Novel tin-containing duplex stainless steel

A duplex stainless steel, a new type of technology, applied in the field of new tin-containing duplex stainless steel, to achieve good corrosion resistance, good mechanical properties and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, a new type of tin-containing duplex stainless steel is composed by mass percentage: Cr: 22.19%, Ni: 5.33%, Si: 0.51%, C: 0.028%, Mn: 1.42%, N: 0.17%, P: 0.021%, S: 0.0006%, Mo: 3.12%, Sn: 0.31%, Ti: 0.3%, V: 0.9%, rare earth elements: 0.006%, and the balance is Fe.

[0038] The traditional conventional electric furnace smelting process is adopted, and Fe60Sn40 master alloy is added in the smelting process. After electric furnace→AOD→LF→continuous casting→rolling.

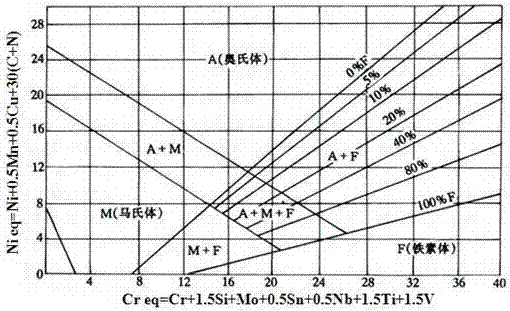

[0039] Cr eq =22.19+1.5×0.51+3.12+0.5×0.31+1.5×0.3+1.5×0.9=28.03,

[0040] Ni eq =5.3+0.5×1.42+30×(0.028+0.17)=11.95,

[0041] according to figure 1 It can be seen that the steel is A+F and the ferrite content is about 40%. After treatment at a solid solution temperature of 1100°C, the ferrite content was measured to be 47%. After spot corrosion by ferric chloride at 35°C, soaked for 24 hours, the corrosion rate is 0.12mg / (dm 2 .d).

Embodiment 2

[0043] In this example, a new type of tin-containing duplex stainless steel is composed by mass percentage: Cr: 22.24%, Ni: 5.51%, Si: 0.44%, C: 0.028%, Mn: 1.42%, N: 0.15%, P: 0.02%, S: 0.0003%, Mo: 3.16%, Sn: 0.34%, Ti: 0.8%, rare earth elements: 0.008%, and the balance is Fe.

[0044] The traditional conventional electric furnace smelting process is adopted, and Fe60Sn40 master alloy is added in the smelting process. After electric furnace→AOD→LF→continuous casting→rolling.

[0045] Cr eq =22.24+1.5×0.44+3.16+0.5×0.34+1.5×0.8=27.43

[0046] Ni eq =5.51+0.5×1.42+30×(0.028+0.15)=11.56

[0047] according to figure 1 It can be seen that the steel is A+F, and the ferrite content is 53% after being treated at a solution temperature of 1080°C. After spot corrosion by ferric chloride at 35°C, soaked for 24 hours, the corrosion rate is 0.08mg / (dm 2 .d).

Embodiment 3

[0049] In this example, a new type of tin-containing duplex stainless steel is composed by mass percentage: Cr: 22.1%, Ni: 5.58%, Si: 0.51%, C: 0.028%, Mn: 1.45%, N: 0.17%, P: 0.021%, S: 0.0005%, Mo: 3.2%, Sn: 0.41%, Nb: 0.17%, Ti: 0.56%, rare earth elements: 0.007%, and the balance is Fe.

[0050] The traditional conventional electric furnace smelting process is adopted, and Fe60Sn40 master alloy is added in the smelting process. After electric furnace→AOD→LF→continuous casting→rolling.

[0051] Cr eq =22.1+1.5×0.51+3.2+0.5×0.41+1.5×(0.17+0.56)=27.365

[0052] Ni eq =5.58+0.5×1.45+30×(0.028+0.17)=12.245

[0053] according to figure 1 It can be seen that the steel is A+F, and the ferrite content is 44% after being treated at a solution temperature of 1080°C. After spot corrosion by ferric chloride at 35°C, soaked for 24 hours, the corrosion rate is 0.21mg / (dm 2 .d).

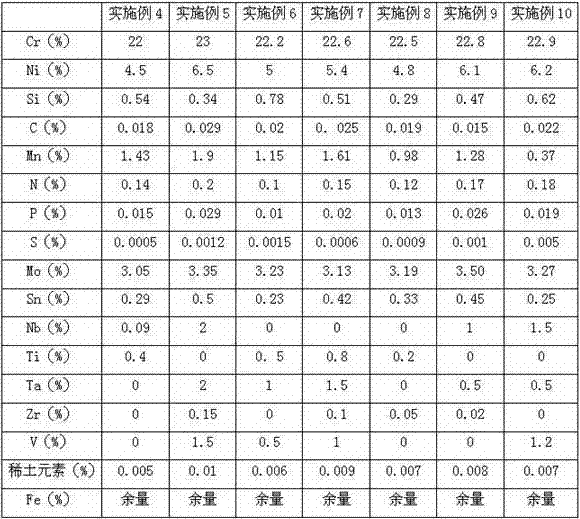

[0054] Examples 4-10 of the present invention are shown in the following table 2, and each component i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com