Thermal packaging used-heating head and packaging device with same

A technology of packaging equipment and heating head, which is applied in the direction of heating element materials, packaging, transportation and packaging, etc. It can solve the problems of affecting the work efficiency of users, the low yield of packaging inflatable bags, and difficult temperature control, etc., and achieves low power consumption, The effect of fast packaging speed and stable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

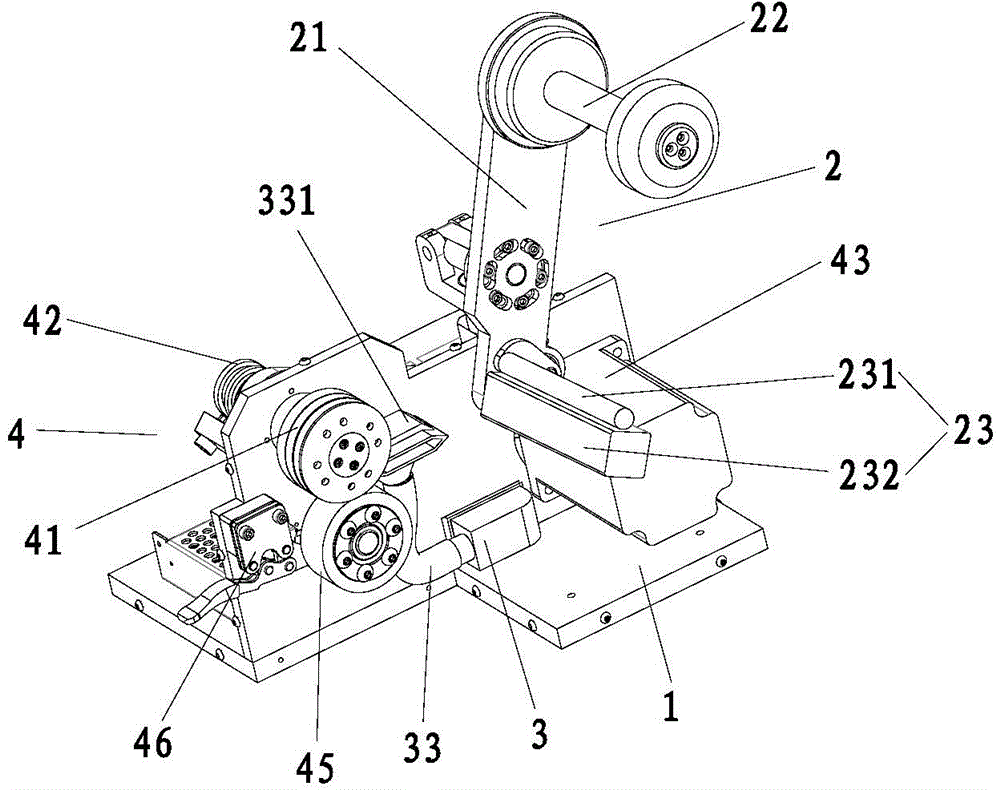

[0044] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

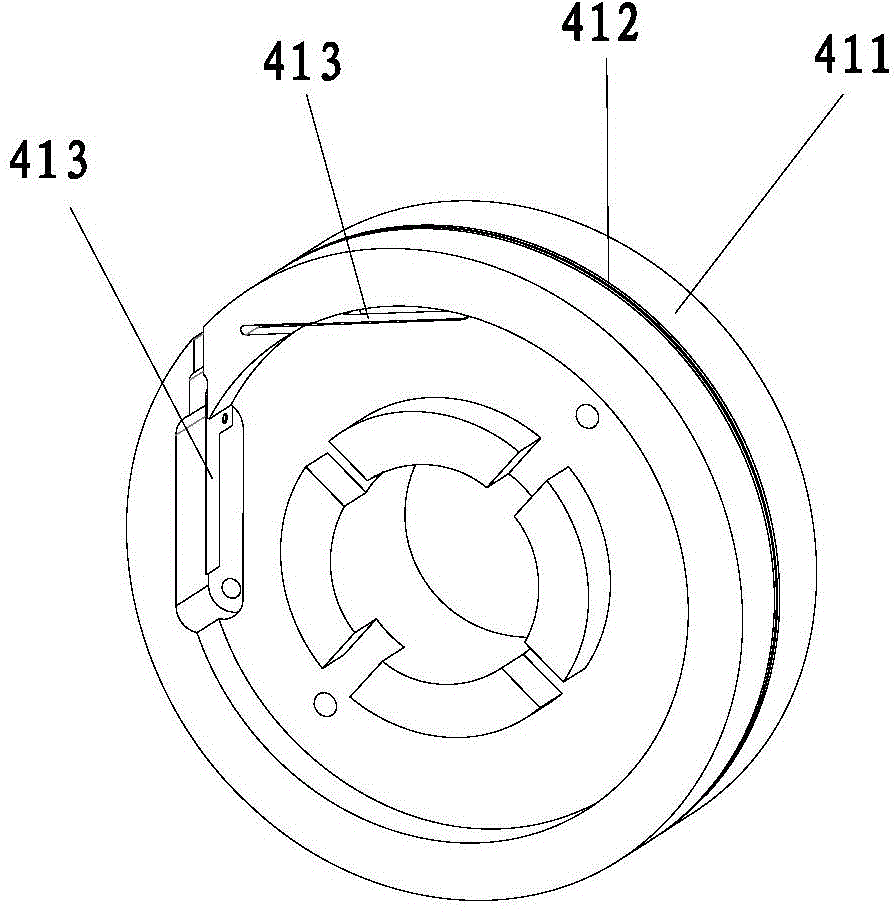

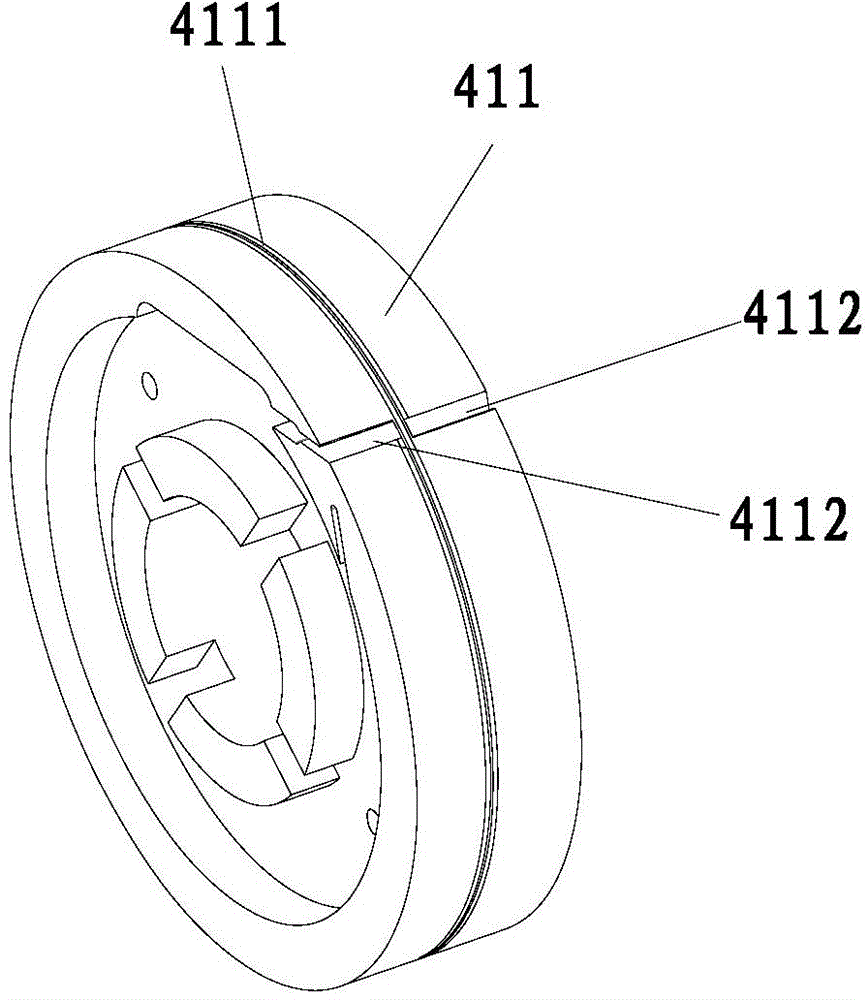

[0045] Such as figure 1 Schematic diagram of the three-dimensional structure of the heating head and figure 2 As shown in the schematic diagram of the structure of the heating head base of the present invention, a heating head for heat sealing, the heating head 41 includes a cylindrical base 411, and the material of the base 411 is polyether ether ketone. One end surface of the base body 411 is hollowed out, and the side surface of the base body 411 is provided with an annular groove 4111 , and a heating wire 412 is installed in the groove 4111 , and the heating wire 412 fits tightly in the groove 4111 .

[0046] In this embodiment, the heating wire 412 is nickel-chromium alloy, and the surface of the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com