Correction method, device and equipment used for optical sensor, and storage medium

A technology of light sensor and calibration method, which is applied in the field of calibration, can solve the problems of different backlight brightness, slow increase or decrease of backlight brightness, different problems, etc., and achieve the effect of consistent backlight brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

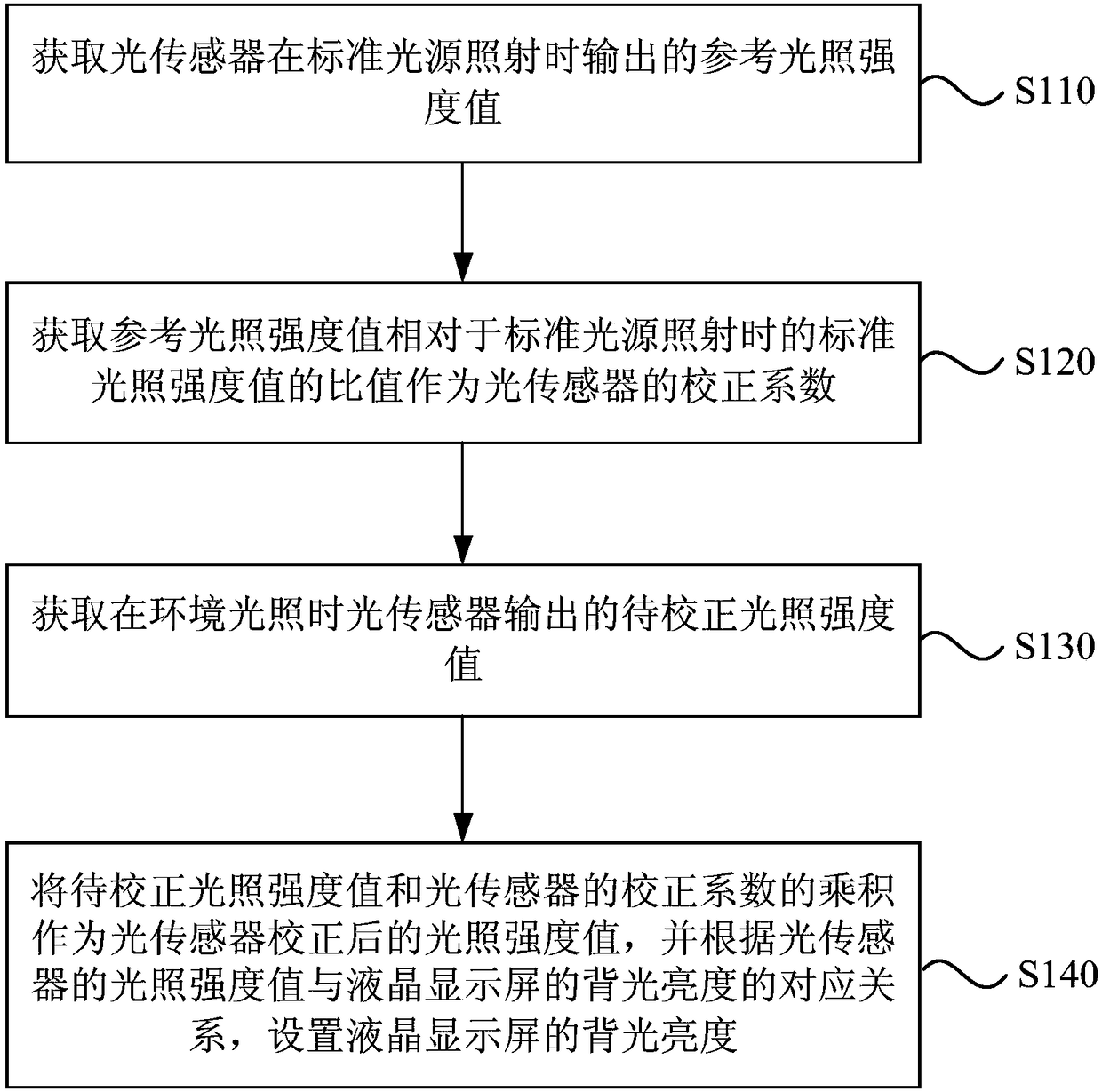

[0045] figure 1 It is a flow chart of a calibration method for a light sensor provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of adjusting a light sensor, and the method can be performed by a calibration device for a light sensor. The device can Implemented in the form of software and / or hardware, the device can be configured in equipment, such as typically mobile phones, tablet computers, and computers. Such as figure 1 As shown, the method specifically includes the following steps:

[0046] S110. Obtain a reference light intensity value output by the light sensor when irradiated by a standard light source;

[0047] In a specific embodiment of the present invention, the standard light source may refer to an artificial light source that simulates various ambient lighting conditions, so that the off-site production factory or laboratory can obtain lighting effects that are basically consistent with the light source in these sp...

Embodiment 2

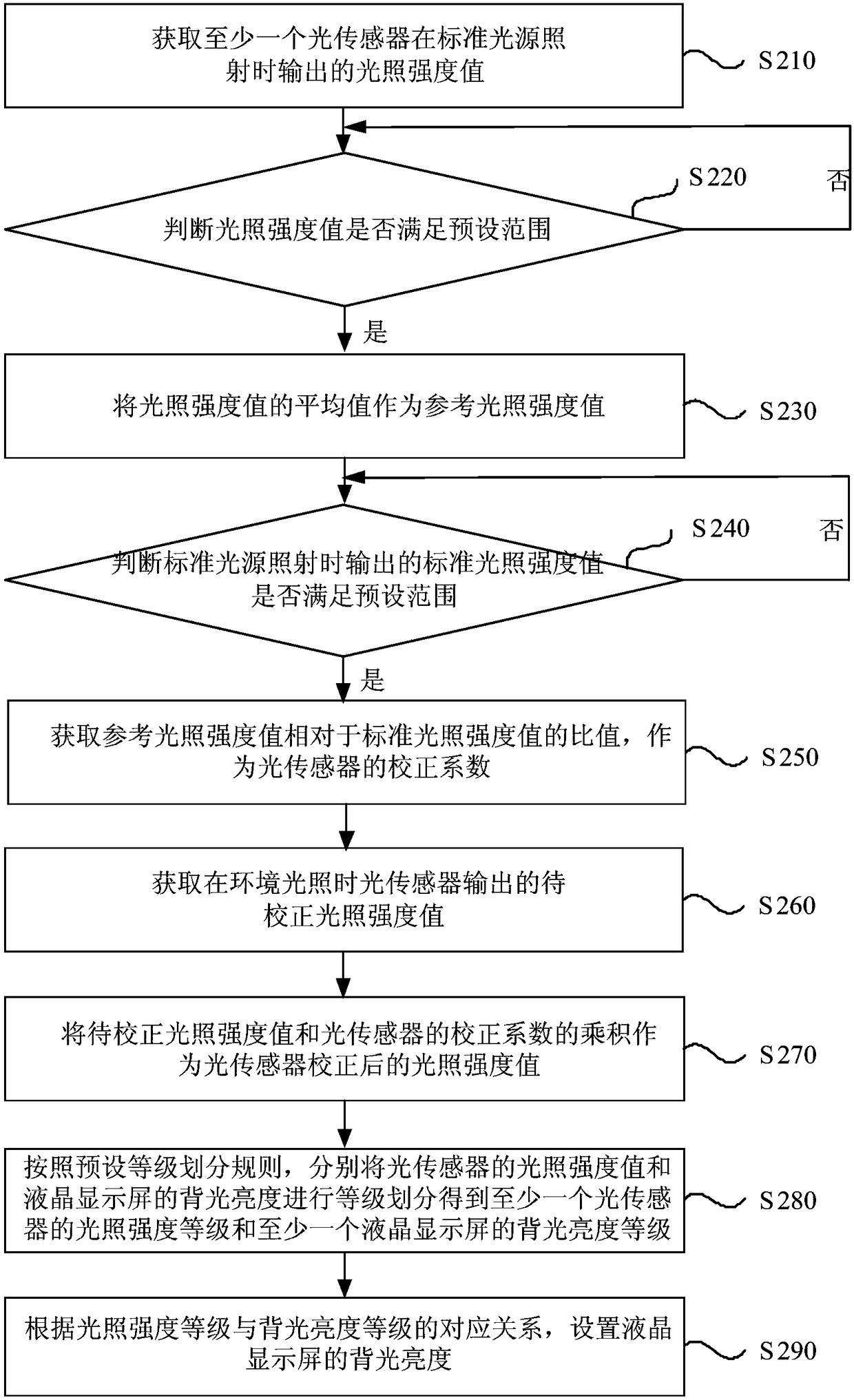

[0078] figure 2 It is a flow chart of a calibration method for a light sensor provided in Embodiment 2 of the present invention. This embodiment is applicable to the situation of adjusting a light sensor. The method can be performed by a calibration device for a light sensor. The device can Implemented in the form of software and / or hardware, the device can be configured in equipment, such as typically mobile phones, tablet computers, and computers. Such as figure 2 As shown, the method specifically includes the following steps:

[0079] S210. Obtain the light intensity value output by at least one light sensor when illuminated by a standard light source;

[0080] S220. Determine whether the light intensity value satisfies the preset range; if yes, execute S230; if not, continue to execute S220;

[0081] S230. Using the average value of the light intensity values as a reference light intensity value;

[0082] S240. Judging whether the standard light intensity value out...

Embodiment 3

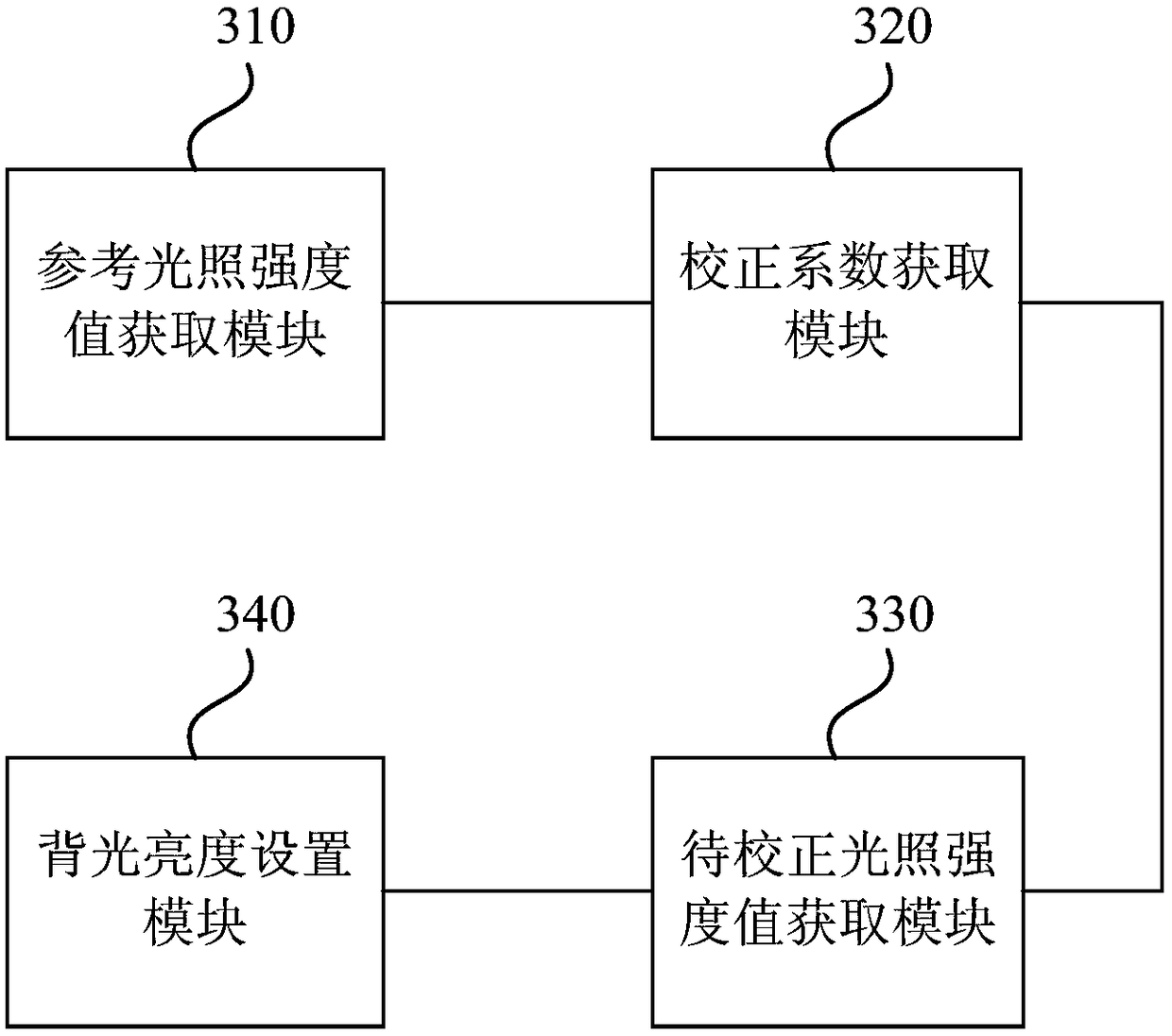

[0092] image 3 It is a schematic structural diagram of a calibration device for optical sensors provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation of adjusting optical sensors. The device can be realized by software and / or hardware, and the device can be configured in devices such as mobile phones, tablets, and computers. Such as image 3 As shown, the device specifically includes:

[0093] A reference light intensity value acquisition module 310, configured to acquire a reference light intensity value output by the light sensor when illuminated by a standard light source;

[0094] The correction coefficient acquisition module 320 is used to obtain the ratio of the reference light intensity value relative to the standard light intensity value when the standard light source is irradiated, as the correction coefficient of the light sensor;

[0095] The light intensity value to be corrected acquisition module 330 is used to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com