High-temperature-resistant and corrosion-resistant high-reflection mirror surface coating film system

A mirror coating and high-reflection technology, applied in mirrors, optics, instruments, etc., can solve problems such as low temperature resistance, poor stability, and poor corrosion resistance, and achieve the effect of good cost, high reliability, and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

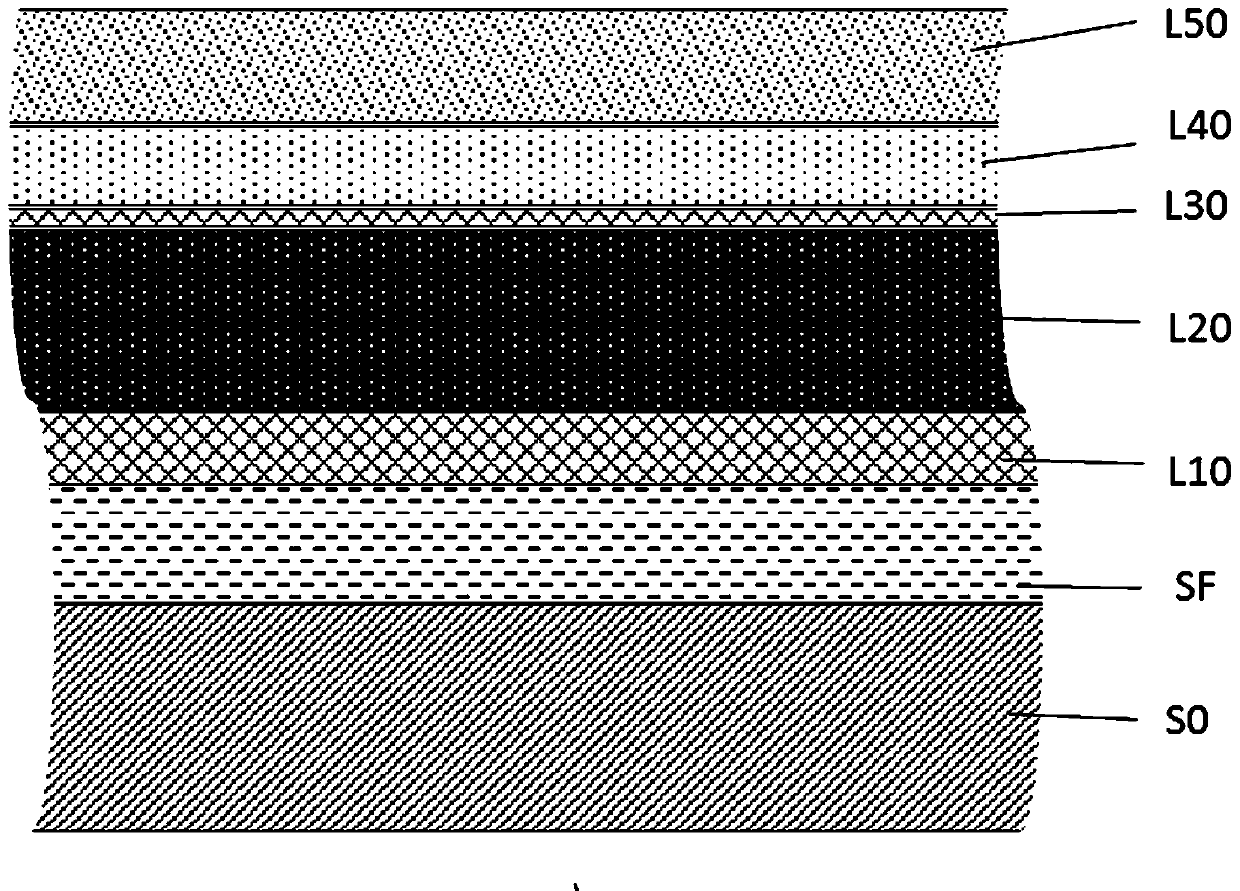

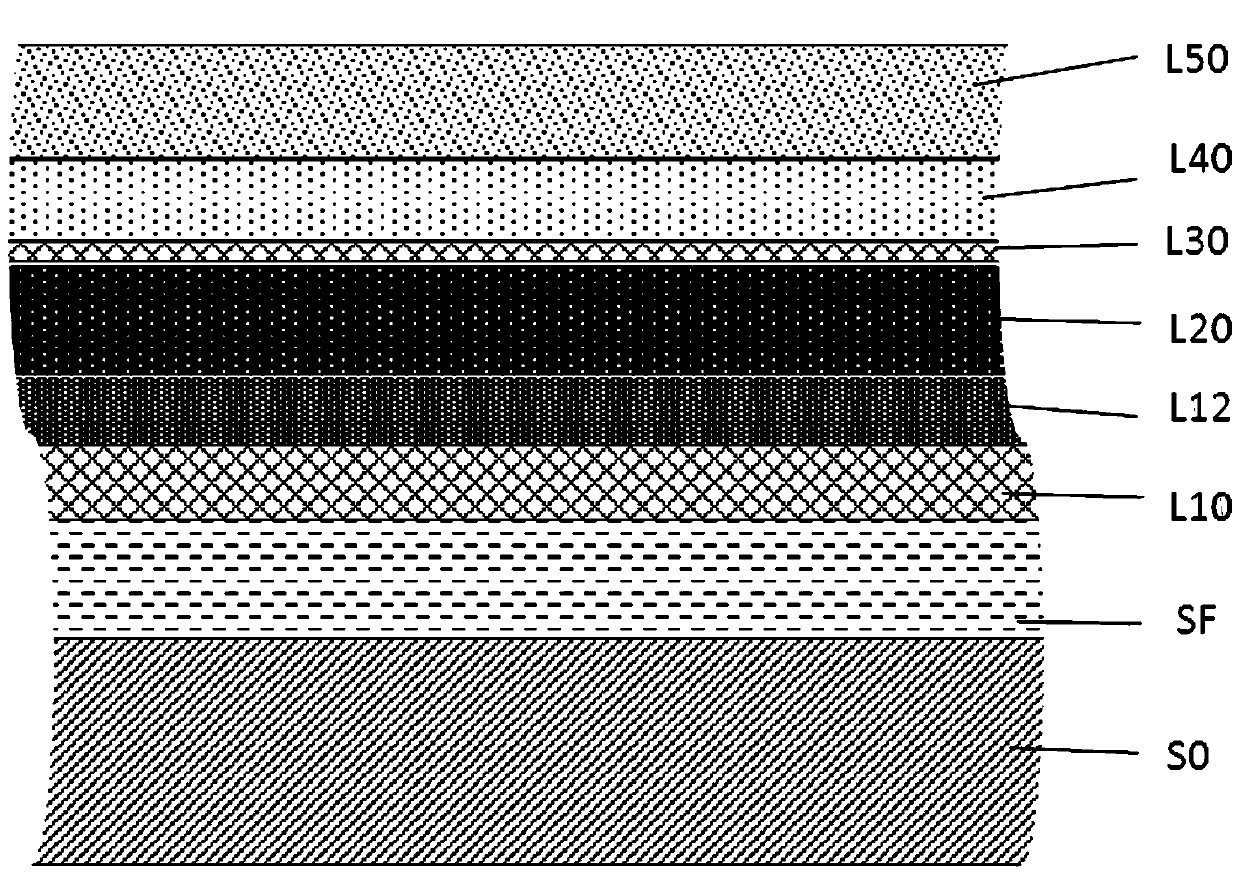

Method used

Image

Examples

example 1

[0077]

[0078] The coating film system in Example 1 was tested under different conditions, and the changes in total light reflectance YD65 / 2° and coating adhesion were observed. Among them, the measurement of the total light reflectance YD65 / 2° is based on the ISO6719:2010 standard and the joint ISO / CIE standard, ISO10526:1999 / CIES005 / E-1998 (the standard illuminant used by CIE for quantitative analysis of chromaticity). Coating adhesion is measured according to the Baigrid cross scratch adhesion test described in ISO2409:2013 and GB / T9286-1998 standards. Concrete coating film system test result in example one is as follows:

[0079]

example 2

[0081]

[0082] The coating film system in Example 2 was tested under different conditions, and the changes in total light reflectance YD65 / 2° and coating adhesion were observed. Among them, the measurement of the total light reflectance YD65 / 2° is based on the ISO6719:2010 standard and the joint ISO / CIE standard, ISO10526:1999 / CIES005 / E-1998 (the standard illuminant used by CIE for quantitative analysis of chromaticity). Coating adhesion is measured according to the Baigrid cross scratch adhesion test described in ISO2409:2013 and GB / T9286-1998 standards. Concrete coating film system test result in example two is as follows:

[0083]

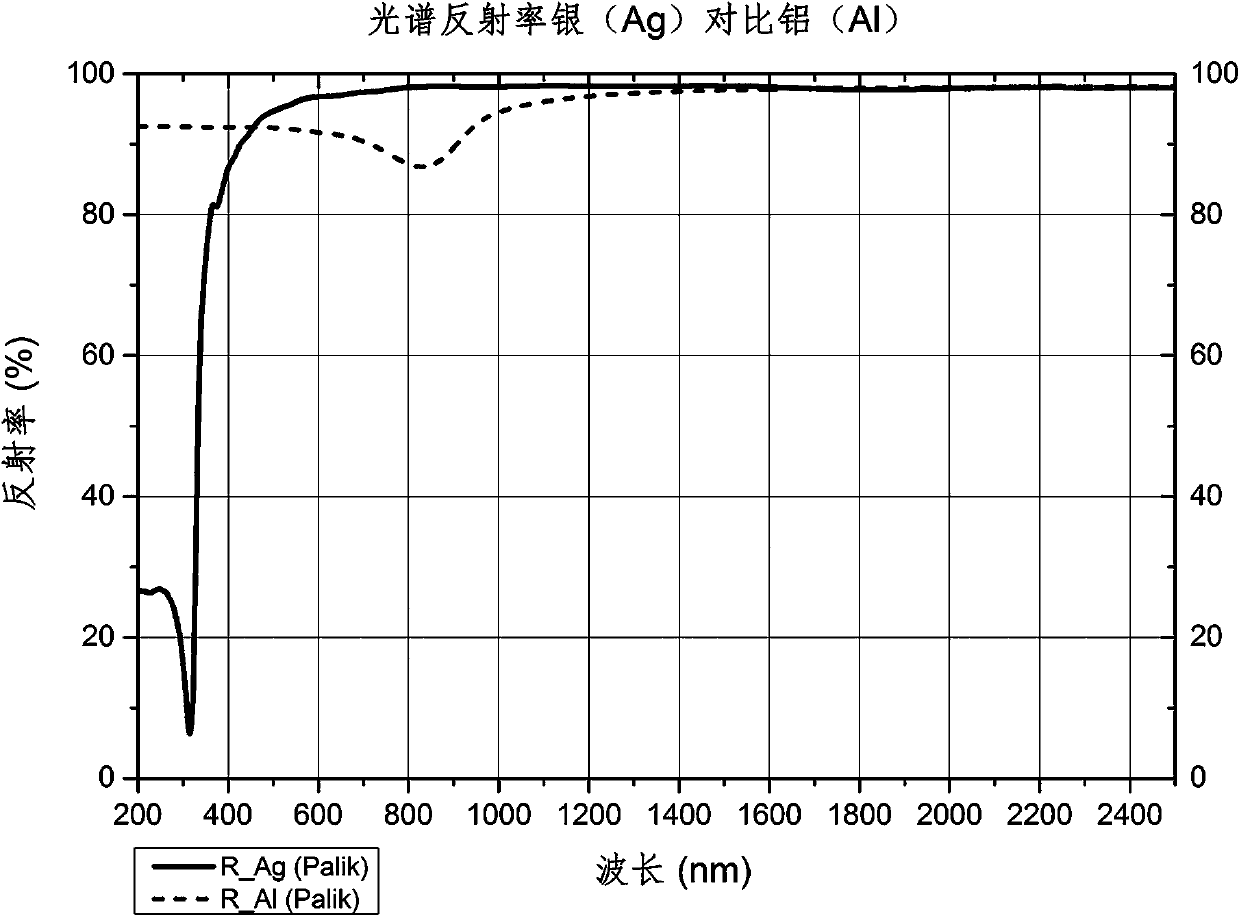

[0084] It can be concluded that the high reflection mirror coating film system disclosed by the present invention has a very high reflectivity in the wavelength range of 400 nm to 2500 nm, and has the advantages of high durability and high reliability under high temperature and corrosive environment conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com