Near field non-standard light source-based in situ obtaining method for three dimensional polishing scratch shapes

A technology of three-dimensional shape and acquisition method, which is applied in the direction of optical device, image data processing, measuring device, etc., can solve the problems of reducing equipment maintenance efficiency and inability to realize in-situ measurement of parts to be tested, and achieve small size and portable Convenience and the effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

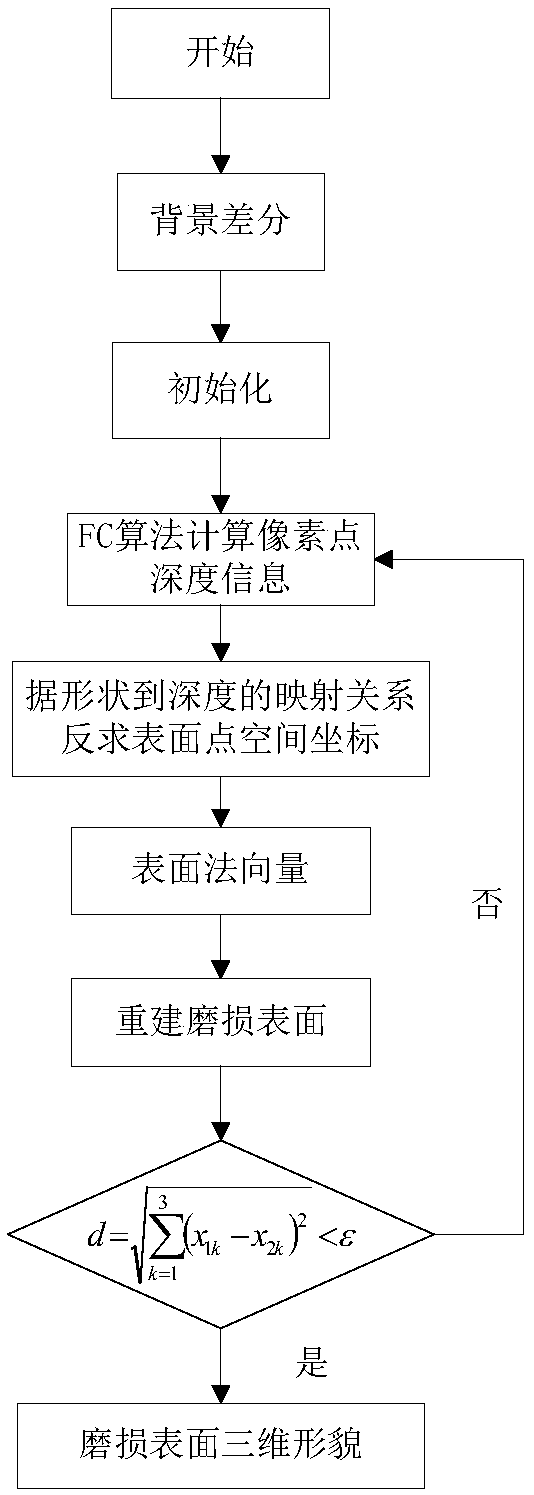

[0023] Below in conjunction with accompanying drawing, take Fig. 3 (a) as example the present invention will be further described:

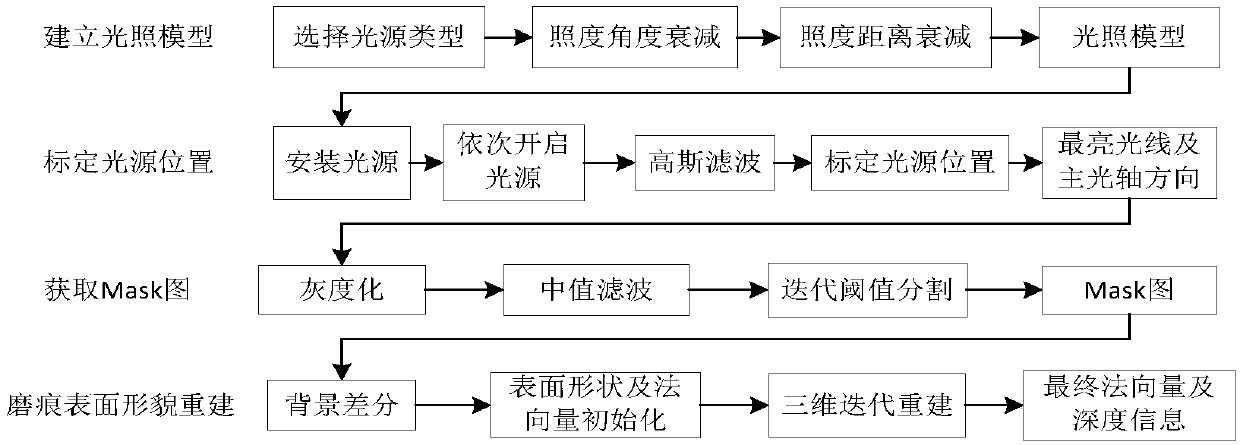

[0024] refer to figure 1 , a method for in-situ acquisition of three-dimensional topography of a worn surface based on a near-field non-standard light source, comprising the following steps:

[0025] Step 1. Establish the illumination model of non-standard point light source. The luminescence model of non-standard point light source Quasi point light source includes angle attenuation and distance attenuation. Combine these two light attenuation models to obtain the illumination model of any point on the surface. As a near-field light source, LED lights are always uneven in illumination conditions, which makes the illuminance on the surface of an object not only related to the distance from the light source to the irradiation point, but also related to the direction of the outgoing light corresponding to the irradiation point. For such non-standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com