Rolling and heat treatment method of 55Ni40Cr3Al bearing steel

A heat treatment method and technology of bearing steel, applied in the direction of metal rolling, etc., can solve the problems of coarse grain, high production cost, uneven structure, etc., and achieve the effect of grain refinement, high hardness, and uniform and stable rolled rod structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0014] Embodiment 1-8: The rolling and heat treatment methods of the 55Ni40Cr3Al bearing steel of the present invention are specifically described as follows.

[0015] (1) The main chemical elements and their weight percentages of the 55Ni40Cr3Al bearing steel are: C 0.01%~0.03%, Mn≤0.30%, Si≤0.30%, S≤0.030%, P≤0.030%, rare earth≤0.010 %, Cr 39.0% to 41.0%, Al 2.70% to 3.30%, and the balance is Ni. The main chemical elements of the 55Ni40Cr3Al bearing steel described in each embodiment are shown in Table 1.

Embodiment 55

[0016] Table 1. The main chemical elements (wt%) of each embodiment 55Ni40Cr3Al

[0017]

[0018] (2) The rolling and heat treatment method of the 55Ni40Cr3Al bearing steel includes pre-forging heat treatment, rolling and aging treatment processes, and the processes of each process are as follows:

[0019] A. Heat treatment process before rolling: keep the forged billet at 600±20°C for 40-60min, and then at 1160±20°C for 120-150min.

[0020] B. Rolling process: the forged billet is first rolled at 1140-1160°C, and then final rolled at 1160-1180°C to obtain a rolled bar;

[0021] C. Aging treatment process: the rolled bar is kept at 540-560° C. for 6-8 hours, and air-cooled to room temperature to obtain a finished 55Ni40Cr3Al bearing steel rolled bar.

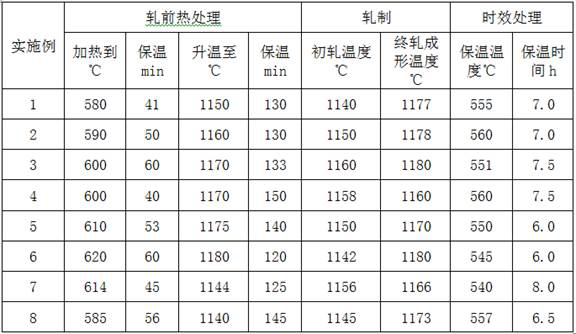

[0022] D, the concrete technology of each embodiment is shown in Table 2.

[0023] Table 2. The concrete process of each embodiment

[0024]

[0025] (3) The tensile properties of the finished 55Ni40Cr3Al bearing steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com