Antibacterial austenitic stainless steel

A technology of austenitic stainless steel and antibacterial stainless steel, which is applied in the field of stainless steel smelting technology, and can solve problems such as hot-rolled surface cracks and yield rate to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An austenitic antibacterial stainless steel, the chemical composition weight percent (wt%) range is as follows: C: 0.047, Si: 0.29, Mn: 1.0, P0.022, S: 0.001, Ni: 8.1, Cr: 18.3, N: 0.041, Ag: 0.06, O: 0.004, and (Ag–10×O)=0.02, the rest is composed of Fe and unavoidable impurities;

[0024] The manufacture method of described austenitic antibacterial stainless steel comprises the following steps:

[0025] 1) Silver and nickel are smelted in proportion to make Ag-Ni binary alloy;

[0026] 2) Mix Ag-Ni binary alloy and other chemical components of the aforementioned austenitic antibacterial stainless steel for smelting and continuous casting into billets;

[0027] 3) Hot rolling: Among them, the initial temperature of hot rolling is 1190°C, and the hot-rolled plate is annealed and pickled after holding at 1030°C for 30s;

[0028] 4) Cold rolling and annealing and pickling after cold rolling at 1040°C for 30s.

Embodiment 2-5

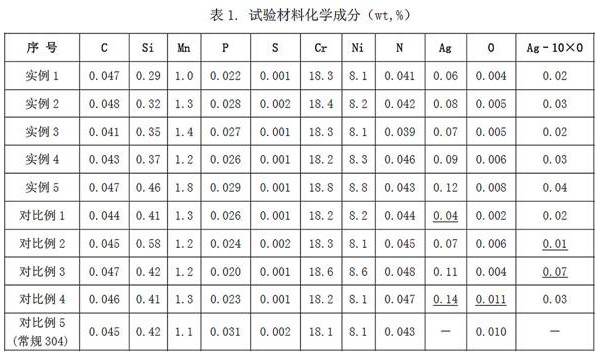

[0030] Embodiment 2-5, comparative example 1-4 are the same as the process of embodiment 1, the difference is that the chemical composition weight percentage and manufacturing process parameters are different, wherein the chemical composition weight percentage of each embodiment is as shown in Table 1, and Table 1 provides at the same time The standard composition of conventional 304 austenitic stainless steel was used as Comparative Example 5.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com