Patents

Literature

383 results about "Standard illuminant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A standard illuminant is a theoretical source of visible light with a profile (its spectral power distribution) which is published. Standard illuminants provide a basis for comparing images or colors recorded under different lighting.

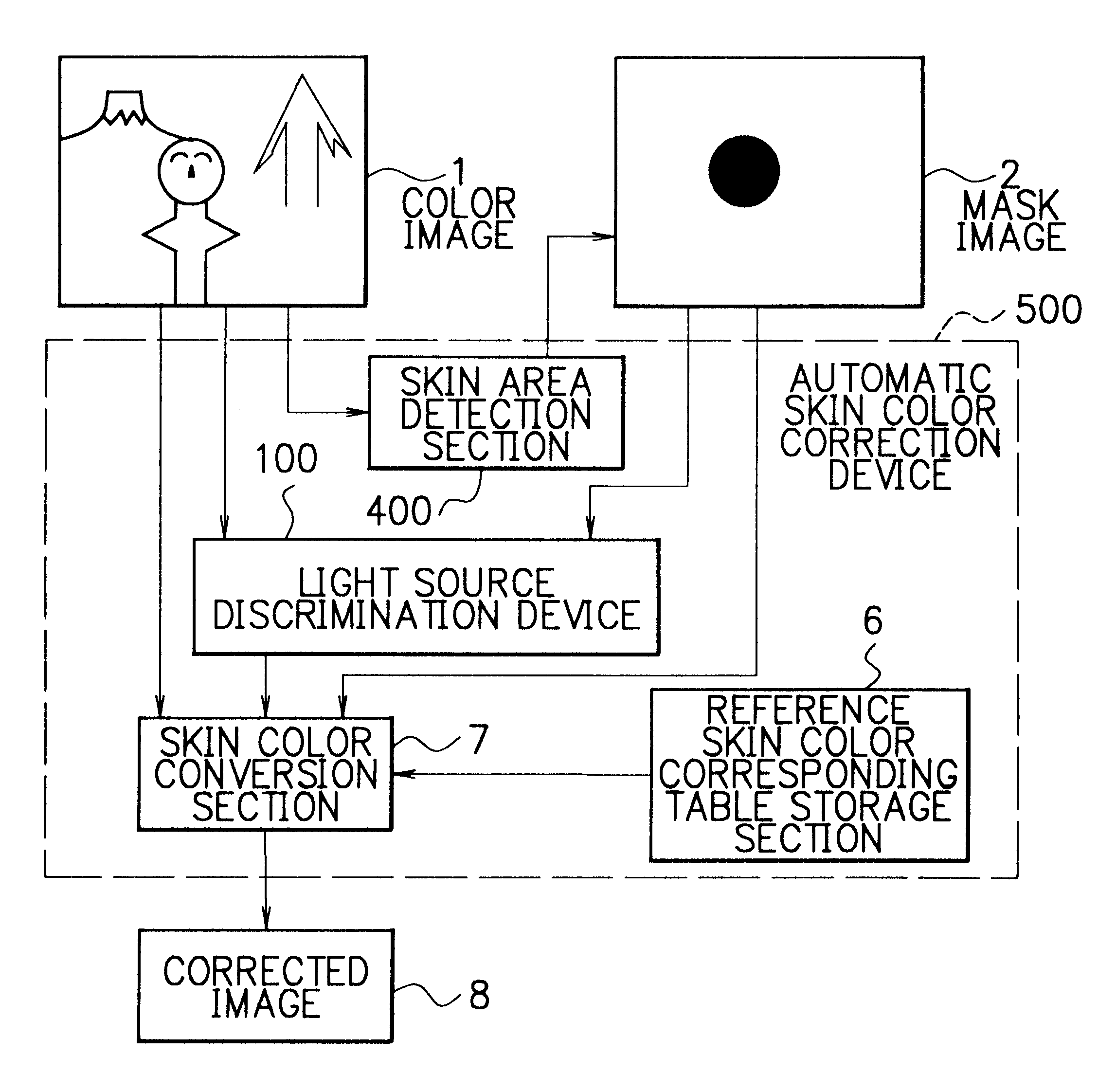

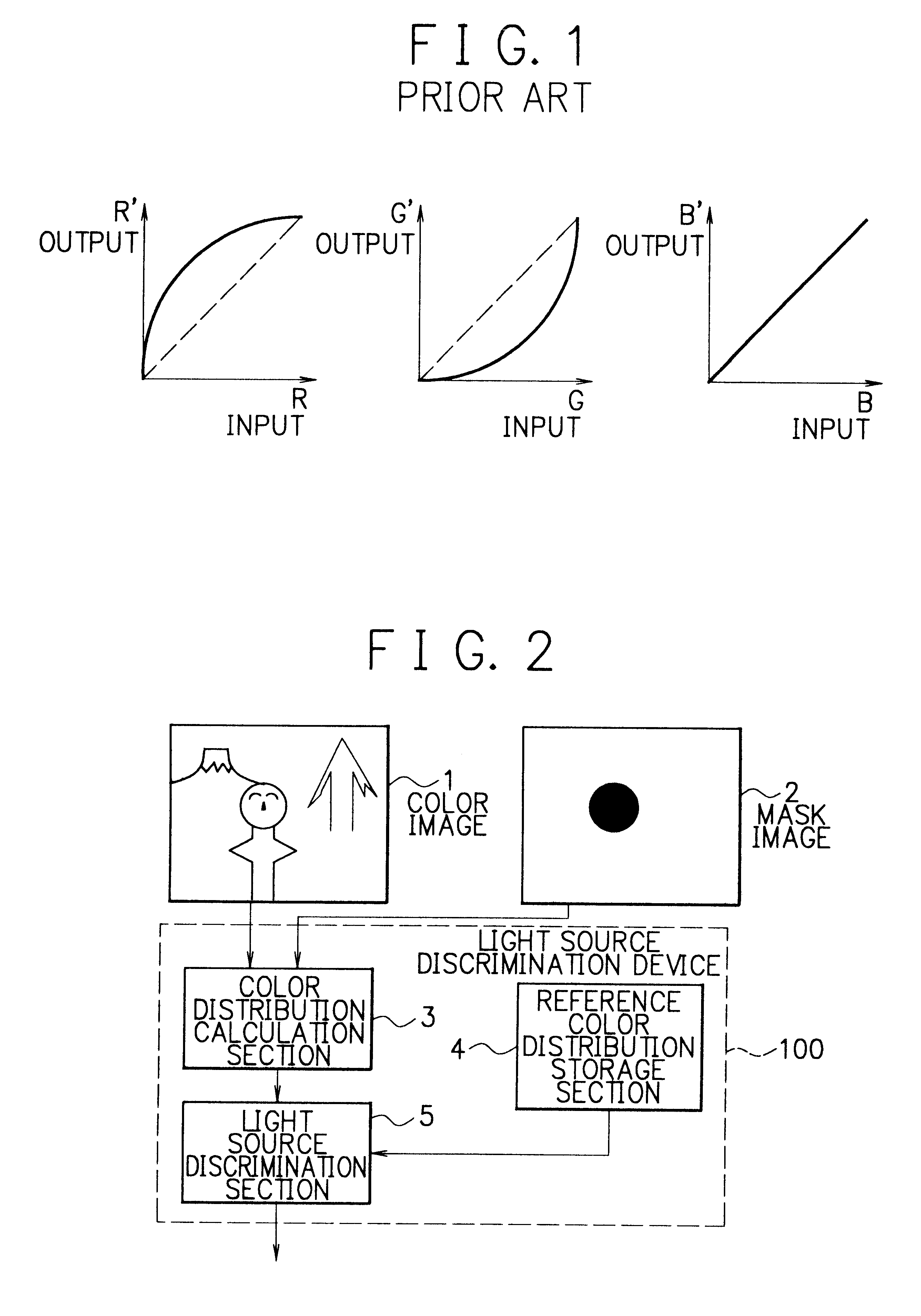

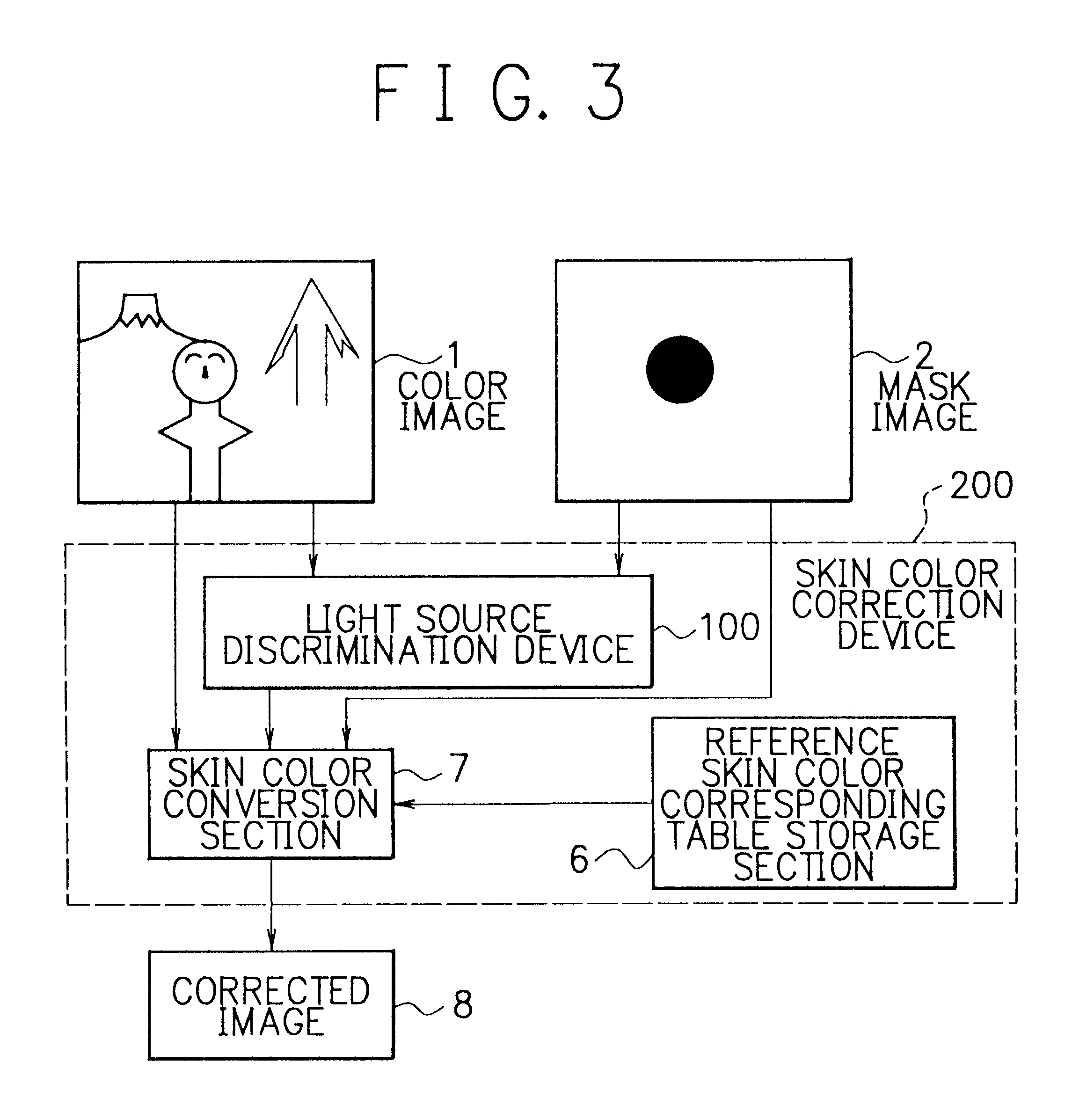

Method and device of light source discrimination, skin color correction, and color image correction, and storage medium thereof capable of being read by computer

A method and a device of light source discrimination, skin color correction, and color image correction, and storage medium thereof capable of being read by a computer always enable reproducibility, of color to be maintained highly regardless of difference of light source. There is calculated color distribution of portion of a face or skin in image by color distribution calculation section. There is compared the color distribution with distribution of skin color taken photograph under respective light sources stored in reference color distribution storage section. A light source discrimination section discriminates the light source at the time of taking photograph. There is corrected color by converting color under the light source of candidate substance into a corresponding color under standard light source.

Owner:NEC CORP

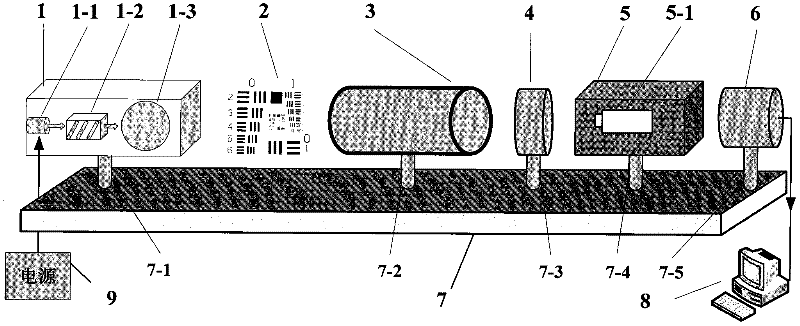

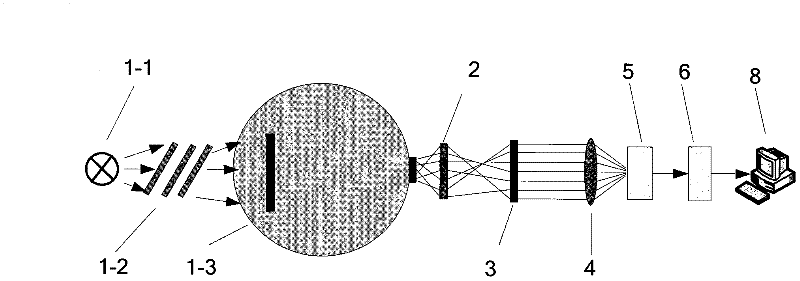

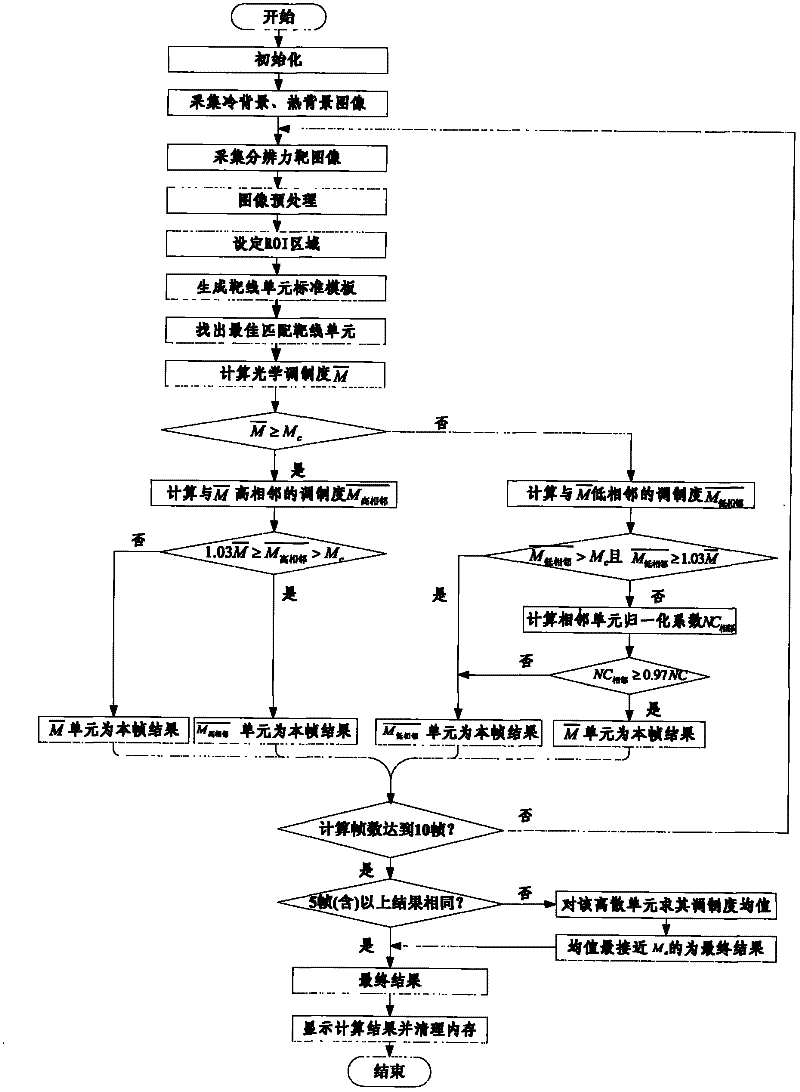

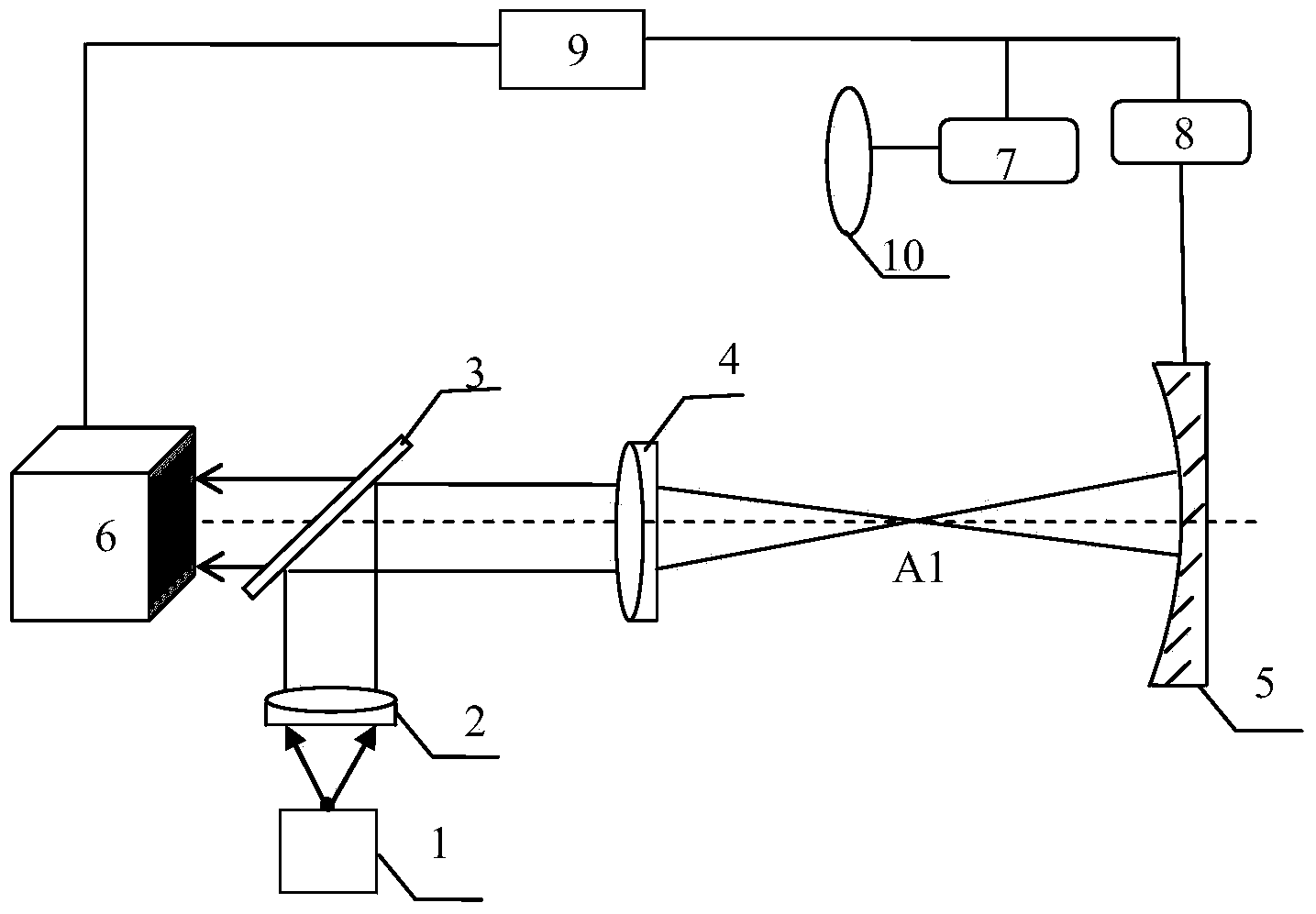

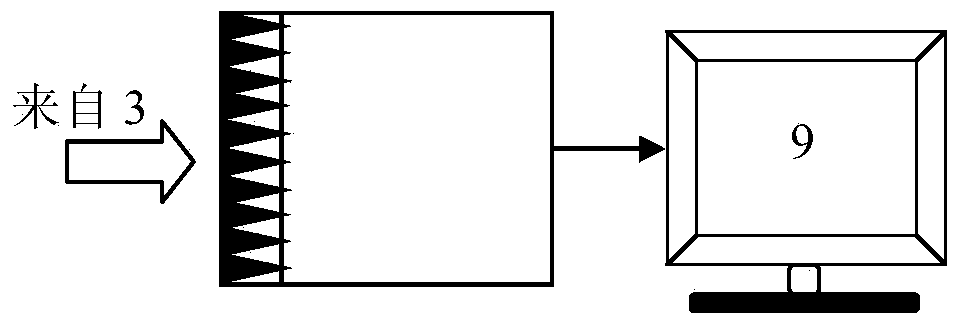

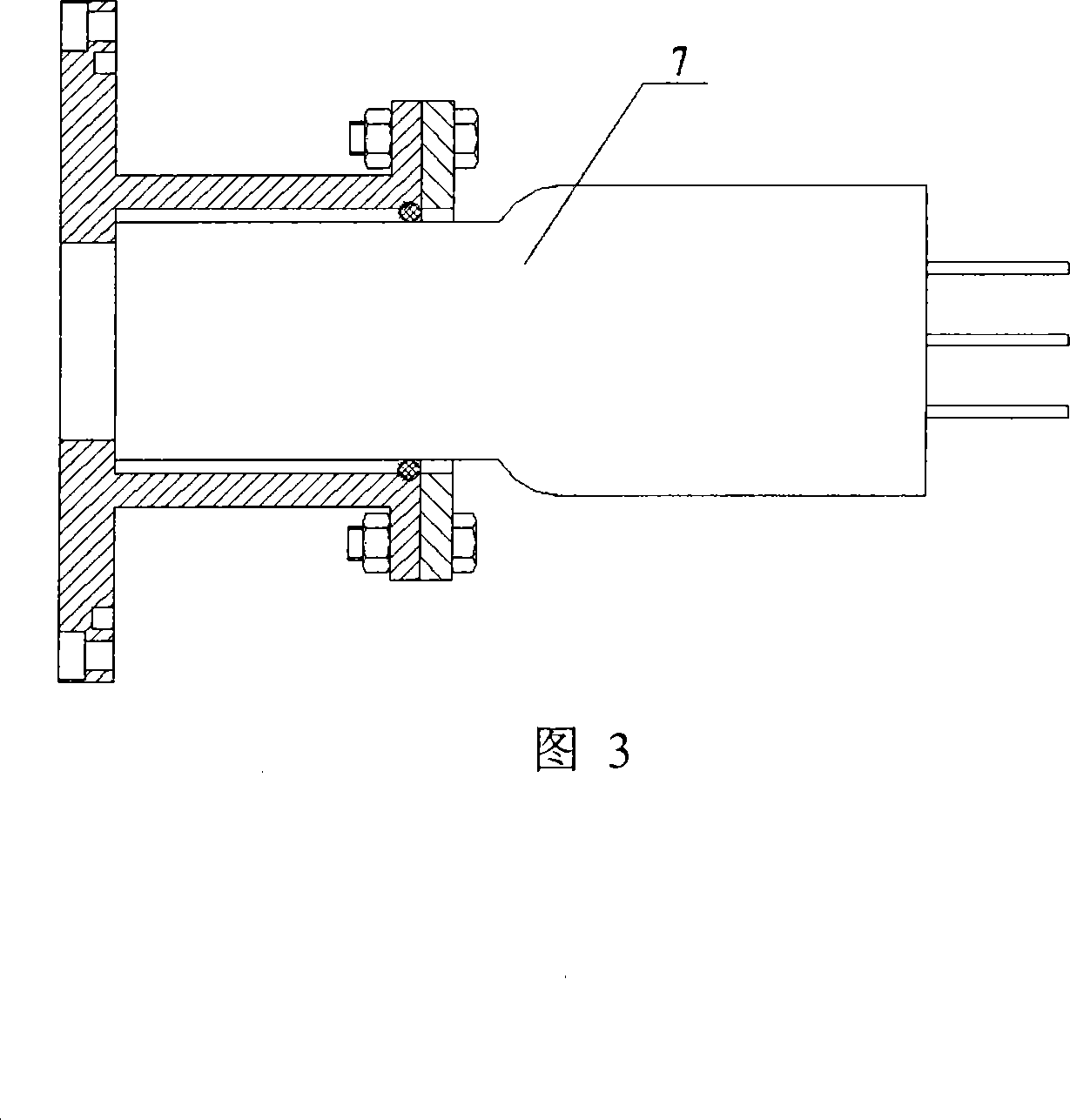

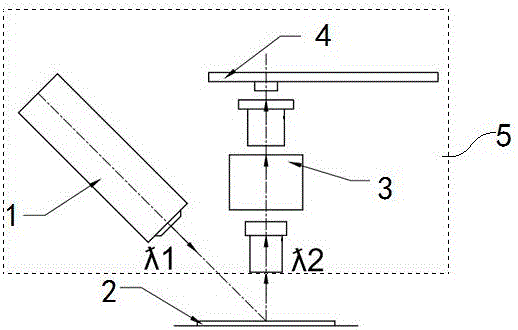

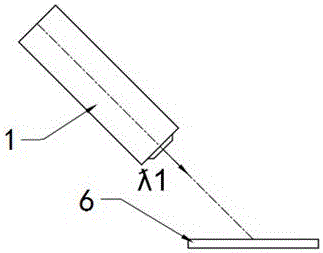

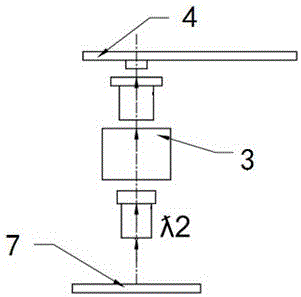

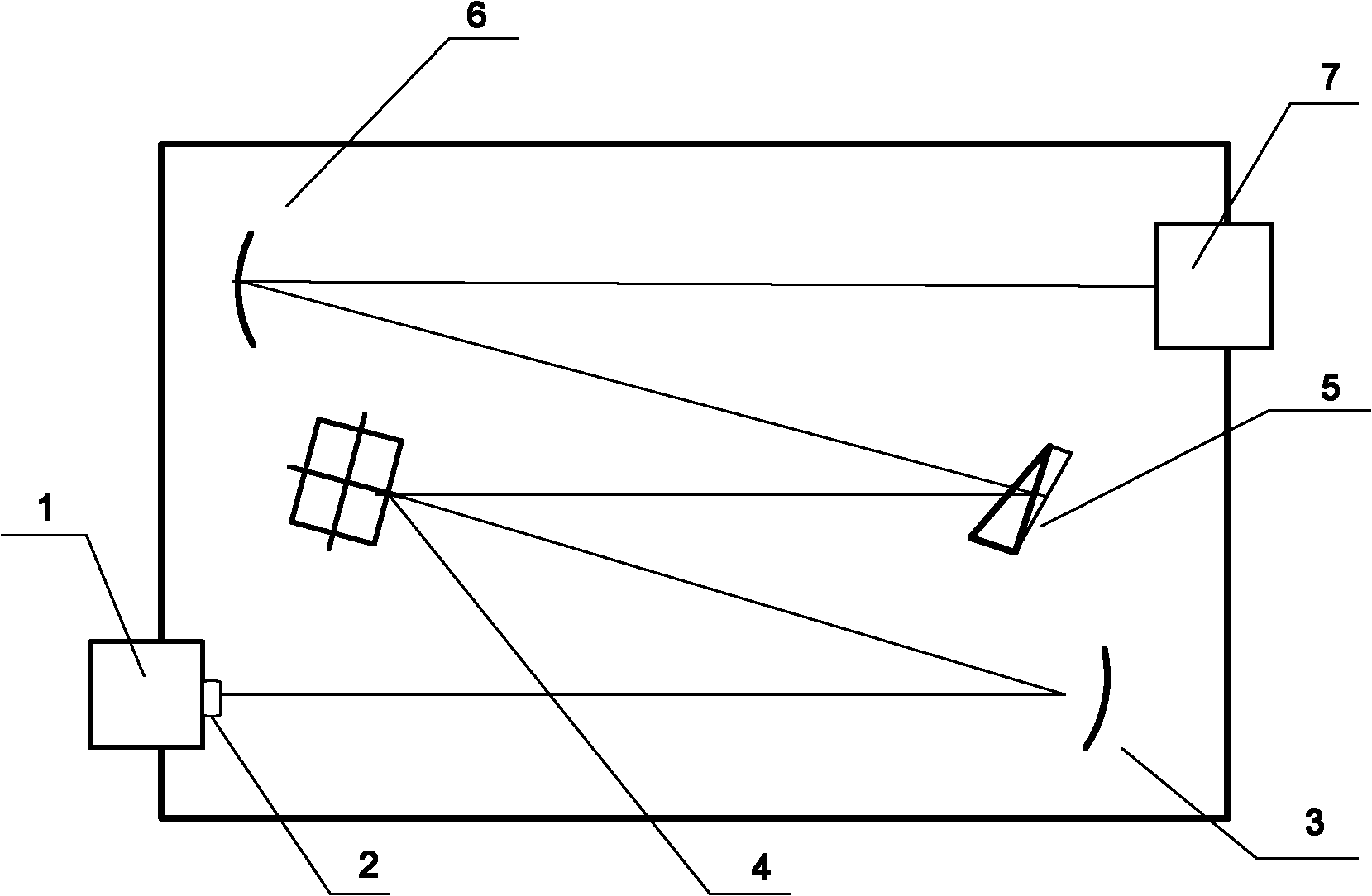

Resolving power measuring device and resolving power evaluation method for three-generation dim light image intensifier

ActiveCN102353519AImprove uniformityCancel noiseTesting optical propertiesMeasurement deviceOptical measurements

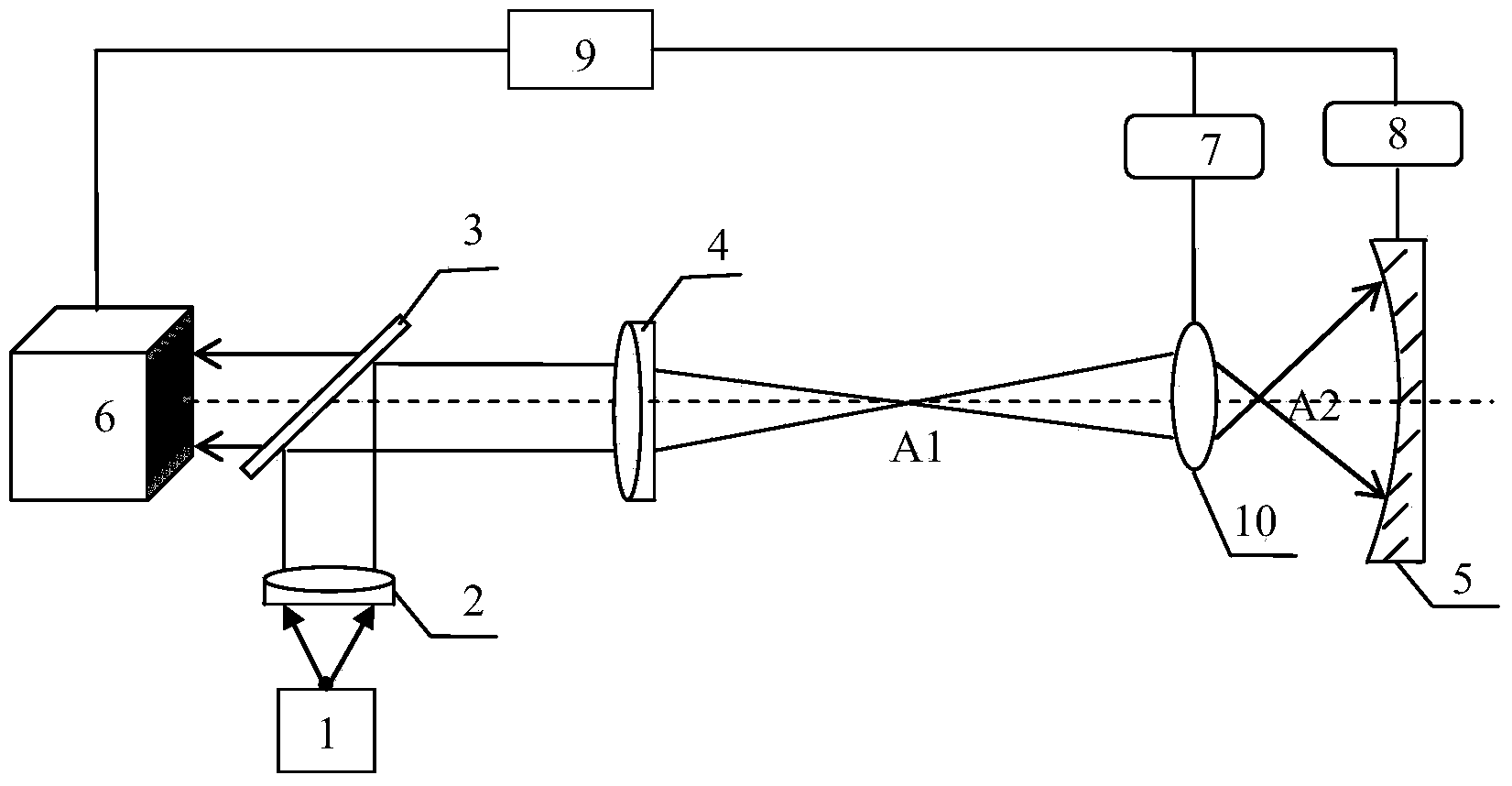

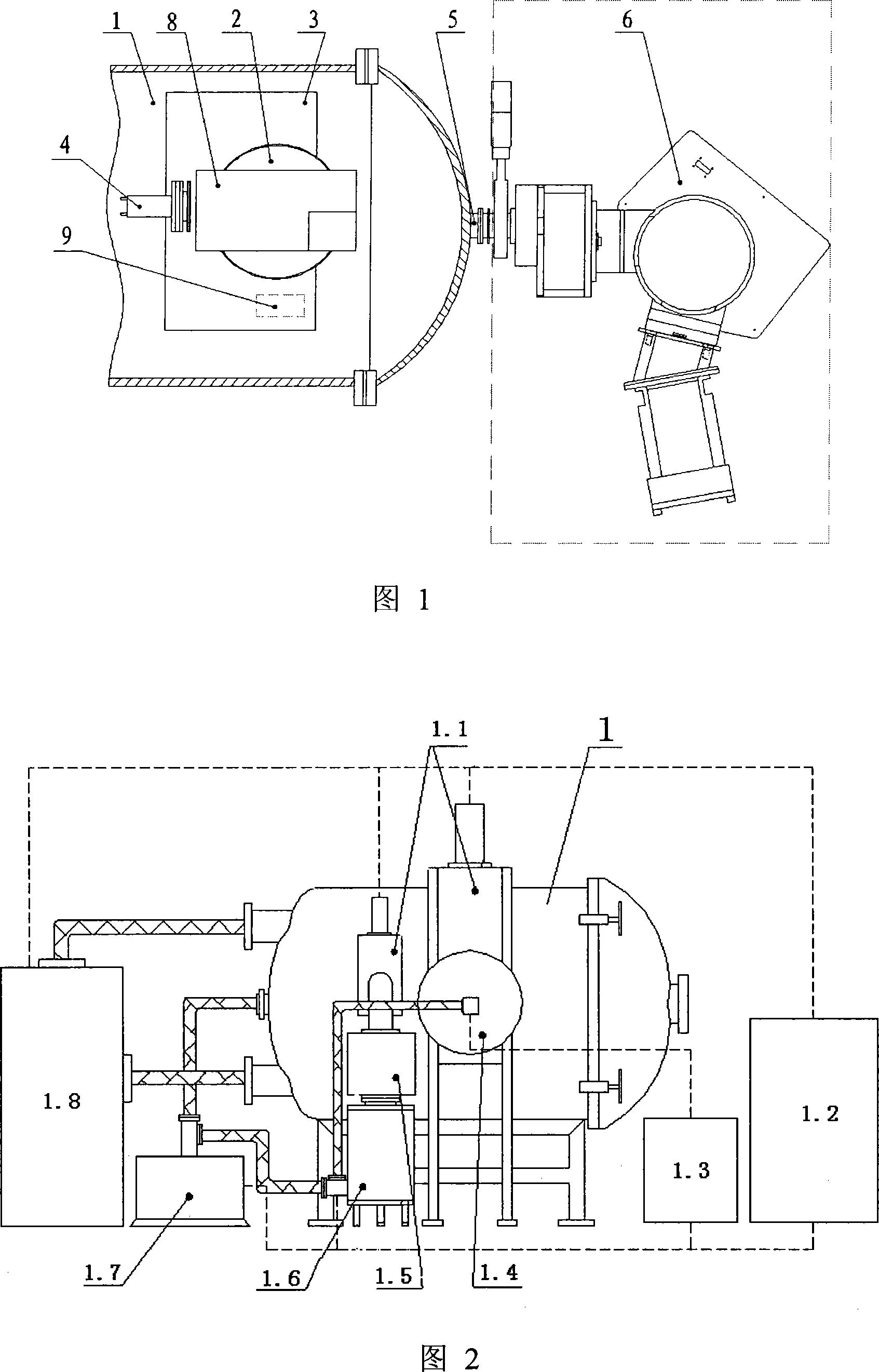

The invention discloses a resolving power measuring device and a resolving power evaluation method for a three-generation dim light image intensifier, and belongs to the field of optical measurement and metering. The resolving power measuring device is characterized by consisting of a light source component, a resolving power target, a collimator tube, an imaging objective lens, a test camera obscura, a charge coupled device (CCD) camera and a computer. The resolving power evaluation method comprises the following steps of: imaging the resolving power target irradiated by a standard light source to a fluorescent screen by using a measured image intensifier; converting into a frame image of a target line by using the CCD camera, and transmitting into the computer; successively processing asingle frame image of the target line by using a normalized cross correlation model and an optical modulation degree model through internal image processing software of the computer to acquire a single frame processing result; and analyzing multi-frame processing results and performing corresponding supplement operation to acquire a final resolving power evaluation result. By the device and the method, the problem of objective evaluation during resolving power measurement of the three-generation dim light image intensifier is solved; and the device and the method can be popularized to other measurement fields such as an intensified charge coupled device (ICCD) measurement field and the like where resolving power is required to be objectively evaluated, and have wide application prospects.

Owner:CHINA NORTH IND NO 205 RES INST

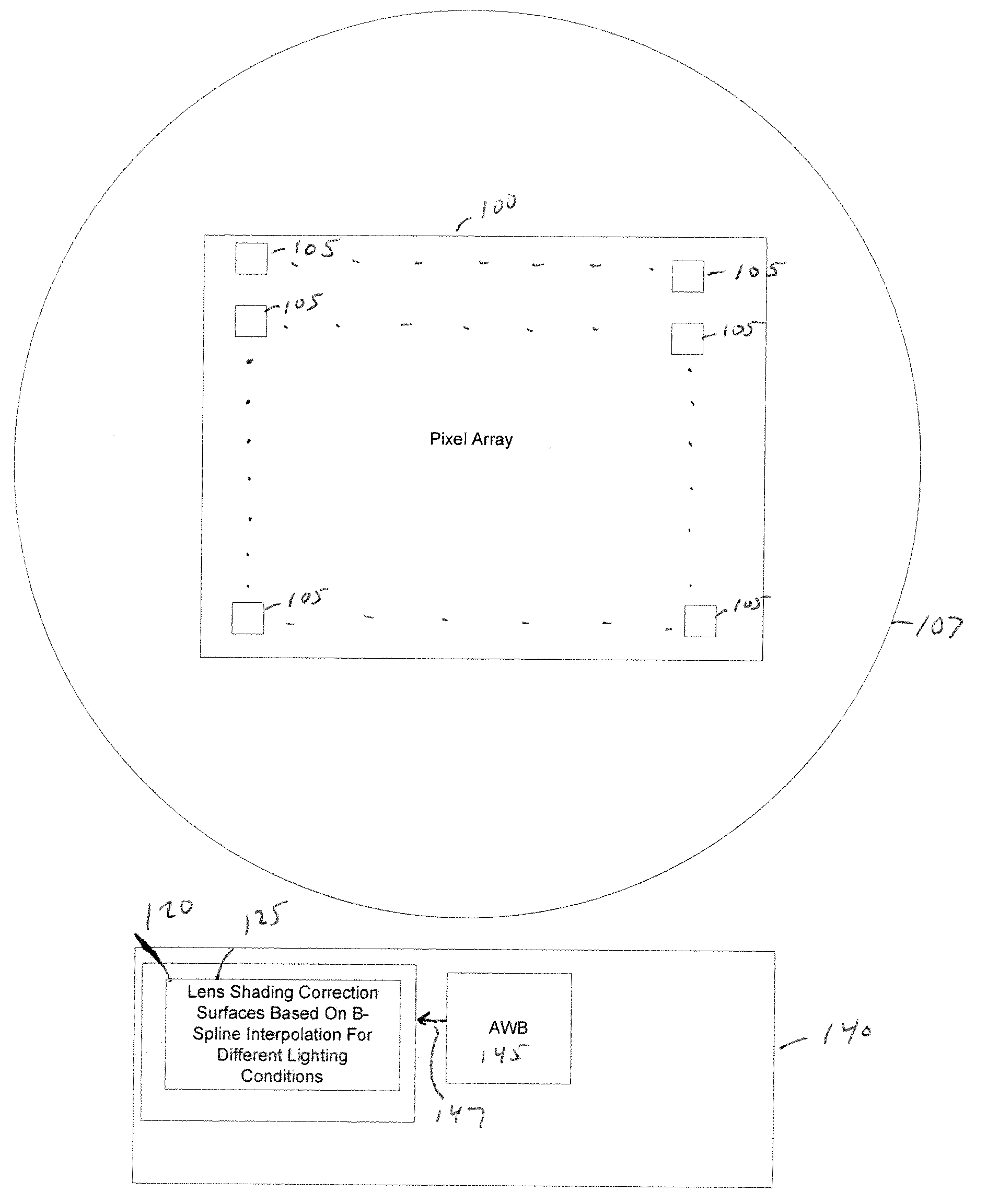

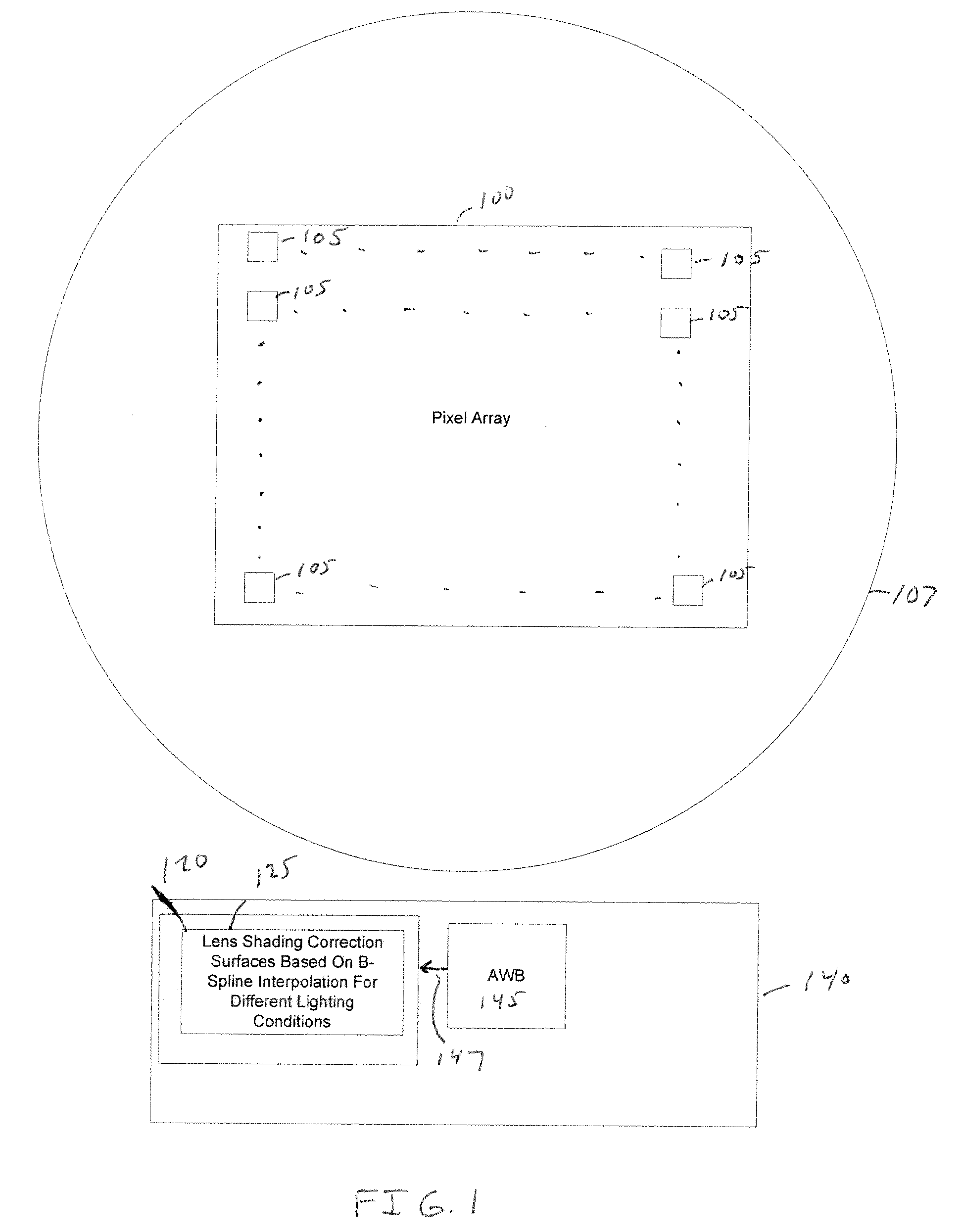

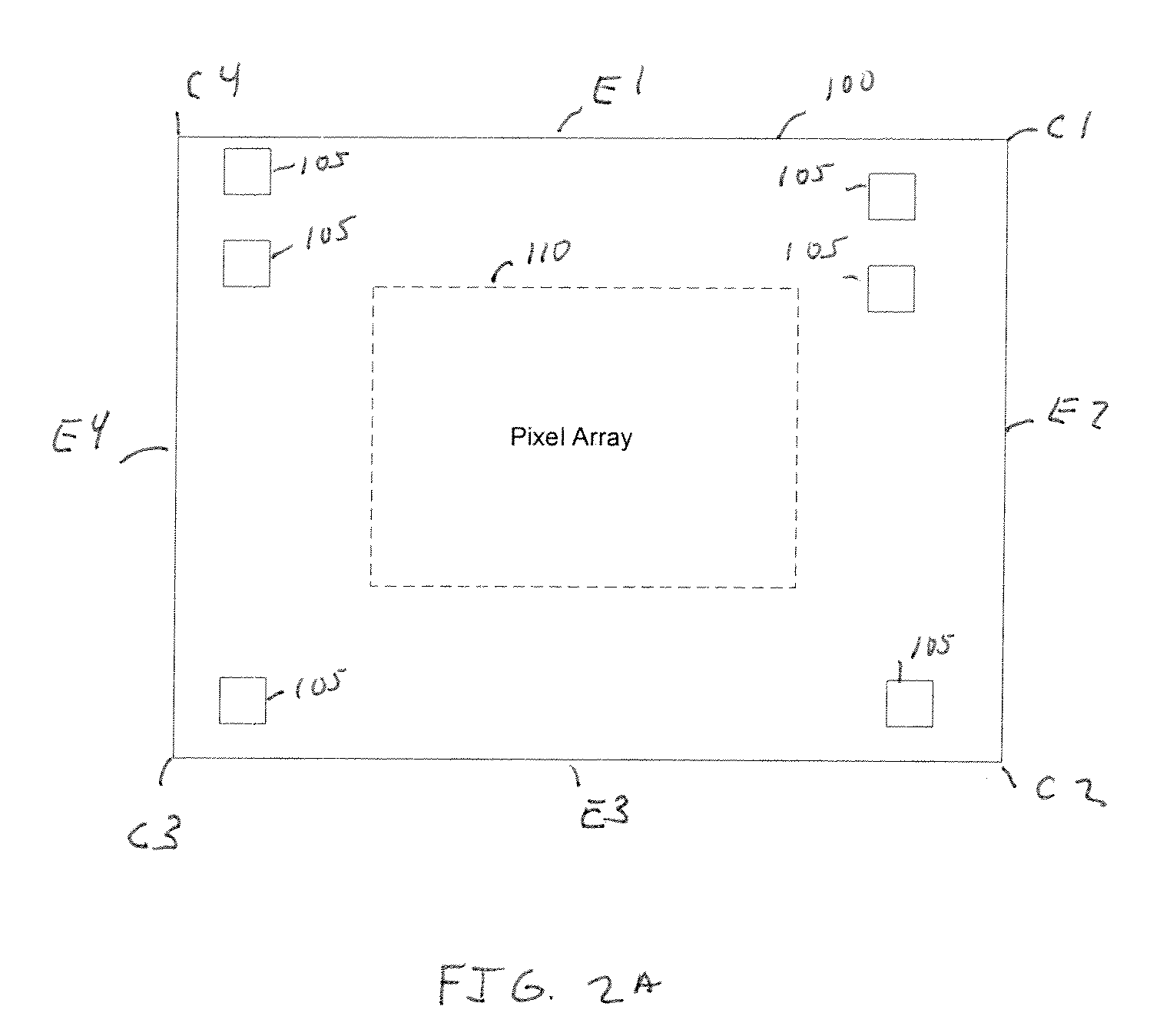

System and Method For Lens Shading Correction Of An Image Sensor Using Splines

ActiveUS20090268053A1Television system detailsColor signal processing circuitsCamera lensStandard illuminant

An image sensing system provides for accurate lens shading correction even when there is significant lens shading asymmetry and non-uniformity. A two-dimensional B-spline technique is used to determine lens shading correction surfaces. The number of zones is selected to achieve accurate correction of center, edge, and corner regions of an image. Separate lens shading correction surfaces are calculated for a set of standard illuminants to permit lens shading correction to be adapted based on the illuminant used to capture the image.

Owner:OMNIVISION TECH INC

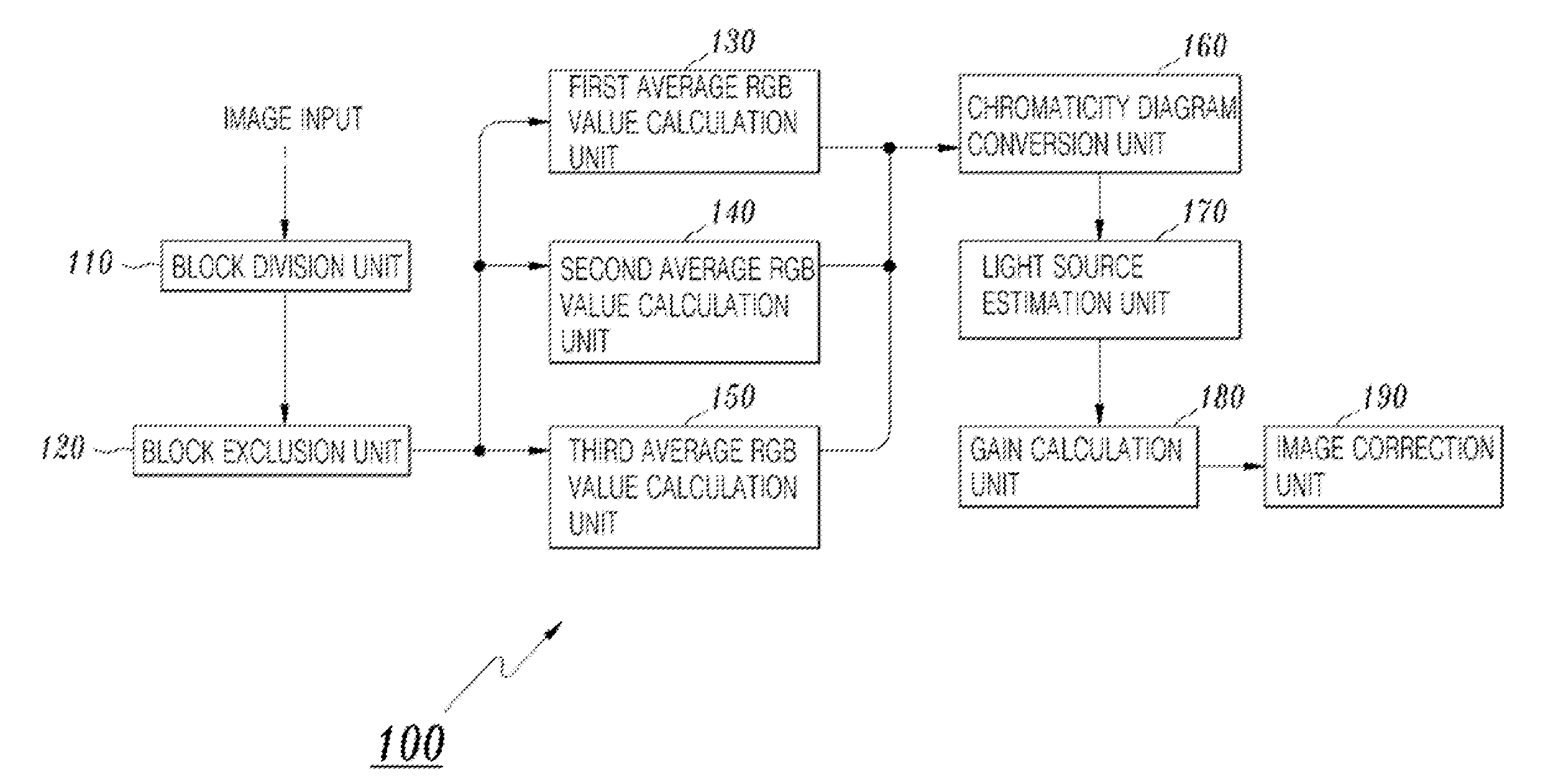

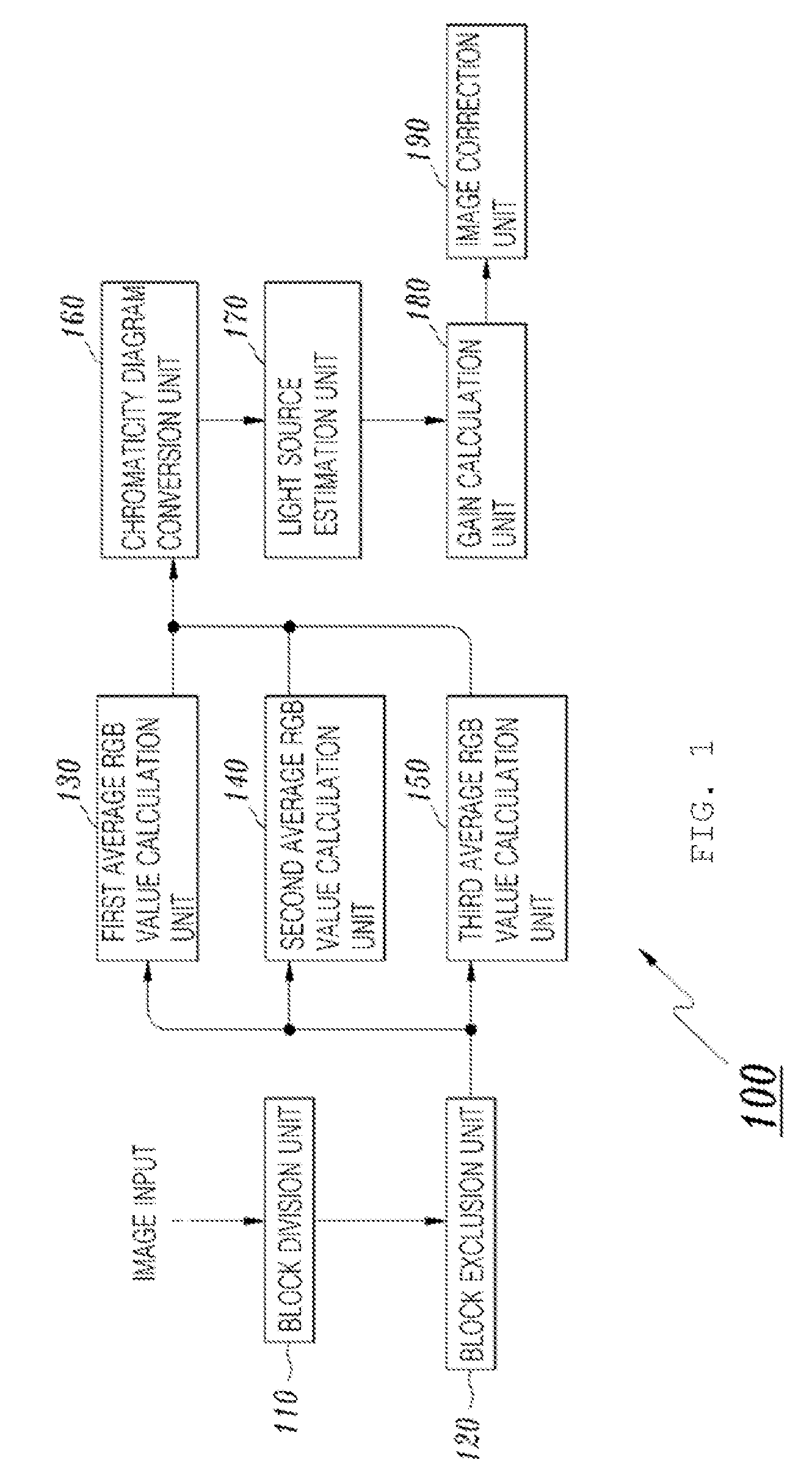

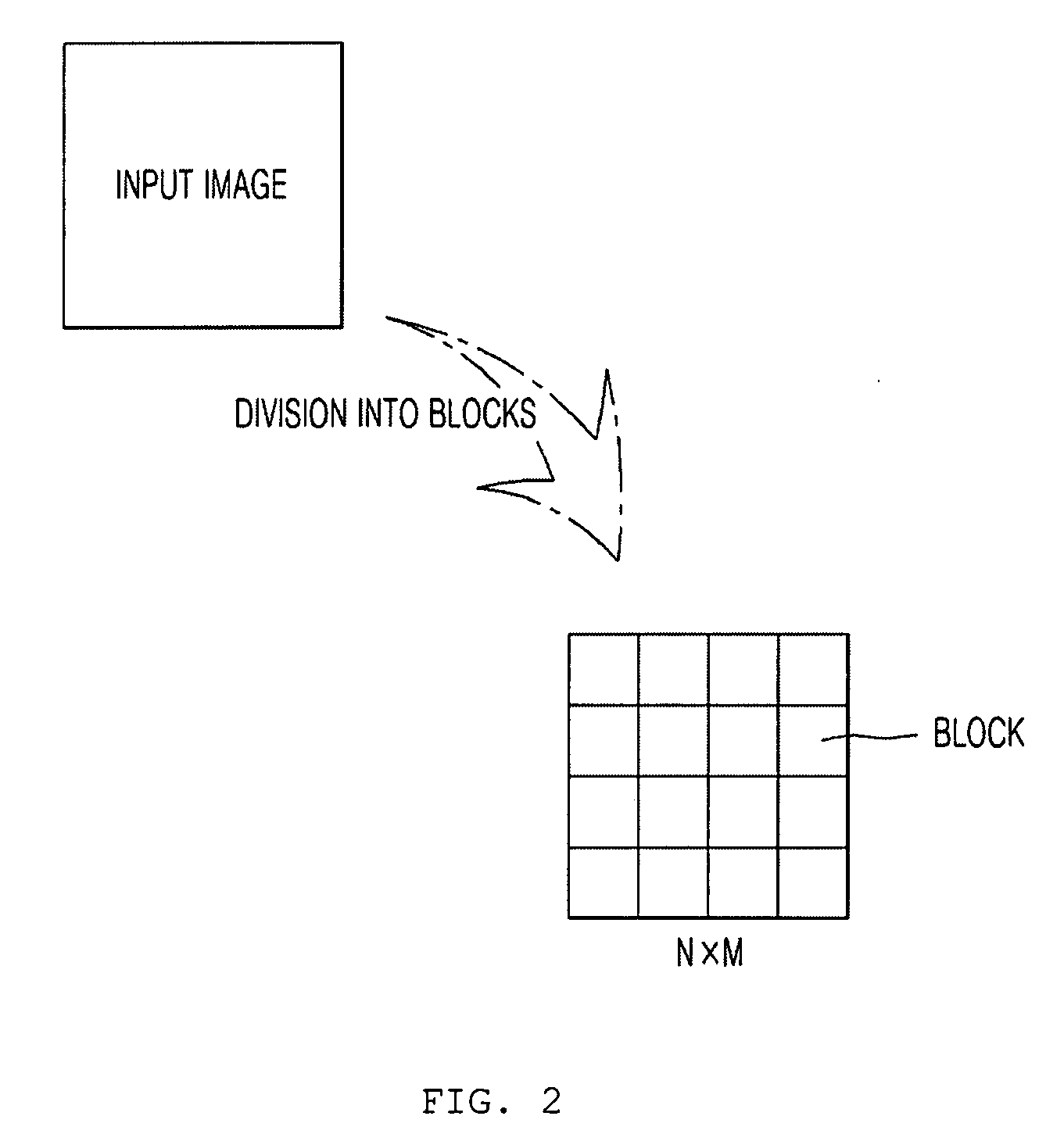

Method of performing robust auto white balance

ActiveUS20090097745A1Improve accuracyImprove reliabilityColor signal processing circuitsCharacter and pattern recognitionHigh colorErrors and residuals

Disclosed herein is a method of performing robust white balance. The method includes a first process of dividing an input image into blocks, a second process of selecting blocks having higher color errors, and calculating average RGB values of the selected blocks, a third process of selecting a specific top percentage of bright blocks, and calculating the average RGB values of these selected blocks, a fourth process of calculating average RGB values through color clustering, a fifth process of converting the average RGB values into CIE xyY color space, a sixth process of calculating the Euclidean distances between the x and y values of standard light sources in a color space and the x and y values of the average RGB values in CIE xyY color space, and selecting an average RGB value having the shortest Euclidean distance (Ed), and a seventh process of calculating white balance gain values using the selected average RGB value, and correcting the input image using the balance gain values.

Owner:KOREA ADVANCED INST OF SCI & TECH

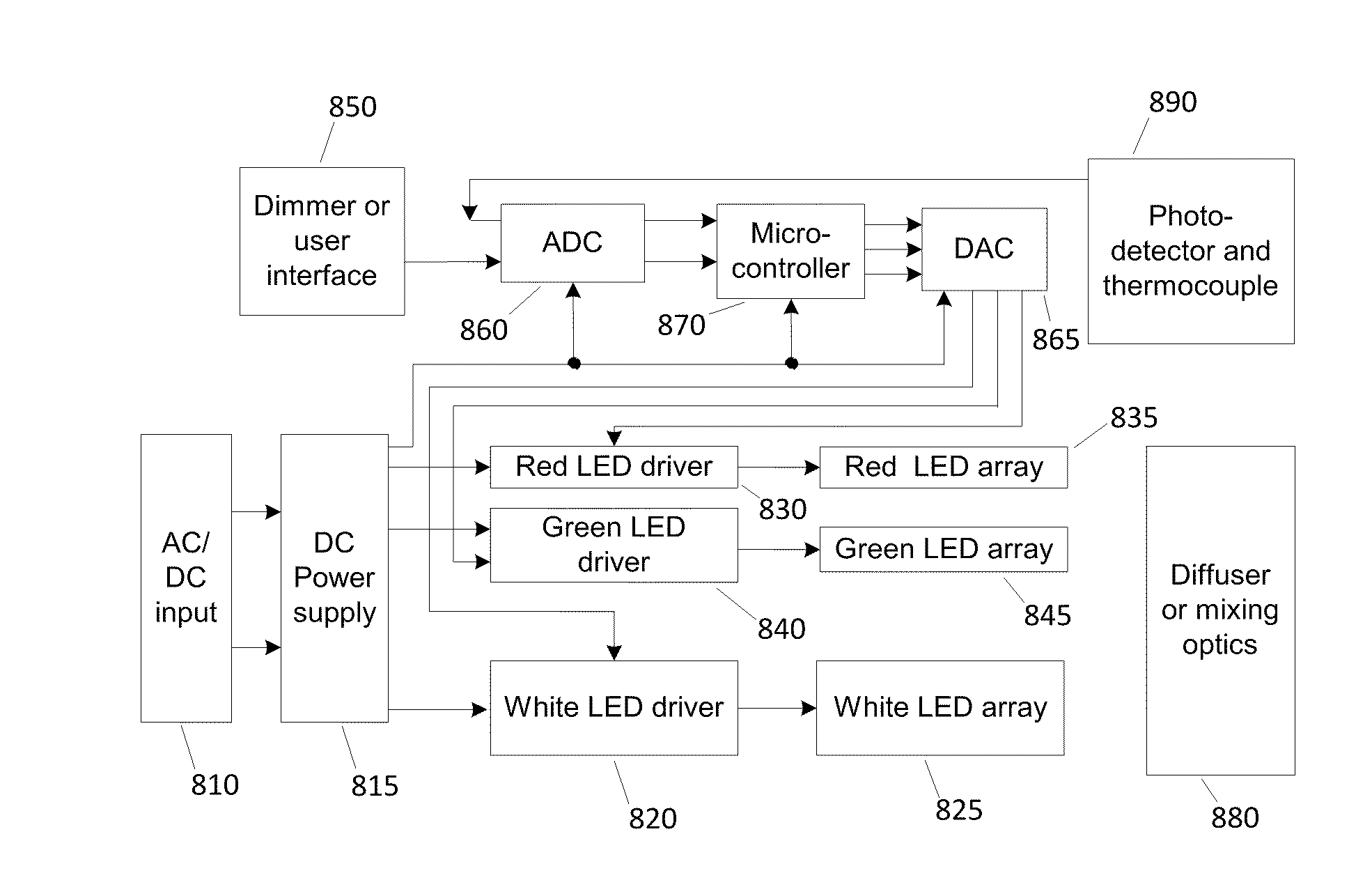

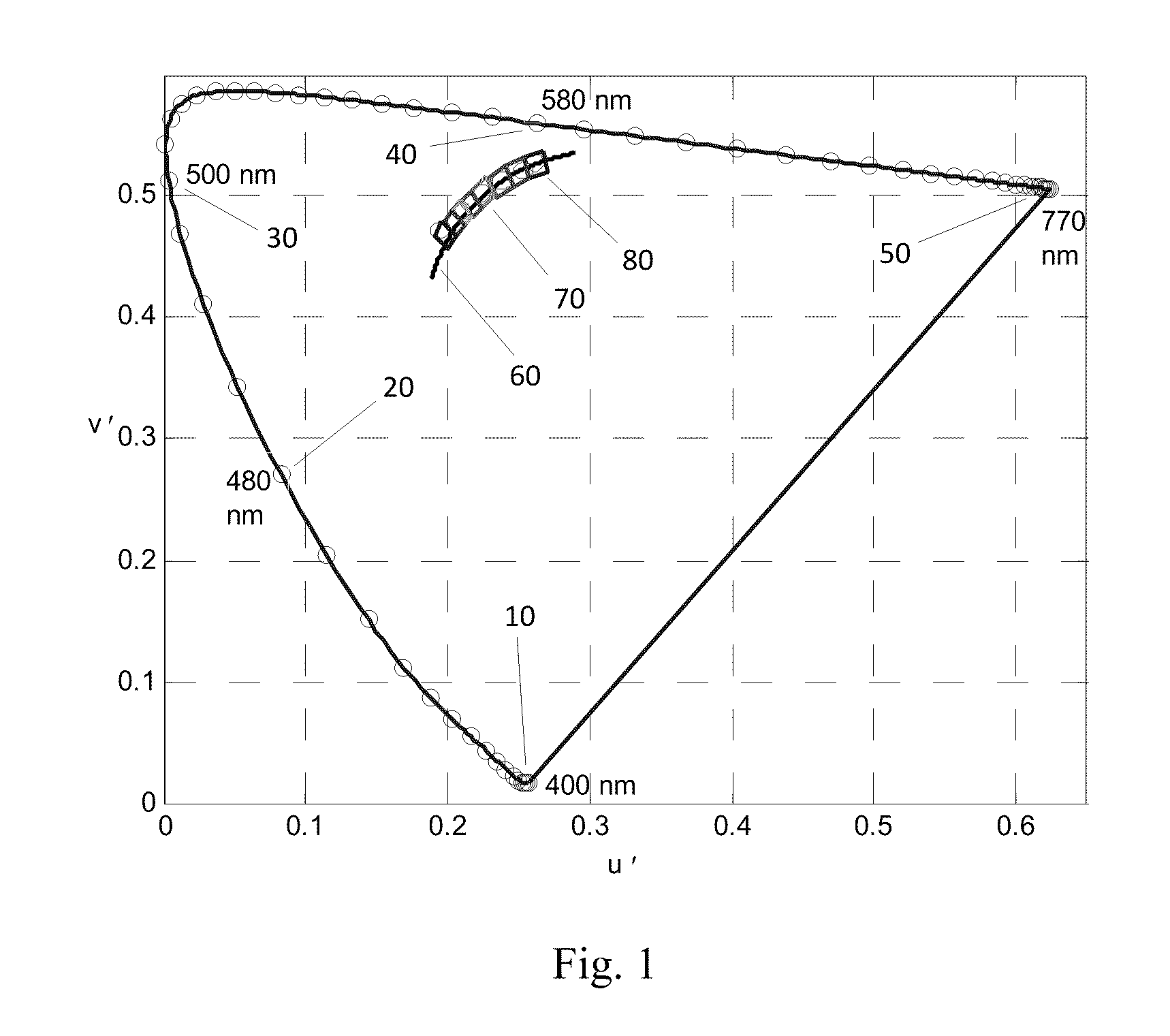

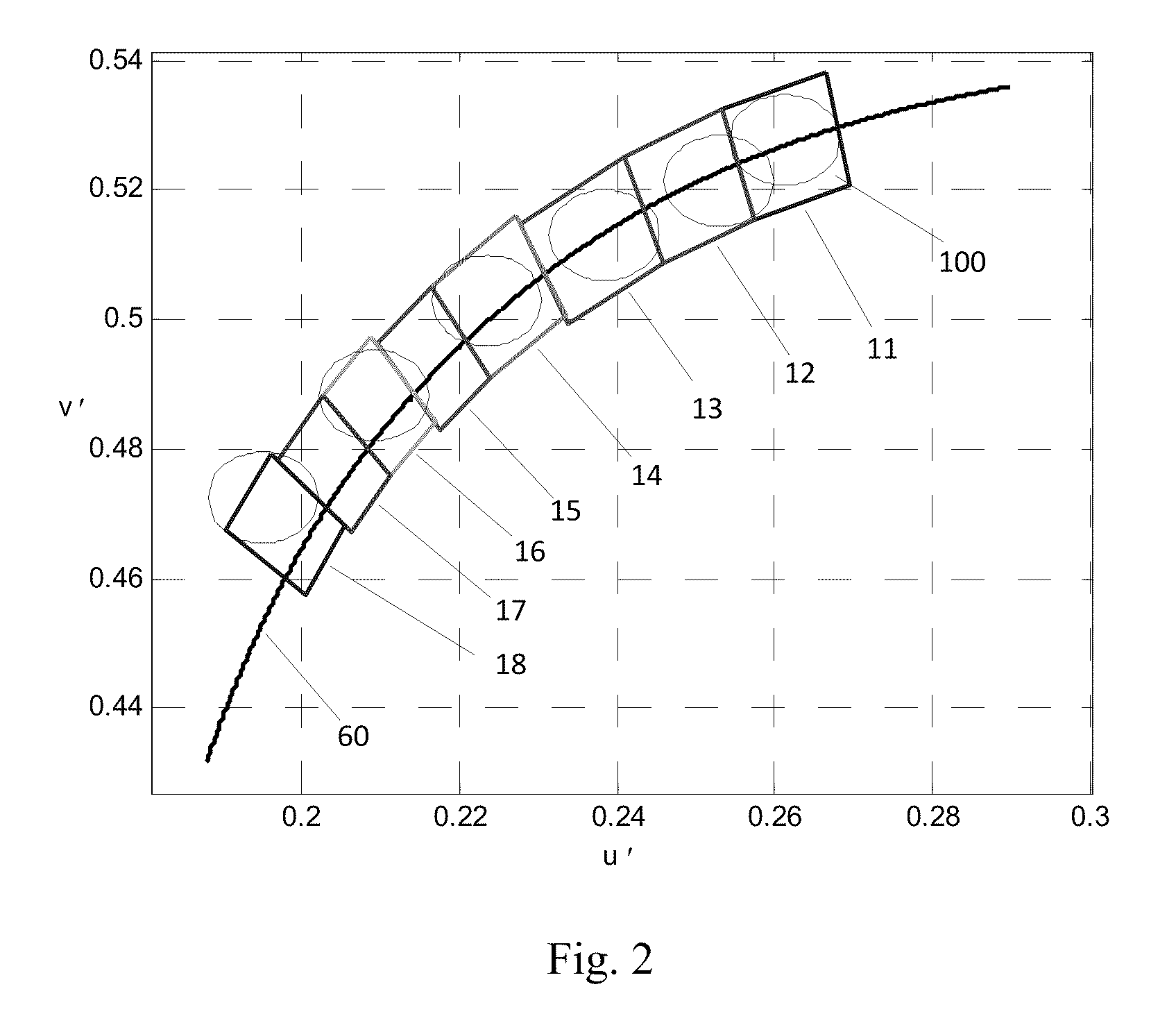

Solid-state lighting of a white light with tunable color temperatures

ActiveUS8358089B2Reduce dependenceImprove distributionLight source combinationsPoint-like light sourceSmart lightingPlanckian locus

Owner:ALEDDRA INC

Wave aberration detection device of objective lens imaging system and system error correction method of wave aberration detection device

ActiveCN104236856AEffective correctionMeasurement does not affectTesting optical propertiesWavefront sensorWave aberration

The invention discloses a wave aberration detection device of an objective lens imaging system. The wave aberration detection device comprises a light source, a collimating mirror, a spectroscope, a focusing mirror, a standard spherical reflector, a data processing unit, a wave-front sensor, a first accurate adjustment table and a second accurate adjustment table, wherein the collimating mirror, the spectroscope, the focusing mirror and the standard spherical reflector are sequentially placed in the light emitting direction of the light source, and the wave-front sensor, the first accurate adjustment table and the second accurate adjustment table are connected with the data processing unit. In the wave aberration detection device, the measurement processes and the system error calibration process are switched by changing the position of the standard spherical reflector 5; in the two measurement processes, the standard spherical reflector 5 has the same adjustment accuracy, and therefore the calibration, measurement and correction of device and system errors can be effectively completed, and the wave aberration measurement accuracy is improved. No high-precision standard light source is needed, and cost is reduced; A system error calibration method of the wave aberration detection device is simple and compact in structure and has the advantages of being easy to obtain and the like, and the wave aberration detection of the objective lens imaging system to be detected can be completed through the simple system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

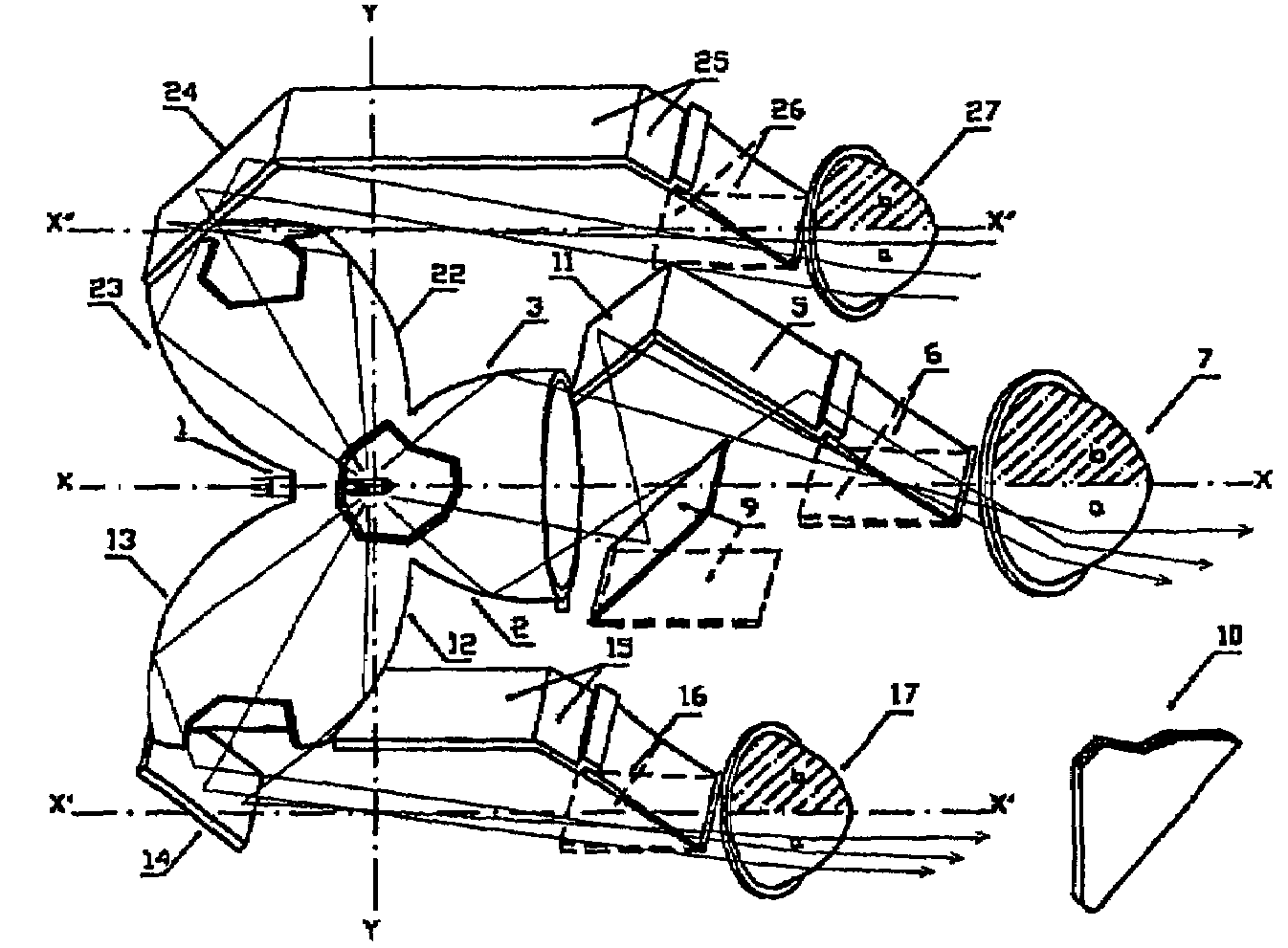

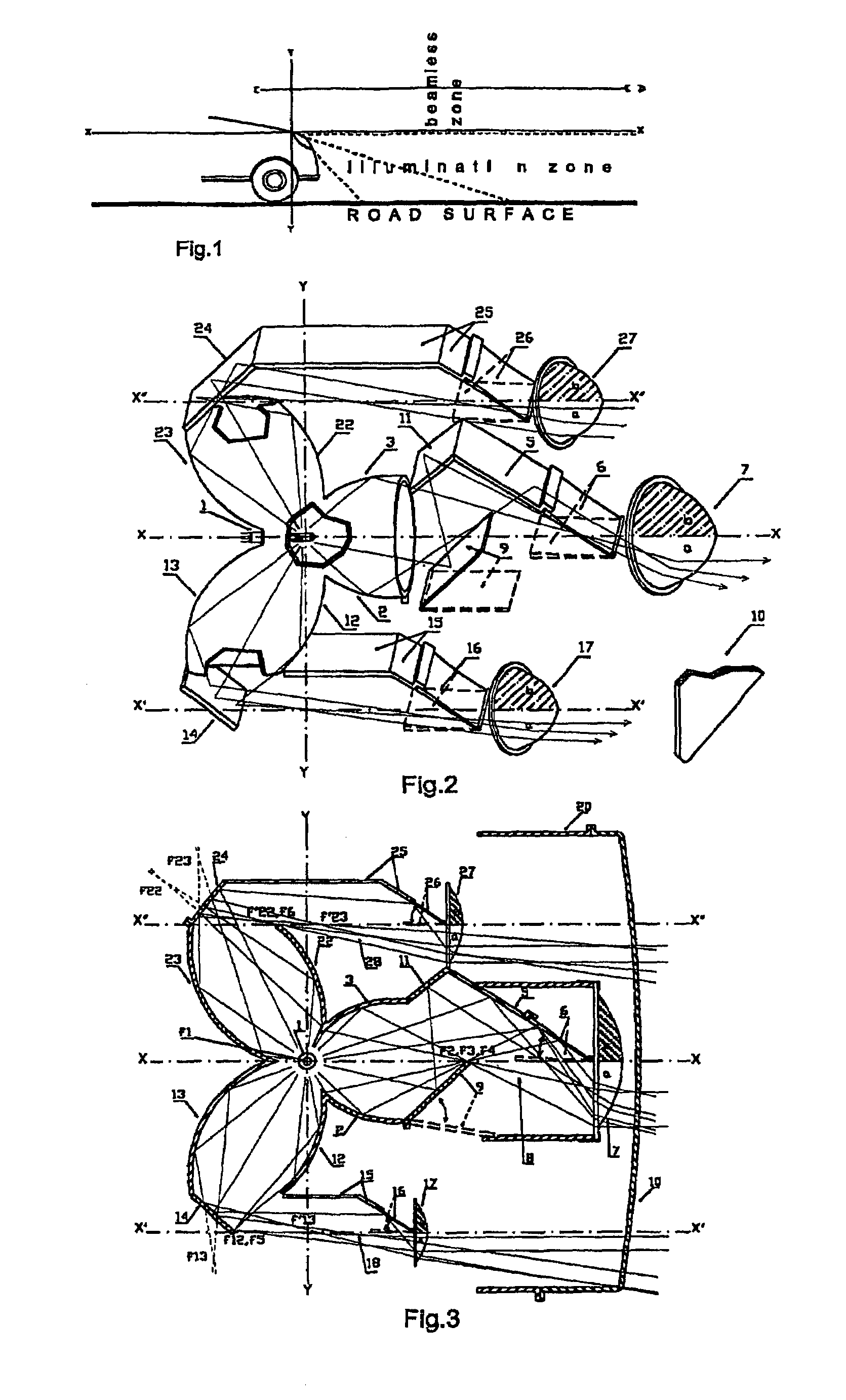

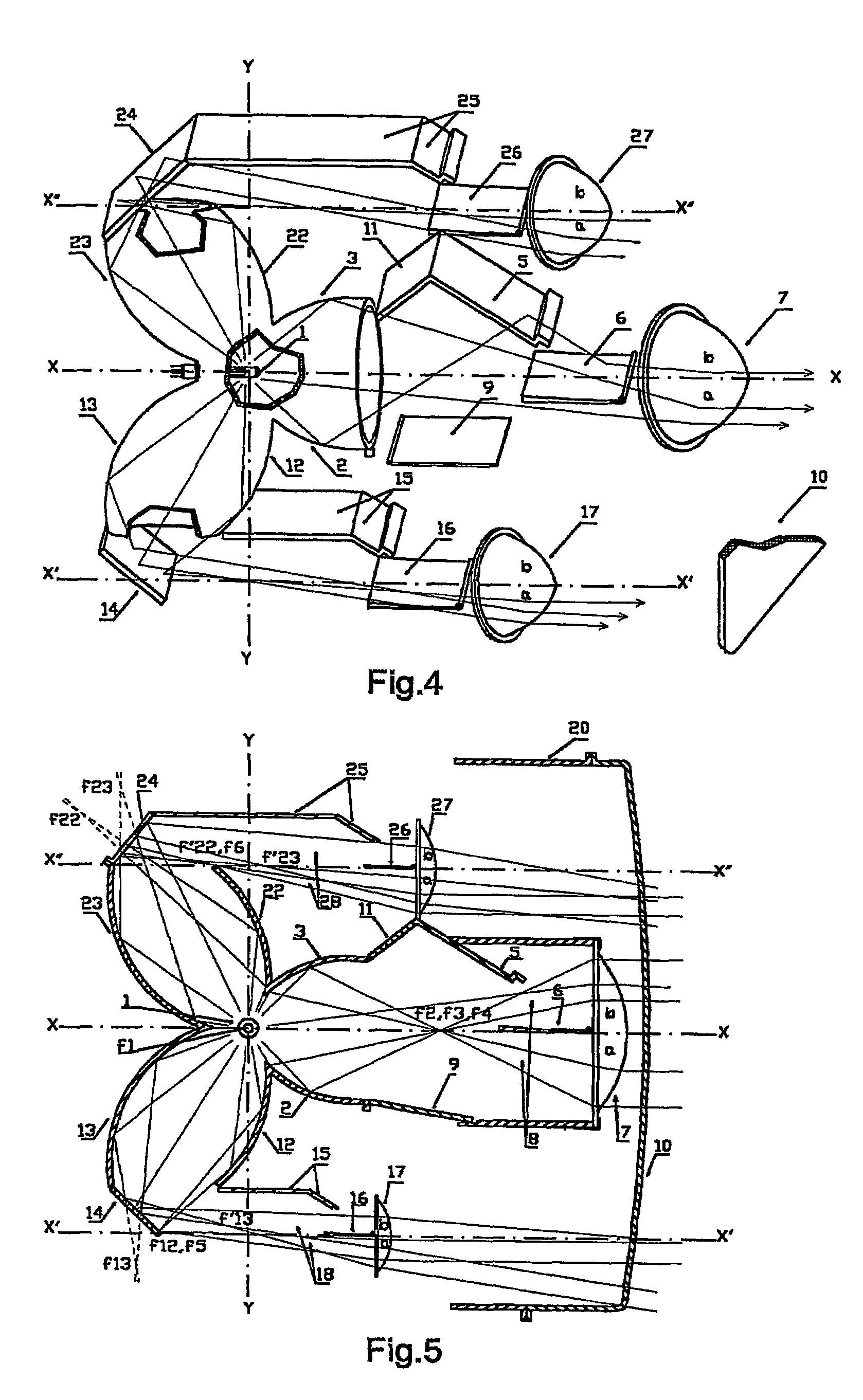

Headlamp with a continuous long-distance illumination without glaring effects

InactiveUS7452115B2Efficient use ofImprove viewing effectVehicle headlampsPoint-like light sourceForward lookingStandard illuminant

Owner:ALCELIK TURHAN

Solid-state lighting of a white light with tunable color temperatures

ActiveUS20110273107A1Alleviates thermal dependenceBroaden spectral power distributionLight source combinationsPoint-like light sourceSmart lightingPlanckian locus

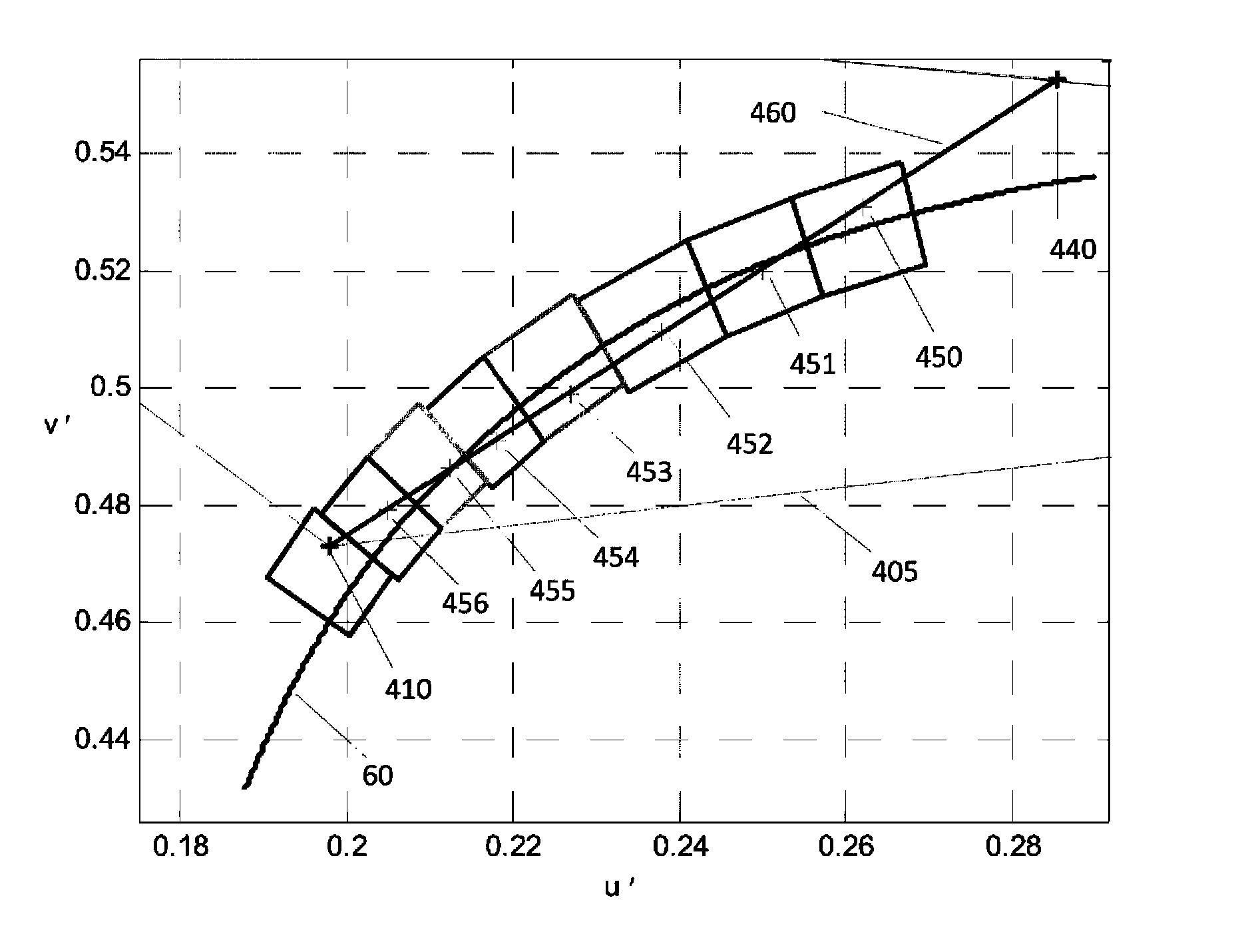

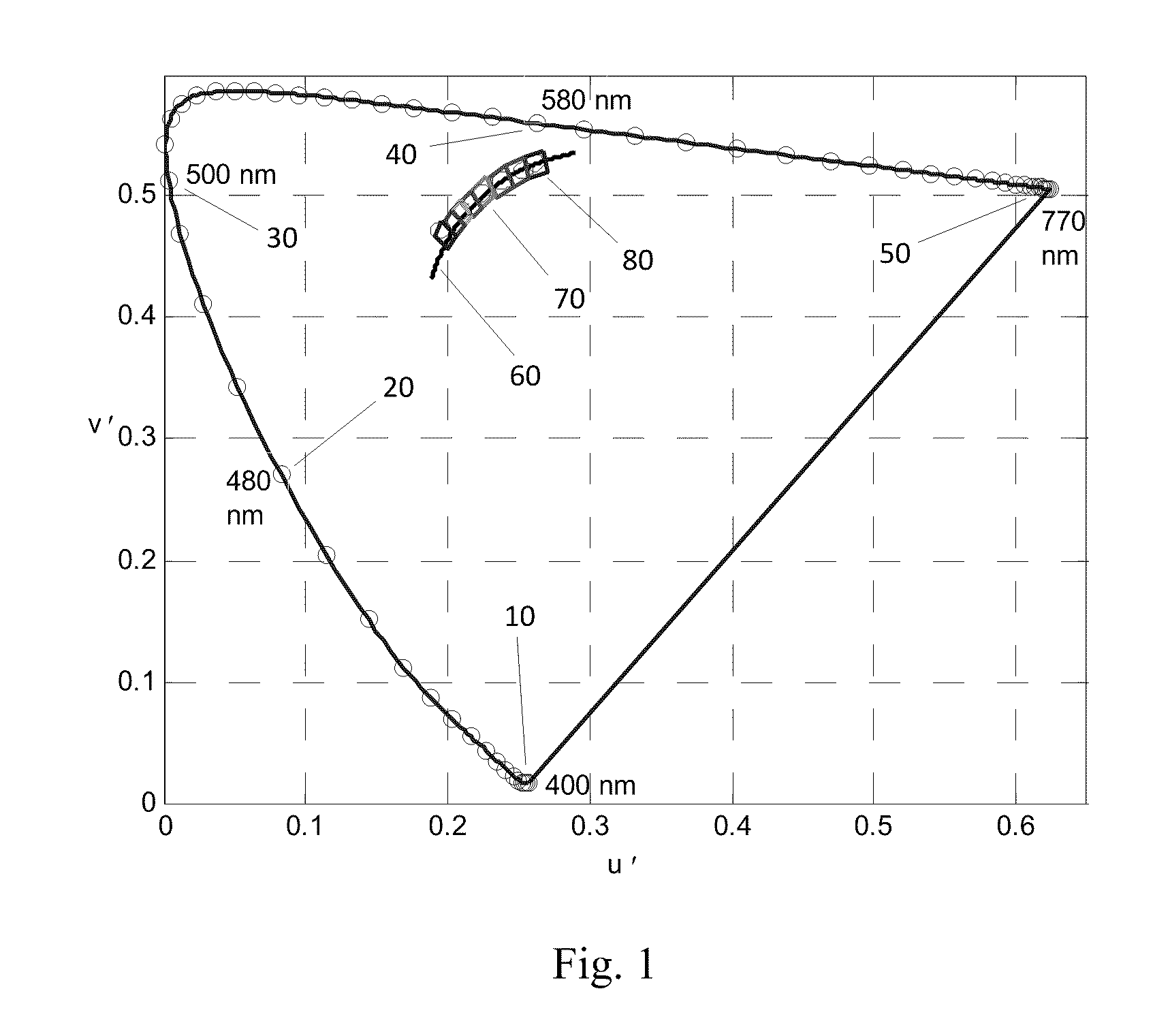

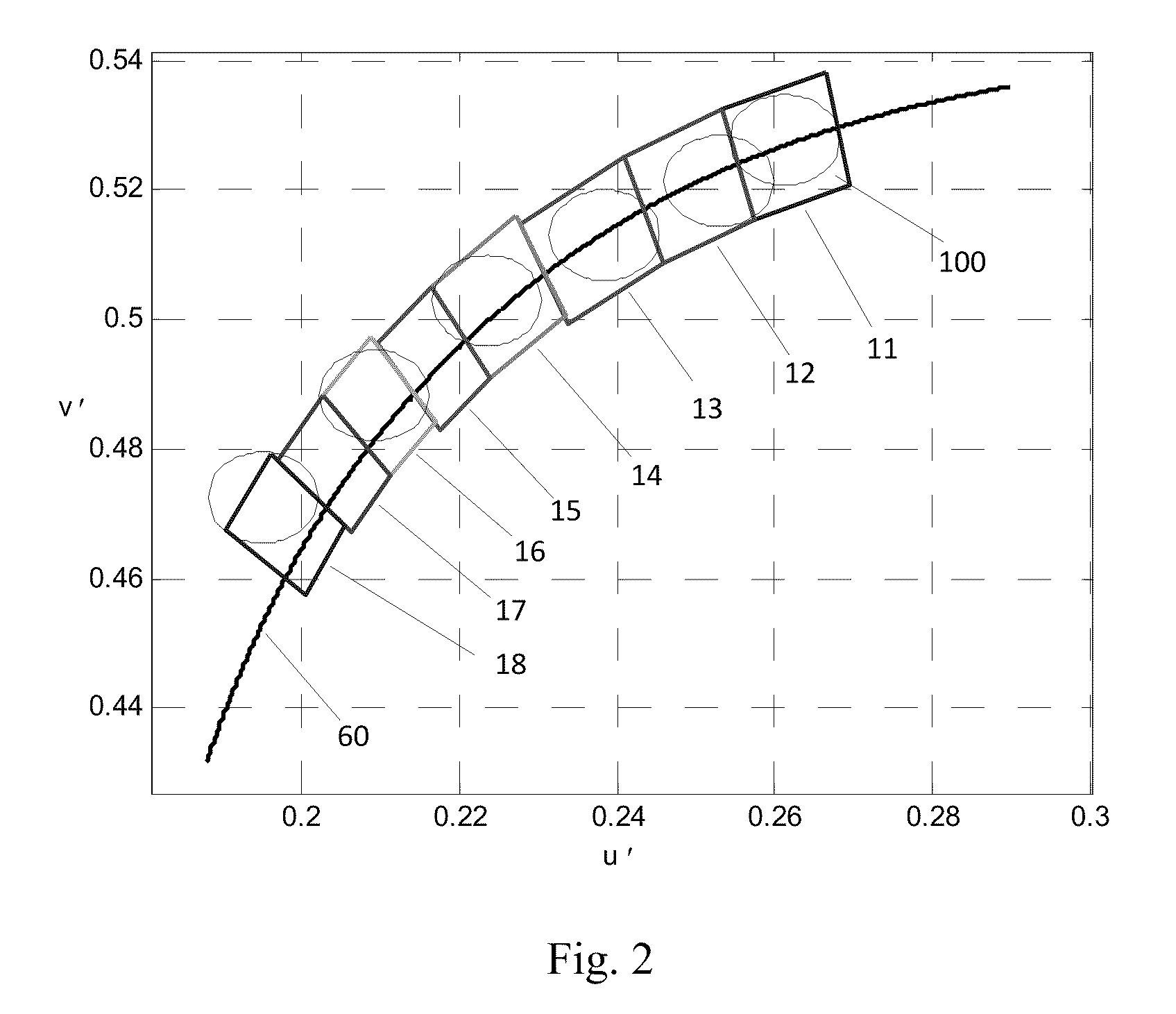

A light-emitting diode (LED)-based solid-state device comprises a color mixing mechanism to dynamically change the correlated color temperature (CCT) of a white light. With different lumen proportions for white phosphor-coated LEDs and integrated red and green LEDs, the light mixtures can be located in any one of eight CCT quadrangles. In practice, CCTs of a white-light can be tuned in a continuous manner. Because all the possible light mixtures on the chromaticity diagram correspond to a line segment that overlays the Planckian locus within the eight CCT tolerance quadrangles, the effect of LED intensity fluctuations that may put the mixture out of white light region is reduced. Also, because the two additional LEDs that mix with the white phosphor-coated LEDs contribute to the overall spectral power distribution (SPD) that substantially matches the SPD of standard illuminants, a CRI of 80 can be reached.

Owner:ALEDDRA INC

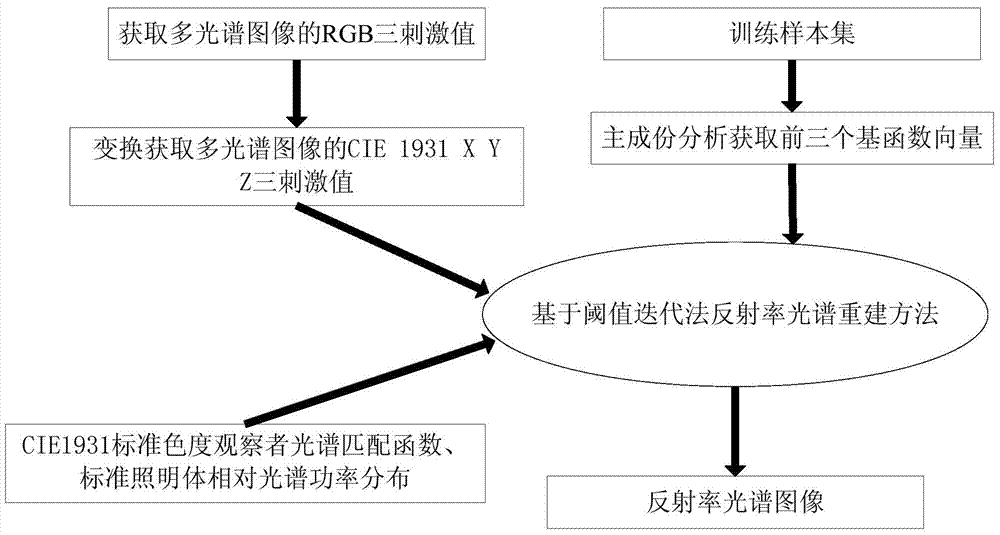

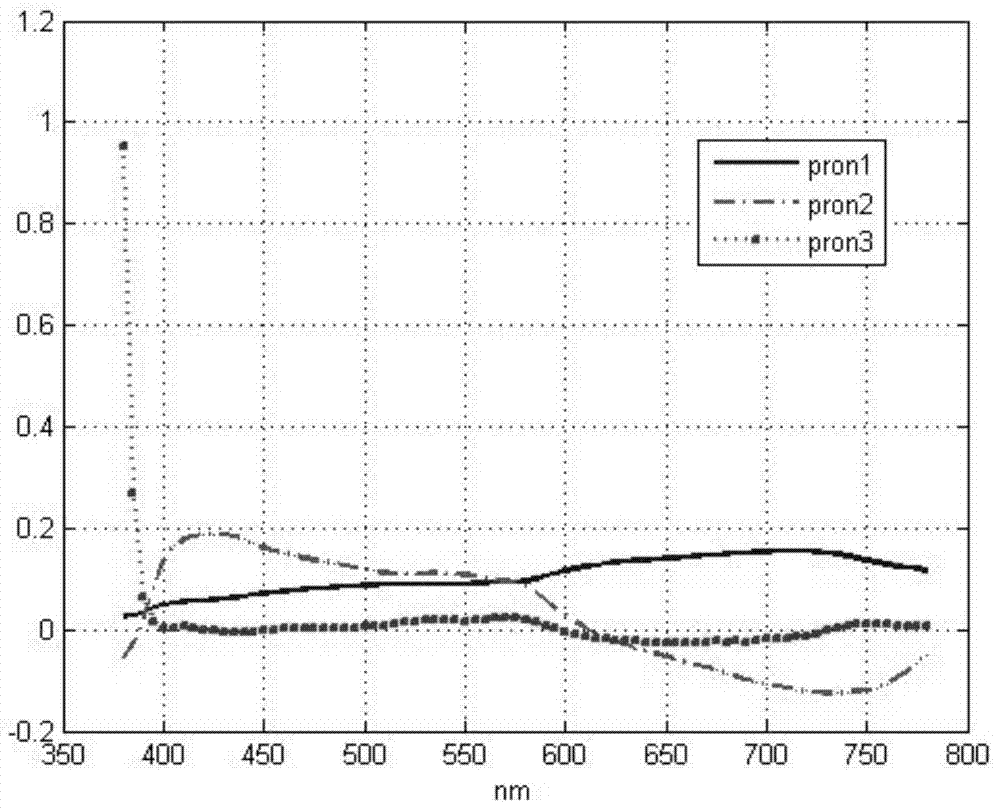

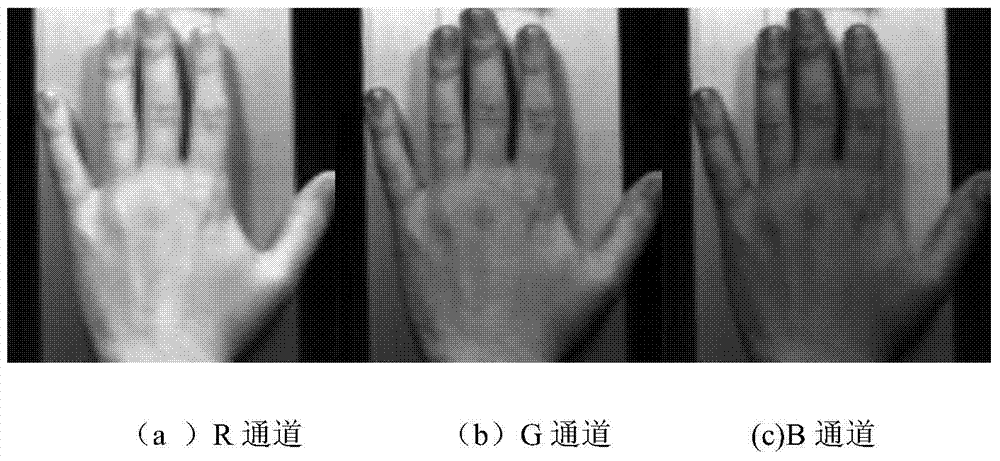

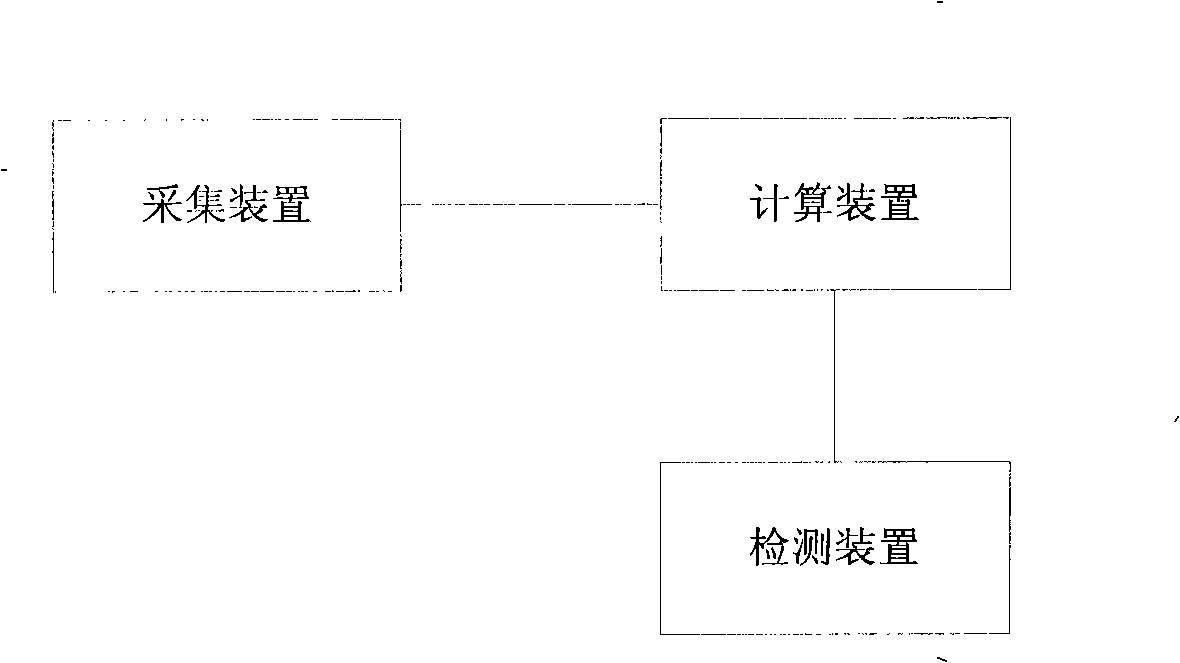

Reflectance spectrum reconstruction method based on iterative threshold method

InactiveCN103528968AImprove rebuild efficiencyImprove reconstruction accuracyColor/spectral properties measurementsPrincipal component analysisReconstruction method

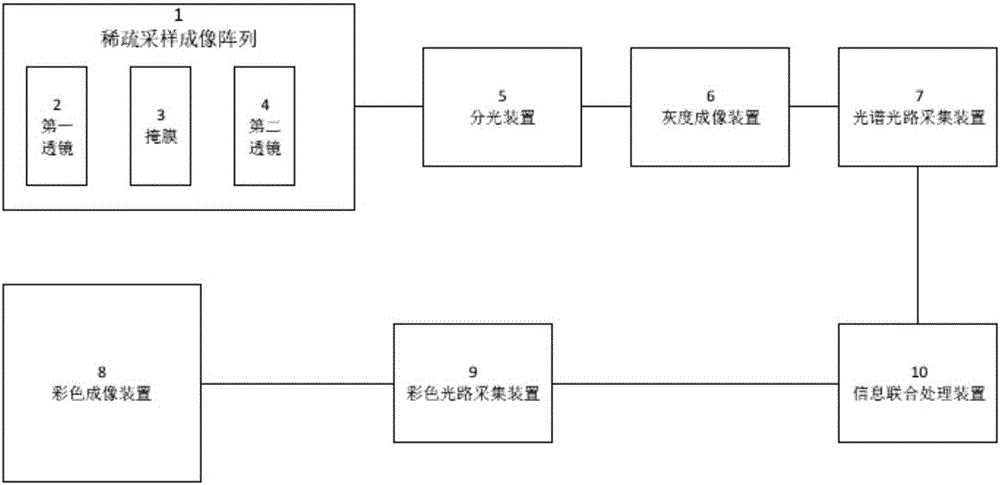

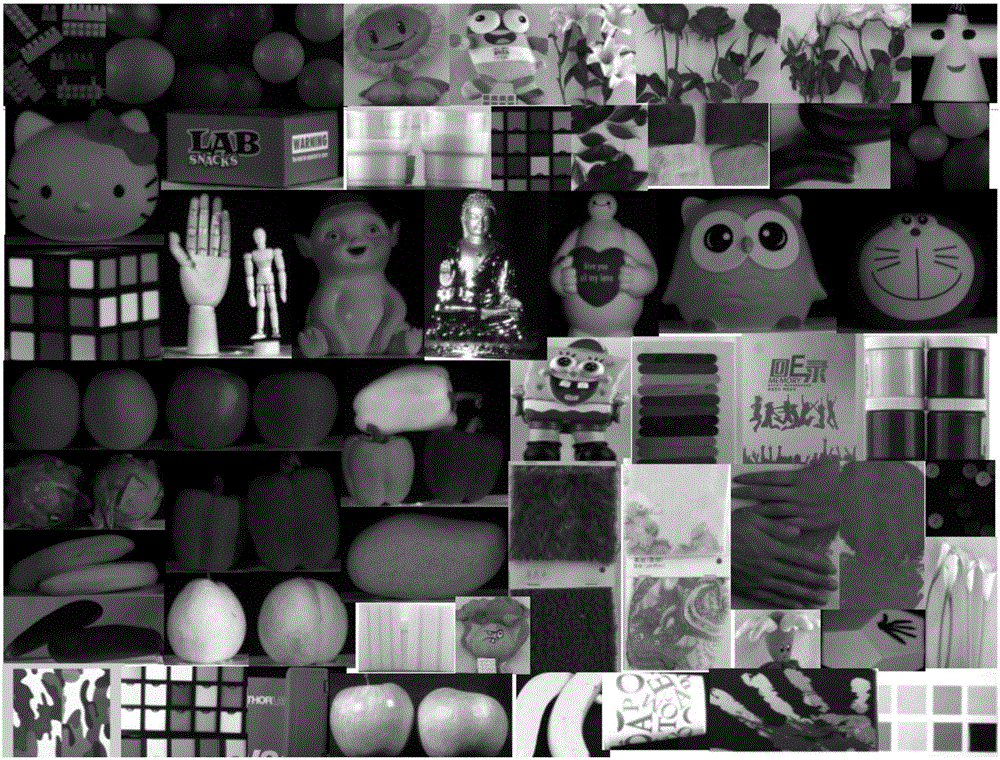

A reflectance spectrum reconstruction method based on an iterative threshold method includes the following steps that principal component analysis is carried out on a training sample set to obtain primary function vectors of the training sample set, and first three primary function vectors are chosen according to the contribution rate to serve as reconstruction primary function vectors; a standard illuminant and a common RGB camera are adopted to obtain RGB tri-stimulus values of a multi-spectral test image, and by means of a conversion matrix, CIE1931 standard colorimetric observer spectral tri-stimulus values are obtained; according to the obtained primary function vectors of the training sample set, CIE1931XYZ tri-stimulus values of the multi-spectral test image, a CIE1931 standard colorimetric observer color matching function and relative spectral power distribution of the standard illuminant, a reflectivity spectral image of the multi-spectral test image is reconstructed by the adoption of the iterative threshold method.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

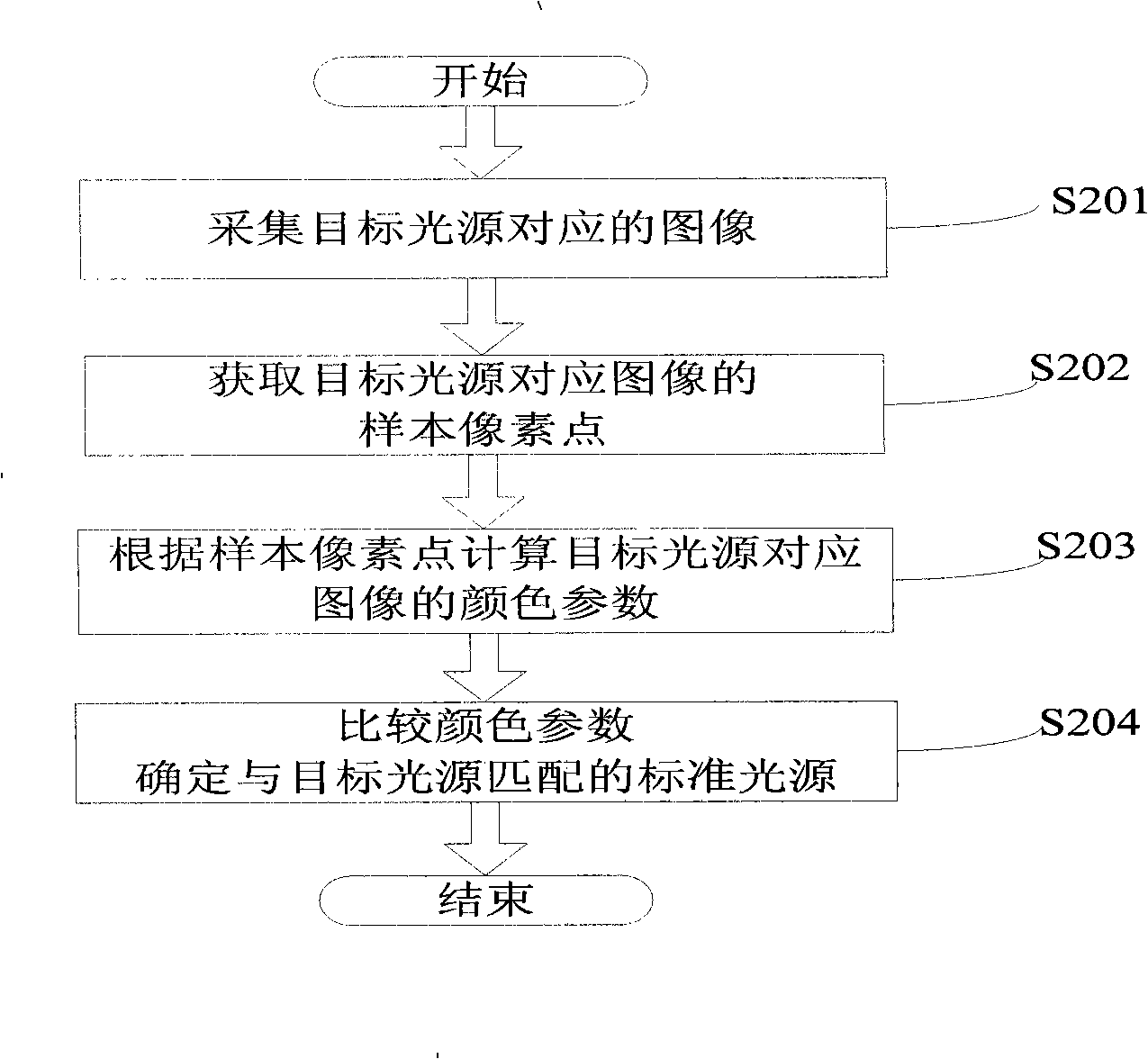

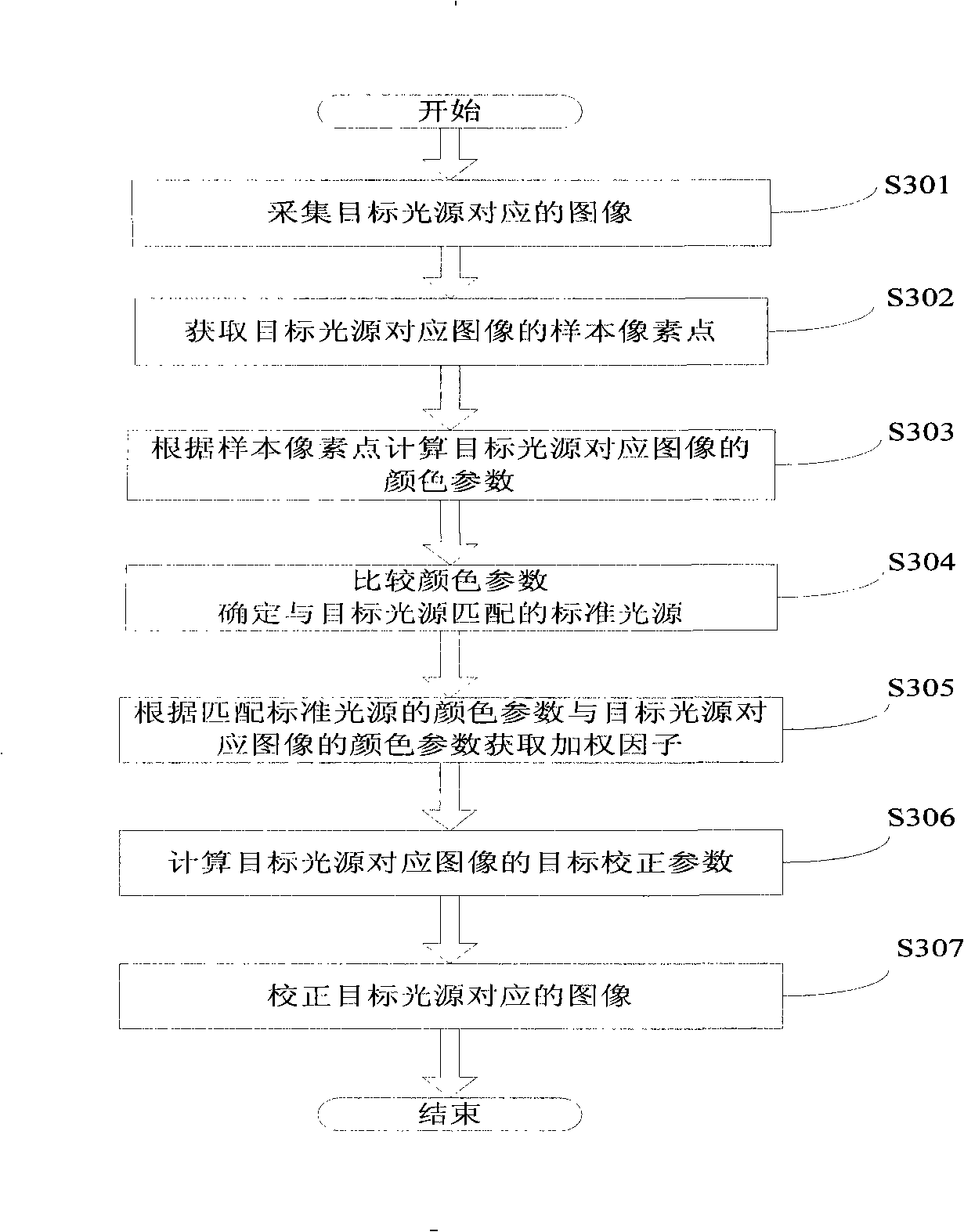

Light source detection apparatus and method as well as image processing method

ActiveCN101282489AReduce computationImprove accuracyColor signal processing circuitsImaging processingStandard illuminant

The invention relates to the field of image processing technology, particularly to a light source detecting equipment and method as well as an image processing method, which are used for gathering images corresponding to the object light source and obtaining sample pixel points of images corresponding to the object light source; computing color parameters of images corresponding to the object light source according to the sample pixel points; comparing the color parameters of images corresponding to the object light source with preset color parameters of various standard light sources, thereby determining a standard light source matched with the object light source. The technical solution of the invention can accurately detect the light source with simple operation.

Owner:北京中星天视科技有限公司

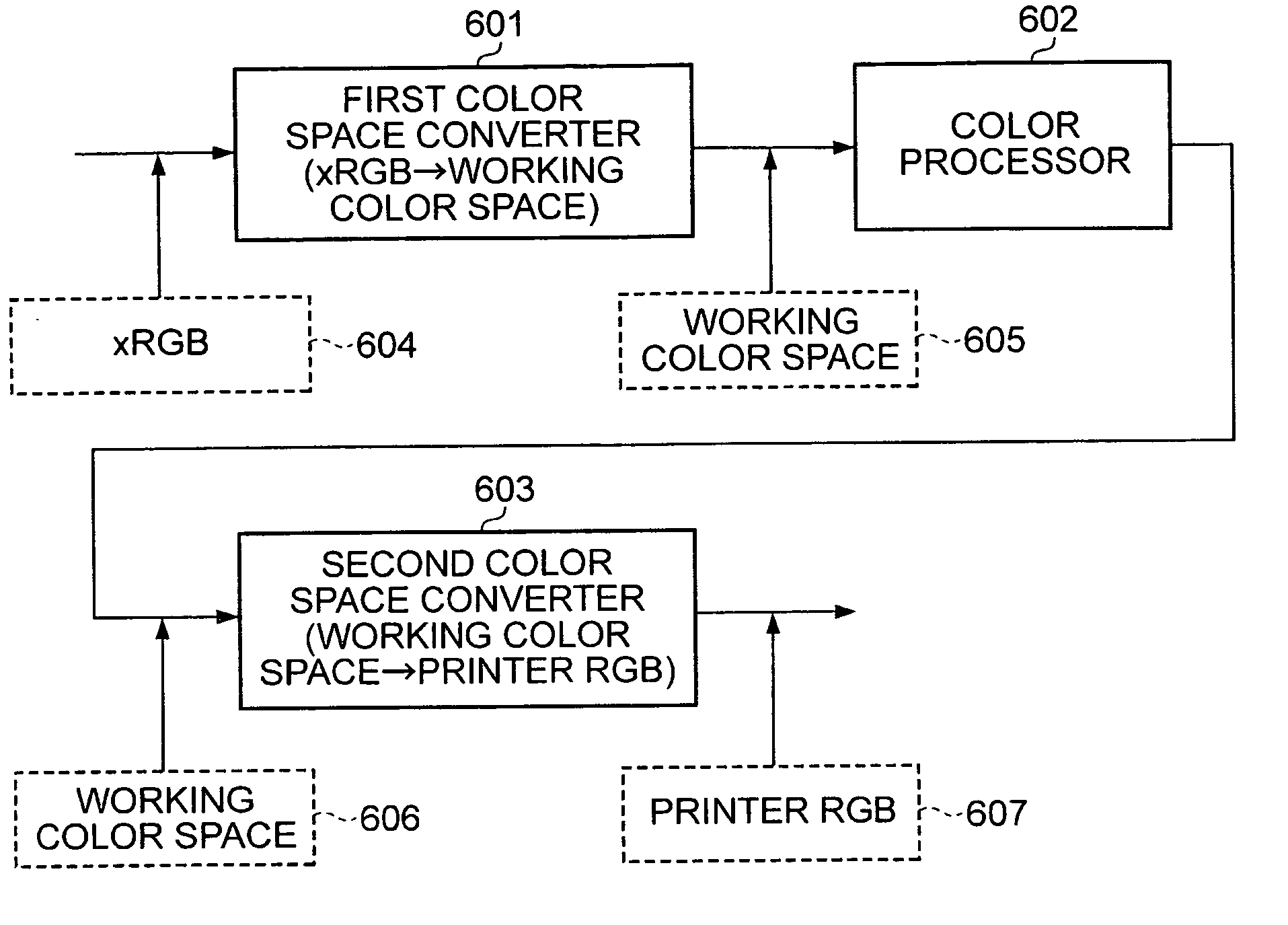

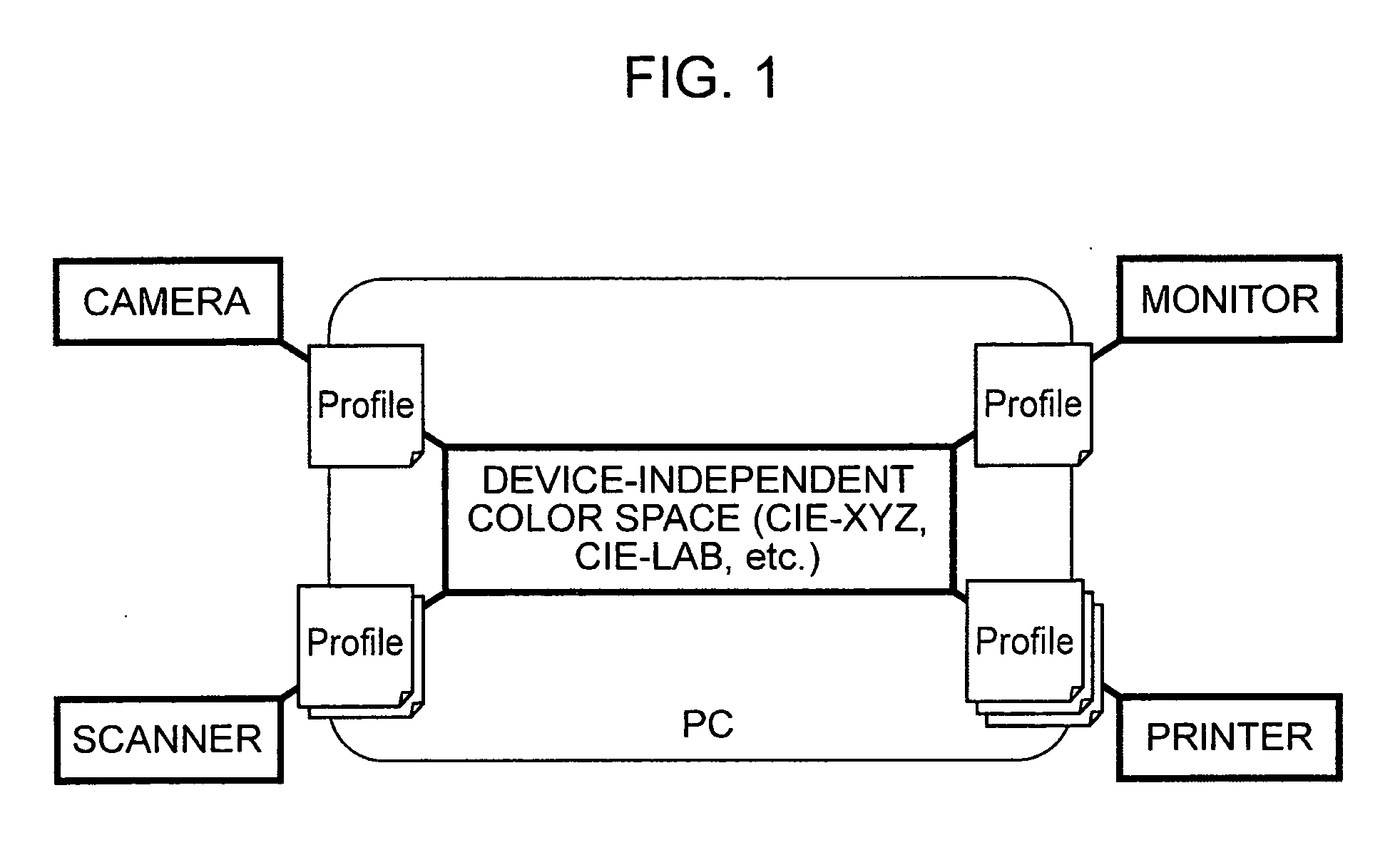

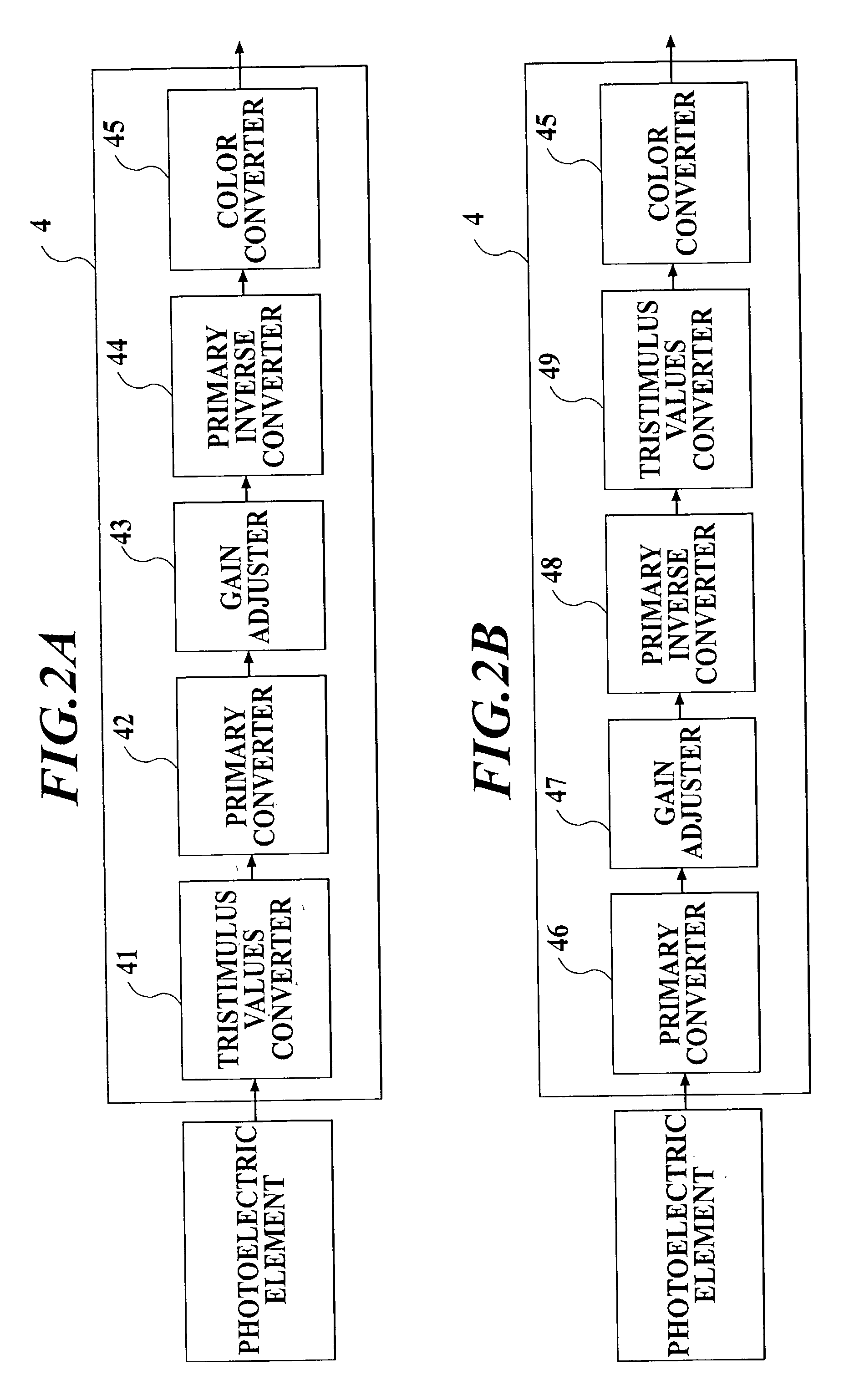

Image processing method, profile creation method, and image processing apparatus

InactiveUS20060232803A1High color reproductionDigitally marking record carriersDigital computer detailsImaging processingGamut

Three primary color points are defined to determine a working color space such that the working color space includes all colors in the color reproduction range of a printer. In addition, the luminance of a white point and a standard light source is defined. A transformation matrix is determined on the basis of these points. The transformation matrix associates an RGB working color space with a color space in the XYZ color system to define the RGB working color space. Thus, when compression gamut mapping is performed on the working color space, colors in the working color space can be mapped to any colors in the color reproduction range of a printer, without dropping any colors reproducible by the printer.

Owner:CANON KK

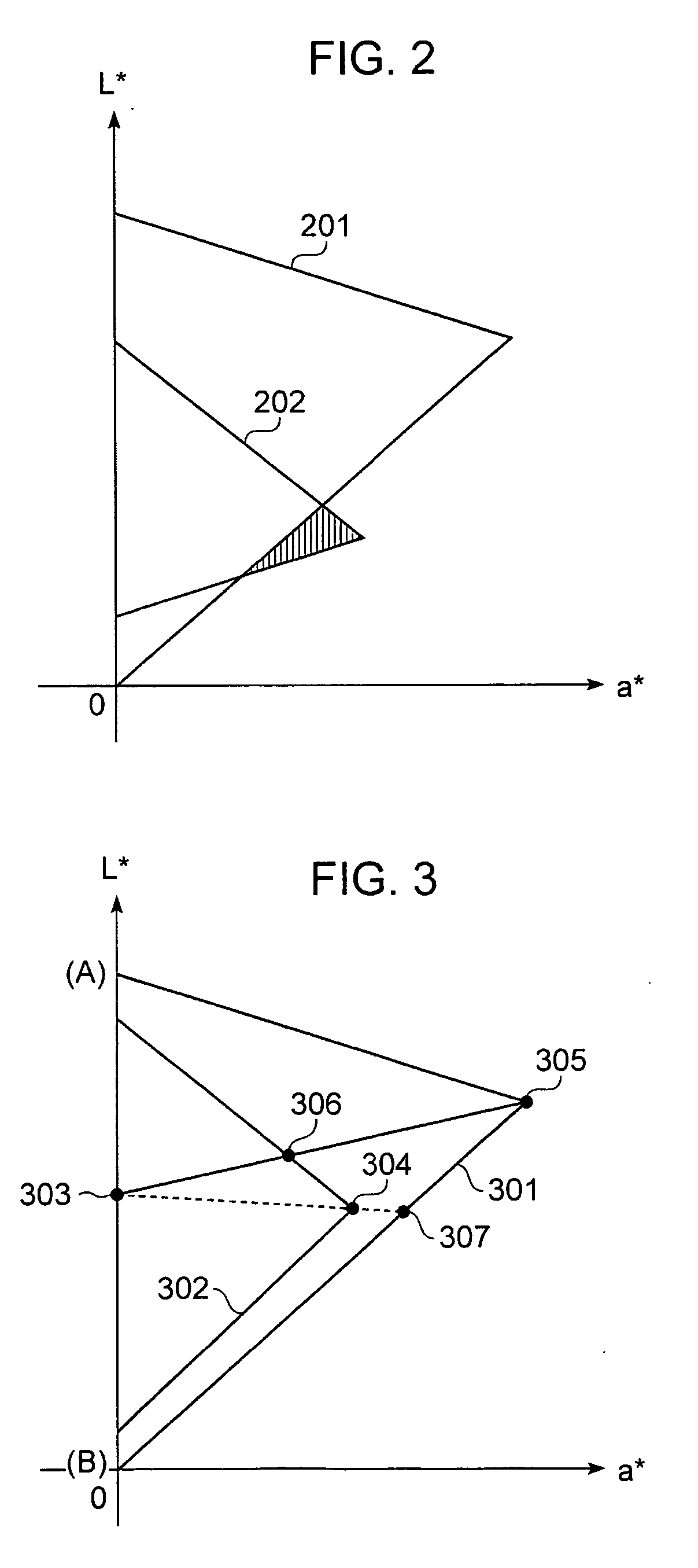

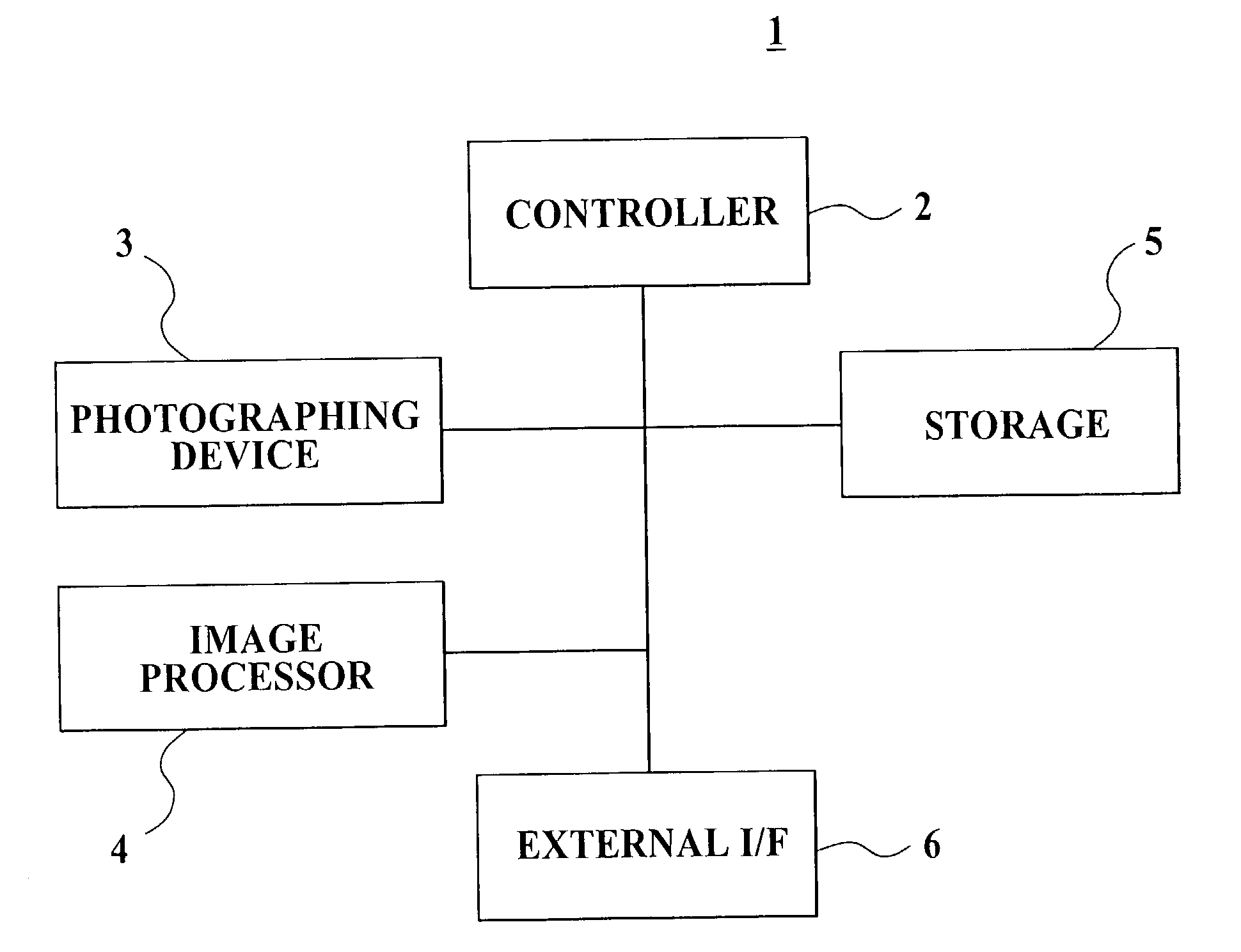

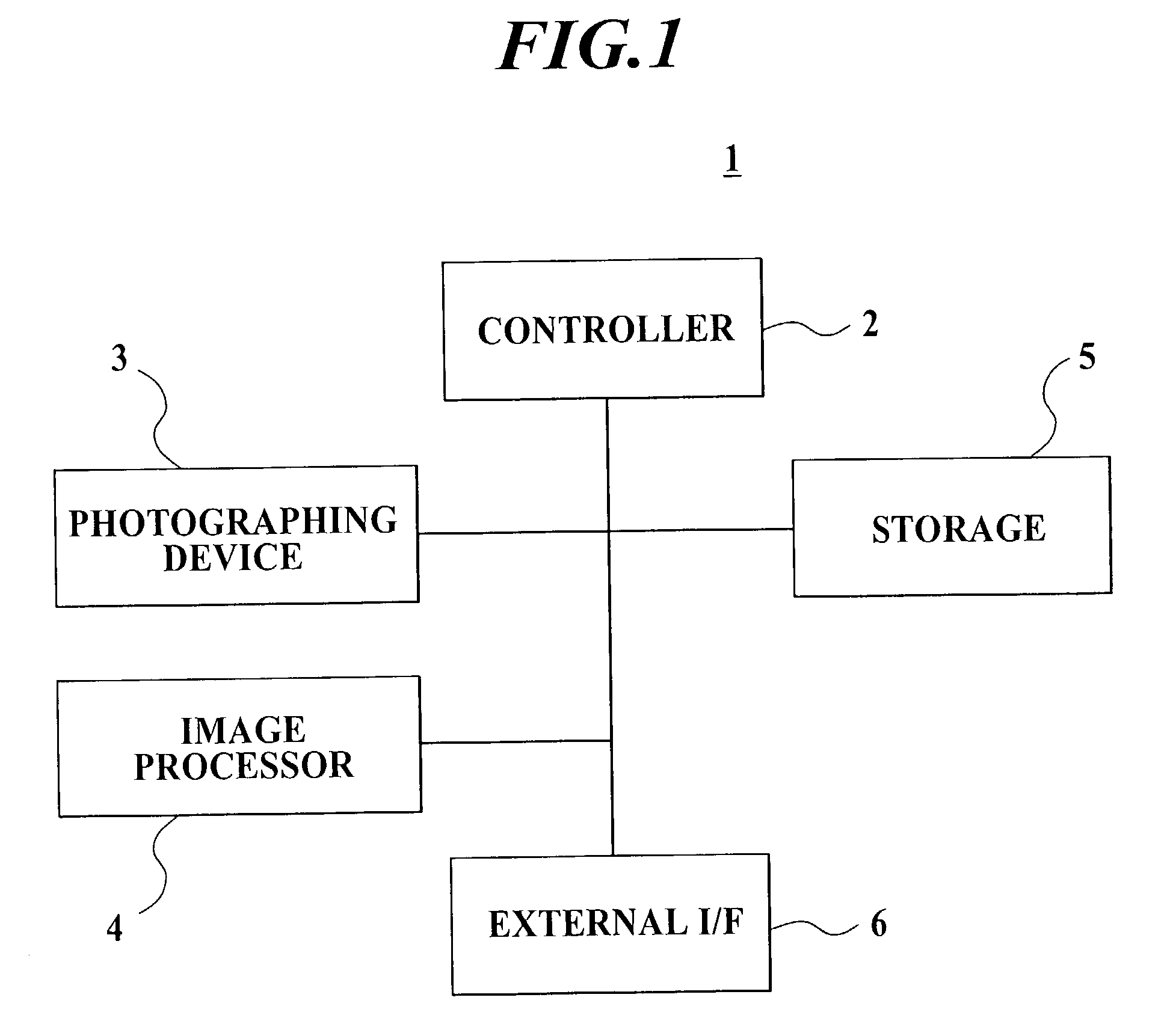

Image processing method, apparatus and system, evaluation method for photographing apparatus, image data storage method, and data structure of image data file

InactiveUS20030164828A1Minimize the differenceEasy to specifyColor signal processing circuitsImage data processing detailsImaging processingData file

An image processing method for balancing colors of an image on the basis of the principle of the color constancy. The image processing method for processing an image photographed by a photographing apparatus, has: converting a color data of the image photographed by the photographing apparatus under a different type light source, so as to adapt at least one different type light source color data which is a color data for color chips including a chromatic color, under at least one different type light source which is different from a standard light source, against a standard light source color data which is a color data for the color chips under the standard light source.

Owner:KONICA CORP

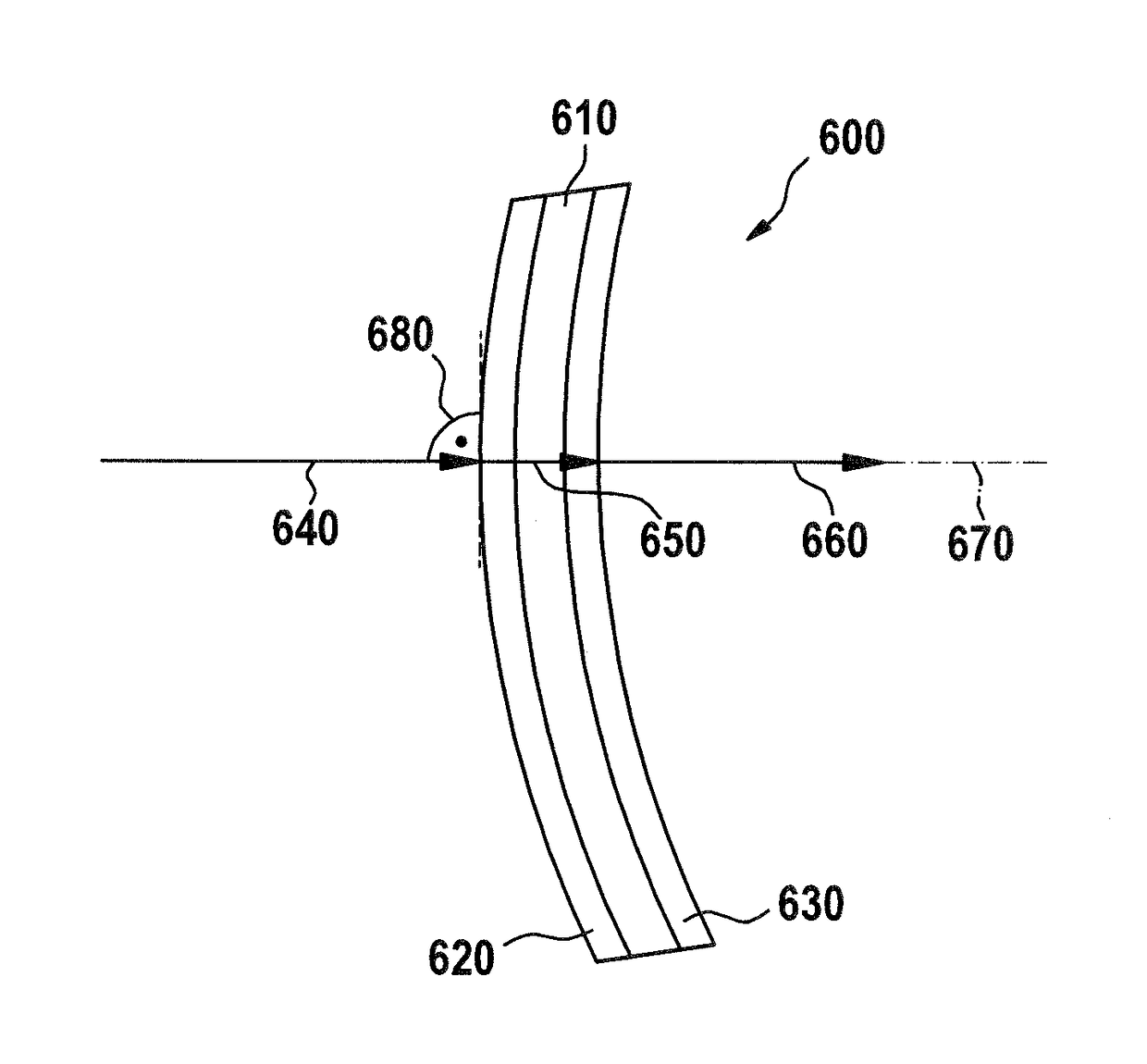

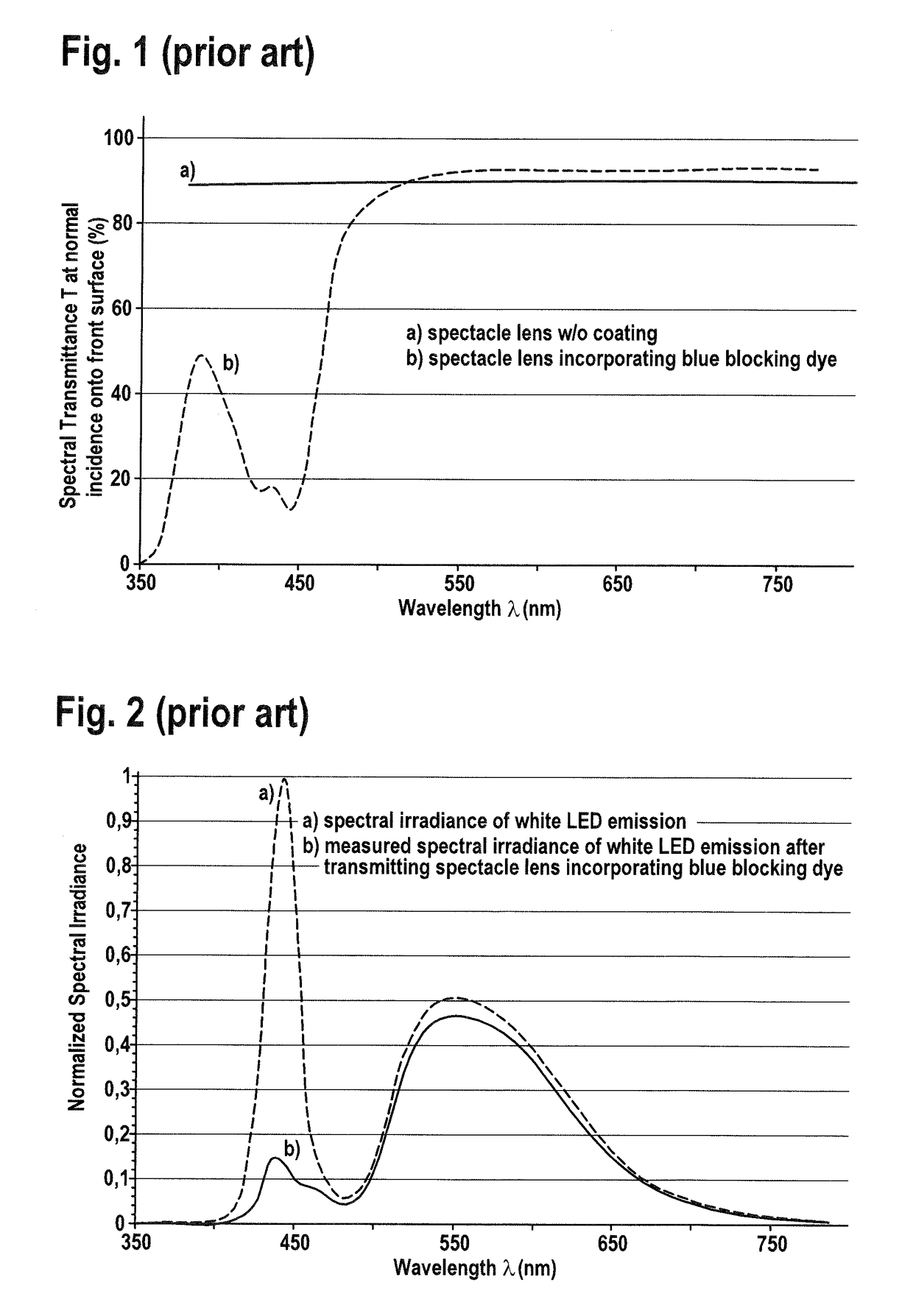

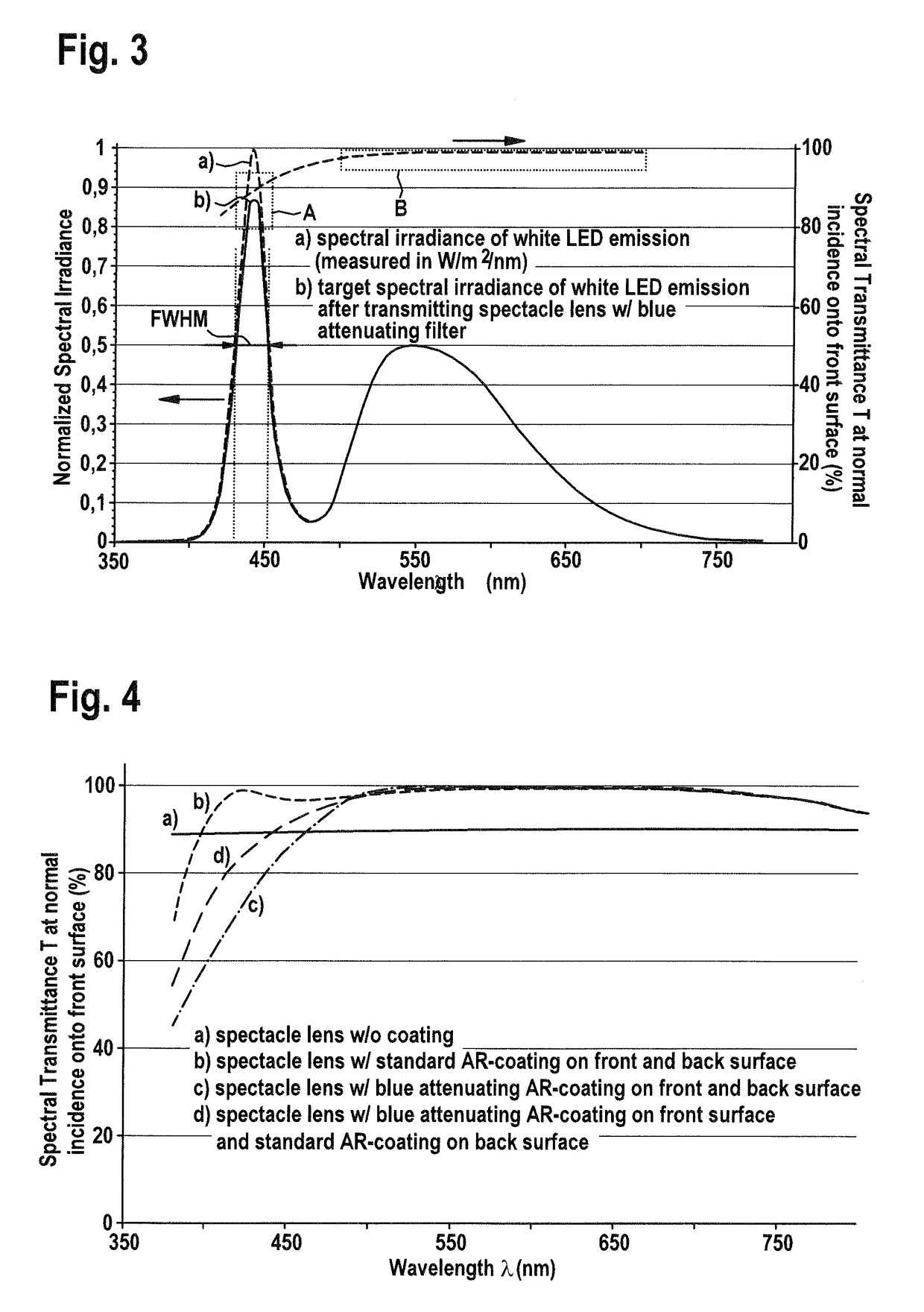

Spectacle lens for car drivers

ActiveUS20170219848A1Improve eyesightSuitable for wearingSpectales/gogglesOptical partsAngle of incidenceWavelength filter

A spectacle lens having a front surface intended to be fitted away from the eye. The spectacle lens includes a substrate made from mineral glass or an organic material. The spectacle lens has selective light wavelength filter properties. The selective light wavelength filter properties include a spectral transmittance between 80% and 95% for all wavelengths in a wavelength range between 428 nm and 452 nm for a light ray entering the spectacle lens on the front surface at an angle of incidence of 0°, a spectral transmittance between 95% and 100% for all wavelengths in a wavelength range between 500 nm and 700 nm for a light ray entering the spectacle lens on the front surface with an angle of incidence of 0° and a yellowness index of no more than 10 for a standard illuminant D65 and a standard observer function of 2° (D65 / 2°).

Owner:CARL ZEISS VISION INT GMBH

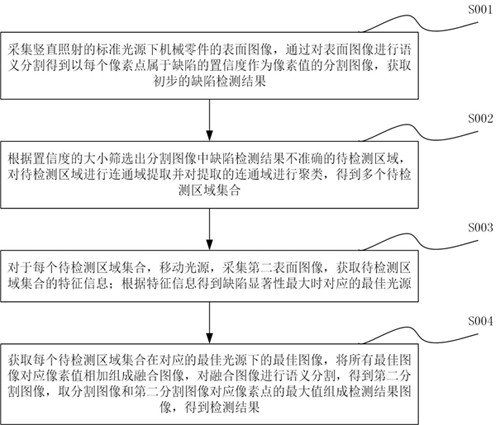

Mechanical part surface defect detection method based on image processing

ActiveCN113538429AReduce information entropyAccurate defect detection resultsImage enhancementImage analysisImaging processingRadiology

The invention relates to the technical field of image processing, in particular to a mechanical part surface defect detection method based on image processing. The method comprises the following steps: acquiring a surface image of a mechanical part under a standard light source, and acquiring a segmented image of the surface image as a preliminary defect detection result; screening out a to-be-detected region in the segmented image, and performing connected domain extraction and clustering on the to-be-detected region to obtain a plurality of to-be-detected region sets; for each to-be-detected area set, moving the light source, collecting a second surface image, and obtaining feature information of the to-be-detected area set in the second surface image; obtaining an optimal light source corresponding to the maximum defect saliency according to the feature information; and obtaining an optimal image of each to-be-detected region set under the corresponding optimal light source to form a fused image, performing semantic segmentation on the fused image to obtain a second segmented image, and obtaining a detection result. According to the embodiment of the invention, the light source can be adaptively adjusted according to different defects, and an accurate defect detection result is obtained.

Owner:NANTONG YOUYUAN ART PATTERN DESIGN CO LTD

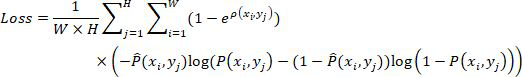

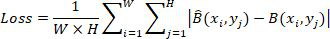

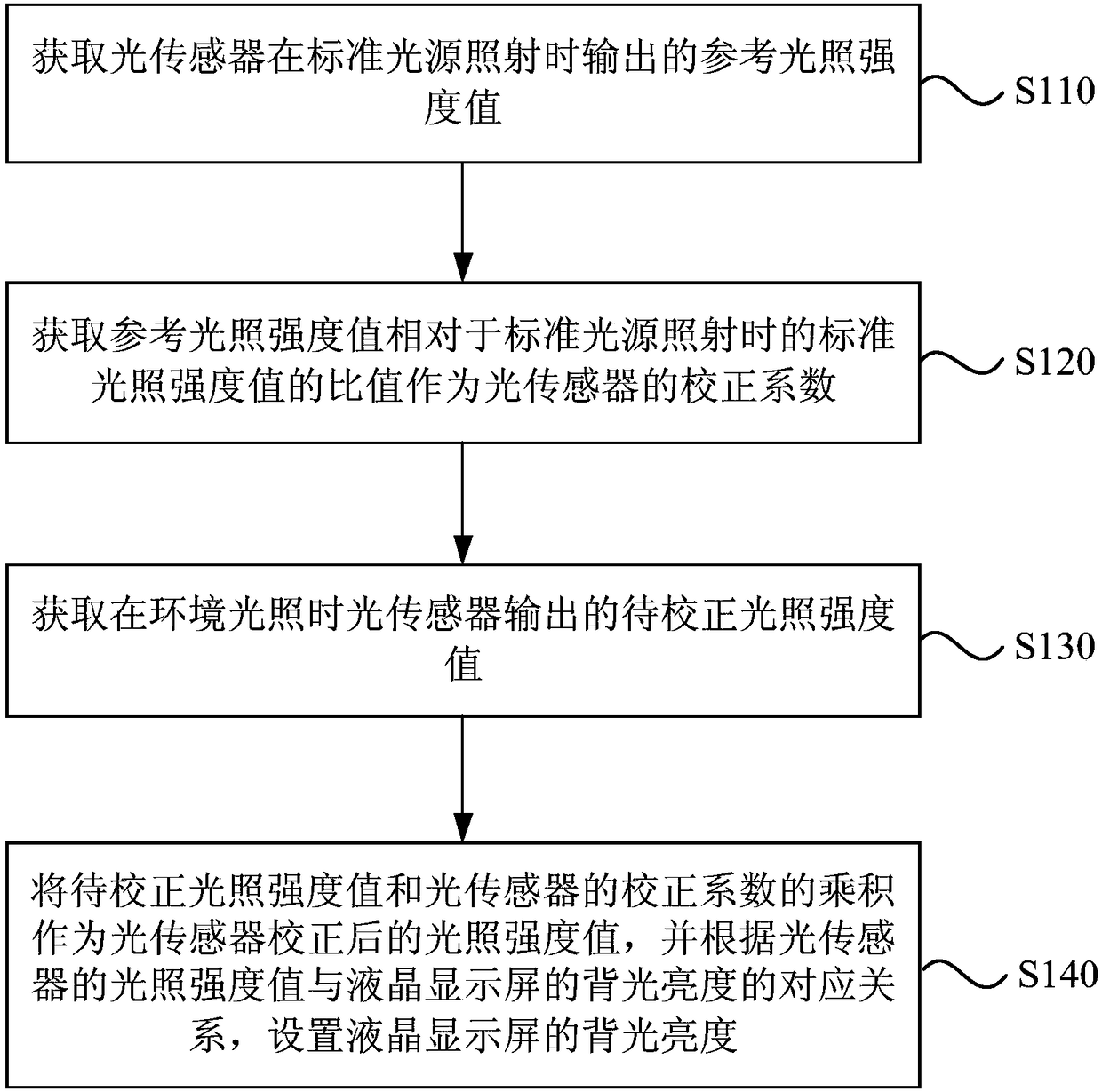

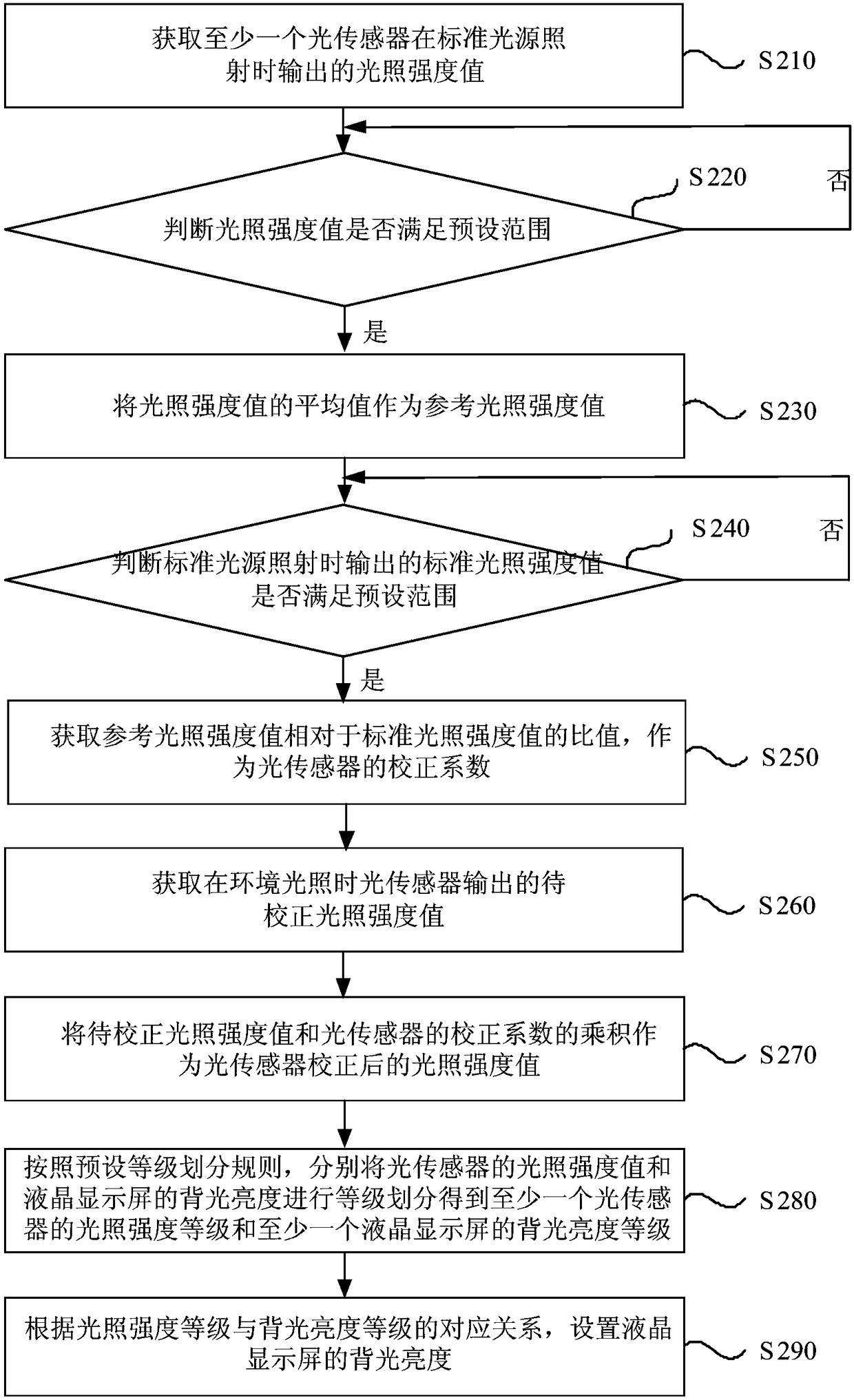

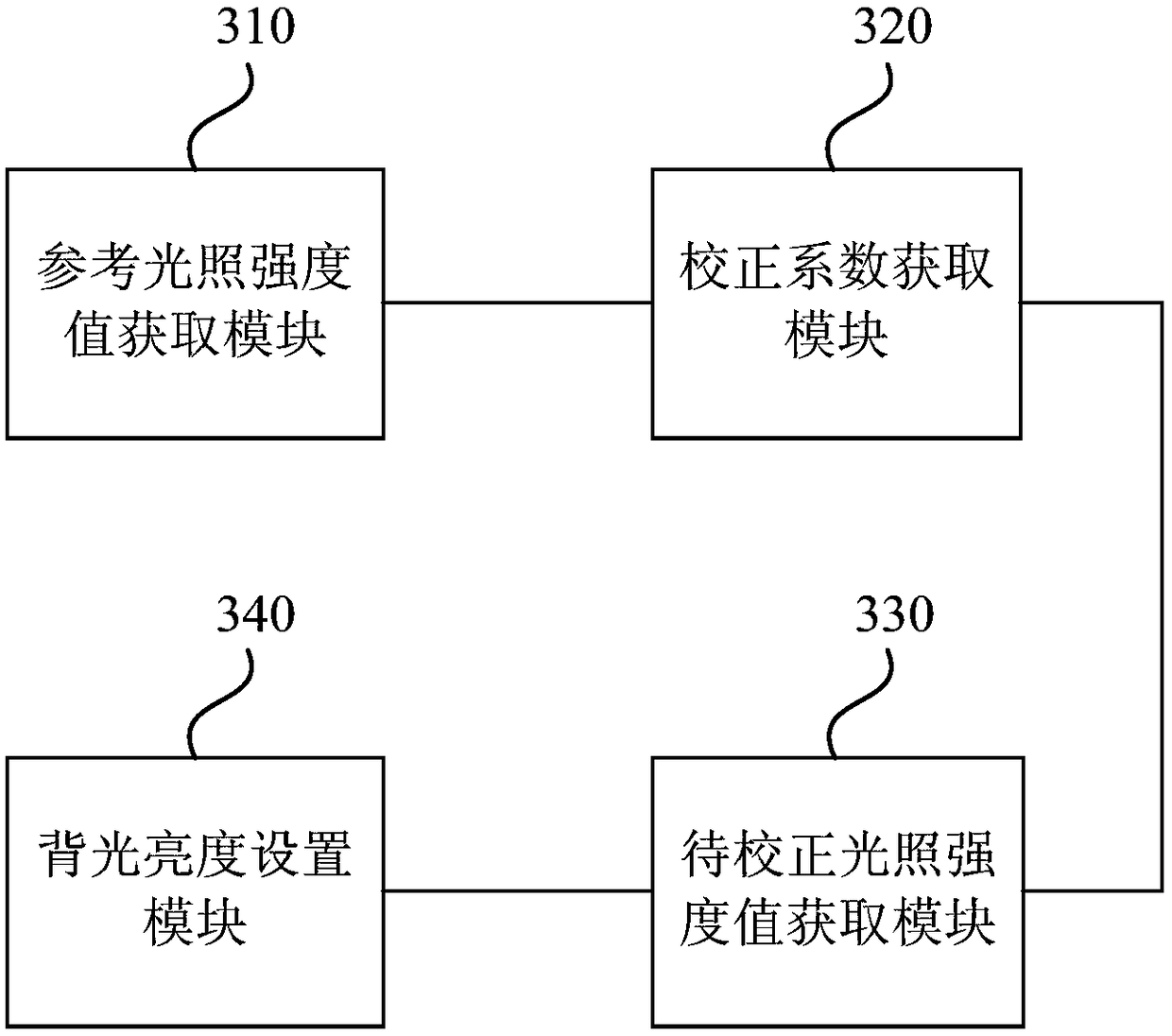

Correction method, device and equipment used for optical sensor, and storage medium

InactiveCN108172175AConsistent backlight brightnessStatic indicating devicesLiquid-crystal displayIrradiation

The invention discloses a correction method, a device and equipment used for an optical sensor, and a storage medium. The method comprises the following steps of acquiring a reference illumination intensity value output by the optical sensor under standard light source irradiation; acquiring the ratio of the reference illumination intensity value relative to a standard illumination intensity valueunder the standard light source irradiation and taking as the correction coefficient of the optical sensor; acquiring an illumination intensity value to be corrected output by the optical sensor under environment illumination; and taking the product of the illumination intensity value to be corrected and the correction coefficient of the optical sensor as the corrected illumination intensity value of the optical sensor, and according to the corresponding relation of the illumination intensity value of the optical sensor and the backlight brightness of a liquid crystal display screen, adjusting the backlight brightness of the liquid crystal display screen so that the optical sensor outputs the corrected illumination intensity value under the environment illumination. In the invention, a problem that the backlight brightness of the same model of equipment under a same illumination environment is not consistent is solved, and the backlight brightness of the equipment under the same illumination environment is consistent.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

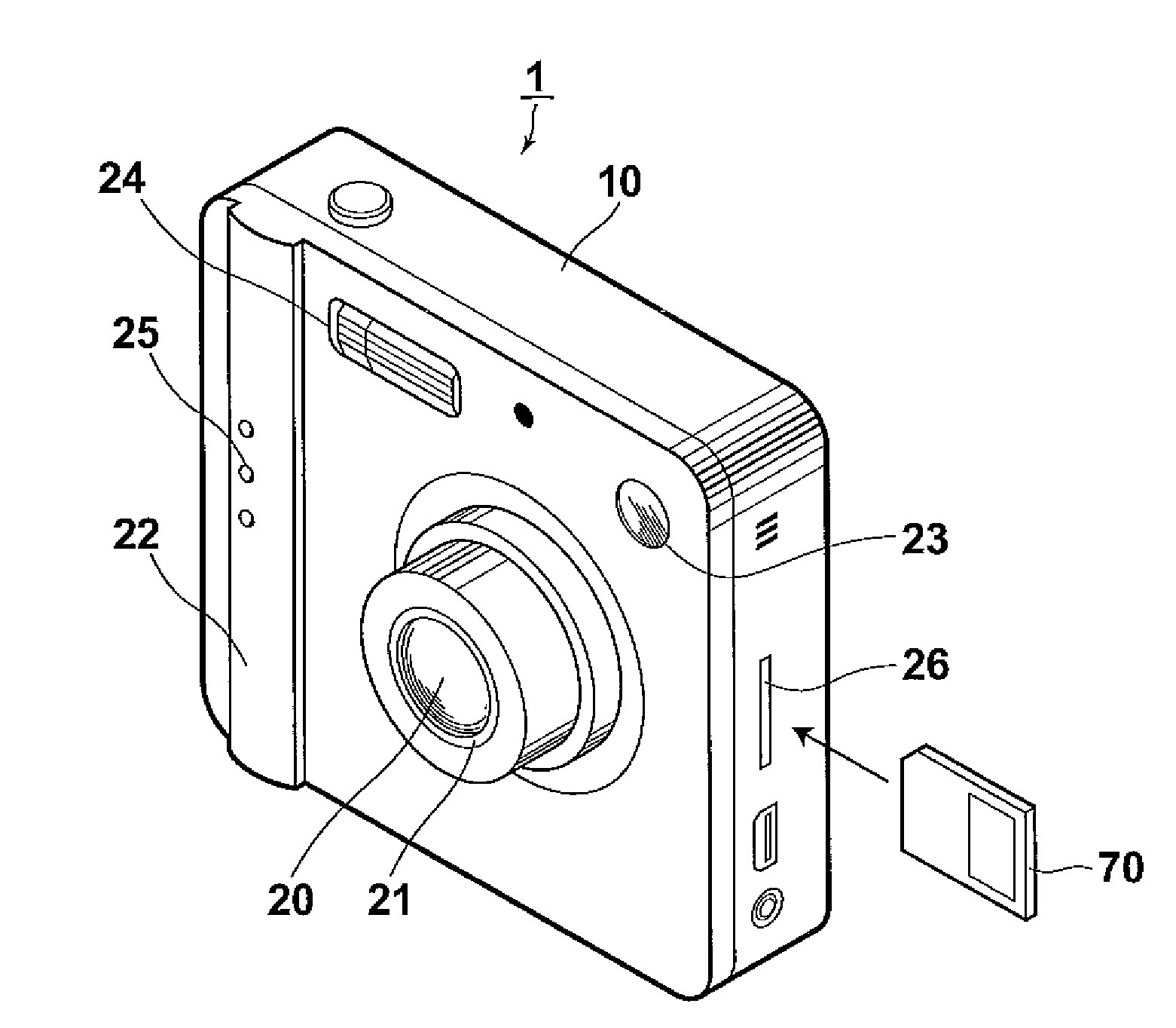

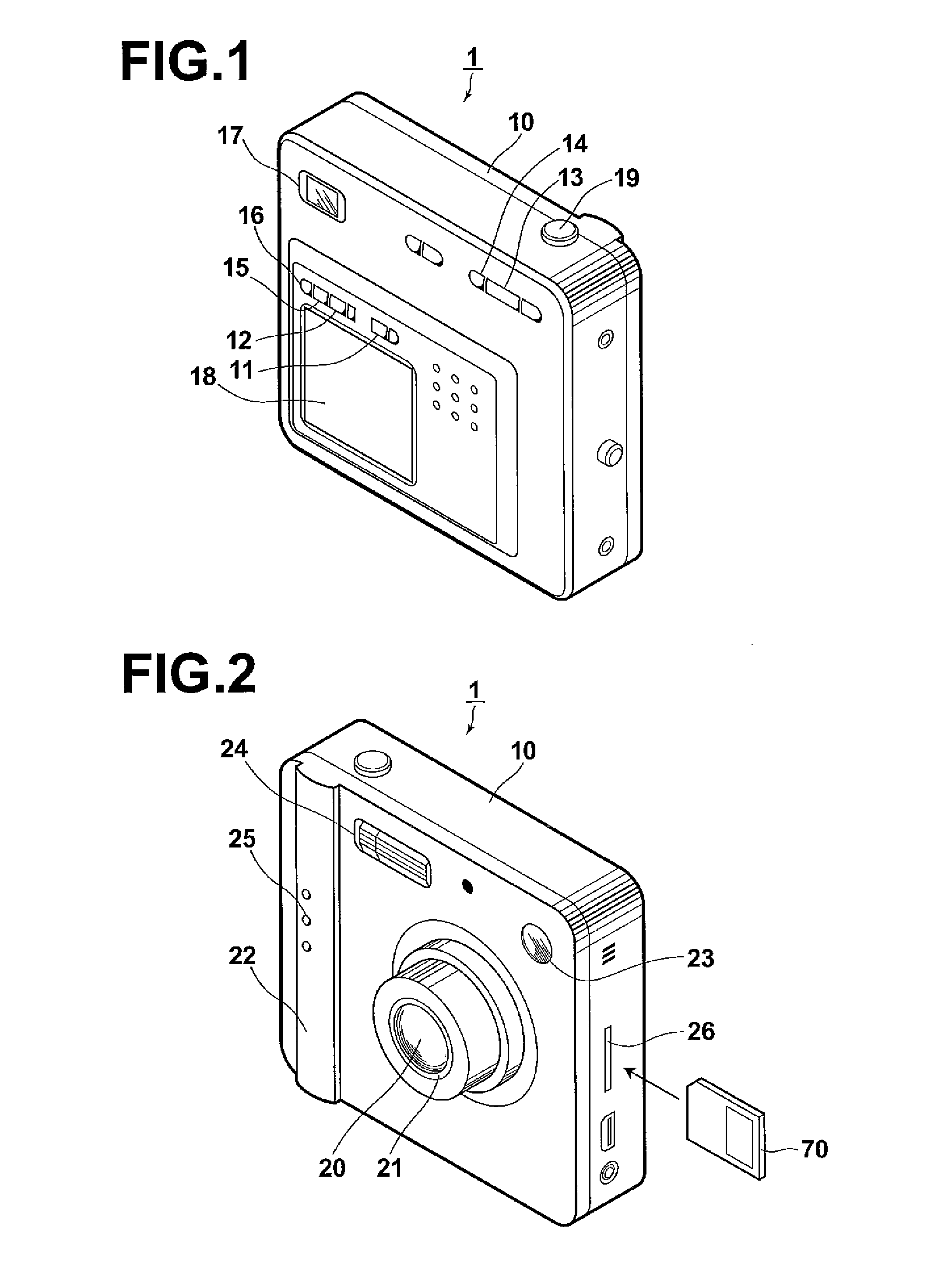

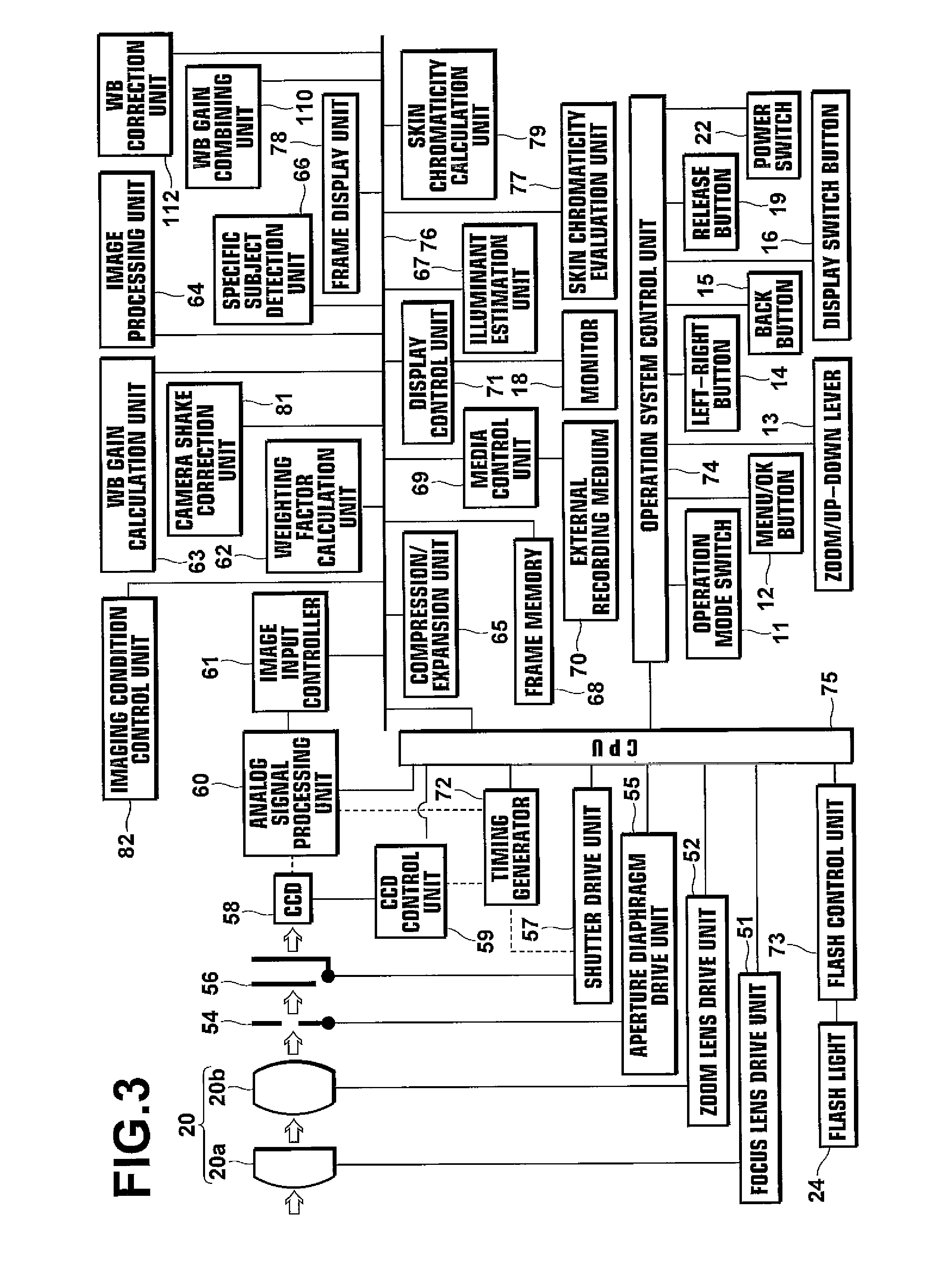

Image processing apparatus, method, and computer program product

An image processing apparatus and method capable of improving illuminant estimation accuracy and performing a stable white balance correction. A specific subject detection unit detects a specific subject having a specific color from assigned image data. A specific chromaticity calculation unit calculates a specific chromaticity from data representing the specific color of the specific subject. Then, a standard chromaticity that approximates to the calculated specific chromaticity is determined from standard chromaticities. A chromaticity difference calculation unit calculates one or more sets of chromaticity difference information representing a chromaticity difference from the determined standard chromaticity to the calculated specific chromaticity. A white chromaticity correction unit obtains one or more white chromaticities corresponding to the selected one or more standard light sources and corrects the one or more white chromaticities by referring to the one or more sets of chromaticity difference information.

Owner:FUJIFILM CORP

Method for identifying hyperspectral material

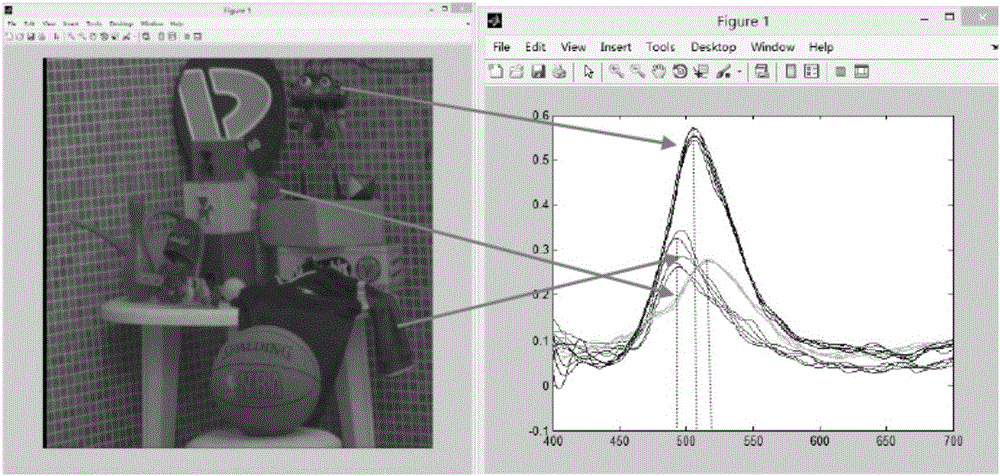

ActiveCN105842173AEfficient identificationReduce distractionsColor/spectral properties measurementsShape changeData information

The invention provides a method for identifying a hyperspectral material. First a standard light source spectrum database is established, a spectral material standard database is established, and standard light source spectra are obtained through a difference method and a control variable method; spectral data information is shot for a material needing to be identified; through preprocessing and intrinsic material information extraction, spectral characteristics of the material are obtained, and then the spectral characteristics are matched with data in the spectral material standard database, so as to perform high-precision identification of the material. According to the method, the interference to spectral information of the material caused by complex factors such as different illumination conditions and material shape changes and the like can be resisted, the problems of metamerism and homogeneity and heterochrome which cannot be solved through conventional red green blue (RGB) and RGBD cameras are solved, and the identification precision rate is high.

Owner:南京智谱科技有限公司

Ultraviolet vacuum ultraviolet spectroscopy radiation transfer characteristic test device

The invention relates to a testing technique for testing transmission characteristics of spectral radiation, particularly to a testing device for testing transmission characteristics of ultraviolet-vacuum ultraviolet spectral radiation. The testing device comprises a monochrometer, a standard light source, a vacuum container, a photomultiplier tube disposed in the vacuum container and fixed at one side of a rotary table, a cryogenic pump and a molecular pump respectively communicated with the cavity of the vacuum container via two gate valves, a dry vacuum pump communicated with the cavity pipeline of the vacuum container, and a cryogenic unit communicated with the vacuum container via a pipeline, wherein a flange interface is provided at one end of the vacuum container and used for alternatively connecting with the monochrometer or standard light source; the movement platform capable of performing translational movement with respect to the vertical direction of the axial line of the interface is disposed in the vacuum container, and the rotary table is disposed on the movement platform. The invention can be used for high-precision calibration of the spectral radiation brightness and the spectral irradiance responsibility of the entire machine of an ultraviolet spectra remote sensing instrument; and can be used for testing the spectral responsibility of an ultraviolet detector and testing the spectral transmission characteristics of an ultraviolet optical element.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

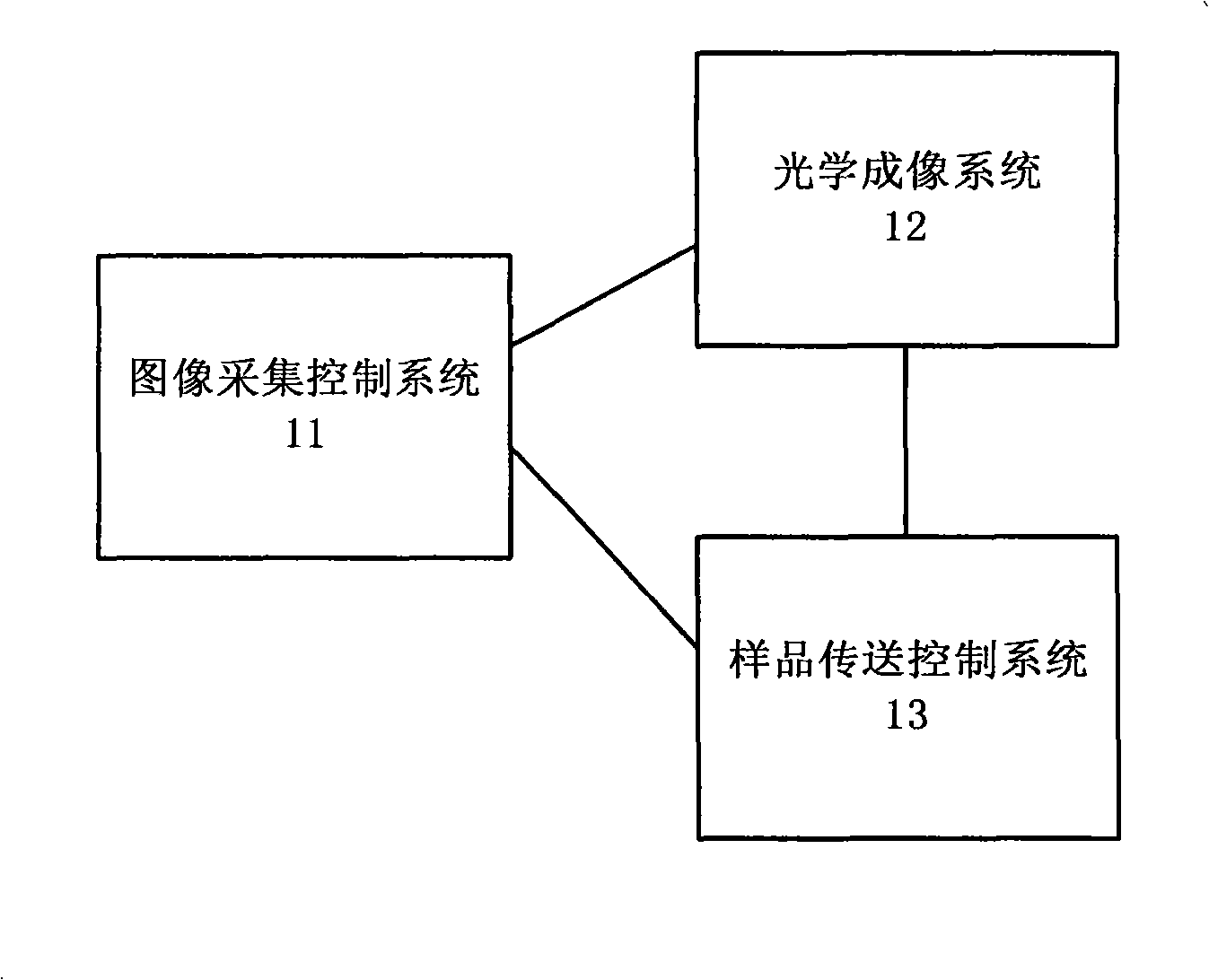

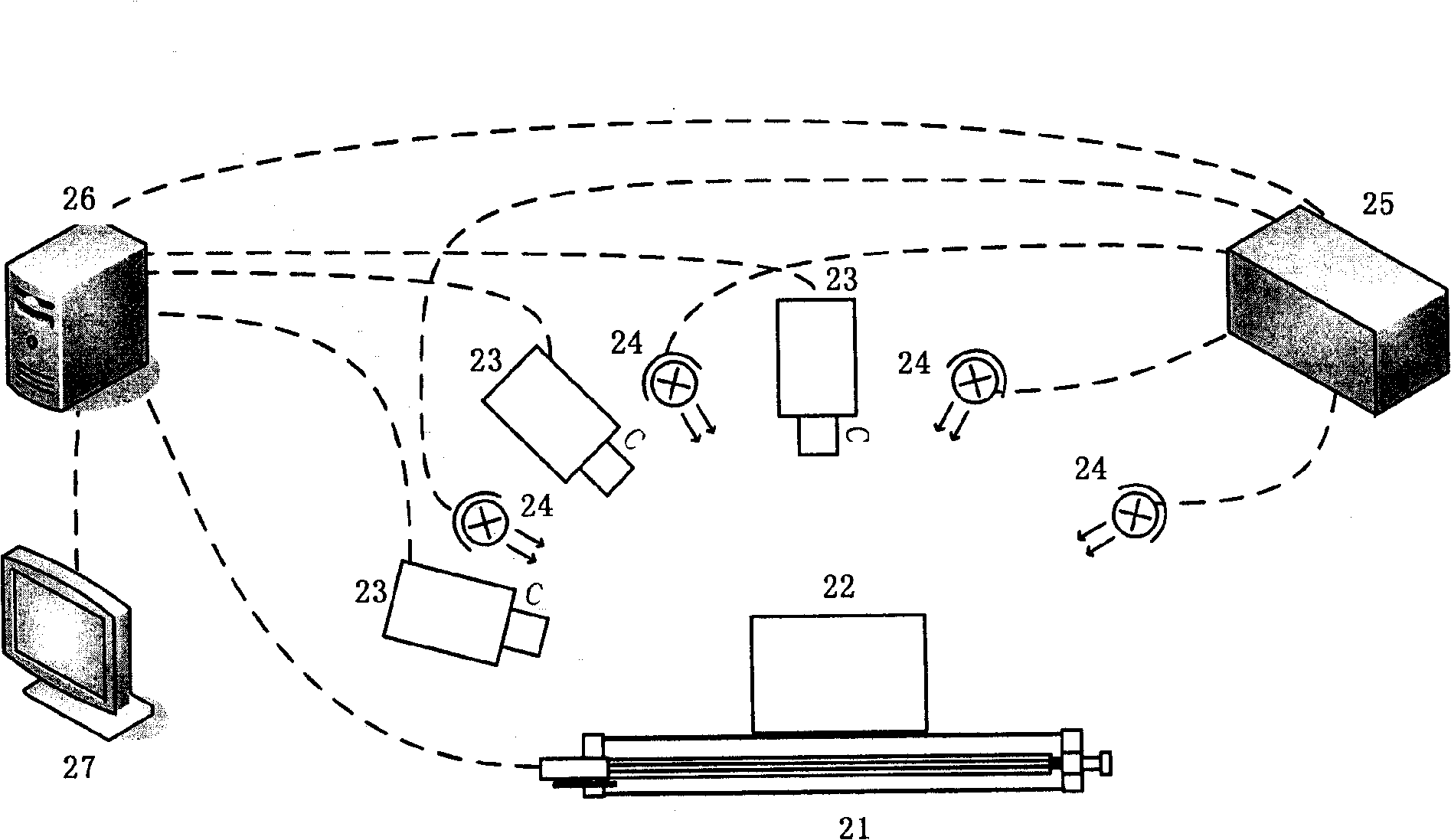

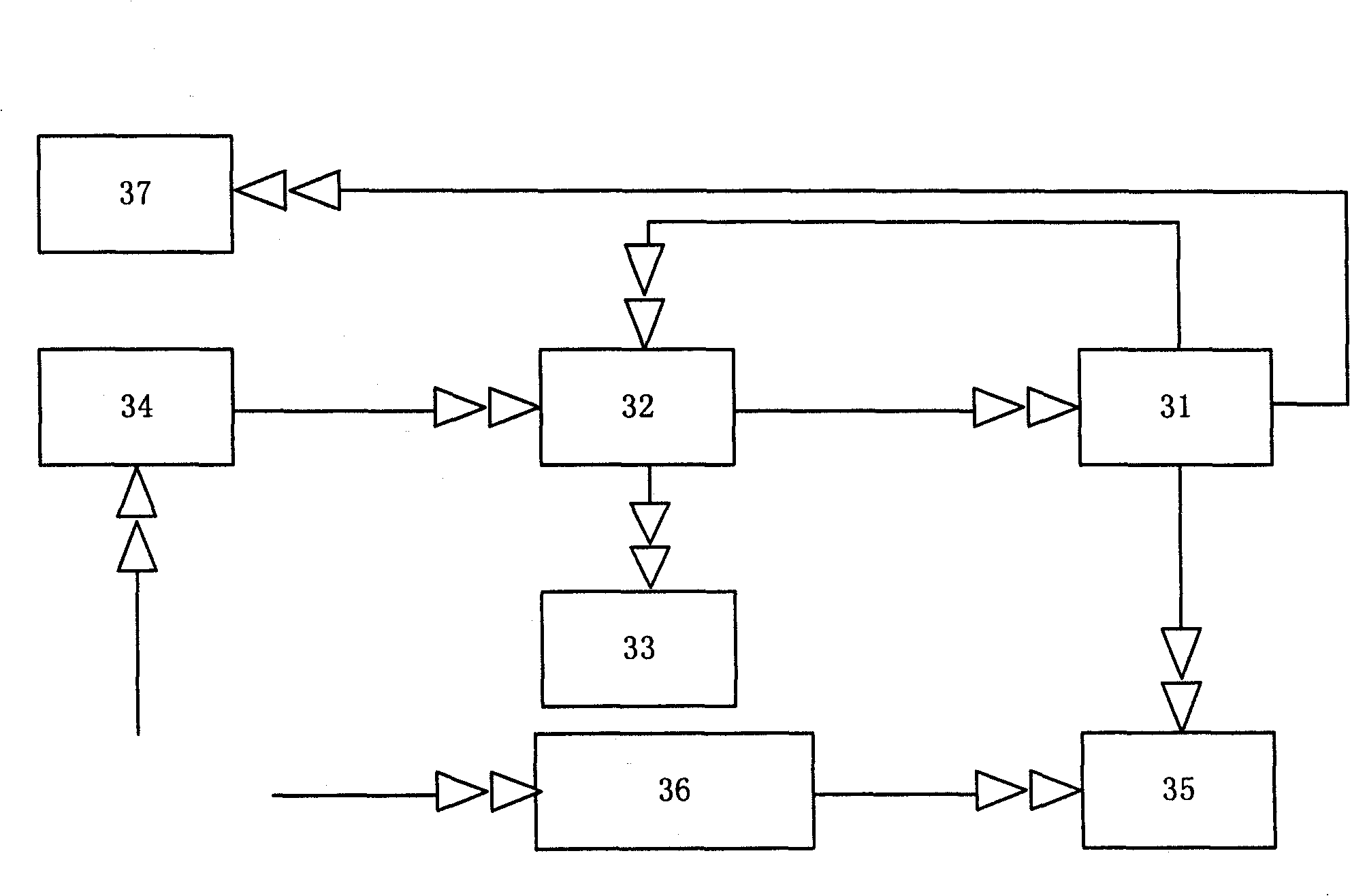

Automatic image data collecting system

InactiveCN101557472AUniform light source environmentSolve the problem of color distortion in captured imagesTelevision system detailsConveyorsControl systemData acquisition

The invention discloses an automatic image data collecting system which comprises a sample transfer control system, an image collecting control system and an optical imaging system. The sample transfer control system is used for transferring samples to a preset position, resting the samples in the preset position and sending image collecting order; the image collecting control system is used for receiving the image collecting order from the sample transfer control system and controlling the image data of the sample collected by the optical imaging system; and the optical imaging system comprises a camera for collecting image data of the samples. The automatic image data collecting system uses the standardized light source system during the image data collecting process of gold, jewel, jade ornaments, automatically collects the image data and solves a series of problems such as low working efficiency, distortion of the received image data, the impossibility of direct usage of the collected images and the like when non-standardized light source is applied to the image collecting process of samples during the data collection of the existing product data base, image collection of the exhibited samples and the image data collection of samples such as jewelry, jade and other ornaments to be appraised.

Owner:HUSNG SHIJI BEIJING TECH DEV

Method for improving measurement precision of photometry measuring instrument

InactiveCN101034006AEasy to changeHigh measurement accuracyPhotometry using electric radiation detectorsMeasuring instrumentDisplay device

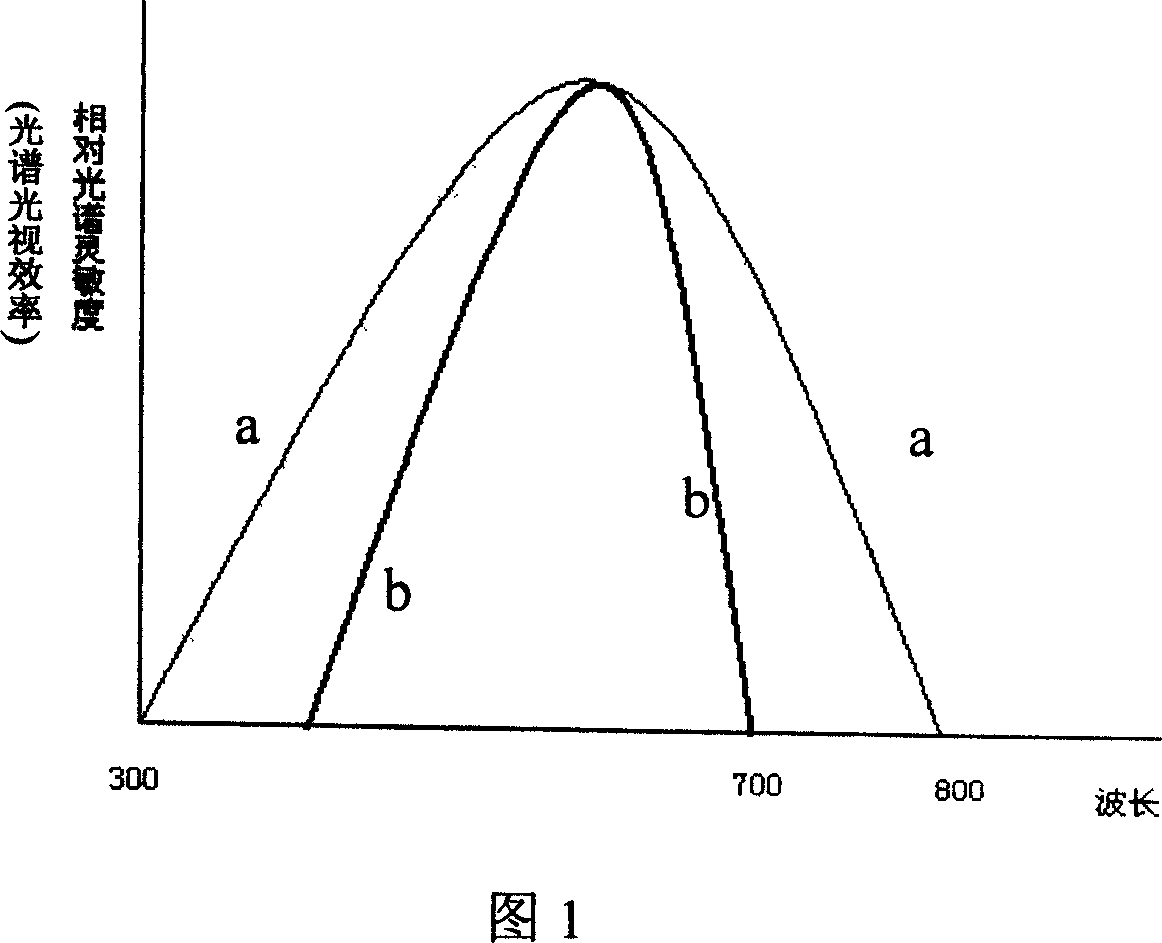

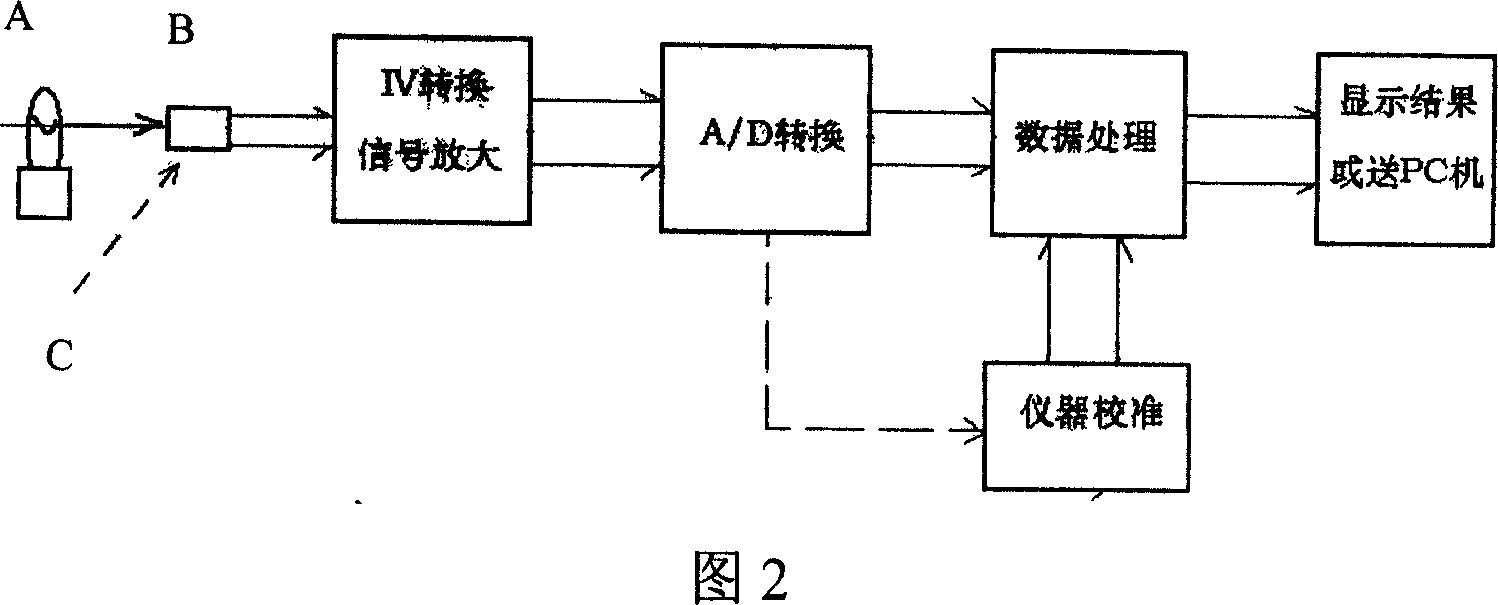

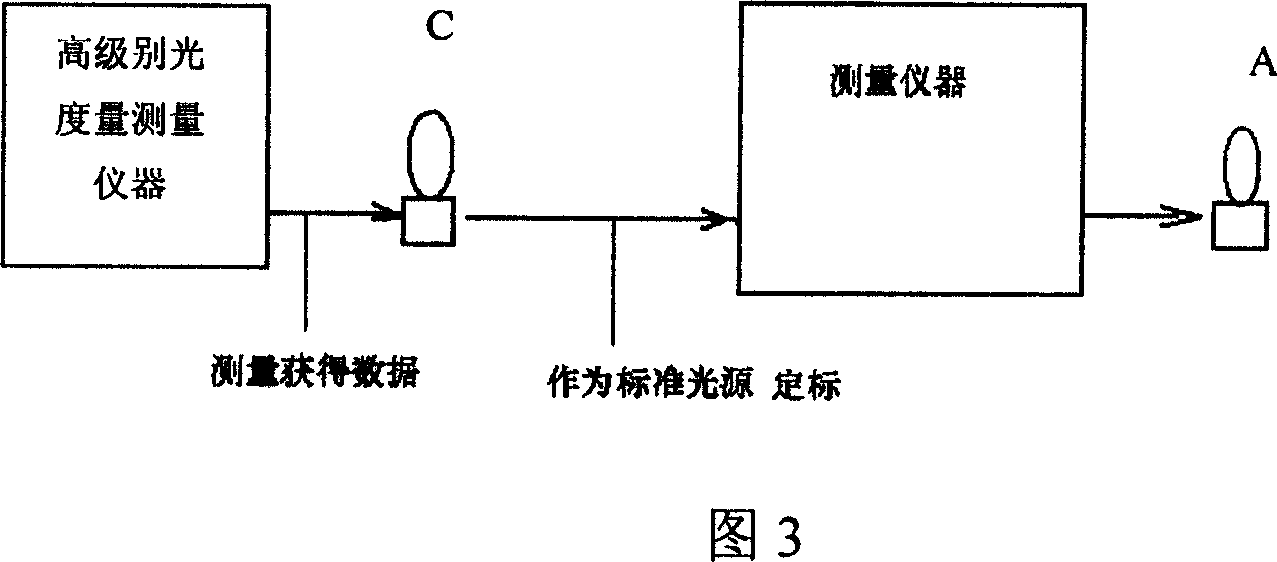

This invention relates to a method of advancing photometric quantity measuring apparatus accuracy of measurement. Method include; measured light through V ( lambda) regulation then be received by detector to turn to current signal, passing iv transducer turn ro voltage alarm, after magnifying then passing A / D transducer turn to digital signal; processing the digital signal, and send the results to PC machine or scope for presentation;this instrument beforehand has passed difference spectral range standard light source adjust, gain different instrument calibration coefficient; And use homologize wave band's instrument calibration coefficient while use this instrument to measure difference wave band light source. The described standard light source is linear light source that has scaling measured by instrument of higher order of accuracy. The described difference spectral range divided into red green blue yellow white five colors.

Owner:郑晓明

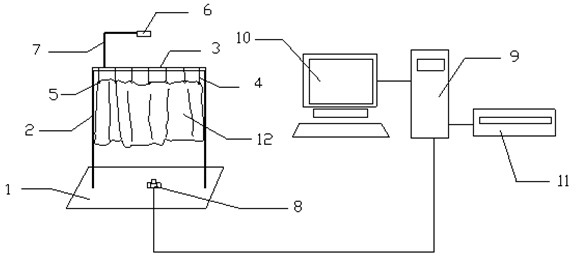

Testing device for draping property of curtain fabric and method

InactiveCN102323268AImprove the simulation effectGood repeatability of experimentMaterial analysis by optical meansDisplay deviceRepeatability

The invention relates to a testing device for draping property of a curtain fabric. The conventional testing method has a poor effect and a testing method. In the invention, a detection table is a flat plate with a smooth surface; a digital camera is fixed in the middle part of the detection table and is connected with a computer; the computer is connected with a display; two supporting rods are symmetrically arranged in length direction of the detection table and close to the edge and are perpendicular to the detection table; one end of each of the supporting rods is fixed to the detection table, and the other ends of the supporting rods are fixed with one end of a suspension rod; the two supporting rods and the suspension rod form a door shape; a plurality of grooves in circumferential direction of the supporting rods are uniformly formed in length direction of the supporting rods; a fine steel wire is arranged at each groove; the fixed end of the fine steel wire is wound on each groove of the supporting rod, and the free end is fixed with a small clamp for suspending the curtain fabric; and a standard light source is arranged just above the suspension rod and is connected with the suspension rod through a bracket. By adopting the device and the method, the draping property of the fabric in different directions can be conveniently tested; and high experimental repeatability is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

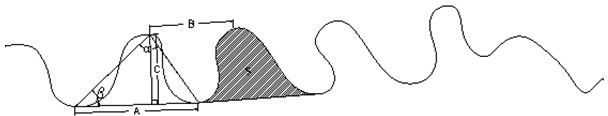

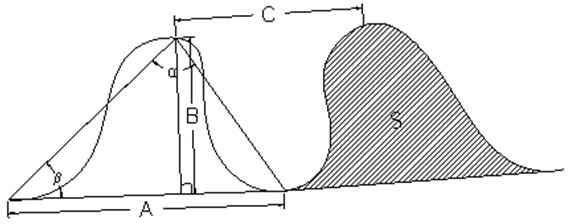

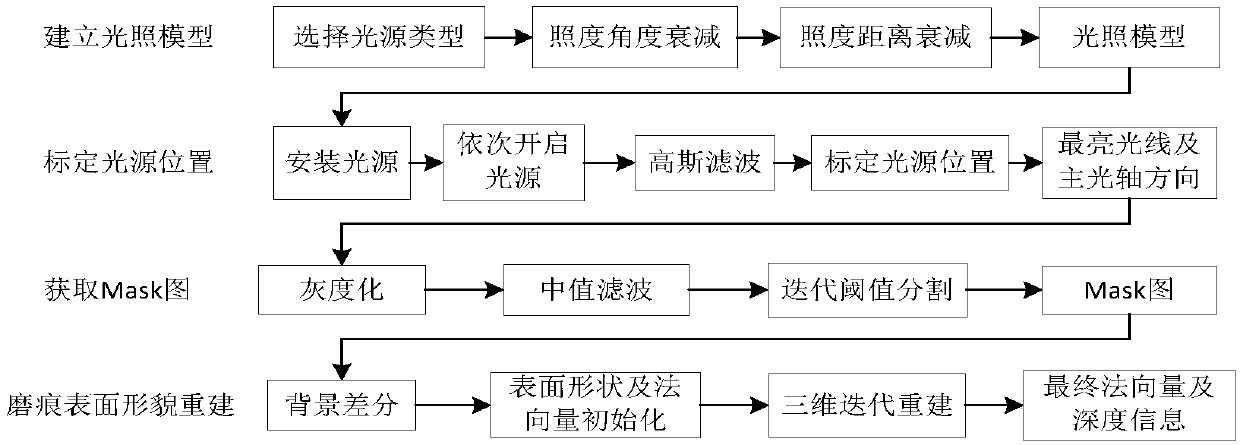

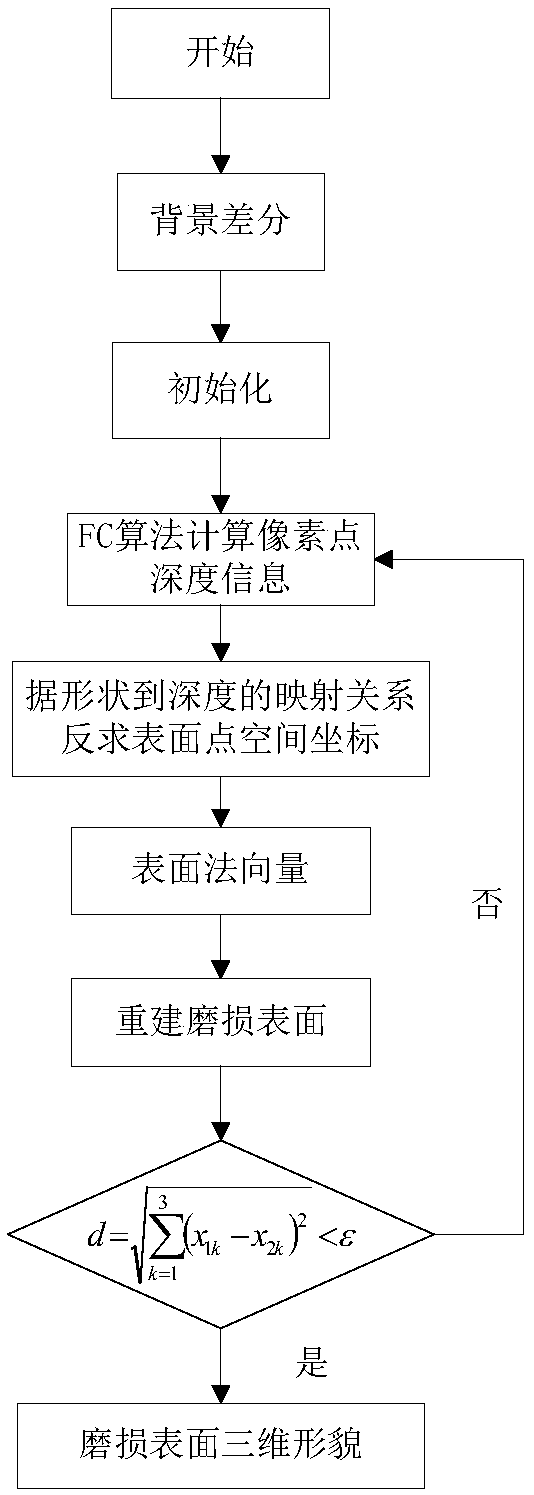

Near field non-standard light source-based in situ obtaining method for three dimensional polishing scratch shapes

A near field non-standard light source-based in situ obtaining method for three dimensional polishing scratch shapes is disclosed. Six LED lights uniformly distributed on a hand held microscope are used as light sources, an illumination model for non-standard light sources is built in near field conditions, relative spatial positions of the light sources are calibrated, the hand held microscope isused for collecting image data of worn-out surfaces of parts, a Mask image is obtained based on image processing technologies, images under the same viewpoint and different light sources are subjected to background difference processing operation, an object image which requires three dimensional rebuilding is obtained, and a final three dimensional polishing scratch shape is rebuilt via iterationbased on combination of a technology for estimating a normal direction based on an image sequence and a technology of recovering surface shapes from the normal direction. According to an actual lightsource position, the illumination model for the near field non-standard light sources is built via use of the method disclosed in the invention after photometric stereo visual near field non-standardpoint light sources are adopted, the method can meet requirements of real measurement conditions, and calculation precision of normal vector and depth information of worn-out surfaces can be improved.

Owner:XI AN JIAOTONG UNIV

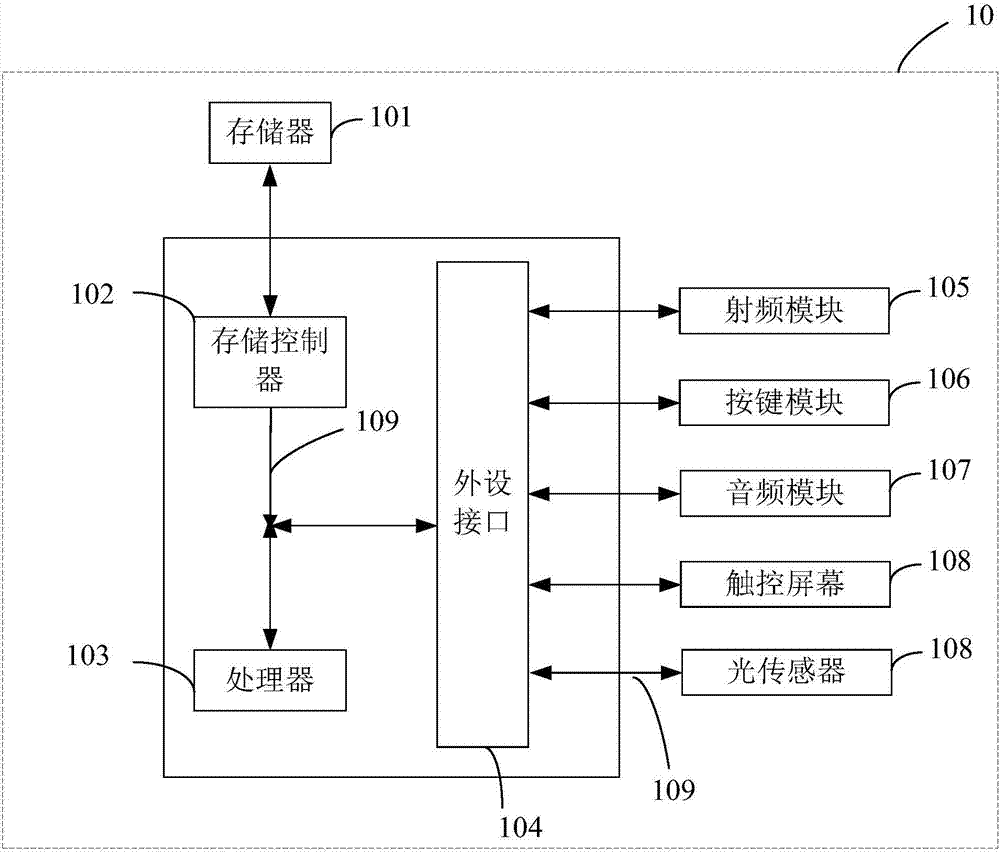

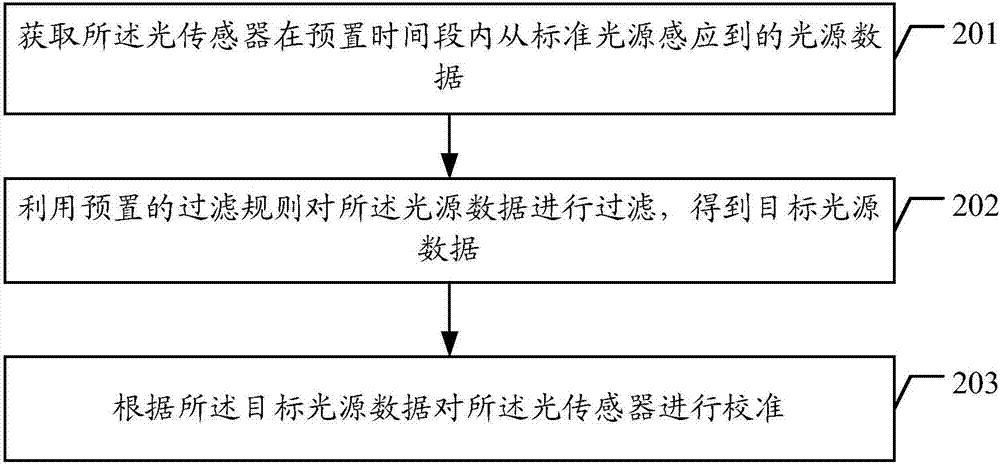

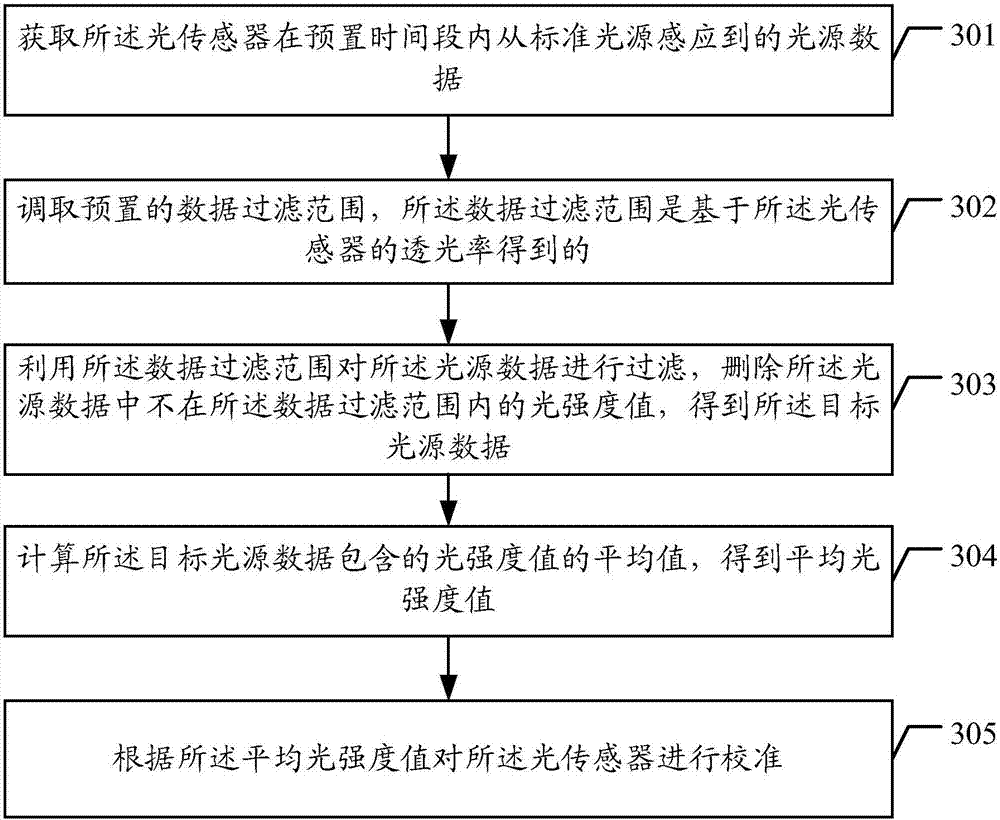

Light sensor calibration method and device, mobile terminal and readable storage medium

The invention discloses a light sensor calibration method and a device, a mobile terminal and a readable storage medium; the method comprises the following steps: obtaining light source data sensed by a light sensor from a standard light source in a preset time period; using preset filtering rules to filter the light source data so as to obtain target light source data; calibrating the light sensor according to the target light source data. Compared with the prior art, the method uses preset filtering rules to filter the light source data sensed by the light sensor from the standard light source, thus filtering abnormal data formed by manual operations or equipment reasons from the standard light source, and forming effective fool-proof effect; the method uses the filtered target light source data to calibrate the light sensor, thus effectively improving the calibration accuracy.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Calibration method of fluorescence detection instrument

PendingCN105928911AImprove consistencySuitable for large quantitiesFluorescence/phosphorescenceUltrasound attenuationFluorescence

The invention discloses a calibration method of a fluorescence detection instrument. The method is used for calibration of fluorescence detection instrument before leaving the factory. The light intensity detection of the fluorescence detection instrument and calibration of signal detection module parameters are carried out into two steps independently. The light intensity detection uses a light intensity measurement instrument; and the calibration of the signal detection module parameters uses a standard light source as a detection light source. The invention adopts the existing standard equipment after measurement determination for the calibration, has standard traceability and uncertainty, and is suitable for mass and accurate measurement. At the same time, the method of the invention can also be used in quality control of instruments to detect light source attenuation after long time operation; if attenuation exists, the light source can be replaced. The invention improves the consistency of fluorescence detection instrument in mass production.

Owner:深圳市华科瑞科技有限公司

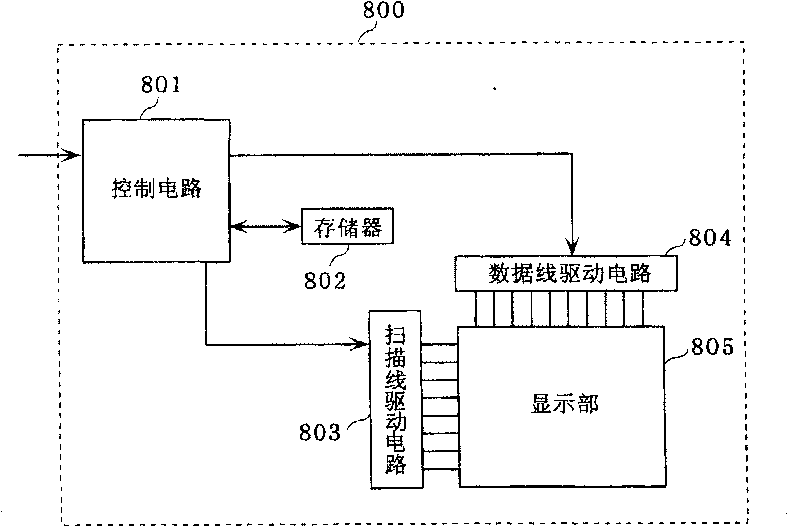

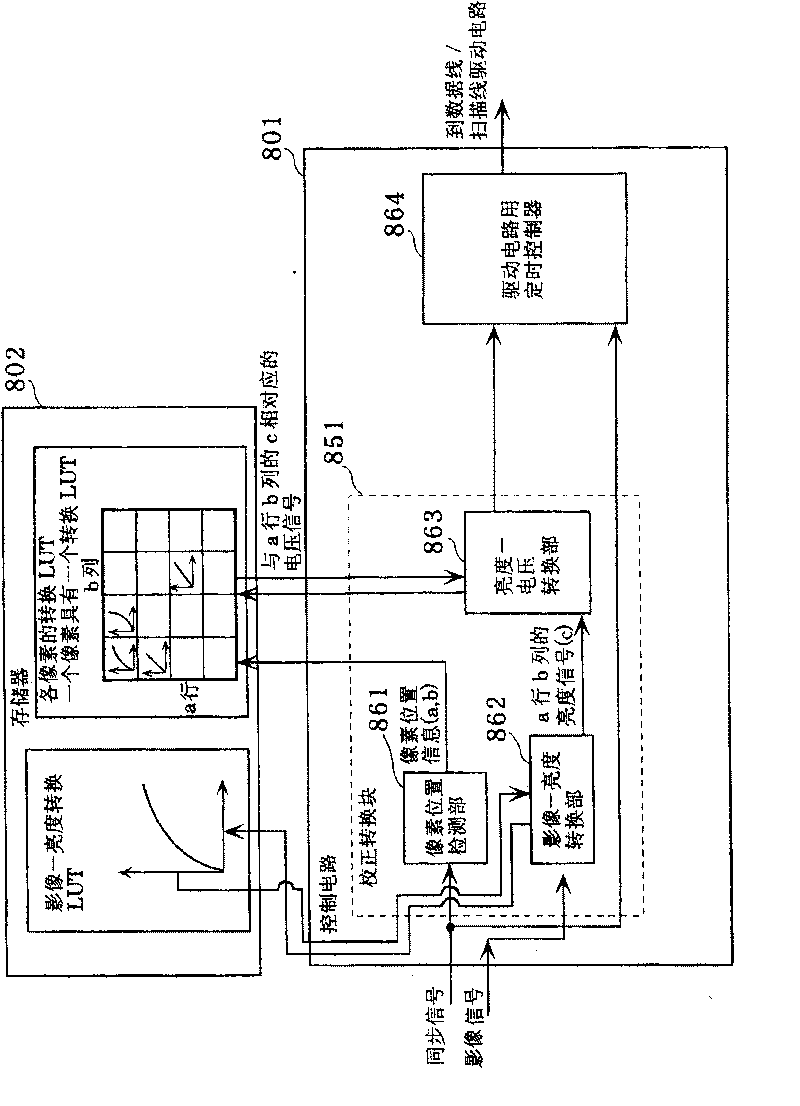

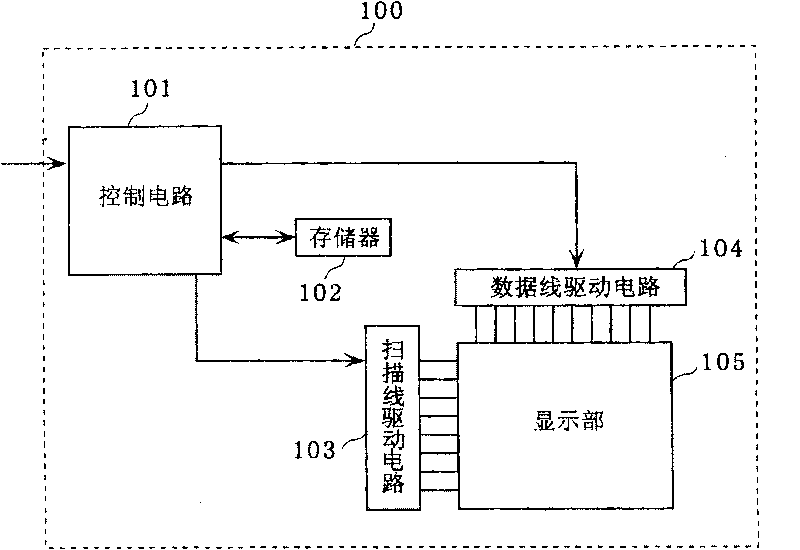

Display device, and manufacturing method and control method thereof

ActiveCN101765874AReduce manufacturing costReduce processing burdenStatic indicating devicesSolid-state devicesManufacturing cost reductionDisplay device

Provided is a display device which reduces the manufacturing costs and can correct uneven luminance caused by non-uniformity in the element characteristics by simple measurement and corrective processes. The display device is comprised of a plurality of pixels which include light-emitting elements and drive elements; a plurality of data lines which supply the data voltages corresponding to the voltages supplied to the drive electrodes; a data line drive circuit which supplies the data voltages to the plurality of data lines; a memory (102) which stores the luminance gain for setting the luminance corresponding to the image signal to the specified standard luminance for each pixel, and stores the information of the representative conversion curve corresponding to the voltage-luminance characteristics shared by the plurality of pixels to be shared by the plurality of pixels; and a correction conversion block (601) which reads out and calculates the corresponding luminance gain with respect to the luminance signal from the memory (102) and corrects to the specified standard luminance, and converts the luminance signal of each corrected pixel into a voltage signal based on the specified information corresponding to the representative conversion curve stored in the memory (102).

Owner:JAPAN DISPLAY DESIGN & DEV CONTRACT CO LTD

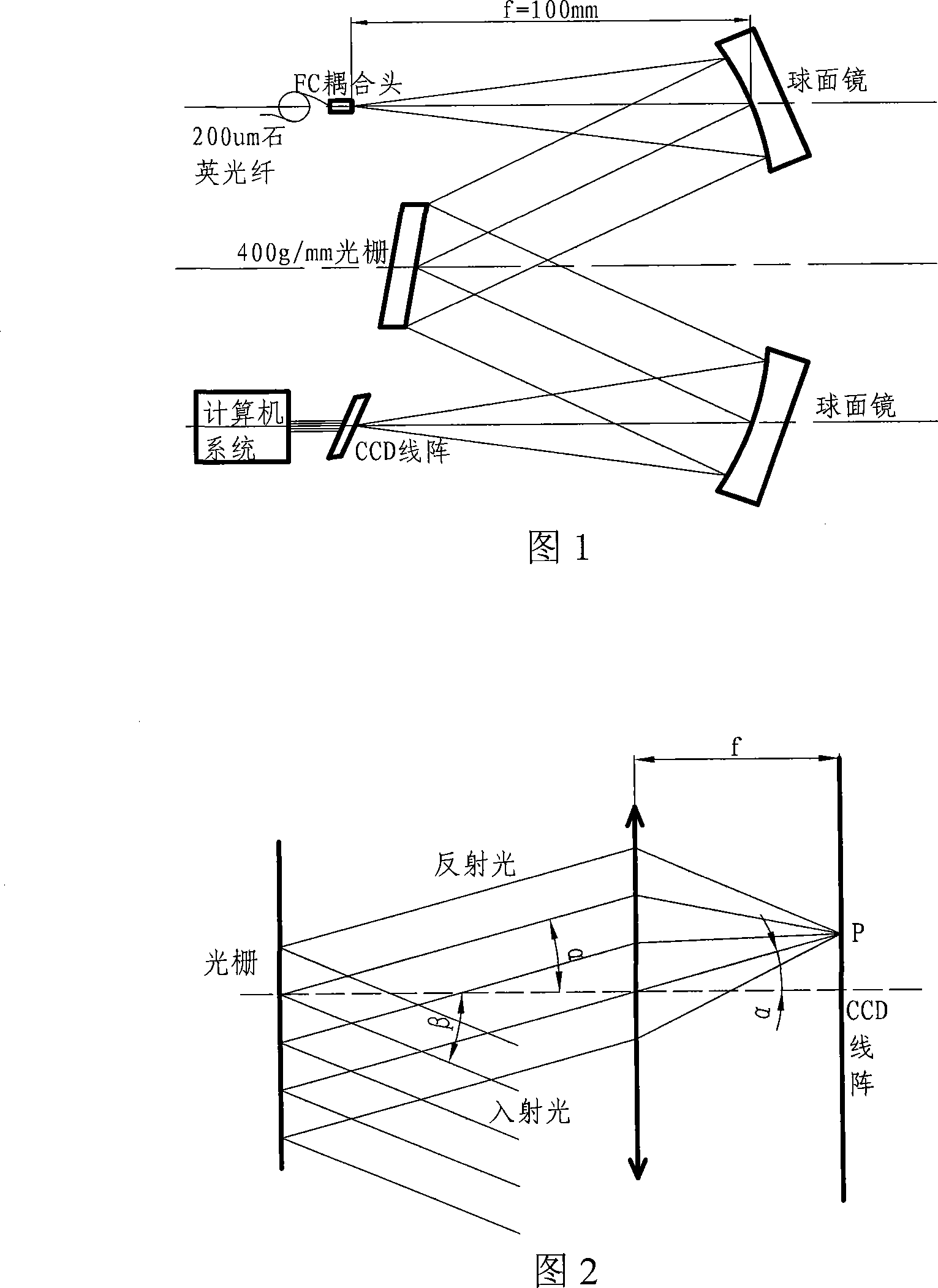

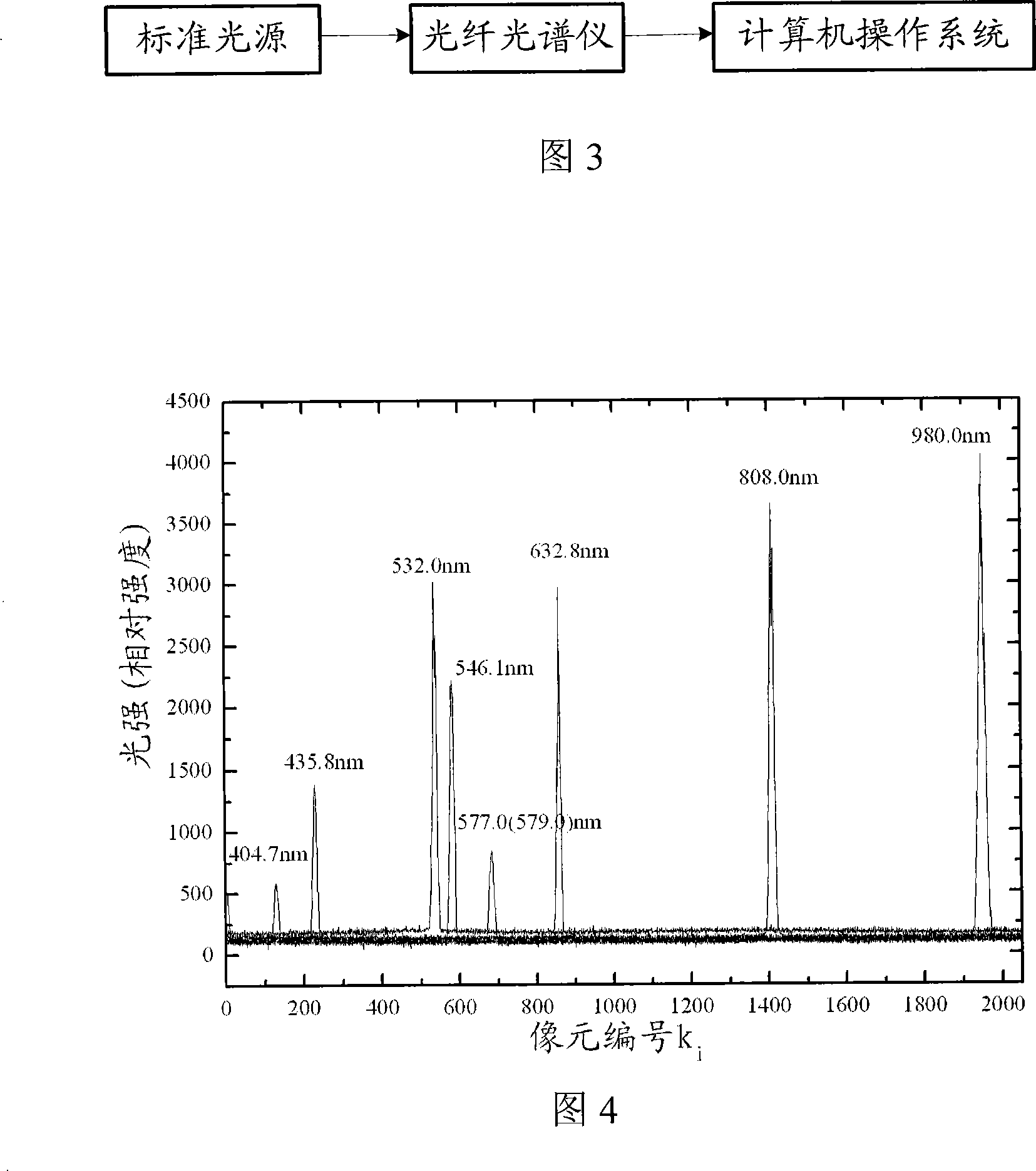

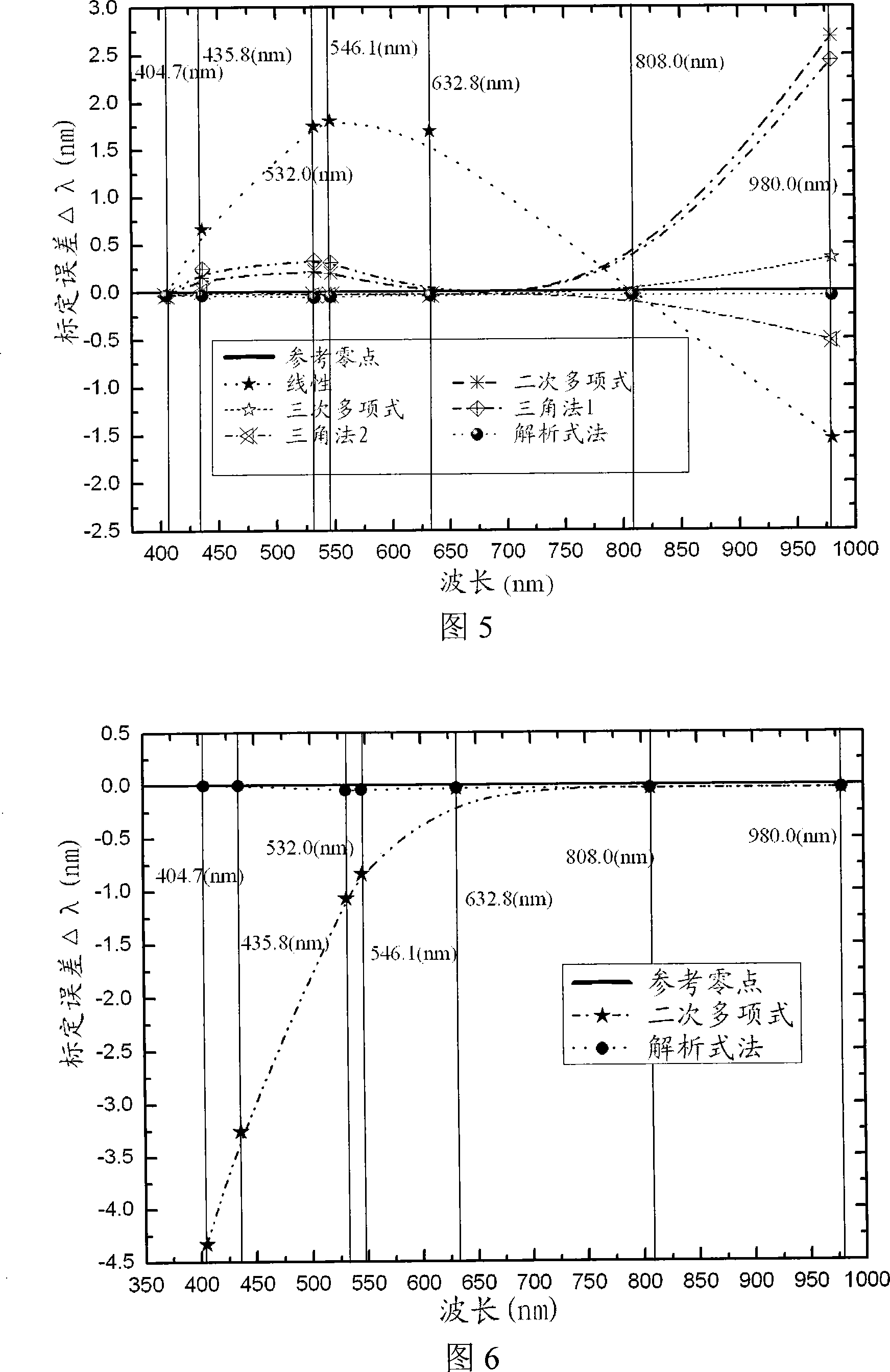

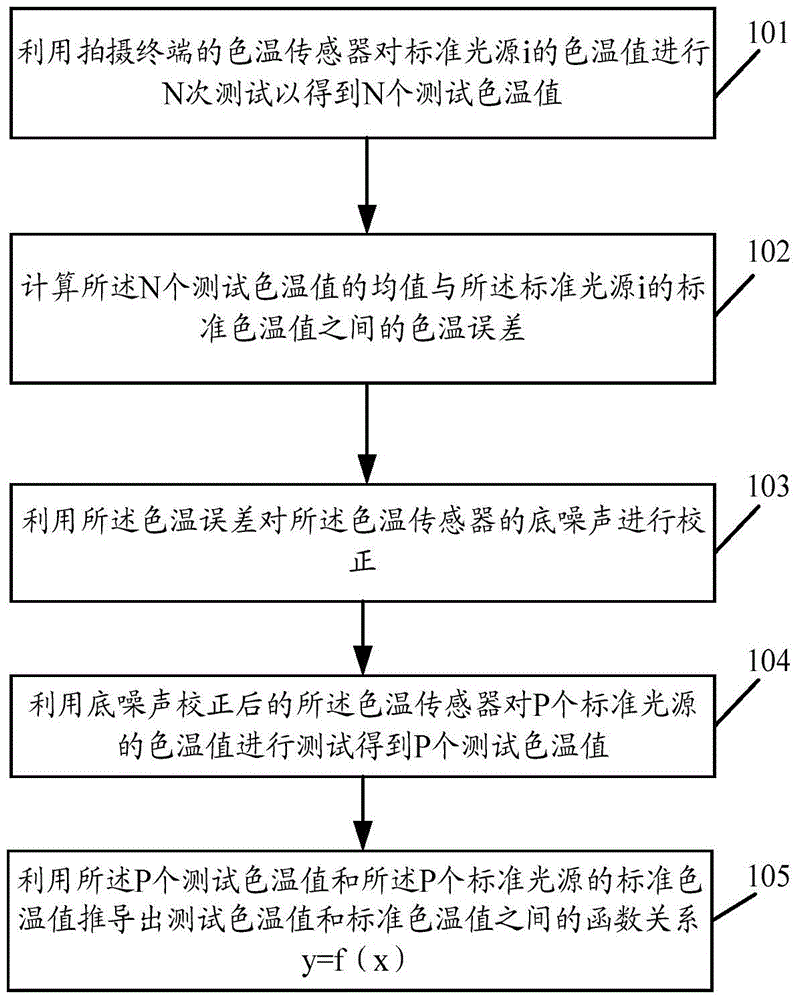

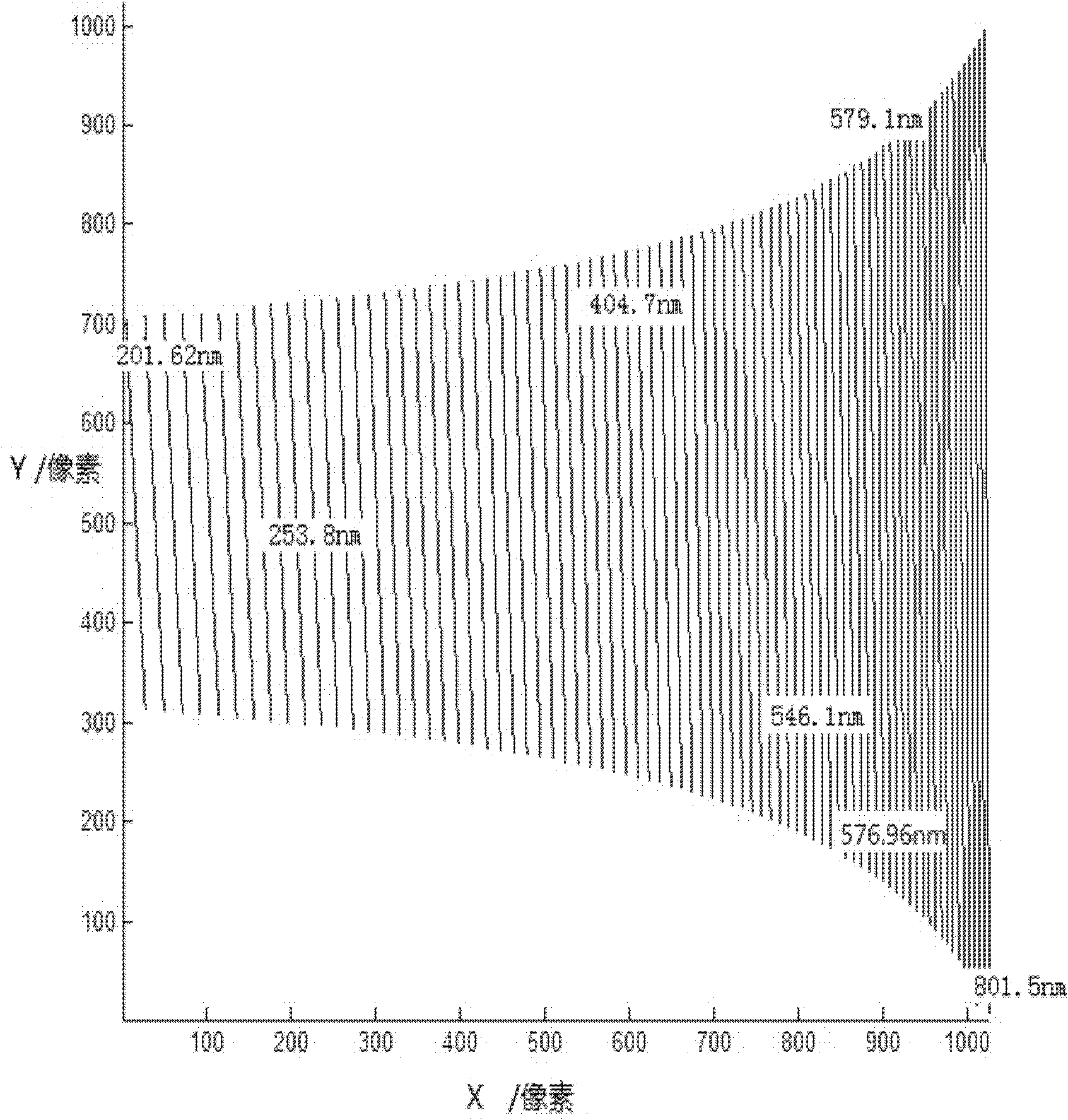

Optical fiber spectrometer wavelength calibration method

InactiveCN101158636AImproved wavelength calibration accuracyReduce calibration errorRadiation pyrometryMaterial analysis by optical meansElement OrderLength wave

The invention discloses a wavelength calibration way for a optical fiber spectrometer, and consists of the following steps, A) a standard light source is applied, standard spectrum is collected through the spectrometer, the image element order number ki of spectrometer receiving element linear array CCD is determined corresponding to the standard light source of different practical wavelength Lambadai; B) the arbitrary three practical wavelength Lambada i and the corresponding image element order number ki are chosen, and in accordance with the above formula, a1, a2, and a3 are determined; C) according to the values of a1, a2, a3 from step B), the calibration calculation wavelength value Lambadai is determined corresponding to every image element order number ki, wherein, the Lambadai is a calibrated wavelength value. The calibrating way of the optical fiber spectrometer is provided by the present invention, the calibration deviation of the calibrating way is much smaller than the calibration deviation of the prior art, and accurate calibration can be done with 3 arbitrary standard spectrum lines, not only the flexibility of the calibration is improved but also the application is easier and more convenient. The invention discloses the calibrated spectrometer applying the above mentioned way at the same time.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

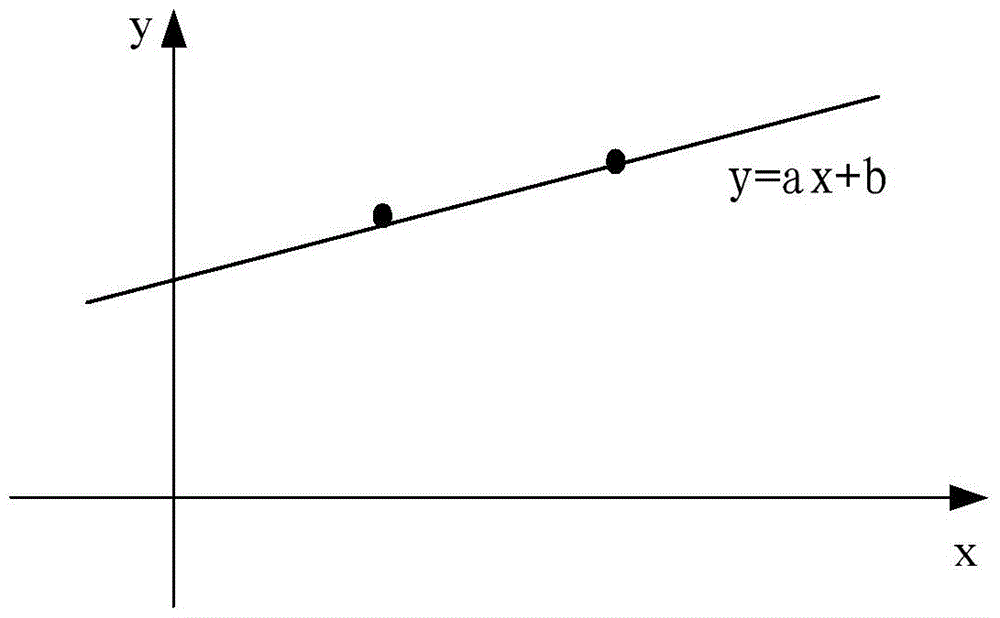

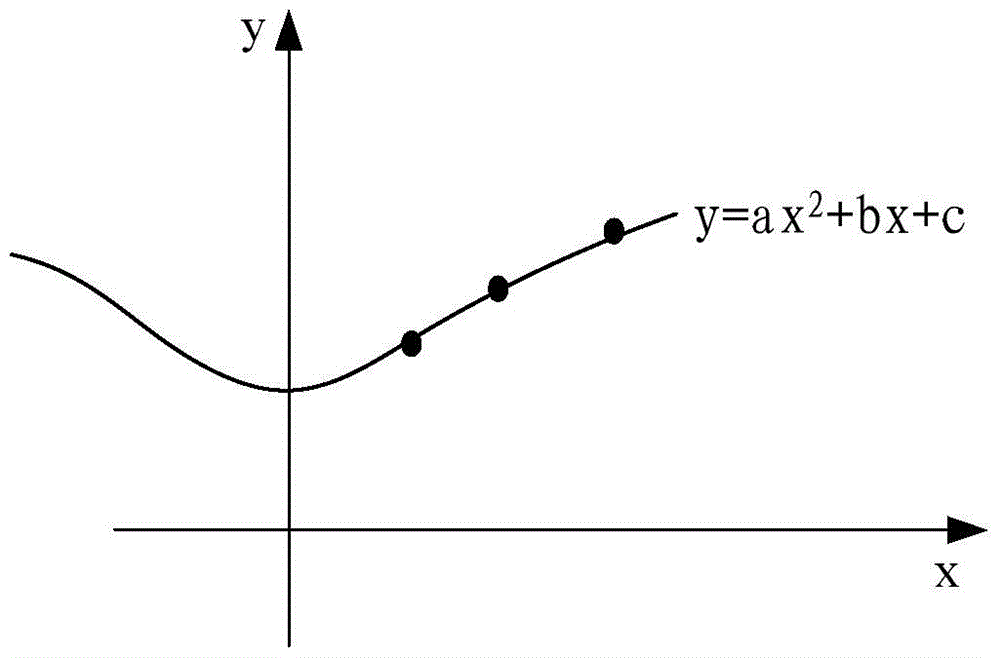

Color temperature sensor calibration method and related device

ActiveCN105681782AExcellent correction is more scientificColor signal processing circuitsTelevision systemsComputer scienceStandard illuminant

The embodiment of the invention discloses a color temperature sensor calibration method and a related device. According to the color temperature sensor calibration method, after the base noises of a color temperature sensor are calibrated by utilizing calculated color temperature errors, the color temperature values of P standard light sources are tested by utilizing the color temperature sensor with calibrated base noises, thus obtaining P test color temperature values; the function relationship y=f(x) between the test color temperatures and the standard color temperatures is derived by utilizing the P test color temperature values and the standard color temperature values of the P standard light sources; and the function relationship y=f(x) is used for calibrating the color temperature value of the color temperature sensor of a photographing terminal detected in the photographing process of the photographing terminal. The technical solution provided by the embodiment of the invention is beneficial for carrying out relatively excellent and scientific calibration to the color temperature sensor of the photographing terminal.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

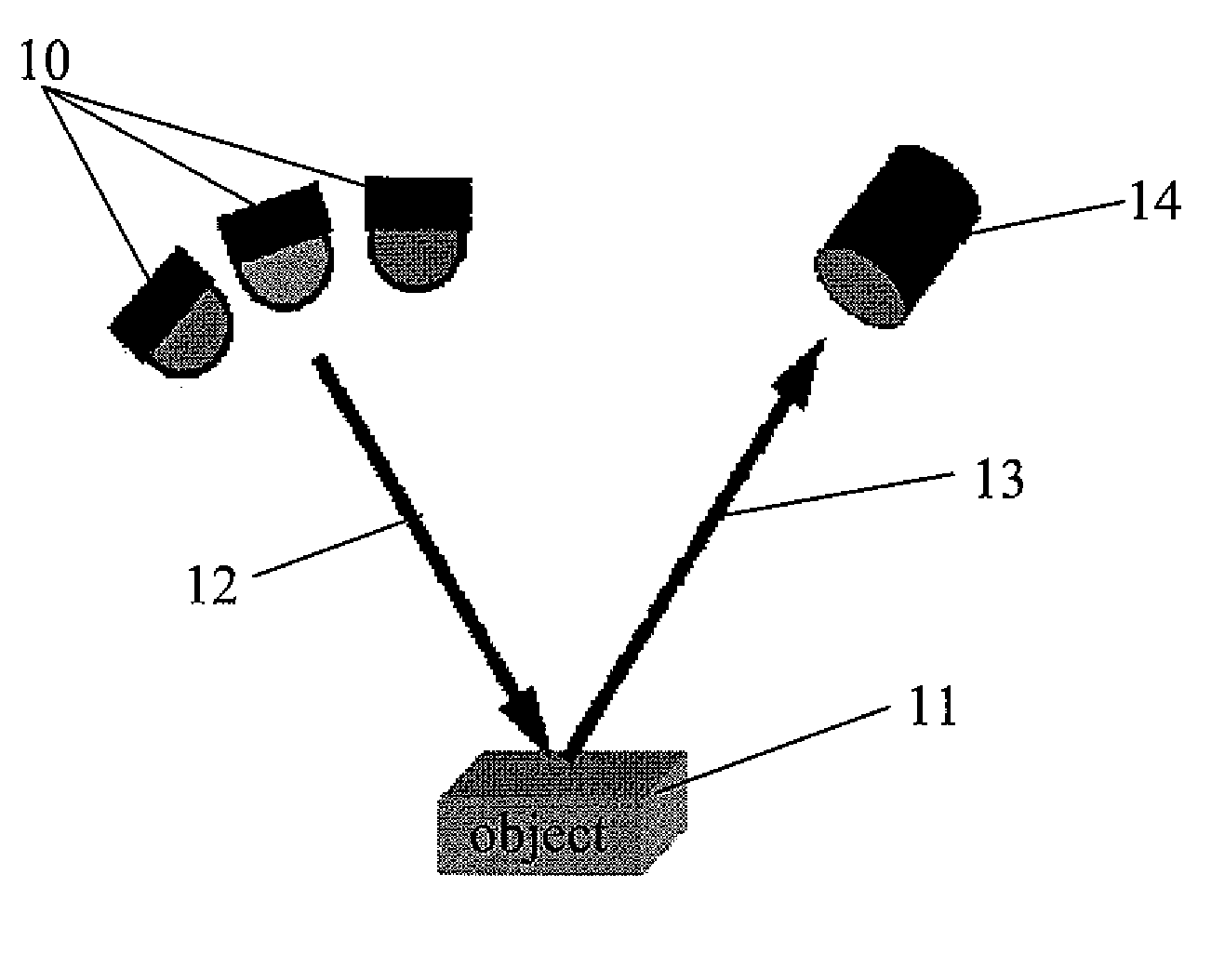

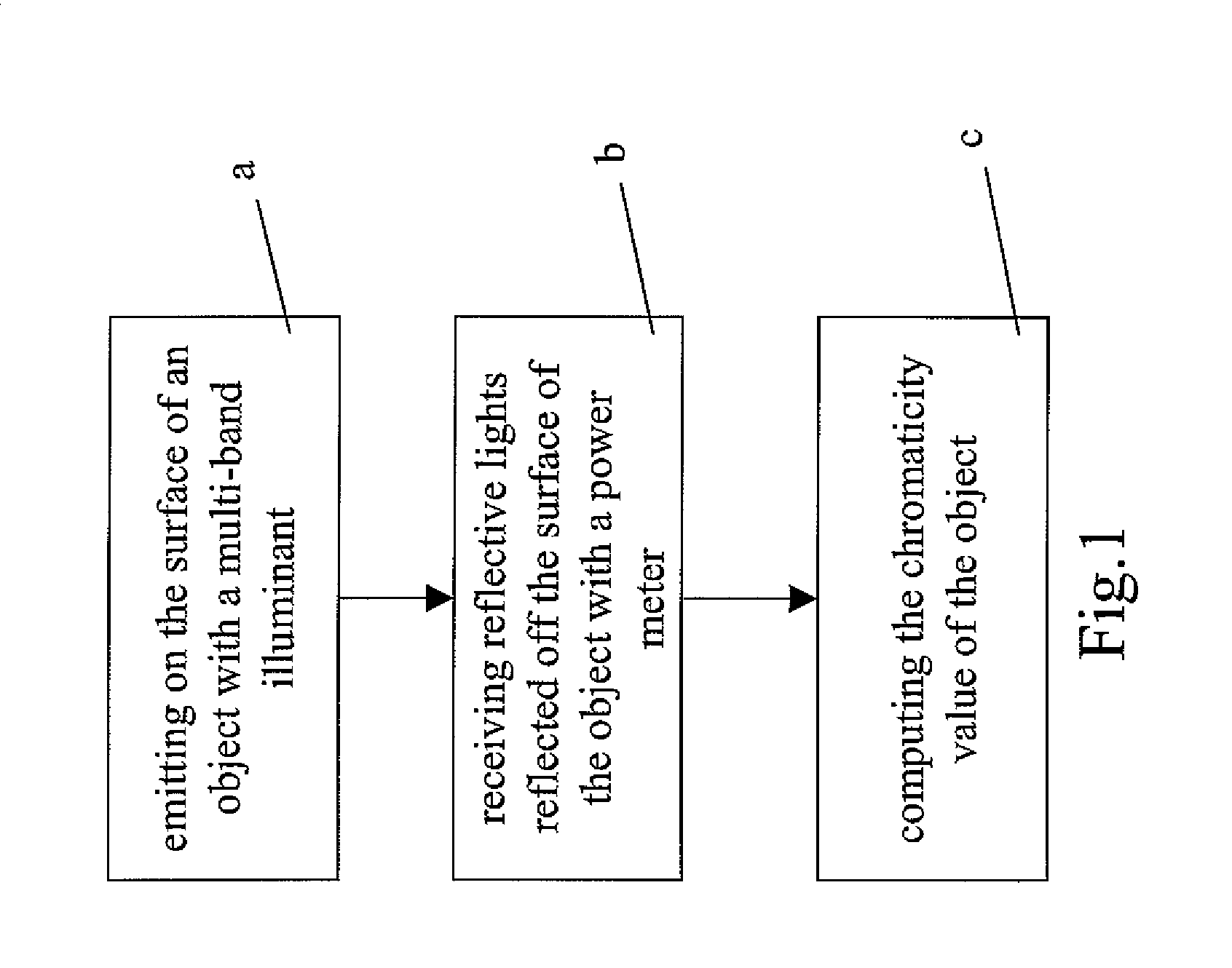

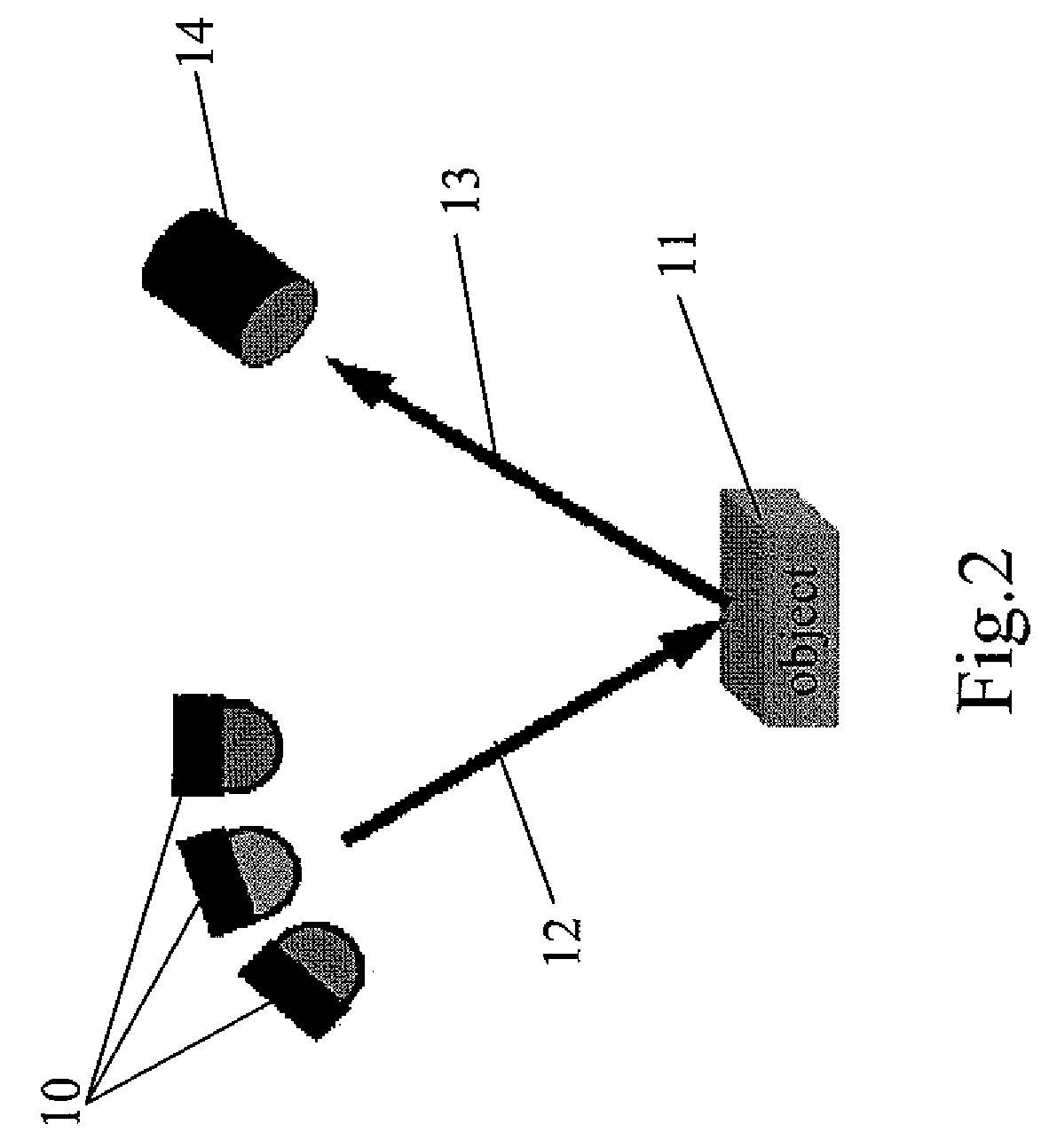

Method for measuring chromaticity values by a colorimeter

InactiveUS7898664B2Less expensiveEasily adjust color temperatureRadiation pyrometryColor/spectral properties measurementsMulti bandStandard illuminant

A method measures chromaticity values using a colorimeter to solve the drawbacks of conventional technologies, such as an inaccurate illuminant, the filter of color-matching function being difficult to be deposited and manufactured within a filter mod colorimeter, and using an expensive spectrometer within a spectrum mode colorimeter. The spectrometer and the filter of color-matching function is not needed, and an accurate chromaticity value of an object by using a multi-band illuminant illuminating the object and a power meter. Further, the multi-band illuminant can adjust the illumination condition of a standard illuminator under different color temperatures, and the chromaticity values of the object can be measured under different color temperatures. The accuracy of the measured chromaticity values is up to the level of the spectrum mode colorimeter, and the price is less than the spectrum mode colorimeter.

Owner:NAT CENT UNIV

Method for detecting raw silks of fresh cocoons by using color photometer

InactiveCN103115873AGuarantee production efficiencyAccurate Raw Silk QualityColor/spectral properties measurementsWhiteboardControl system

The invention relates to a method for detecting the whiteness of raw silks, and in particular relates to a method for judging the types of raw silks of fresh cocoons and raw silks of dried cocoons, and identifying the type differences of raw silks. The invention discloses a method for detecting raw silks of fresh cocoons by using a color photometer, which comprises the following specific steps: connecting a spectro-color photometer with a computer, starting a switch of the color photometer, setting a standard light source, opening a color quality control system, carrying out zero correction and whiteboard correction, and establishing data storage files and the like. According to the invention, by using the characteristics of color difference among different raw silks, the exponential value of whiteness is measured by using a spectro-color photometer, and according to a rule that the exponential value of whiteness of raw silks of fresh cocoons is greater than the exponential value of whiteness of raw silks of dried cocoons, the dried and fresh types of raw silks are judged. The method disclosed by the invention has the advantages that the method is rapid, accurate and convenient and the like, facilitates the accurate grasping of quality of raw silks, and ensures the quality of products and the production efficiency of silk articles.

Owner:ZHEJIANG UNIV

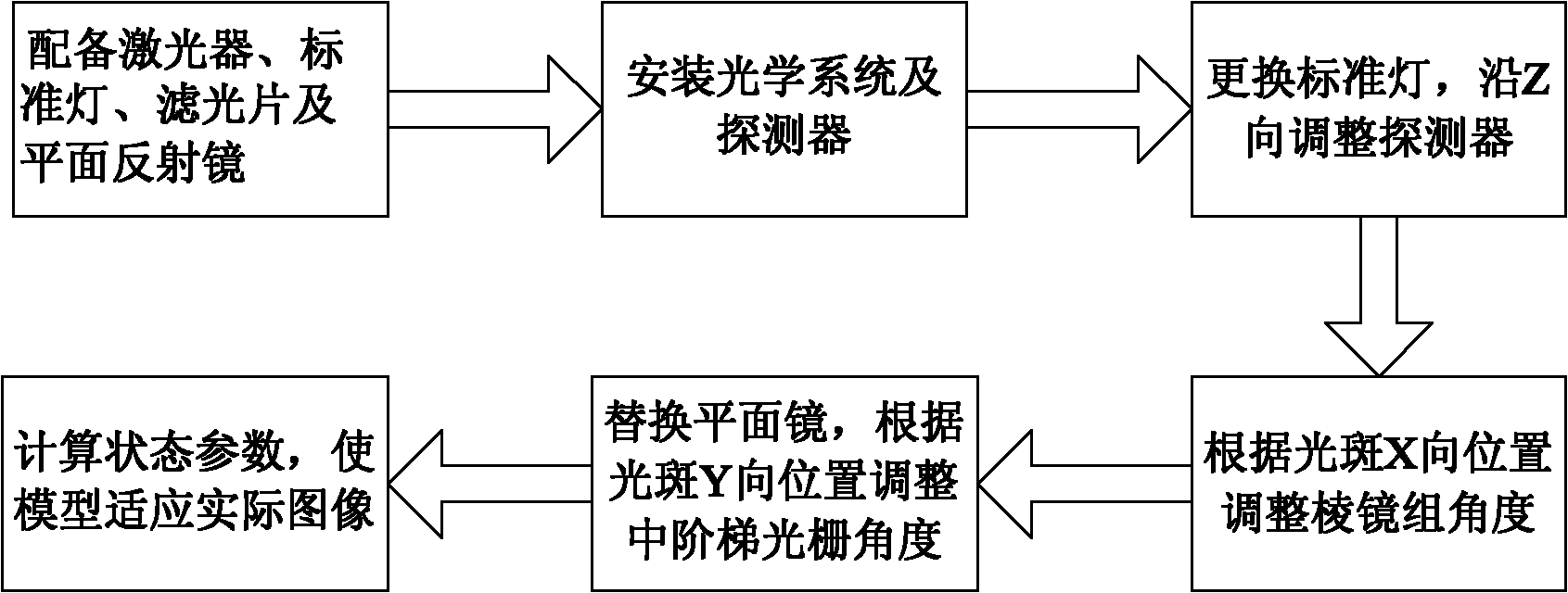

Debugging method of echelle grating spectrograph

InactiveCN102155990AHigh resolutionWide spectral rangeSpectrum investigationSpectrum generation using diffraction elementsGratingState parameter

The invention provides a debugging method of an echelle grating spectrograph, belonging to the technical field of spectrums. The method comprises the following steps: allocating a laser, a standard light source and a plane mirror for debugging; installing an optical system and detector assemblies of the spectrograph by taking the laser light as reference beam, and replacing the echelle grating by the plane mirror; replacing the standard light source, adjusting the position of the detector according to a spectrum image obtained on the detector to optimize the whole image quality; according to the deviation between an X-directional position of light spots on the spectrum and a spectral line position of an ideal spectrum model, adjusting the placing angle of a reflecting prism unit; replacing the plane mirror by the echelle grating, and adjusting a pitch angle of the echelle grating according to an Y-directional position of the light spots in the spectrum; and comparing the spectrum images of the adjusted detector with the ideal spectrum models, when the spectrum images are similar to the ideal spectrum models, reversely calculating accurate state parameters according to the practical spectrum and adjusting the spectrum models to adapt to the practical images. The method has the advantages that less tools are need and the operation is simple; and furthermore, the debugging operation of the echelle grating spectrograph can be effectively simplified.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com