A method for preparing a thin-walled cylindrical part with a curved surface of revolution

A technology of curved surfaces of revolution and thin-walled cylinders, which is applied in the field of material processing, can solve the problems of cold bending forming that is difficult to meet design requirements, strict equipment and process requirements, and difficult machining and clamping, so as to achieve easy clamping, short production cycle, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of shaping mold

[0037] The shaping mold includes a female mold matched with the inner surface of the thin-walled cylindrical part with a curved surface of revolution, and a male mold matched with the outer surface of the thin-walled cylindrical part with a curved surface of revolution, and the female mold and the male mold are prepared respectively. In this embodiment, the male mold includes two modules, and the modules are connected through a flange to form a female mold. Wherein, the shaping mold adopts 45# steel.

[0038] (2) Raw material cutting

[0039] Cut the titanium alloy sheet according to the product surface expansion diagram to obtain the initial embryo. In this embodiment, the raw material is TC4 alloy with a thickness of 0.5mm.

[0040] (3) Assembly and heat treatment

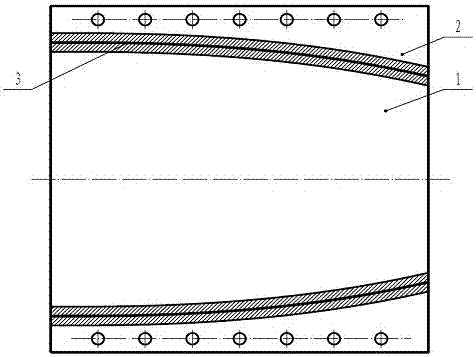

[0041] Tightly install the embryonic plate cut out in step 2 into the cavity of the fish shaping mold, and the assembly structure is as follows: figure 1 As shown, th...

Embodiment 2

[0045] (1) Preparation of shaping mold

[0046] The shaping mold includes a female mold matched with the inner surface of the thin-walled cylindrical part with a curved surface of revolution, and a male mold matched with the outer surface of the thin-walled cylindrical part with a curved surface of revolution, and the female mold and the male mold are prepared respectively. In this embodiment, the male mold includes two modules, and the modules are connected through a flange to form a female mold. Among them, the setting mold adopts 304 stainless steel.

[0047] (2) Raw material cutting

[0048] Cut the titanium alloy sheet according to the product surface expansion diagram to obtain the initial embryo. In this embodiment, the raw material is TA1 titanium alloy with a thickness of 1.0 mm.

[0049] (3) Assembly and heat treatment

[0050] The first blank plate cut out in step 2 is tightly fixed in the cavity of the fish-shaped mold to obtain the first workpiece. Place the ...

Embodiment 3

[0053] (1) Preparation of shaping mold

[0054] The shaping mold includes a female mold matched with the inner surface of the thin-walled cylindrical part with a curved surface of revolution, and a male mold matched with the outer surface of the thin-walled cylindrical part with a curved surface of revolution, and the female mold and the male mold are prepared respectively. Among them, the setting mold is made of 316L stainless steel.

[0055] (2) Raw material cutting

[0056] Cut the titanium alloy sheet according to the product surface expansion diagram to obtain the initial embryo. In this embodiment, the raw material is TC21 alloy with a thickness of 0.3 mm.

[0057] (3) Assembly and heat treatment

[0058] The first blank plate cut out in step 2 is tightly fixed in the cavity of the fish-shaped mold to obtain the first workpiece.

[0059] Place the assembled and shaped first workpiece in a vacuum heat treatment furnace for heat treatment. The heat treatment temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com