Method for preparing magnesium diboride superconductive Josephson junction through secondary mask method

A magnesium diboride and mask technology, which is applied in the field of preparation of superconducting thin film Josephson junctions, can solve the problems of difficult preparation of superconducting Josephson junctions, connectivity, etc., and achieves short annealing time, reduced component diffusion, and temperature rise and fall speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

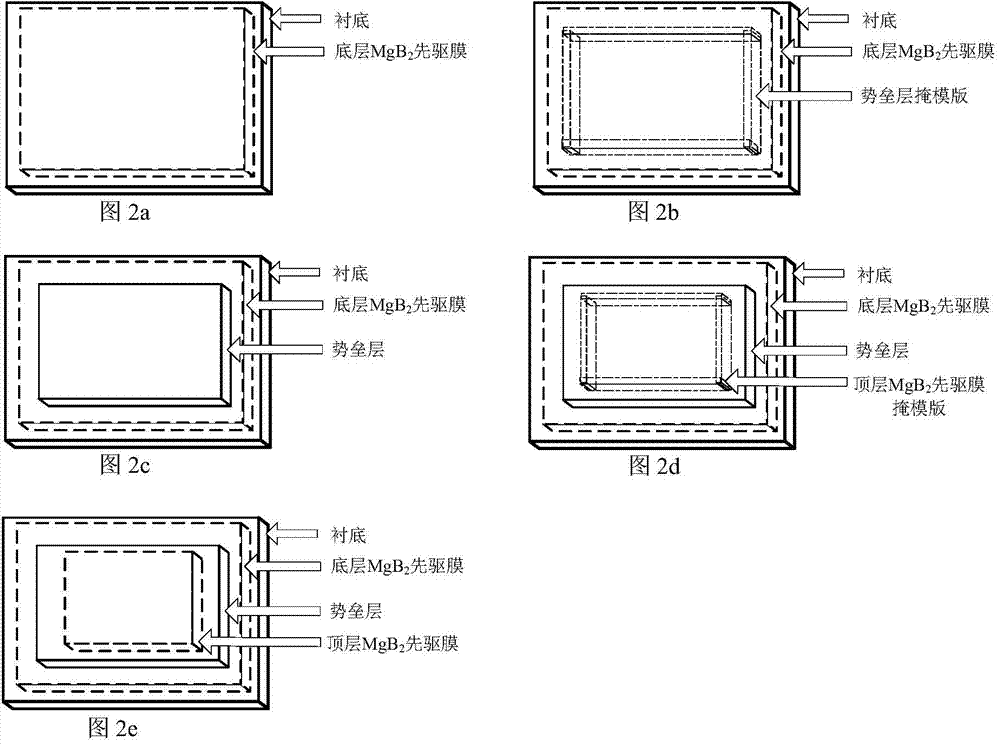

Method used

Image

Examples

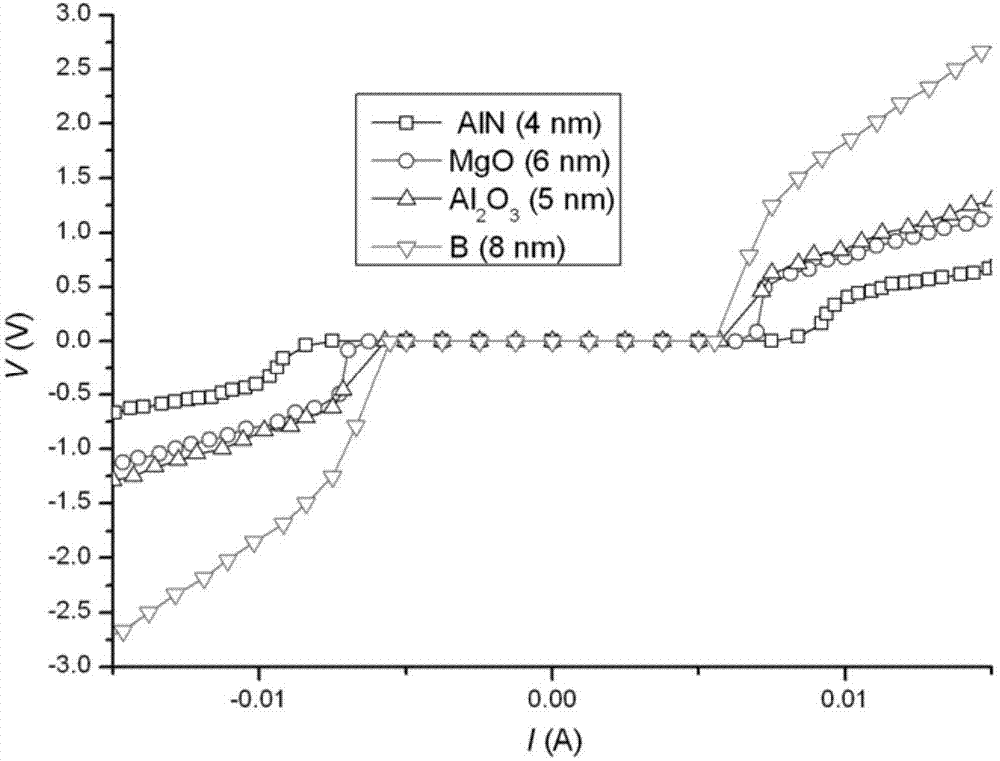

Embodiment 1

[0052] The preparation of the precursor film in this example was completed in a ZZXS-500 electron beam coating machine, and the electron beam annealing was performed on a self-made EBW-6 electron beam welding machine. The precursor film structure is [Mg(15nm)+B(10nm)] 6 —B(8nm)—[Mg(15nm)+B(10nm)] 5 , the thickness of the precursor film is 283nm, and the size of the substrate SiC is 10.0mm×3.0mm.

[0053] 1. Preparation of precursor film

[0054] (1) Preparation of the underlying precursor film

[0055] (1.1) Fix the SiC bare substrate with a size of 10.0mm×3.0mm on the sample workpiece stage;

[0056] (1.2) Place the sample workpiece table in the ZZXS-500 electron beam coating machine and start vacuuming;

[0057] (1.3) Wait for the vacuum degree to be higher than 5×10 -5 After Pa, turn on the quartz crystal thin film coating controller;

[0058] (1.4) Evaporate layer B on the bare SiC substrate, and the number on the display panel of the quartz crystal thin film coating...

Embodiment 2

[0089] The preparation of the precursor film in this example was completed in a ZZXS-500 electron beam coating machine, and the electron beam annealing was performed on a self-made EBW-6 electron beam welding machine. The precursor film is [Mg(12nm)+B(8nm)] 5 —AlN(4nm)—[Mg(12nm)+B(8nm)] 5 , the thickness of the precursor film is 204nm, and the size of the substrate SiC is 10.0mm×3.0mm.

[0090] 1. Preparation of precursor film

[0091] (1) Preparation of the underlying precursor film

[0092] (1.1) Fix the SiC bare substrate with a size of 10.0mm×3.0mm on the sample workpiece stage;

[0093] (1.2) Place the sample workpiece table in the ZZXS-500 electron beam coating machine and start vacuuming;

[0094] (1.3) Wait for the vacuum degree to be higher than 5×10 -5 After Pa, turn on the quartz crystal thin film coating controller;

[0095] (1.4) Evaporate layer B on the bare SiC substrate, and the number on the display panel of the quartz crystal thin film coating controlle...

Embodiment 3

[0126] The preparation of the precursor film in this example was completed in a ZZXS-500 electron beam coating machine, and the electron beam annealing was performed on a self-made EBW-6 electron beam welding machine. The precursor film is [Mg(12nm)+B(8nm)] 5 —Al 2 o 3 (5nm)—[Mg(15nm)+B(10nm)] 3 , the film thickness is 180nm, and the substrate Si size is 10.0mm×3.0mm.

[0127] 1. Preparation of precursor film

[0128](1) Preparation of the underlying precursor film

[0129] (1.1) Fix the bare Si substrate with a size of 10.0mm×3.0mm on the sample workpiece stage;

[0130] (1.2) Place the sample workpiece table in the ZZXS-500 electron beam coating machine and start vacuuming;

[0131] (1.3) Wait for the vacuum degree to be higher than 5×10 -5 After Pa, turn on the quartz crystal thin film coating controller;

[0132] (1.4) Evaporate layer B on the bare Si substrate, and the number on the display panel of the quartz crystal thin film coating controller is After stop c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com