Continuous and dynamic reduction device and method of fluorescent powder

A fluorescent powder and dynamic technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of uneven distribution of temperature and reducing gas, inability to meet the requirements of phosphor powder preparation, and slow temperature rise and fall, so as to facilitate mass transfer and heat transfer, fast heating and cooling speed, sufficient and uniform contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

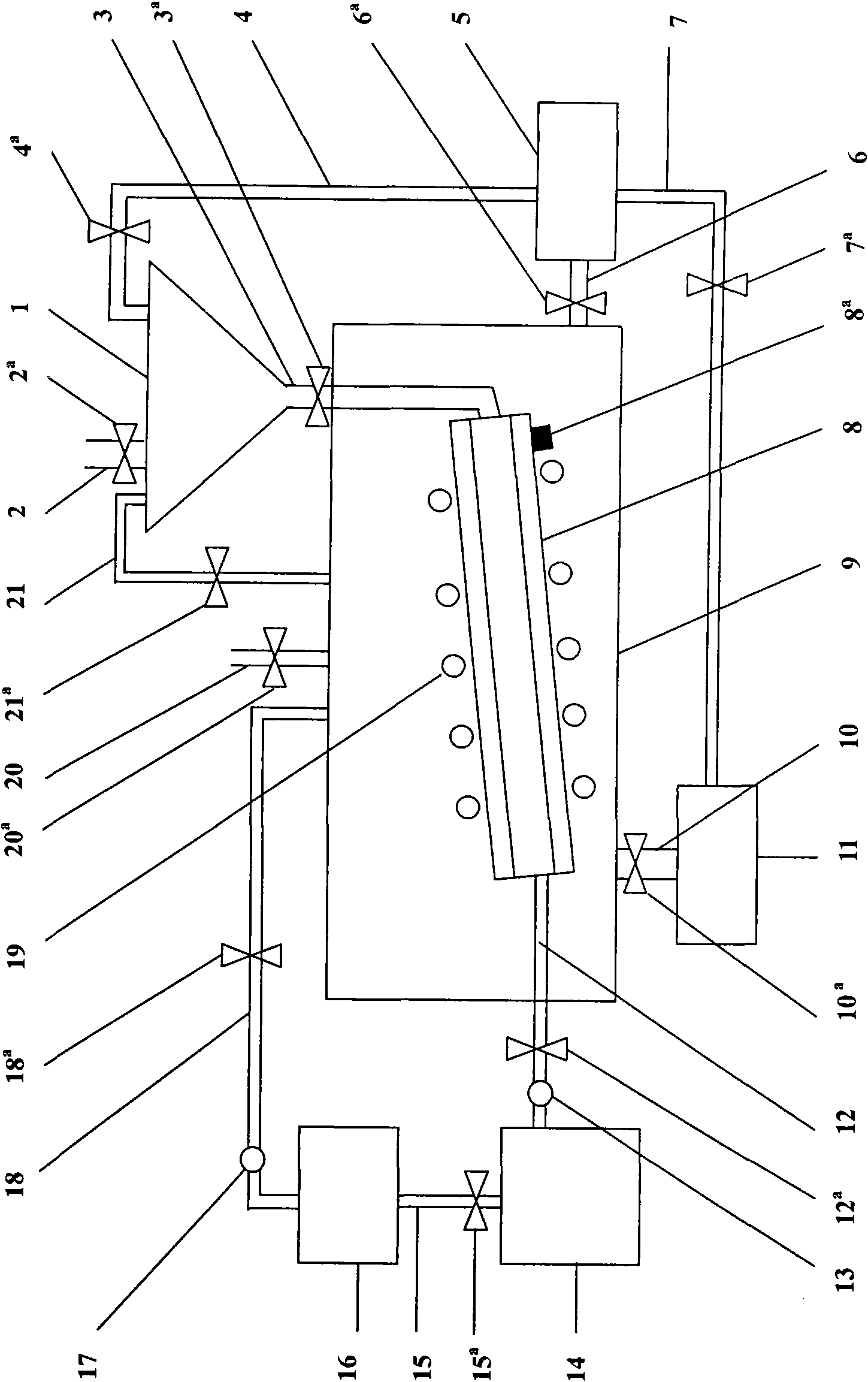

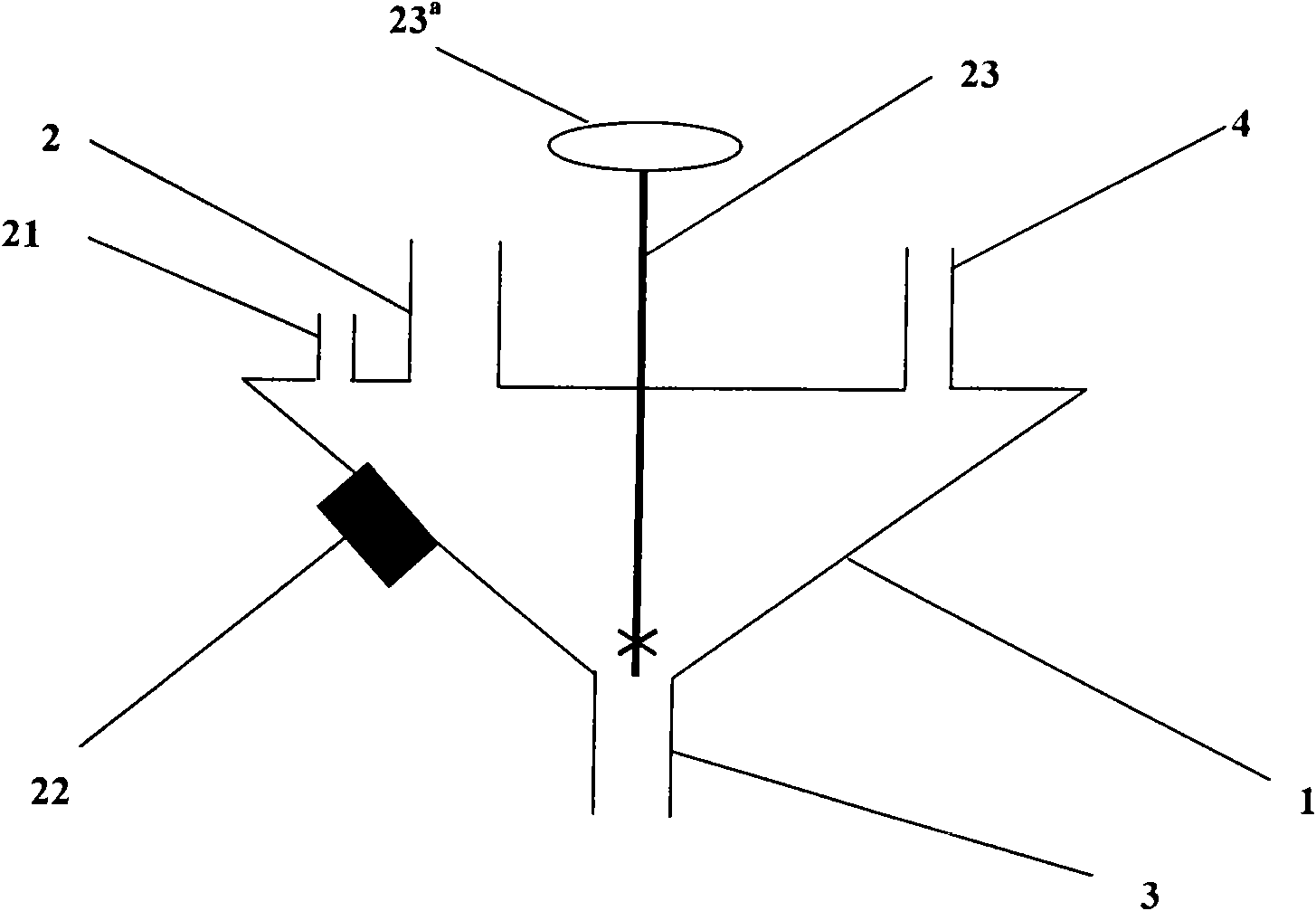

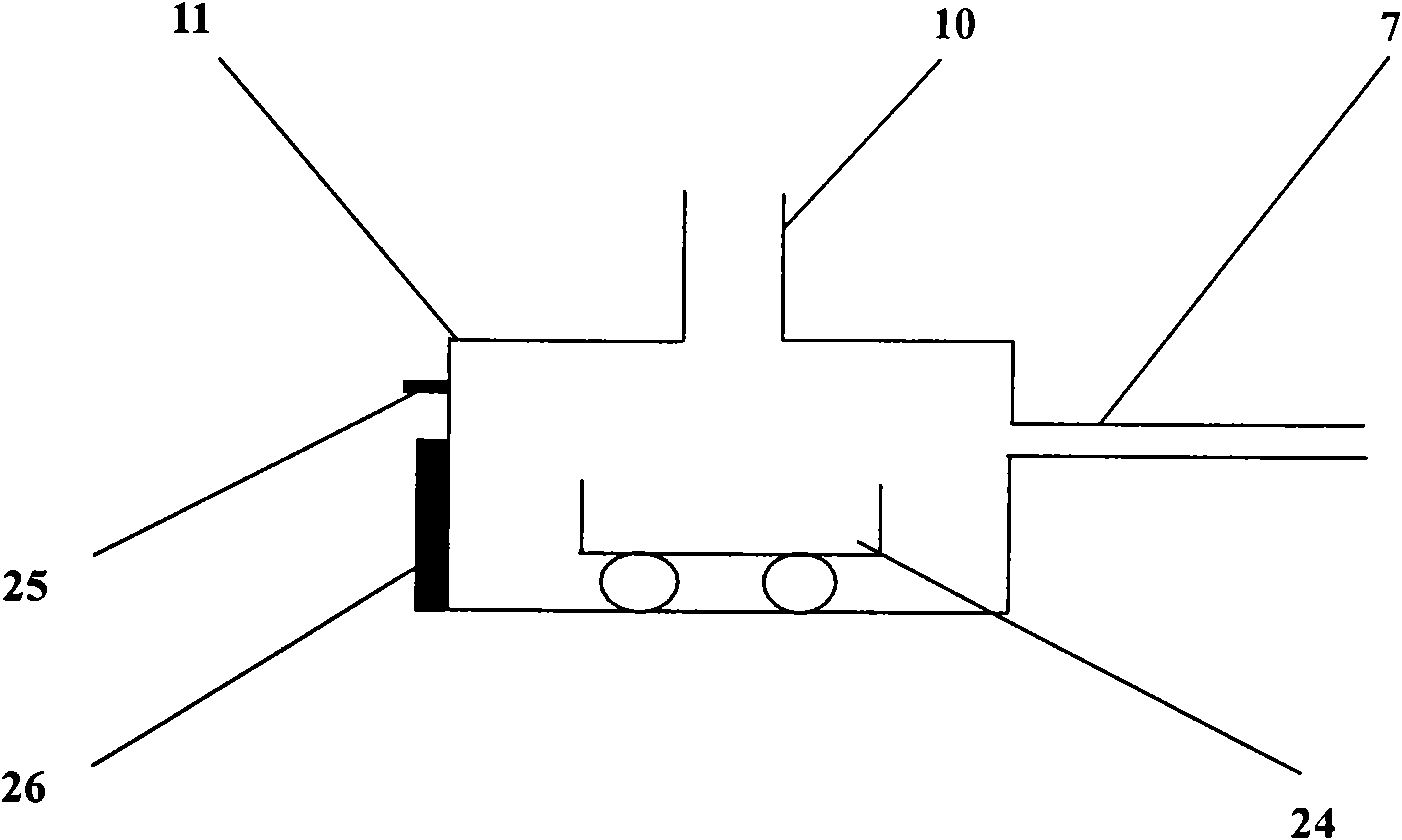

[0041] Firing to 20kgBa in a vacuum environment 0.93 MgAl 10 o 17 :Eu 2+ 0.07 Blue phosphor. Before the operation starts, such as figure 1 , figure 2 with image 3 All equipment and valves are shown closed. The operation steps are as follows:

[0042] 1. According to the stoichiometric ratio, weigh the corresponding weight of BaCO 3 , MgO, Al 2 o 3 and Eu 2 o 3 , ball milled for 48 hours and mixed evenly;

[0043] 2. Open the valve 2 a Feed 10kg, then close valve 2 a ;

[0044] 3. Open the valve 4 a ,6 a and 10 a ; Start the vacuum equipment 5 so that the internal air pressure of the feeding device 1, body of furnace 9 and quenching device 11 drops to -3Pa, then close the valve 4 a ;

[0045] 4. Start the transmission equipment 8 of the rotary kiln type reaction vessel 8 a , the inclination angle between the rotary kiln type reaction vessel and the ground is 1°, and the rotation speed is 1.1 rev / min;

[0046] 5. Turn on the circulating cooling water out...

Embodiment 2

[0054] Firing to 20kgBa in a vacuum environment 0.93 MgAl 10 o 17 :Eu 2+ 0.07 Blue phosphor. Manufacturing steps 1-7 and 9-11 are similar to embodiment 1, except that an empty container 24 is placed in step 8, and the quenching medium is a vacuum environment at this time, and embodiment 2 is obtained.

Embodiment 3

[0056] Use with 75% H 2 H 2 and N 2 Mixed atmosphere firing 20kgCe 0.69 MgAl 11 o 19 :Tb 3+ 0.31 Green fluorescent powder, and the waste gas after use needs to be purified and recycled, before the operation starts, such as figure 1 , figure 2 with image 3 All equipment and valves are shown closed. The operation steps are as follows:

[0057] 1. According to the stoichiometric ratio, weigh the corresponding weight of CeO 2 , MgO, Al 2 o 3 and Tb 4 o 7 , ball milled for 48 hours and mixed evenly;

[0058] 2. Open the valve 2 a Feed 10kg, then close valve 2 a ;

[0059] 3. Open the valve 4 a ,6 a and 10 a ; Start the vacuum equipment 5 so that the internal air pressure of the feeding device 1, body of furnace 9 and quenching device 11 drops to -3Pa, then close the valve 4 a and 6 a ;Open valve 12 a , into the prepared 75% H 2 H 2 and N 2 Mixed gas so that the internal air pressure of body of furnace 9 and quenching device 11 is 1.05 atmospheric pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com