Co-based alloy

A technology based on alloy and quality, applied in the direction of machine/engine, high-efficiency propulsion technology, mechanical equipment, etc., can solve the problem that high temperature strength characteristics may not be sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

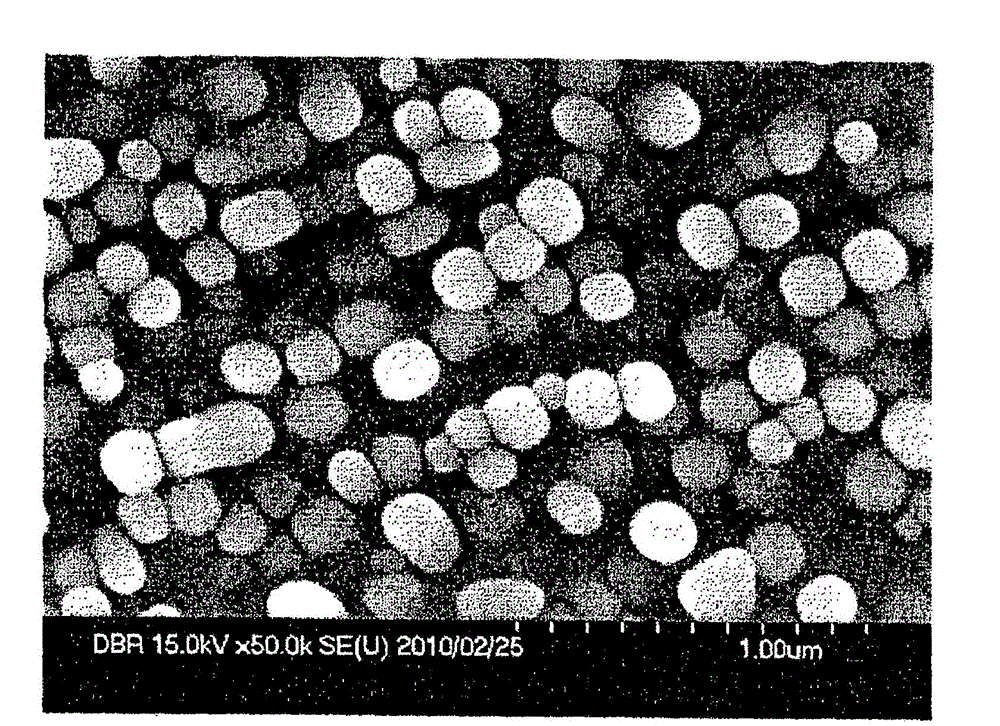

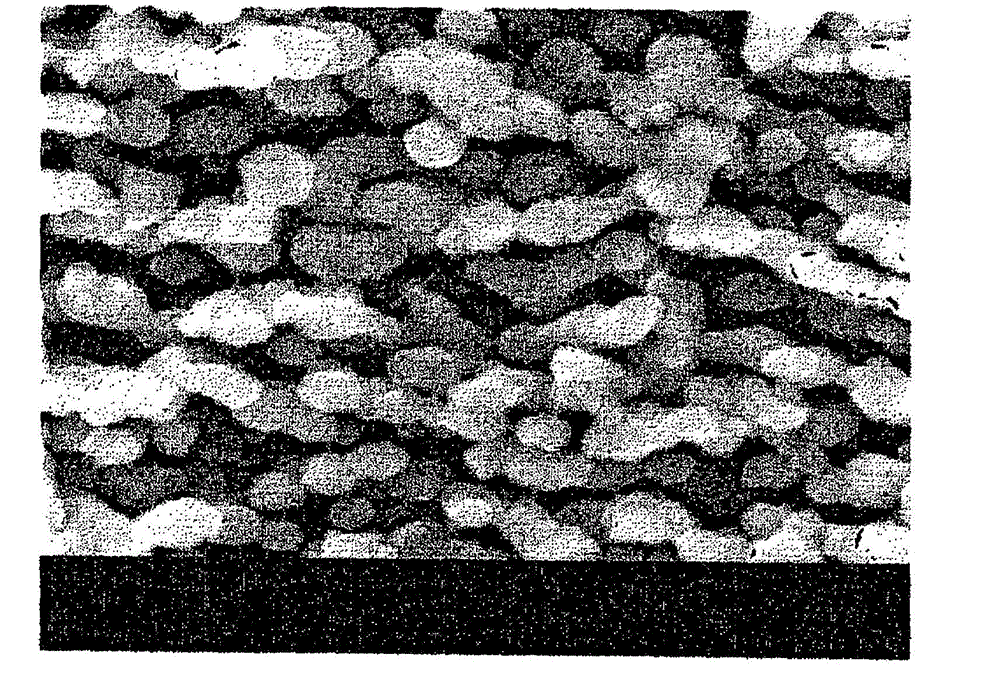

Image

Examples

Embodiment 1~27、 comparative example 31~52

[0109] [1. Production of samples]

[0110] Alloys having the compositions shown in Table 1 and Table 2 were melted in a vacuum induction furnace to obtain a 50 kg ingot. The melted ingot was subjected to a homogenization heat treatment at 1200°C for 16 hours, and then forged into a rod of φ16mm. For the forged material, after implementing solution heat treatment (ST) at 1200 °C for 1 hour in air cooling, air cooling at 900 °C for 24 h, and 2-stage aging treatment (AG) at 800 °C for 24 h in air cooling.

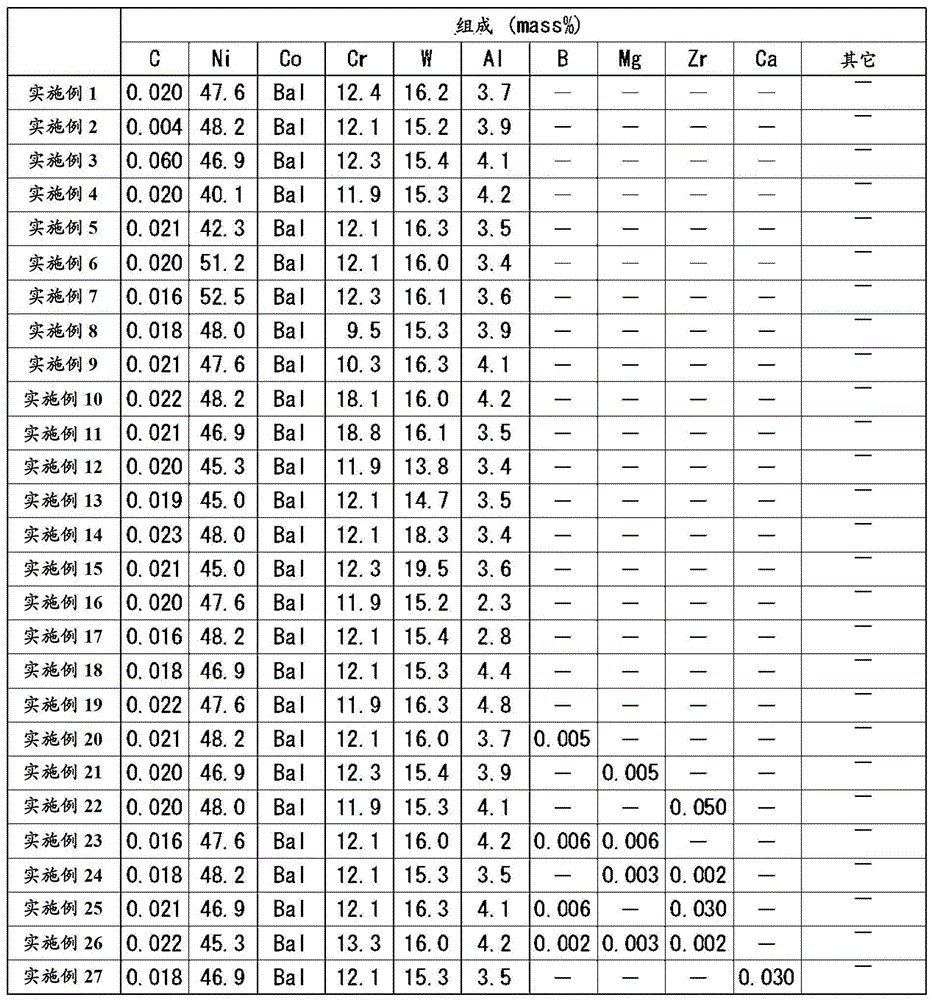

[0111] 【Table 1】

[0112]

[0113] 【Table 2】

[0114]

Embodiment

[0139] 【Table 4】

[0140]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com