Microwave annealing method for improving electrochemistry property of hydrogen storage alloy M1(NiCoMnAlCu)5.05

A technology for hydrogen storage alloy and microwave annealing is applied in the fields of hydrogen storage material, microwave technology and metal material heat treatment, which can solve problems such as difficulties and achieve the effects of reducing activation times, improving comprehensive electrochemical performance and short annealing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

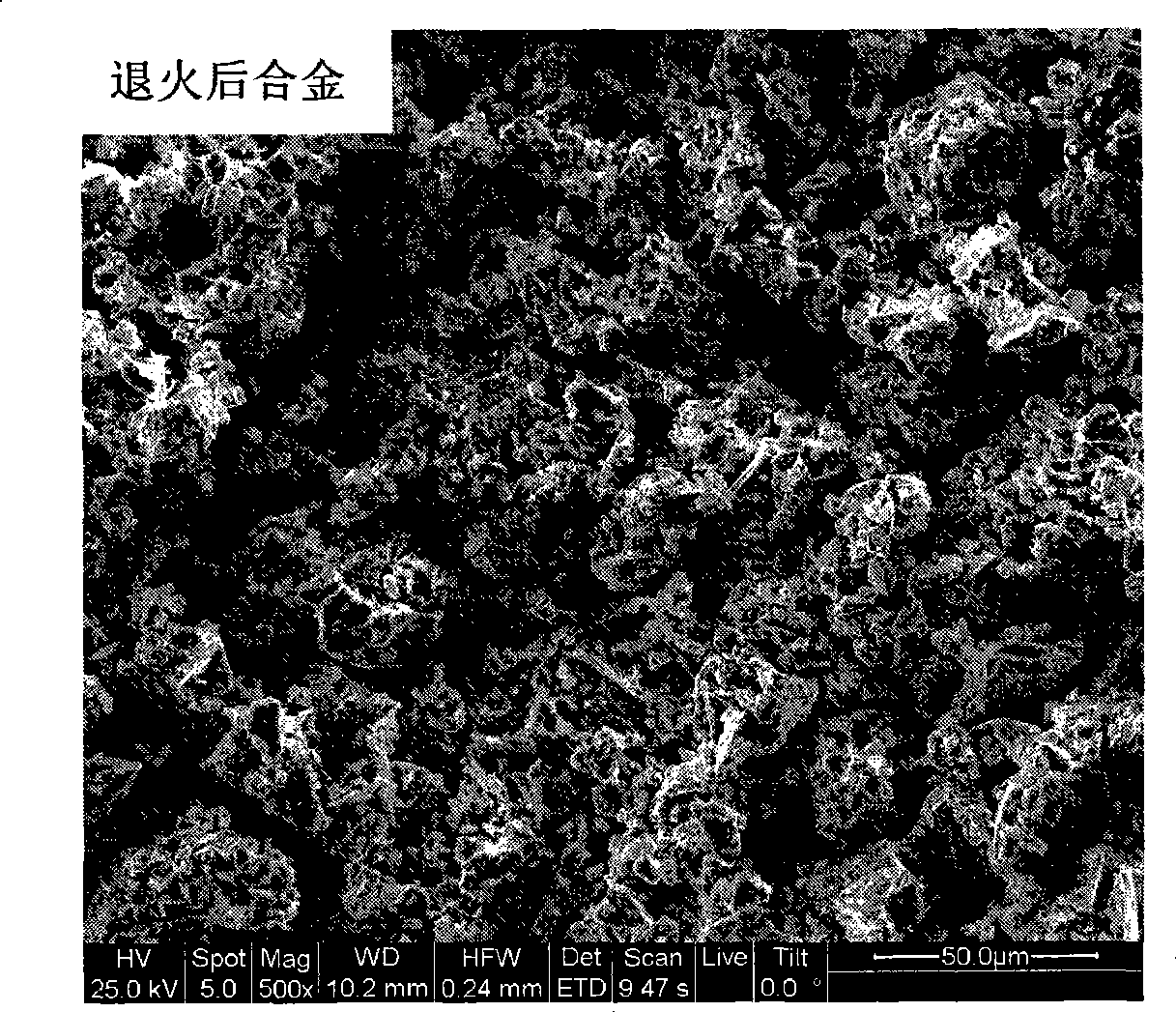

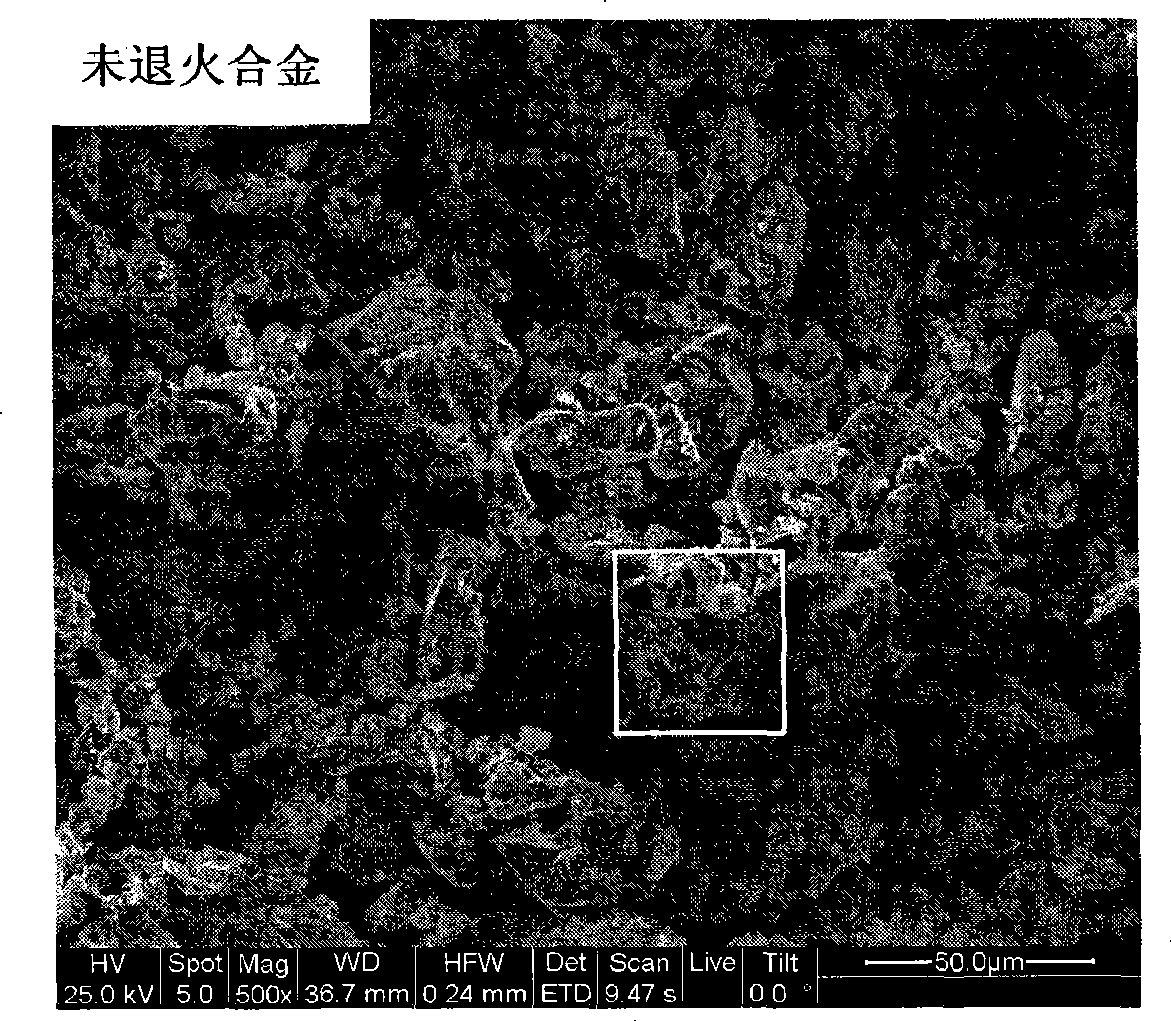

Image

Examples

Embodiment 1

[0015] Weigh 3.0g Ml(NiCoMnAlCu) of 300~400 mesh 5.05 The hydrogen storage alloy powder is made into tablets on a tablet press with a pressure of 10 MPa, and the holding time is 10 minutes. The hydrogen storage alloy flakes are small discs with a diameter of 10 mm and a thickness of 5 mm. The pressed hydrogen storage alloy sheet is placed in the cavity of a microwave oven, and several sheets of MoC are placed around it as an auxiliary heat material. During the microwave annealing process, under the protection of argon, the annealing temperature was 300°C, and the temperature was kept for 14 minutes. After annealing, it was cooled to room temperature with the furnace, and then the obtained hydrogen storage alloy was subjected to electrochemical experiments. The results showed that the activation times of the alloy were 15 times (As-cast state) is reduced to 2 times (after microwave heat treatment), the maximum discharge capacity is 291.1mAh / g, and the capacity decay rate after ...

Embodiment 2

[0017] Weigh 3.0g Ml(NiCoMnAlCu) of 300~400 mesh 5.05 The hydrogen storage alloy powder was made into tablets on a tablet press with a pressure of 15 MPa, and the holding time was 7 minutes. Place the pressed hydrogen storage alloy sheet in the cavity of a microwave oven, and place several sheets of SiC around it as an auxiliary heat material. During the microwave annealing process, under the protection of argon, the annealing temperature was 350°C, and the heat preservation time was 12 minutes. state) to 4 times (after microwave heat treatment), the maximum discharge capacity is 298.4mAh / g, and the capacity decay rate after 200 electrochemical cycles is only 0.154.

Embodiment 3

[0019] Weigh 3.0g Ml(NiCoMnAlCu) of 300~400 mesh 5.05 The hydrogen storage alloy powder was made into tablets on a tablet machine with a pressure of 15 MPa, and the holding time was 4 minutes. Place the pressed hydrogen storage alloy sheet in the cavity of a microwave oven, and place several sheets of SiC around it as an auxiliary heat material. During the microwave annealing process, under the protection of argon, the annealing temperature was 400°C, and the heat preservation time was 10 minutes. state) to 5 times (after microwave heat treatment), the maximum discharge capacity is 305.5mAh / g, and the capacity decay rate after 200 electrochemical cycles is only 0.145.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com