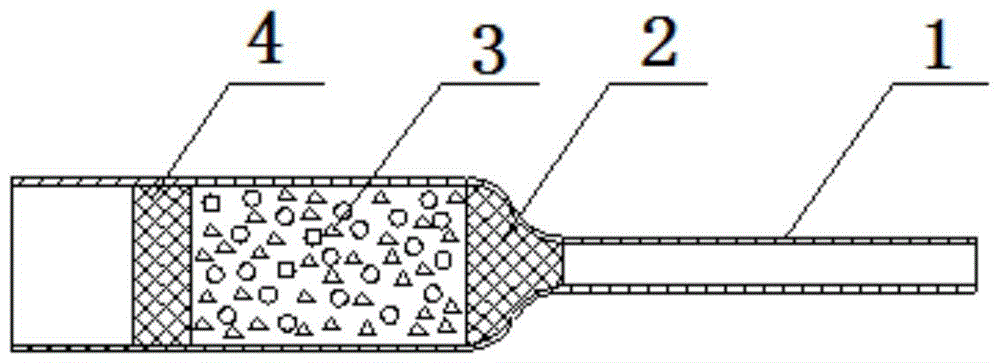

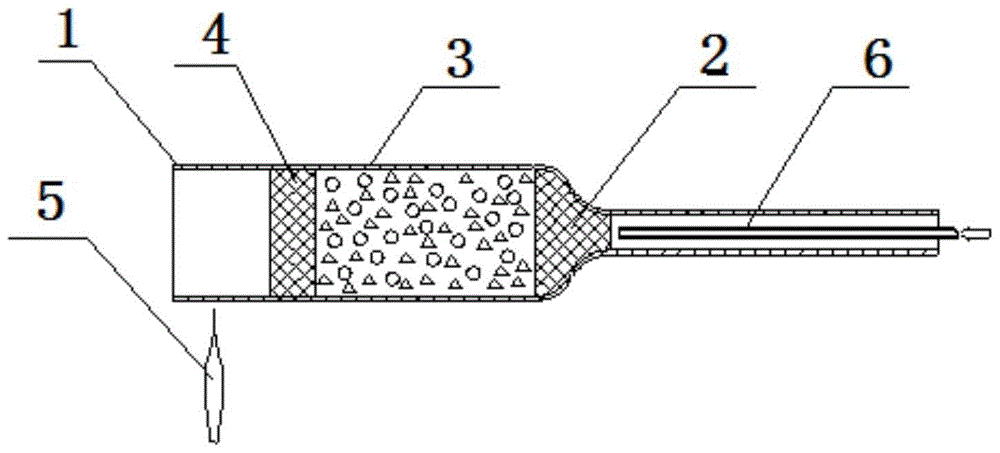

[0032] (1) Take a glass tube 1 with a large end and a small end, preheat and dry;

[0033] (2) Put the protective net, cathode component or active material 3 into the large end of the glass tube 1, and the two sides of the cathode component or active material 3 are respectively fixed by the protective net;

[0034] (3) Seal the end face of the big end of glass tube 1 under the protection of protective gas;

[0035] (4) Encapsulate the small end of the glass tube 1 on a vacuum exhaust table, and carry out vacuum treatment;

[0036] (5) Seal the glass tube 1 on the vacuum exhaust table 8 to complete the vacuum packaging of the glass tube 1 to the cathode component or the active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com