Patents

Literature

65 results about "Microwave annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid-state microwave annealing is an attractive method for rapid thermal annealing of implanted SiC. Using this technique, annealing temperatures as high as 2100 °C can be reached with a ramp-up rate of 600 °C/s and afall rate of 400 °C/s.

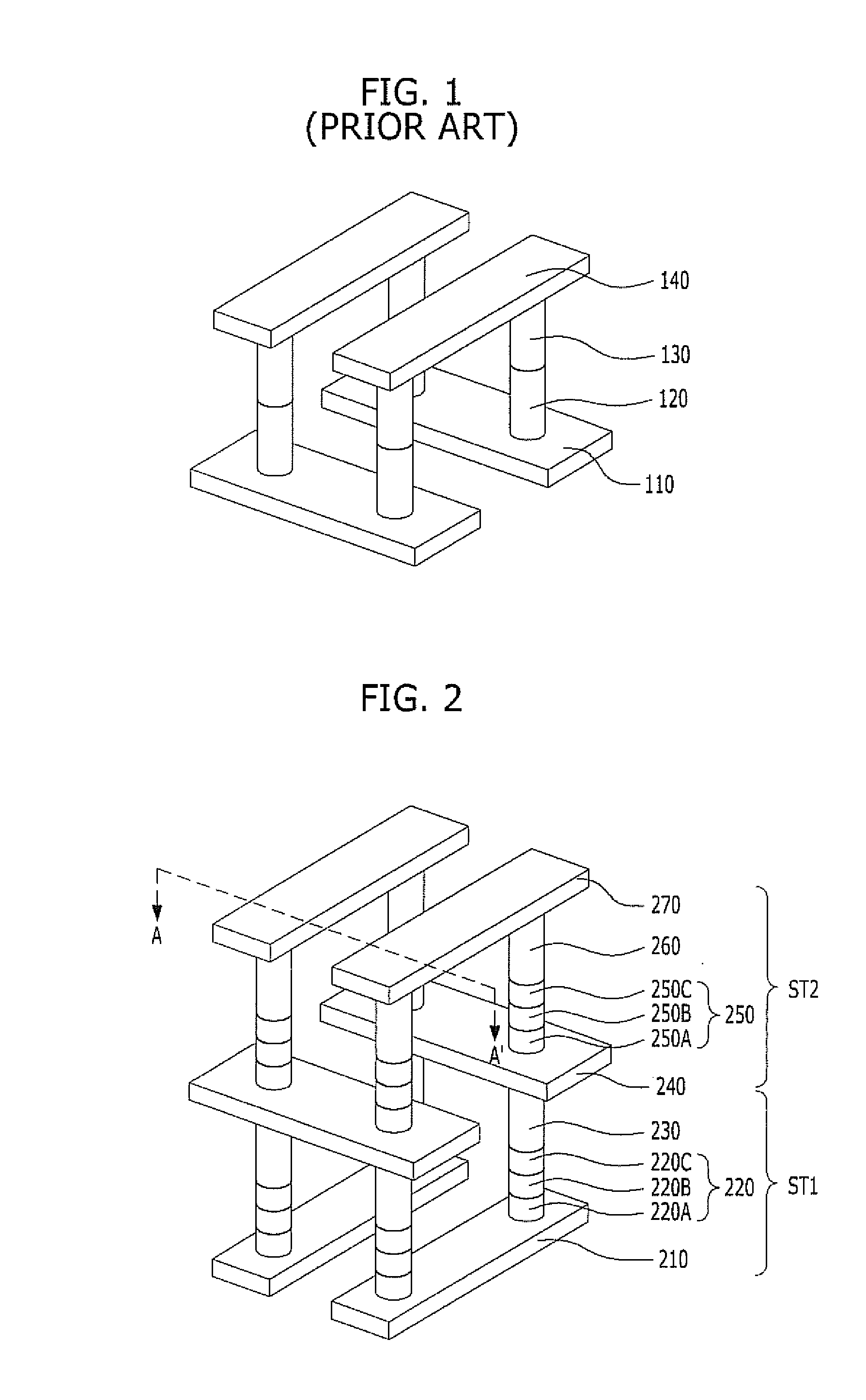

System for and method of microwave annealing semiconductor material

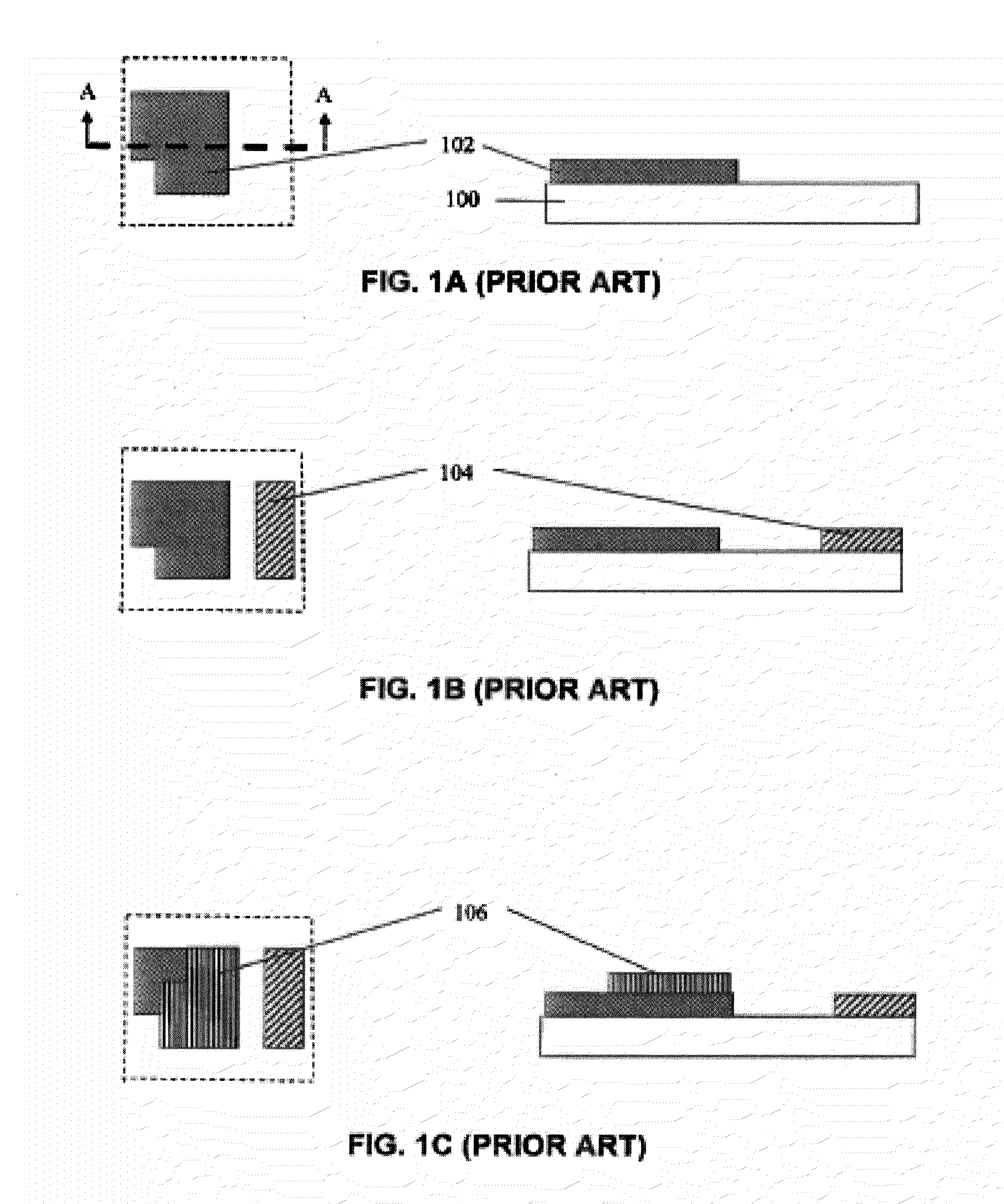

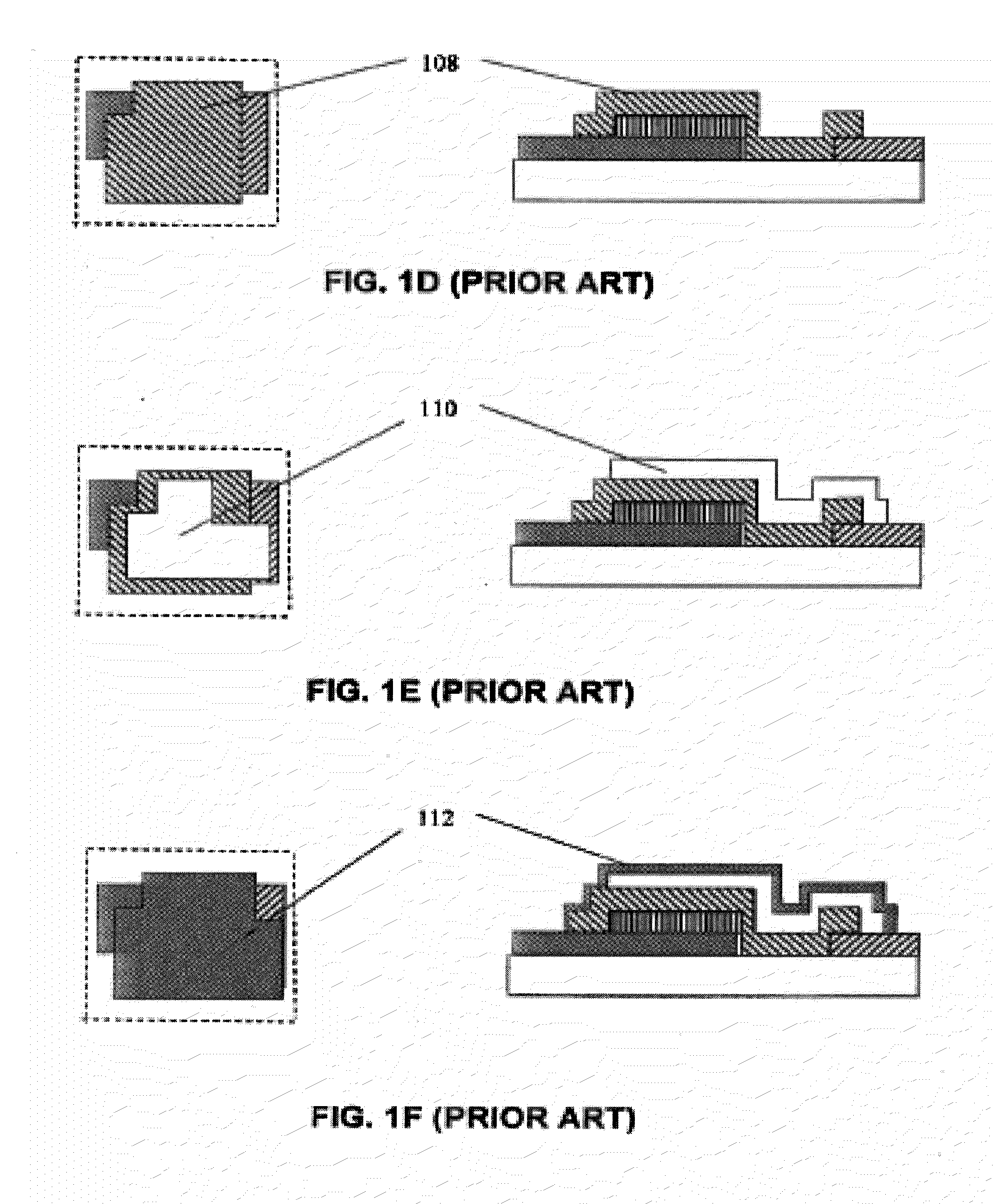

ActiveUS20090184399A1Inhibited DiffusionLong heating timeSemiconductor/solid-state device manufacturingMicrowave heatingSusceptorSemiconductor materials

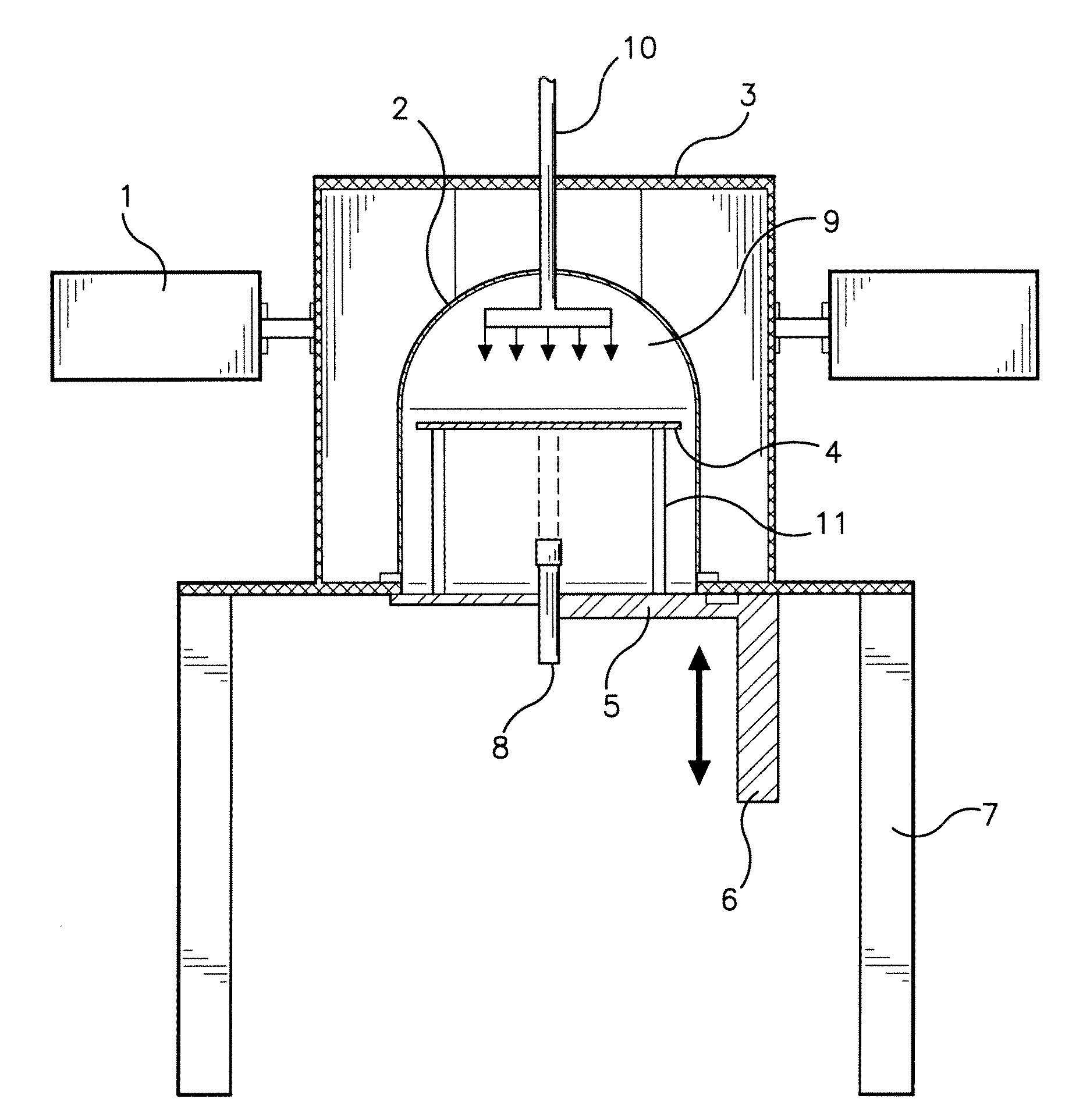

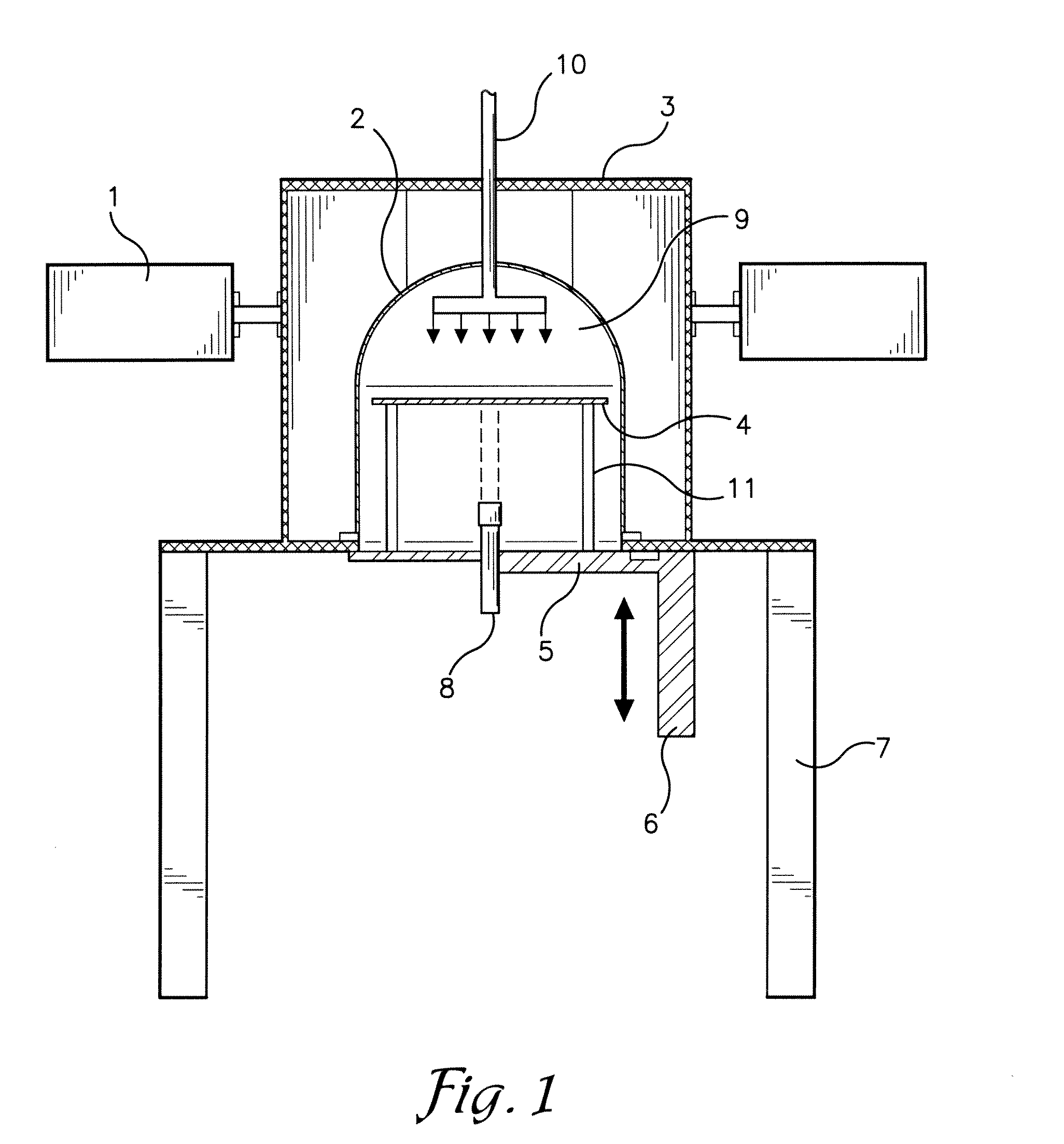

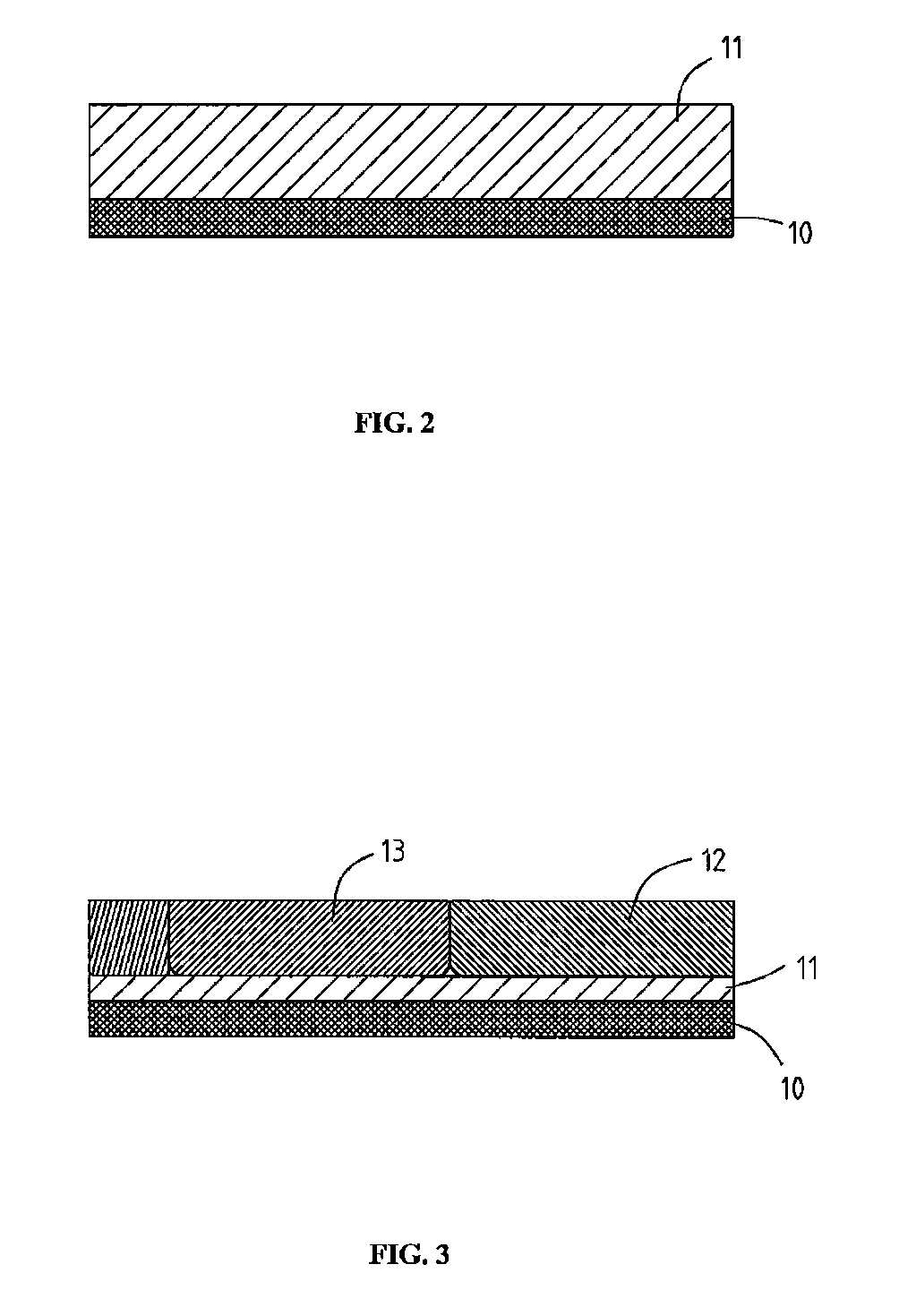

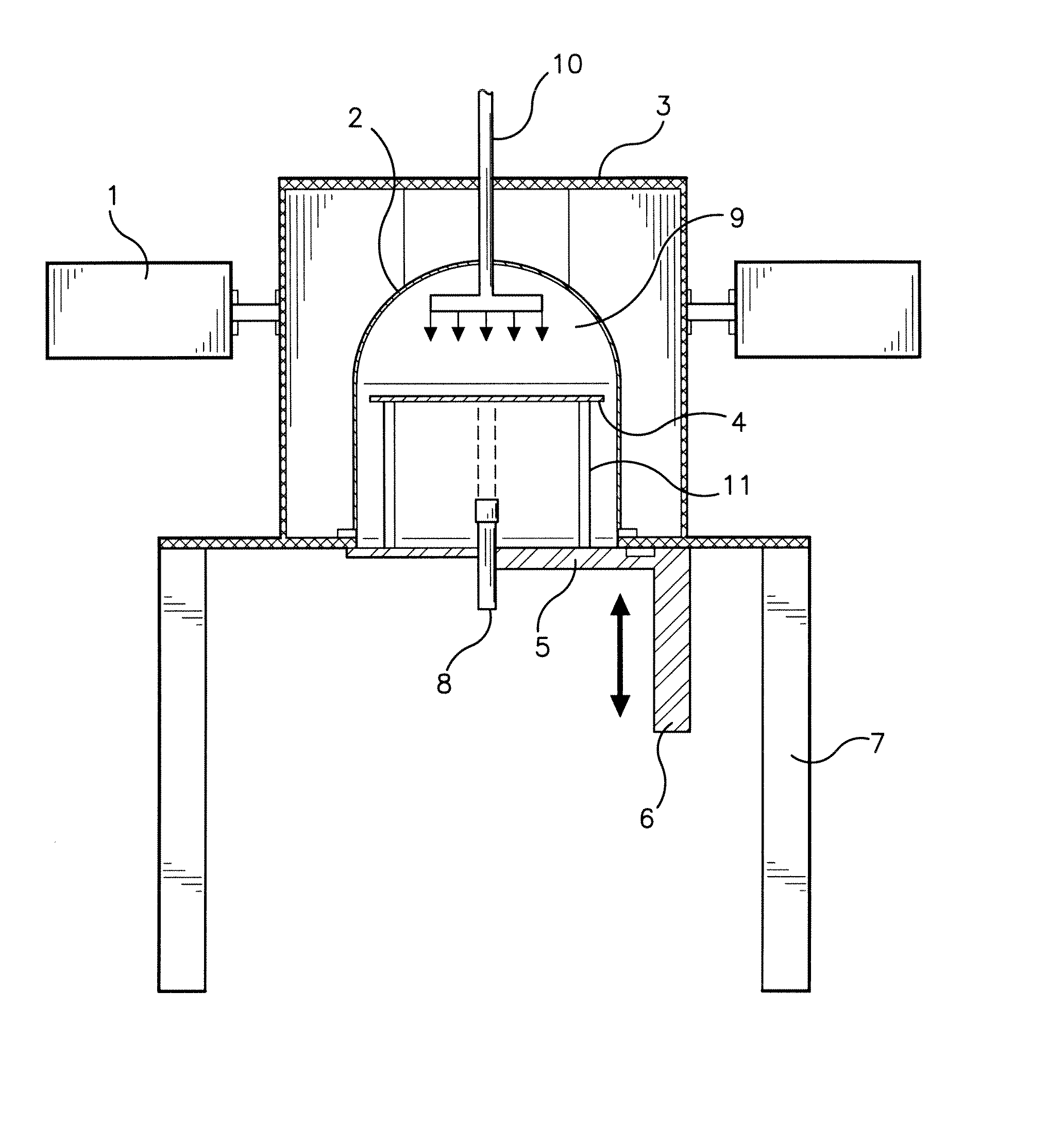

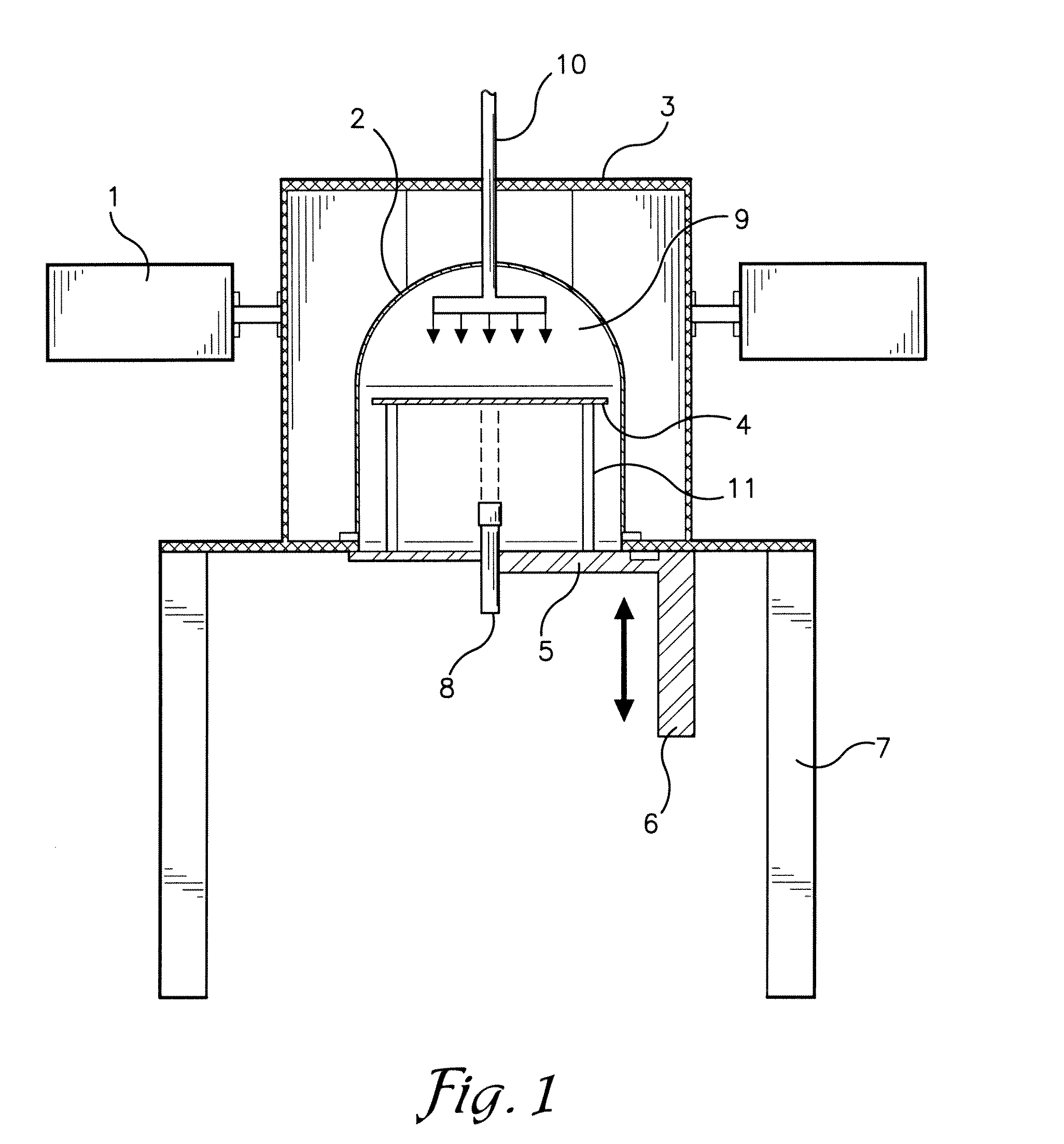

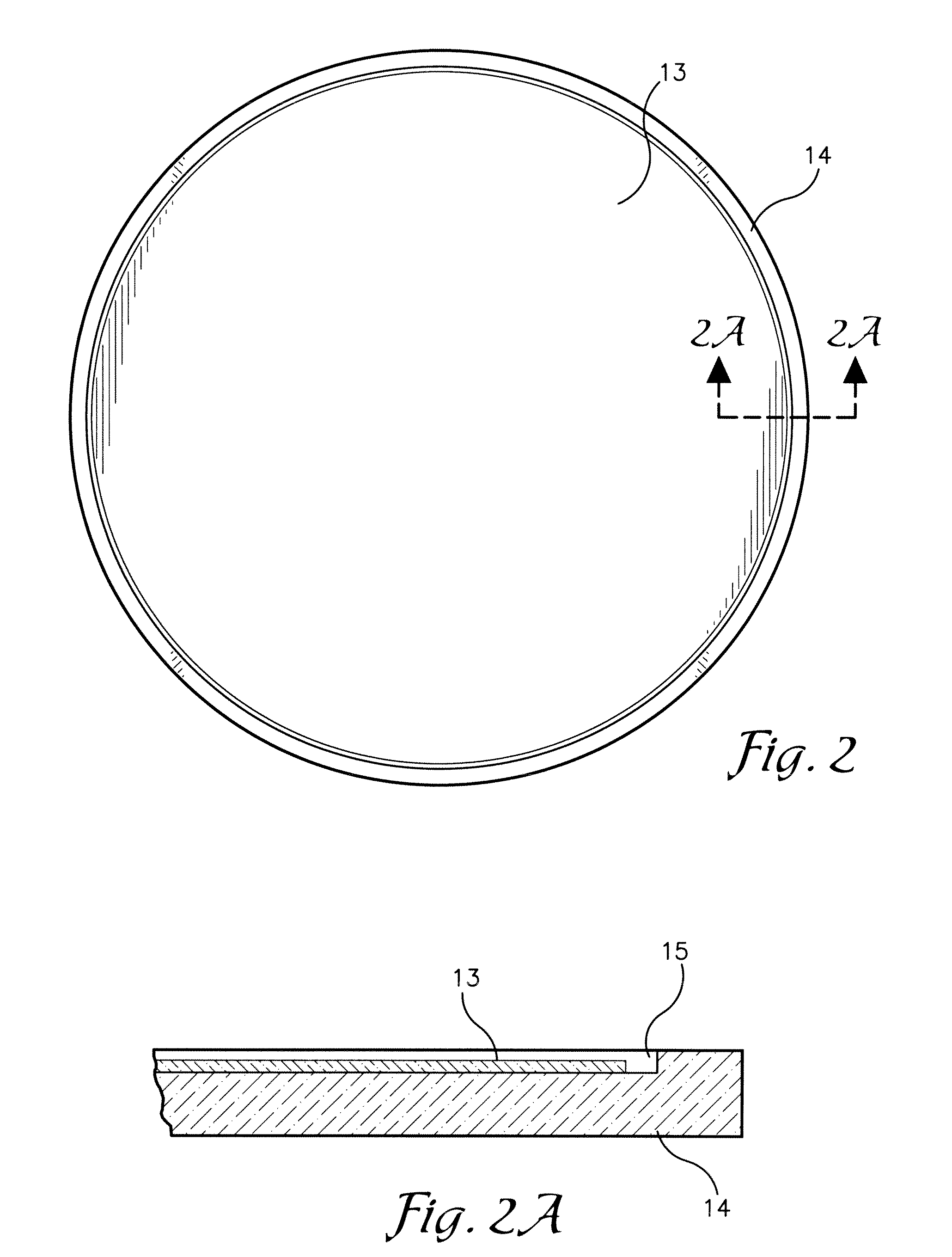

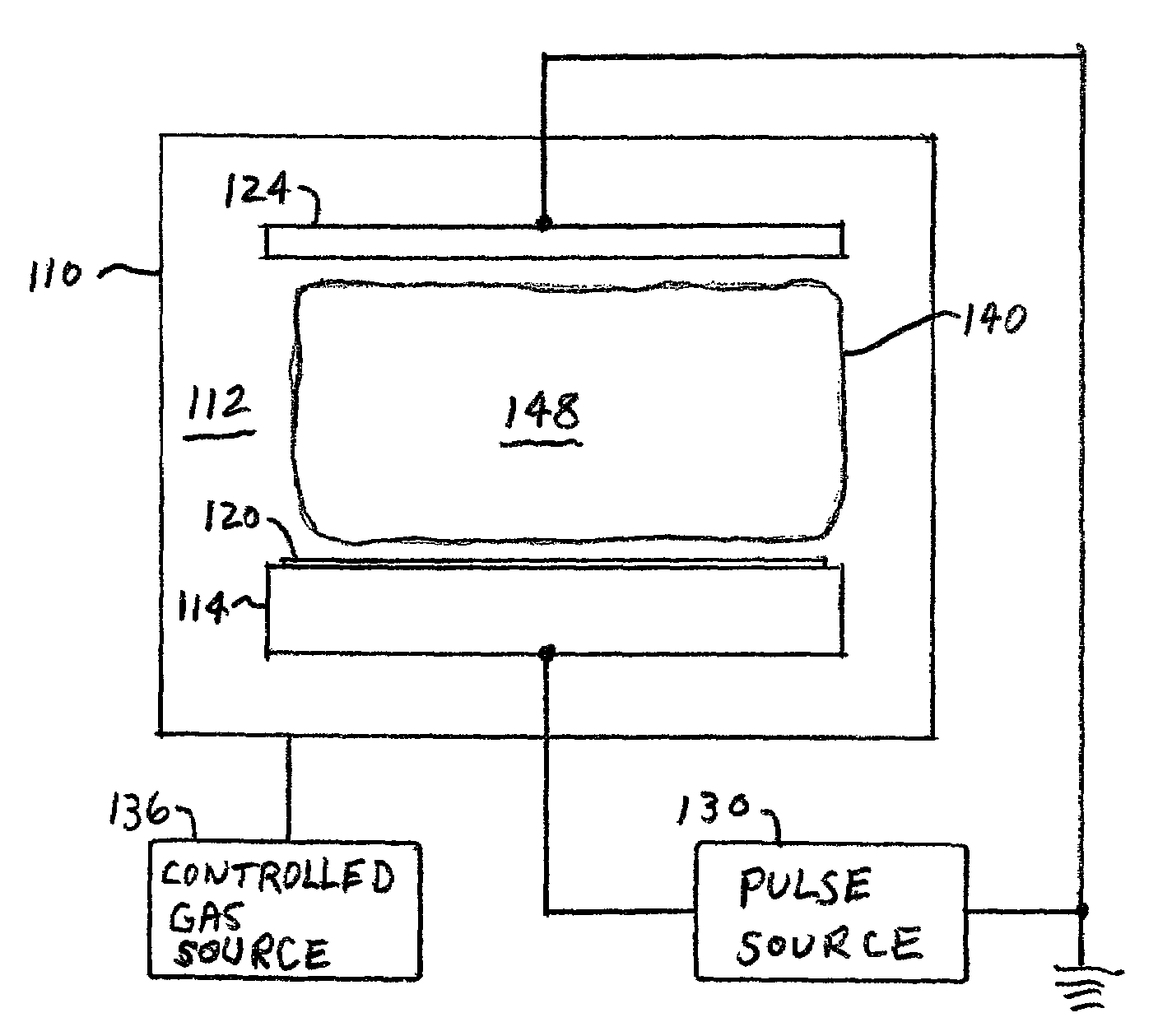

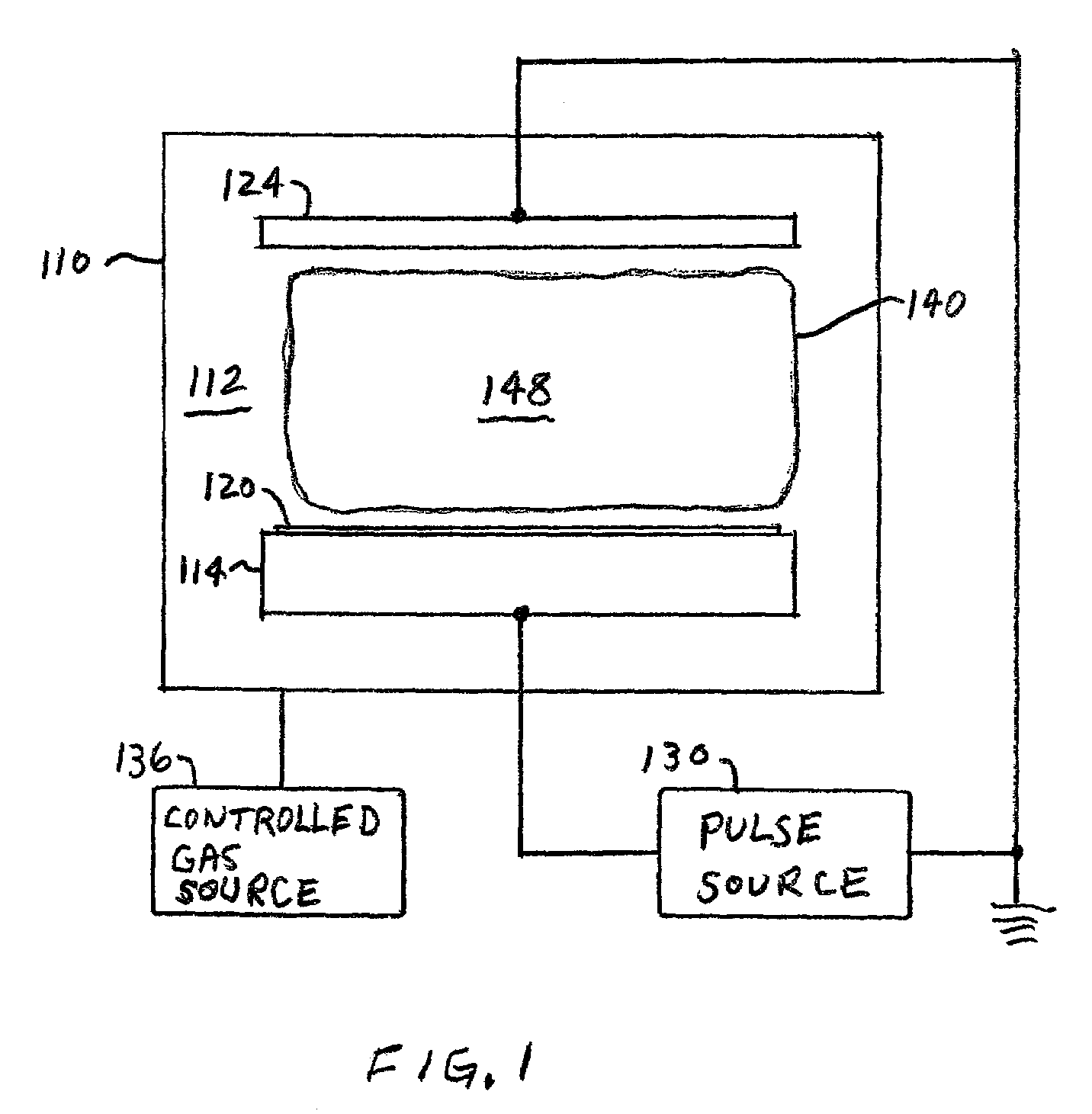

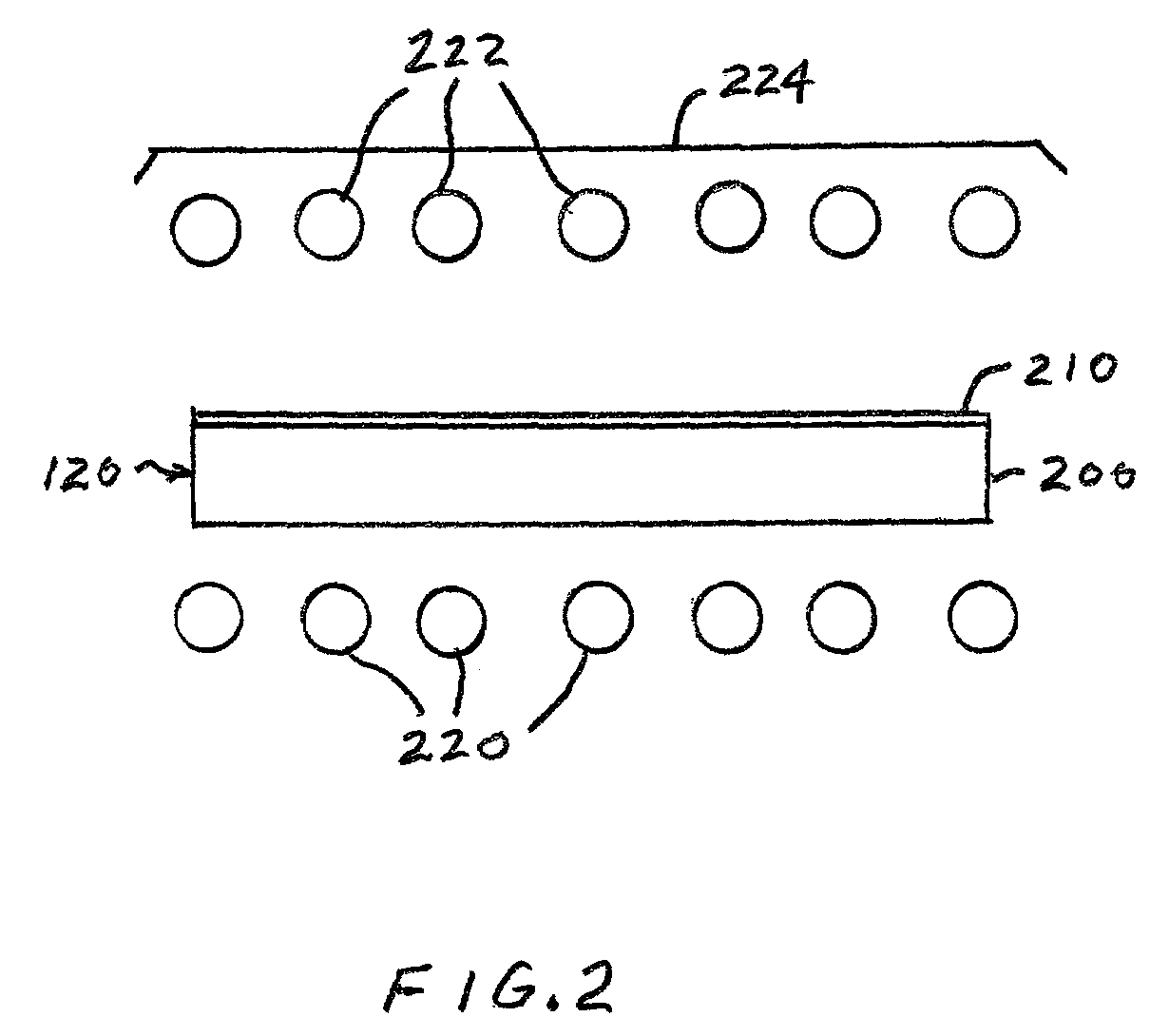

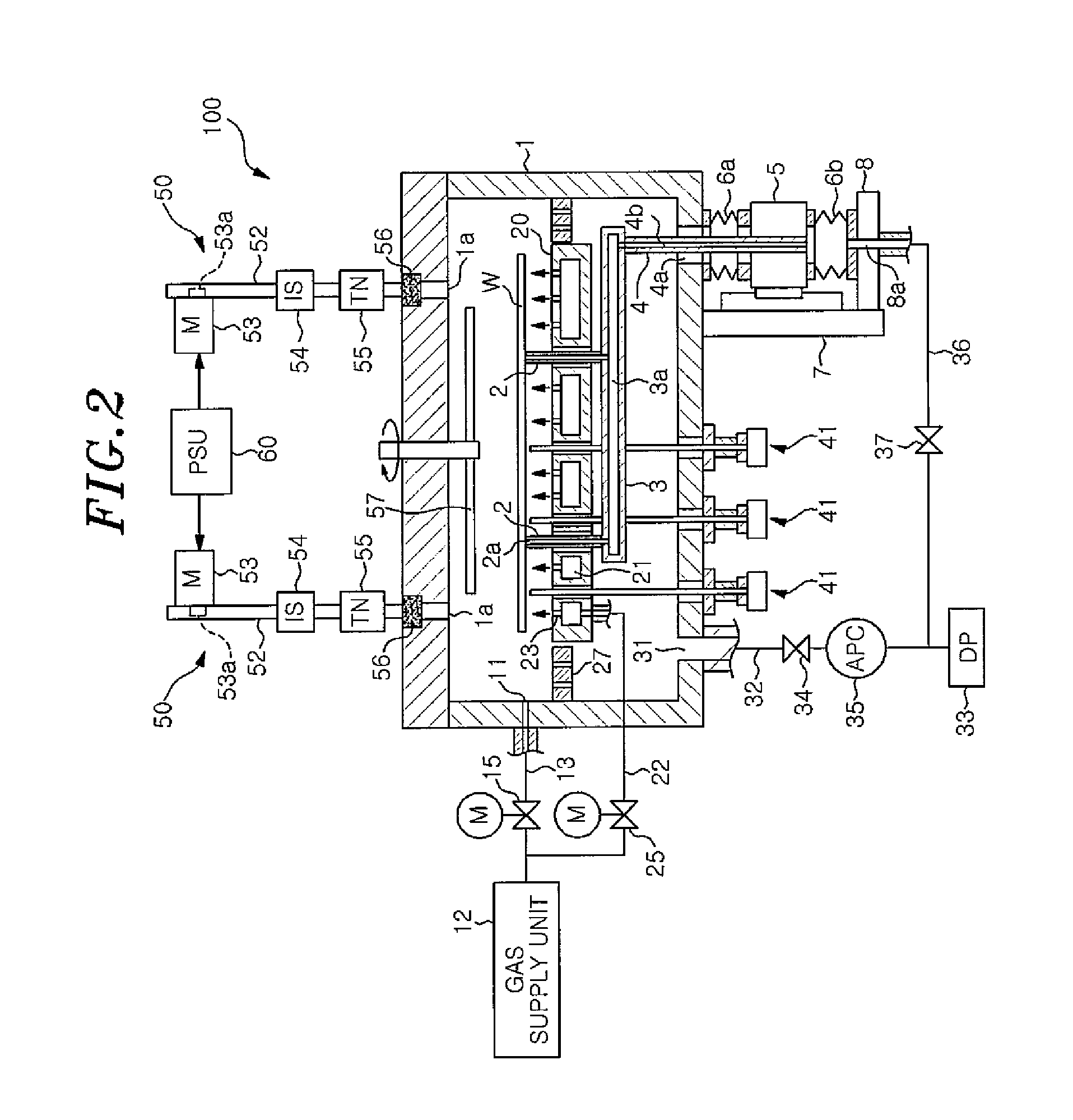

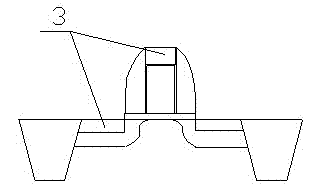

A system for and method of processing, i.e., annealing semiconductor materials. By controlling the time, frequency, variance of frequency, microwave power density, wafer boundary conditions, ambient conditions, and temperatures (including ramp rates), it is possible to repair localized damage lattices of the crystalline structure of a semiconductor material that may occur during the ion implantation of impurities into the material, electrically activate the implanted dopant, and substantially minimize further diffusion of the dopant into the silicon. The wafer boundary conditions may be controlled by utilizing susceptor plates (4) or a water chill plate (12). Ambient conditions may be controlled by gas injection (10) within the microwave chamber (3).

Owner:DSGI

Microwave anneal of a thin lamina for use in a photovoltaic cell

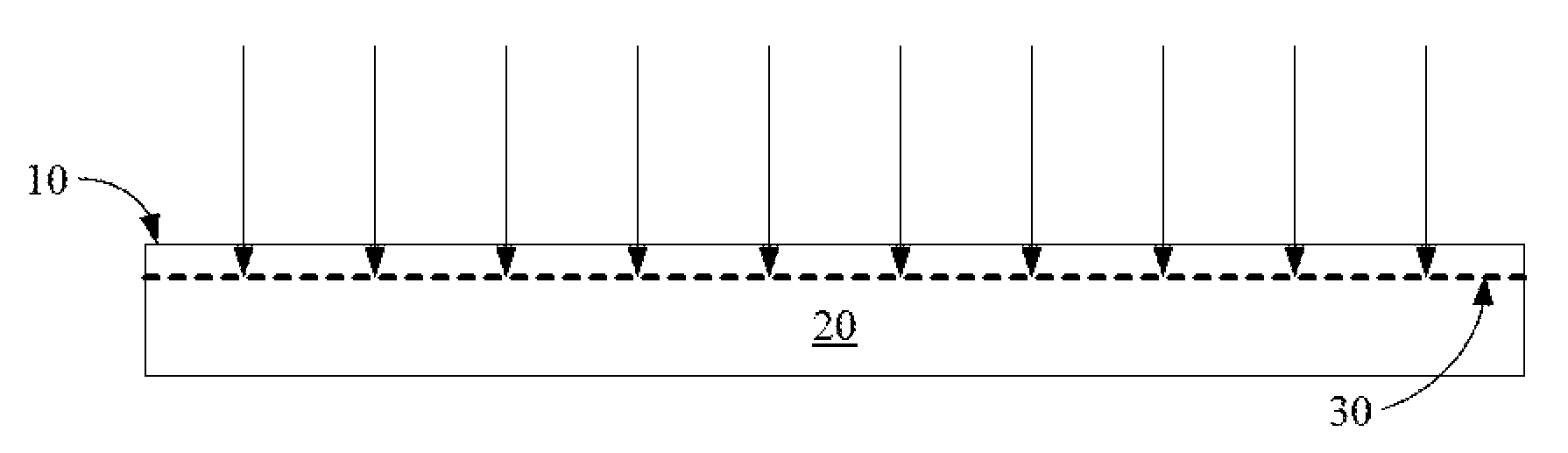

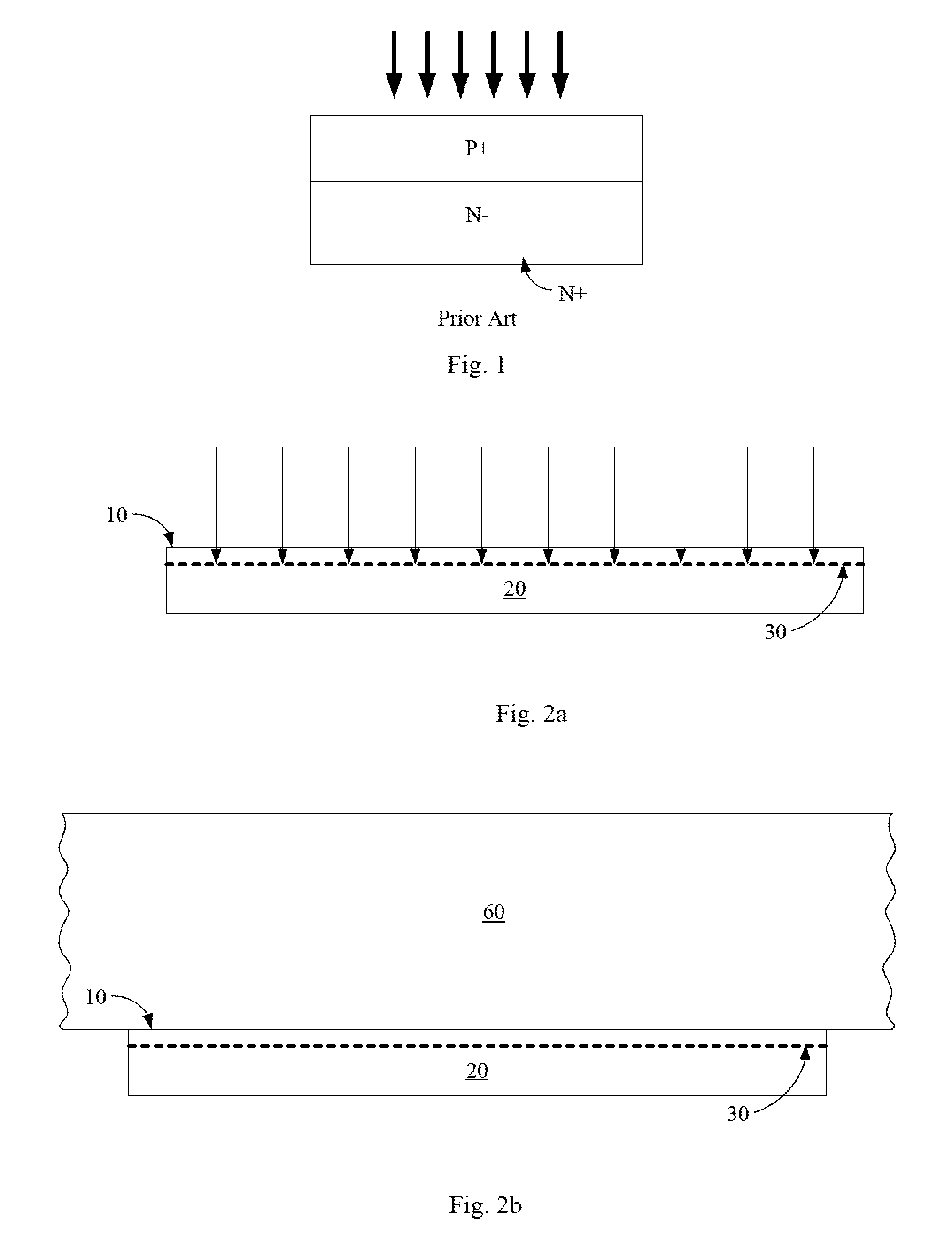

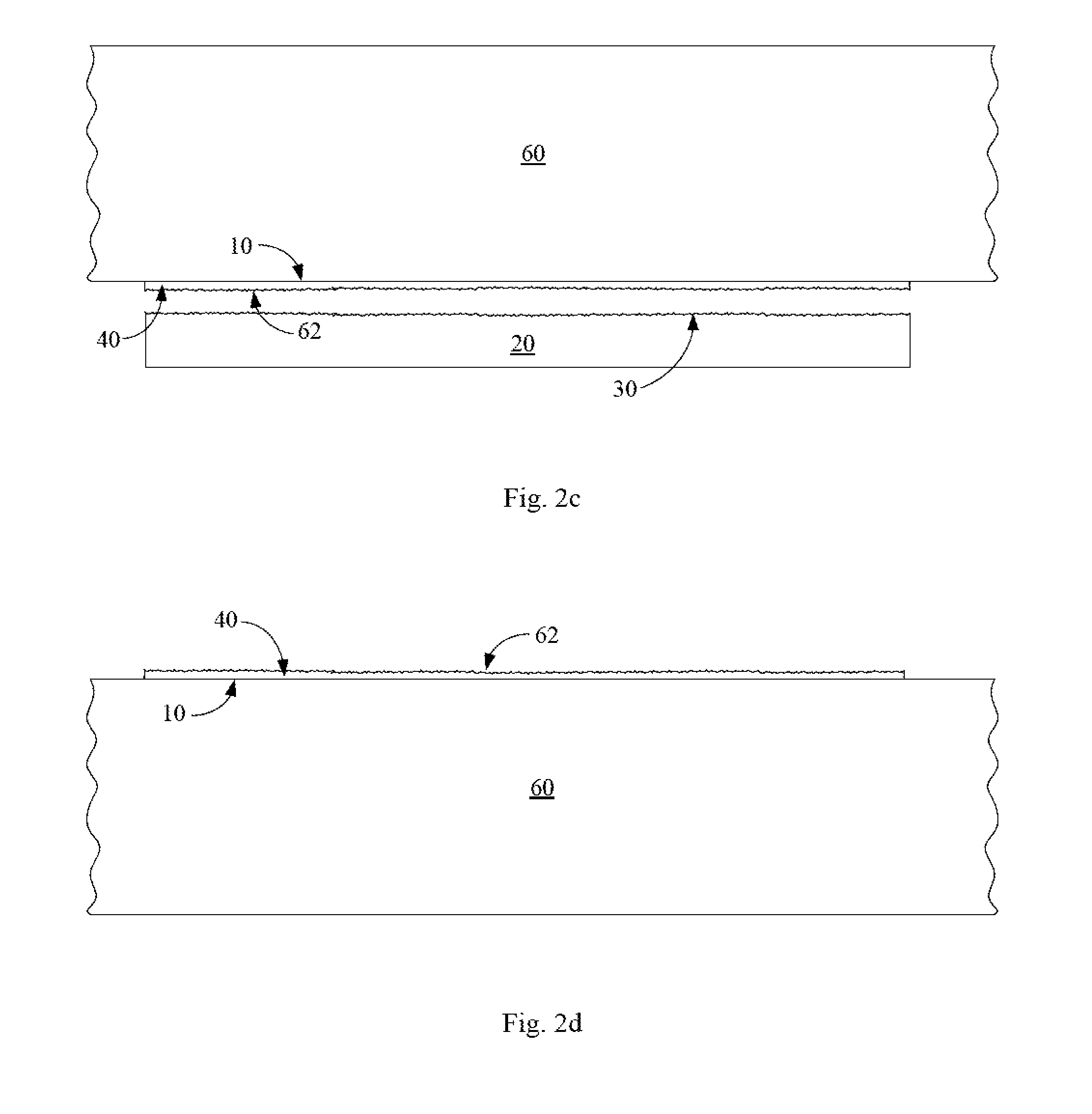

InactiveUS20110143480A1Suitable for useFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMicrowave annealing

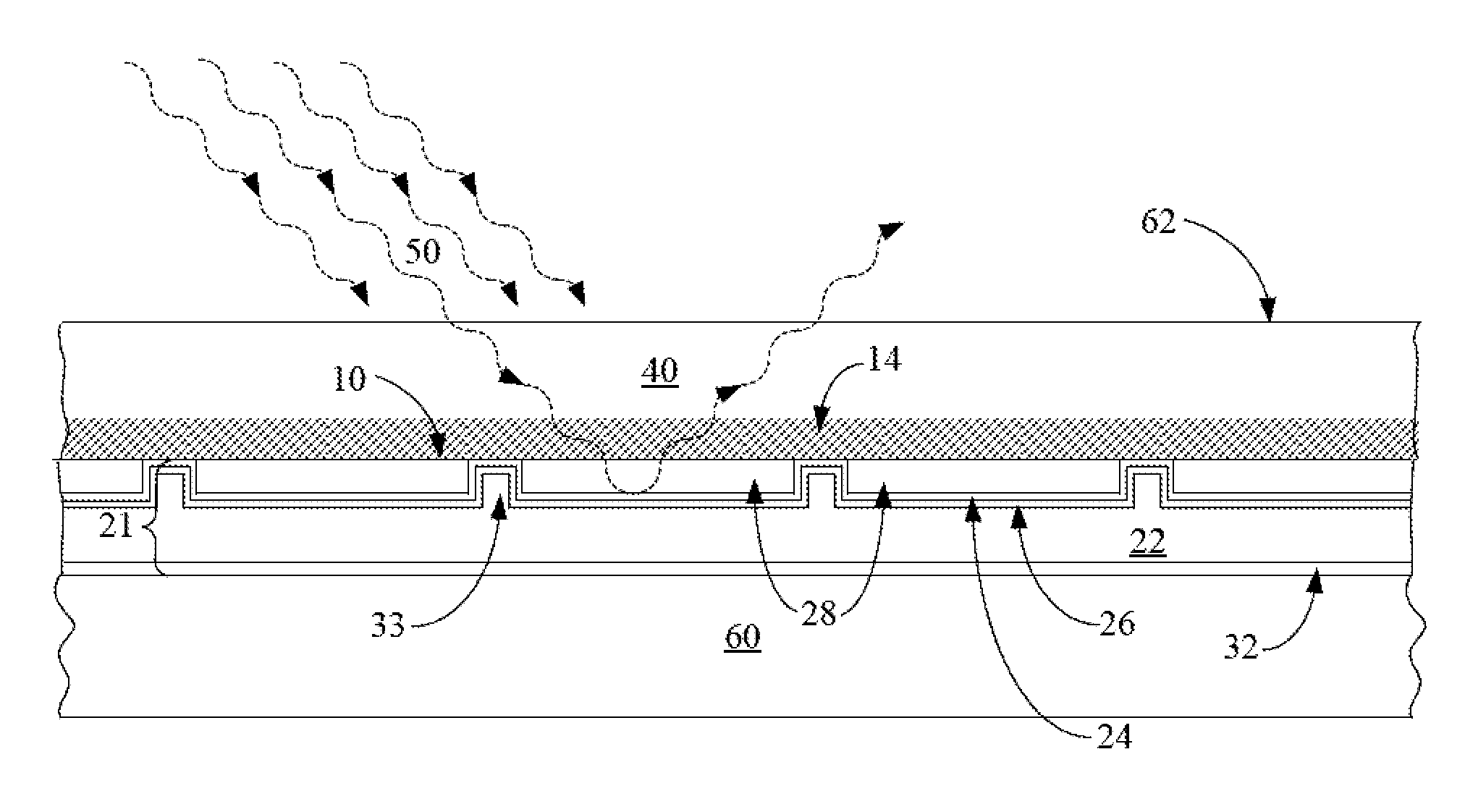

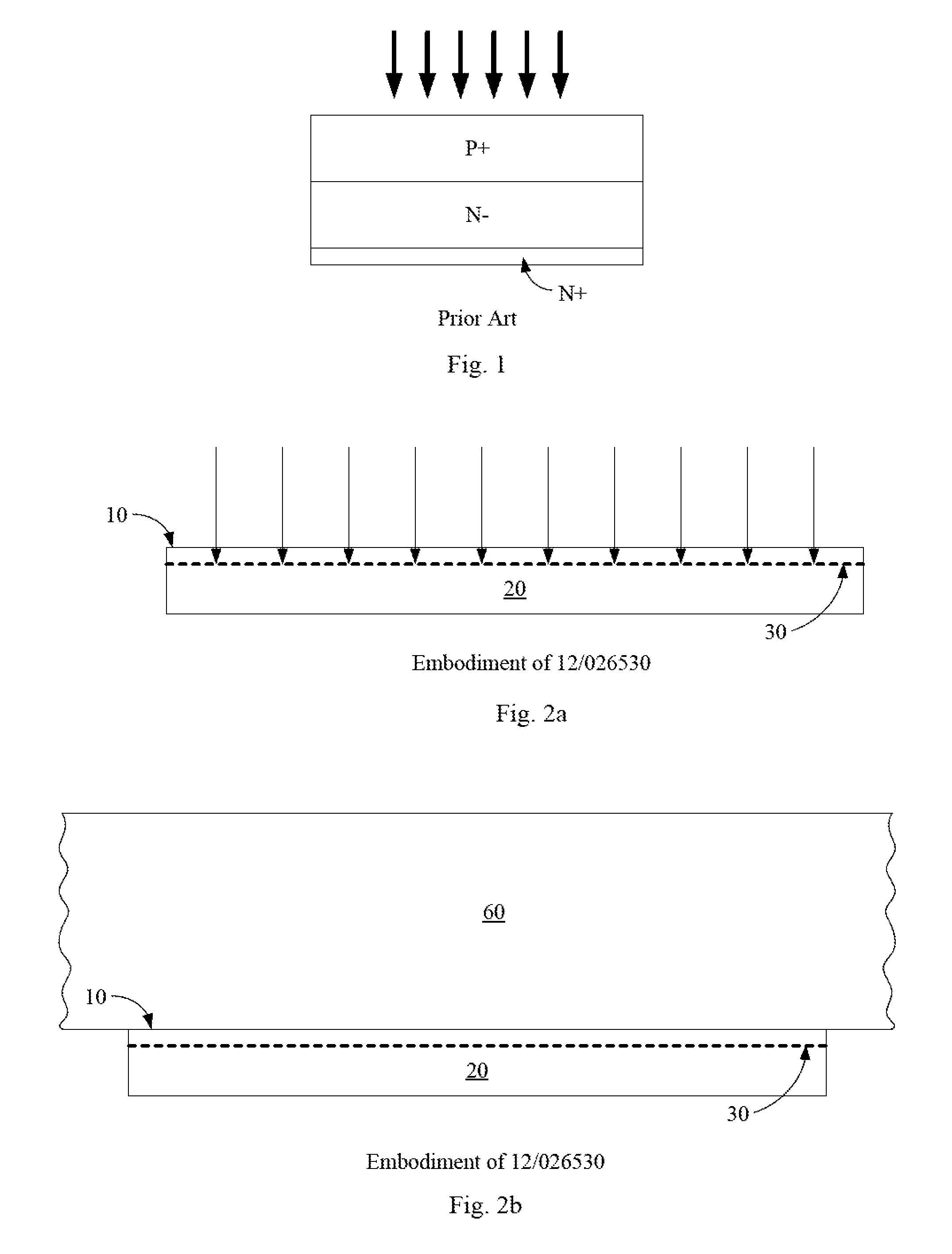

A cleave plane is defined in a semiconductor donor body by implanting ions into the wafer. A lamina is cleaved from the donor body, and a photovoltaic cell is formed which comprises the lamina. The implant may cause some damage to the crystal structure of the lamina. This damage can be repaired by annealing the lamina using microwave energy. If the lamina is bonded to a receiver element, the receiver element may be either transparent to microwaves, or may reflect microwaves, while the semiconductor material absorbs the microwaves. In this way the lamina can be annealed at high temperature while the receiver element remains cooler.

Owner:NEUTRON THERAPEUTICS LLC

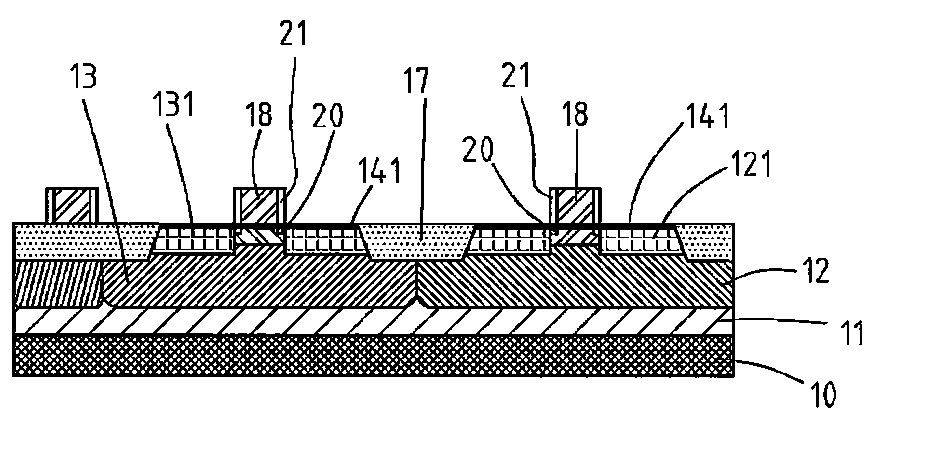

Microwave activation annealing process

InactiveUS20100120263A1High electron mobilityImprove efficiencyTransistorSemiconductor/solid-state device manufacturingState of artBiological activation

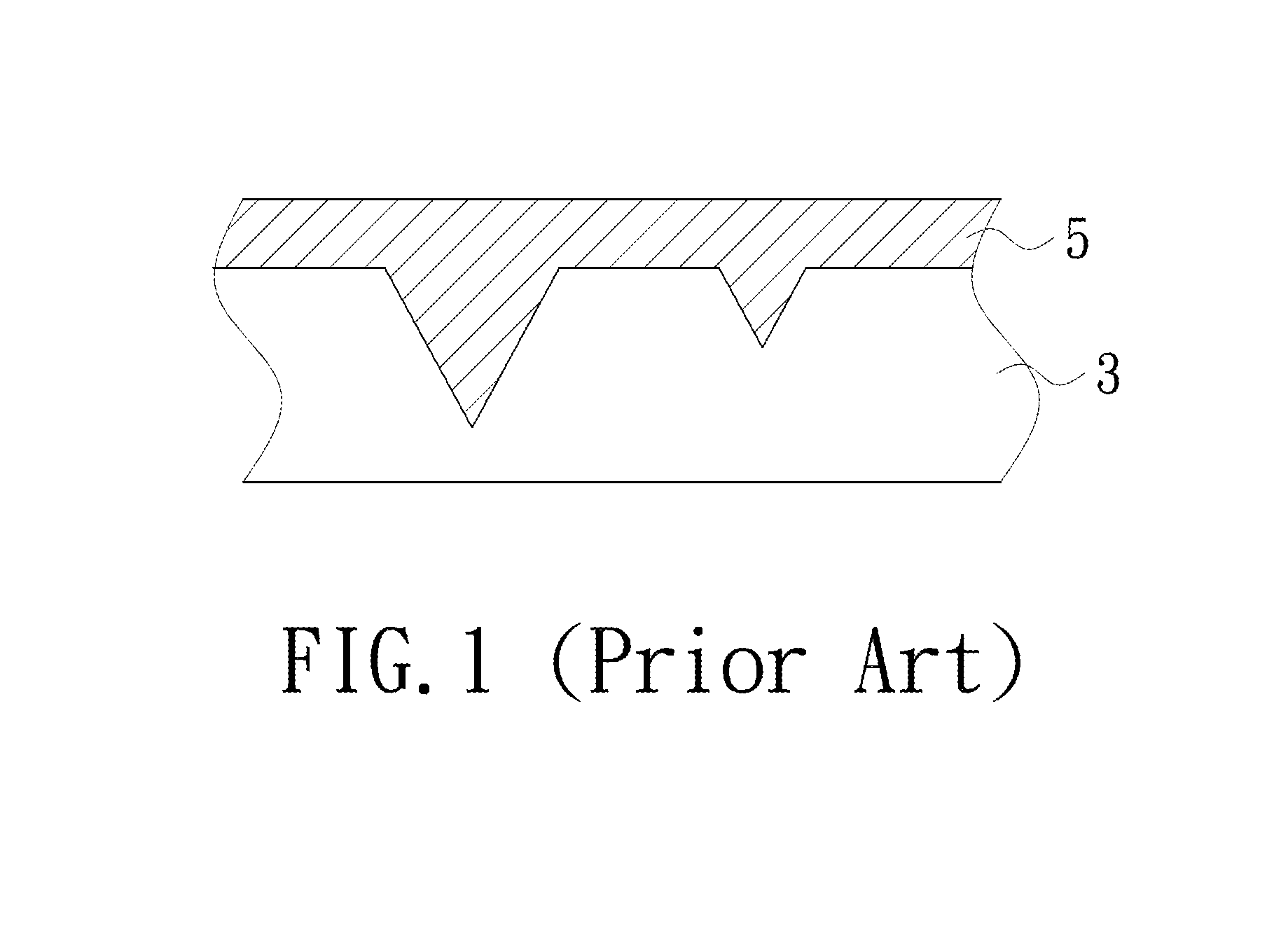

The present invention relates a microwave activation annealing process, which includes: the providing of a semiconductor process to form a semiconductor device on a substrate; activation: using a microwave device to perform microwave activation on the semiconductor device with frequency in the range of 2.45 GHz and 24.15 GHz and temperature in the range of 100° C. and 600° C.; annealing: using the microwave device to perform microwave annealing on the semiconductor device with frequency in the range 2.45 GHz to 24.15 GHz and temperature in the range 100° C. to 600° C.; by doing so, the present invention can, in the premise without the destruction of material property and structural interface and be able to shorten process time and enhance heating homogeneity, achieve the objective of activation annealing, hence, it can solve the defects caused by the heat treatment technique of prior art high temperature activation annealing.

Owner:NAT APPLIED RES LAB

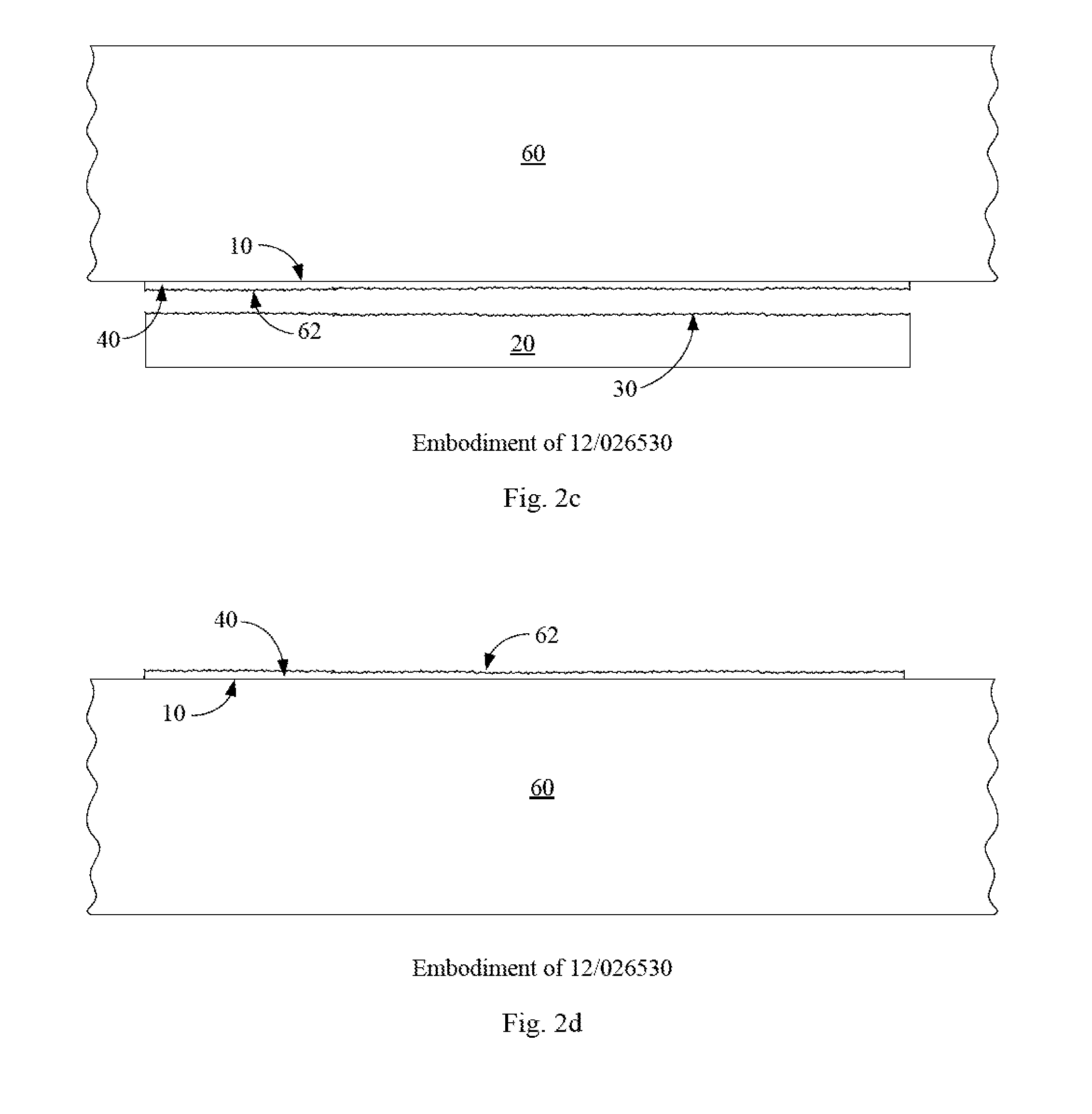

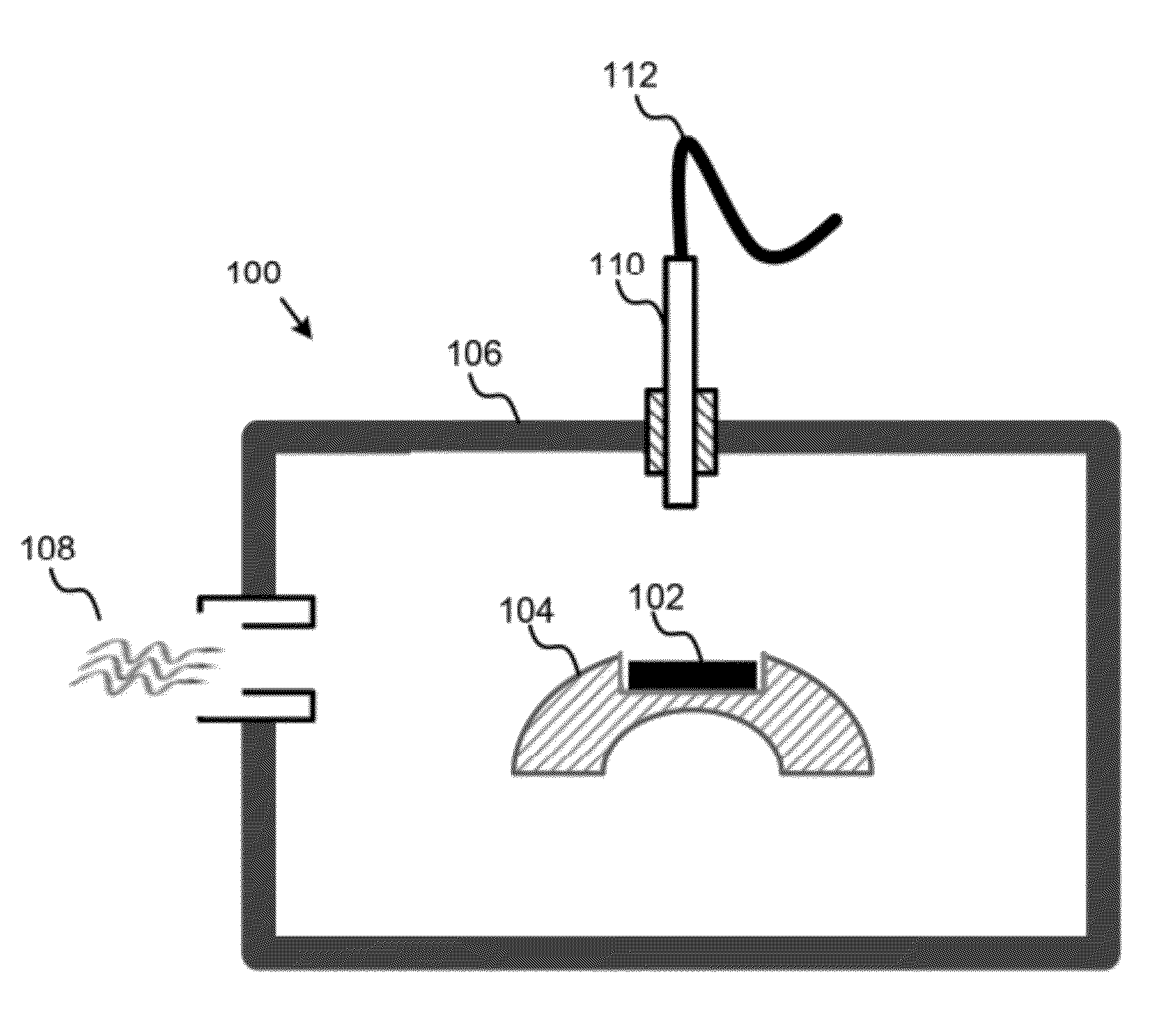

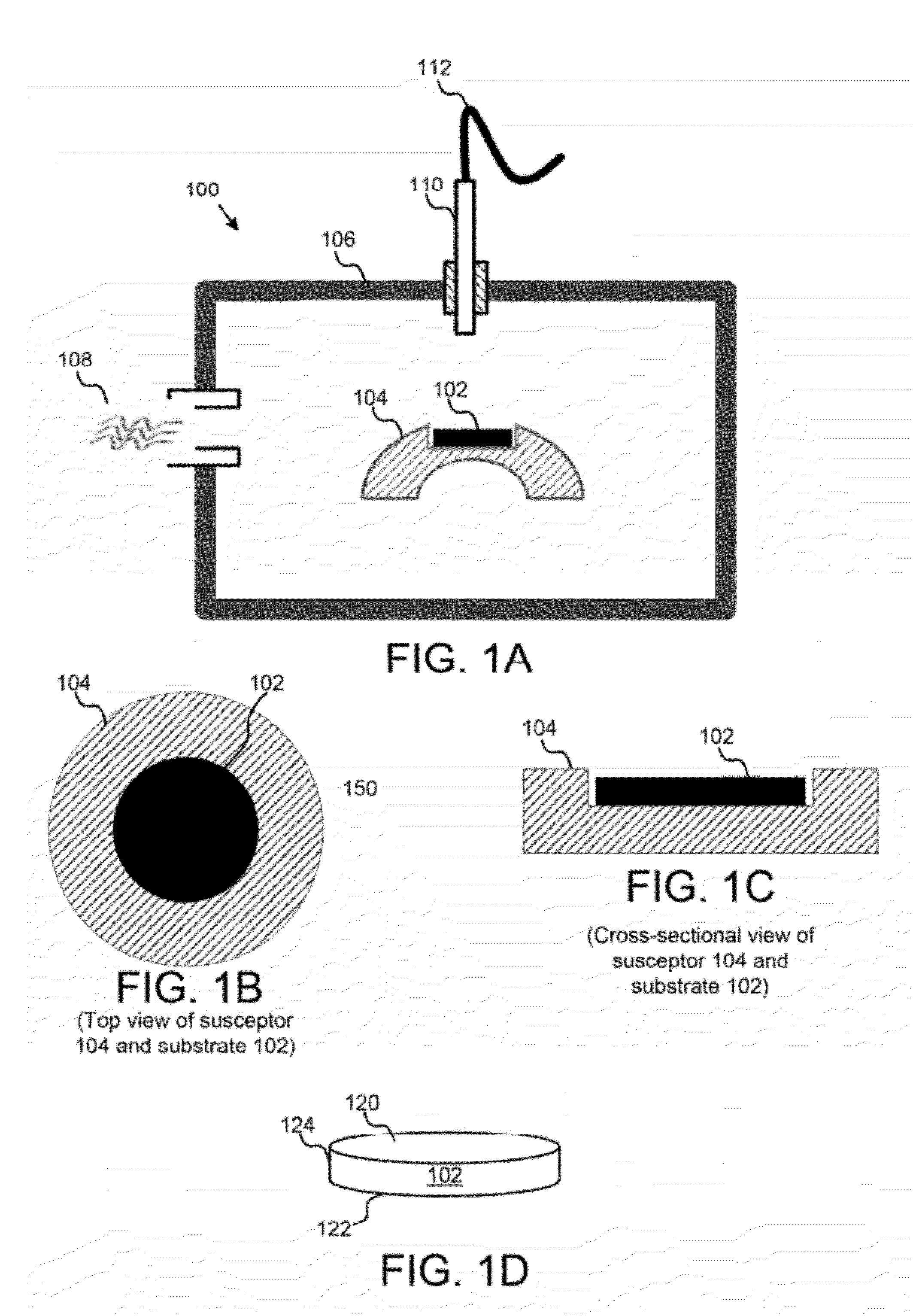

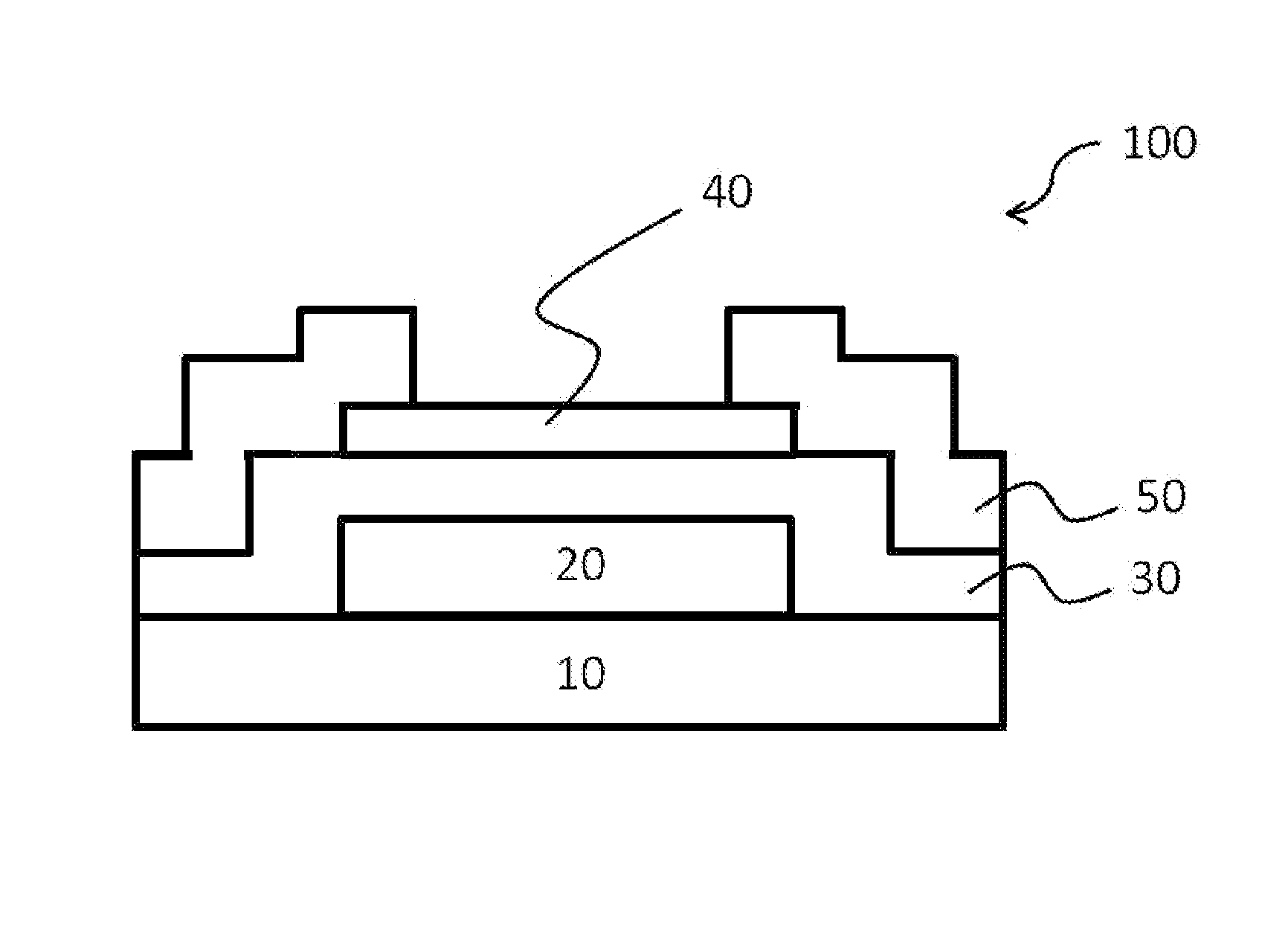

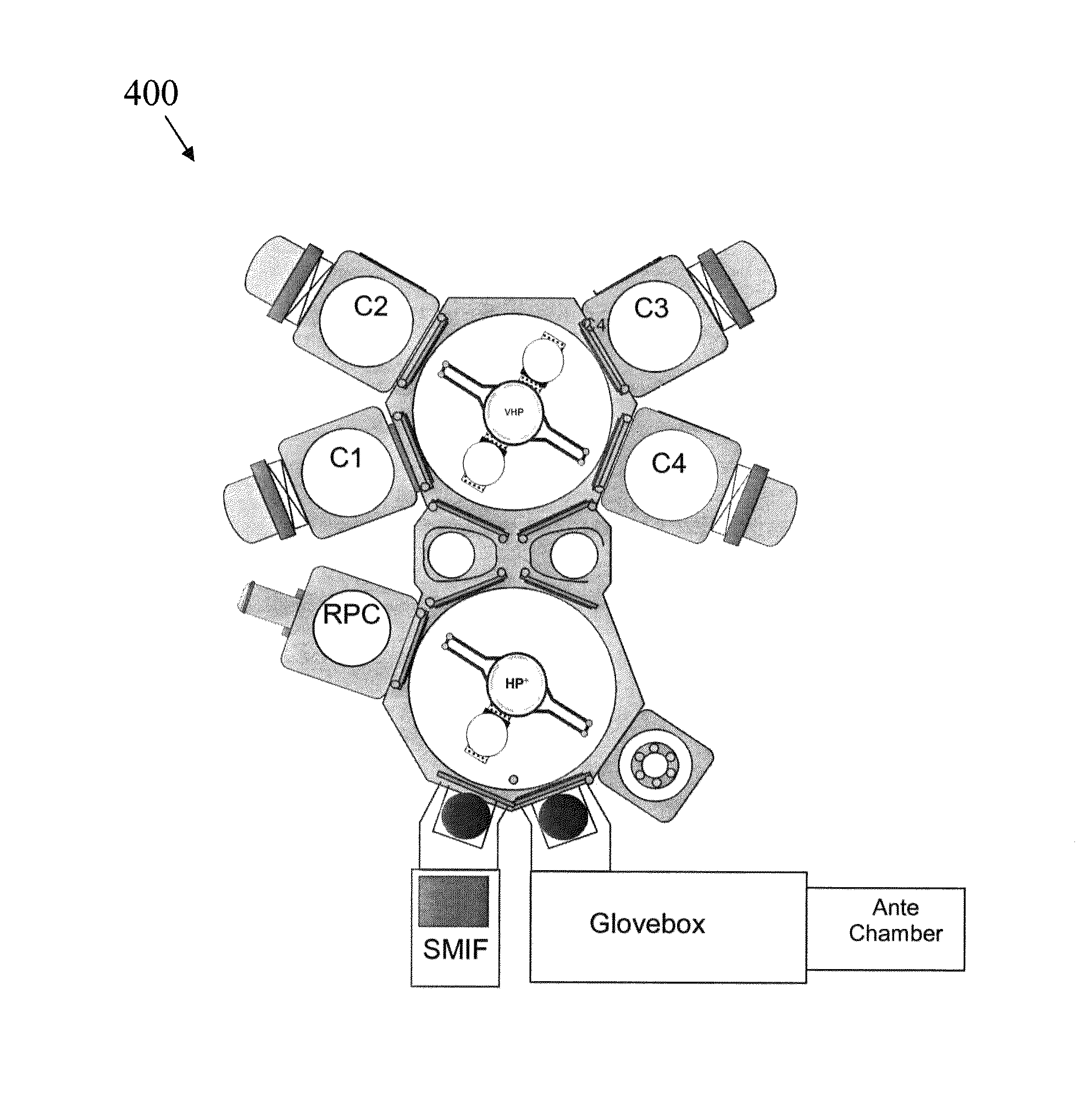

Systems and Methods for Susceptor Assisted Microwave Annealing

InactiveUS20120196453A1Semiconductor/solid-state device manufacturingMicrowave heatingSusceptorMicrowave emission

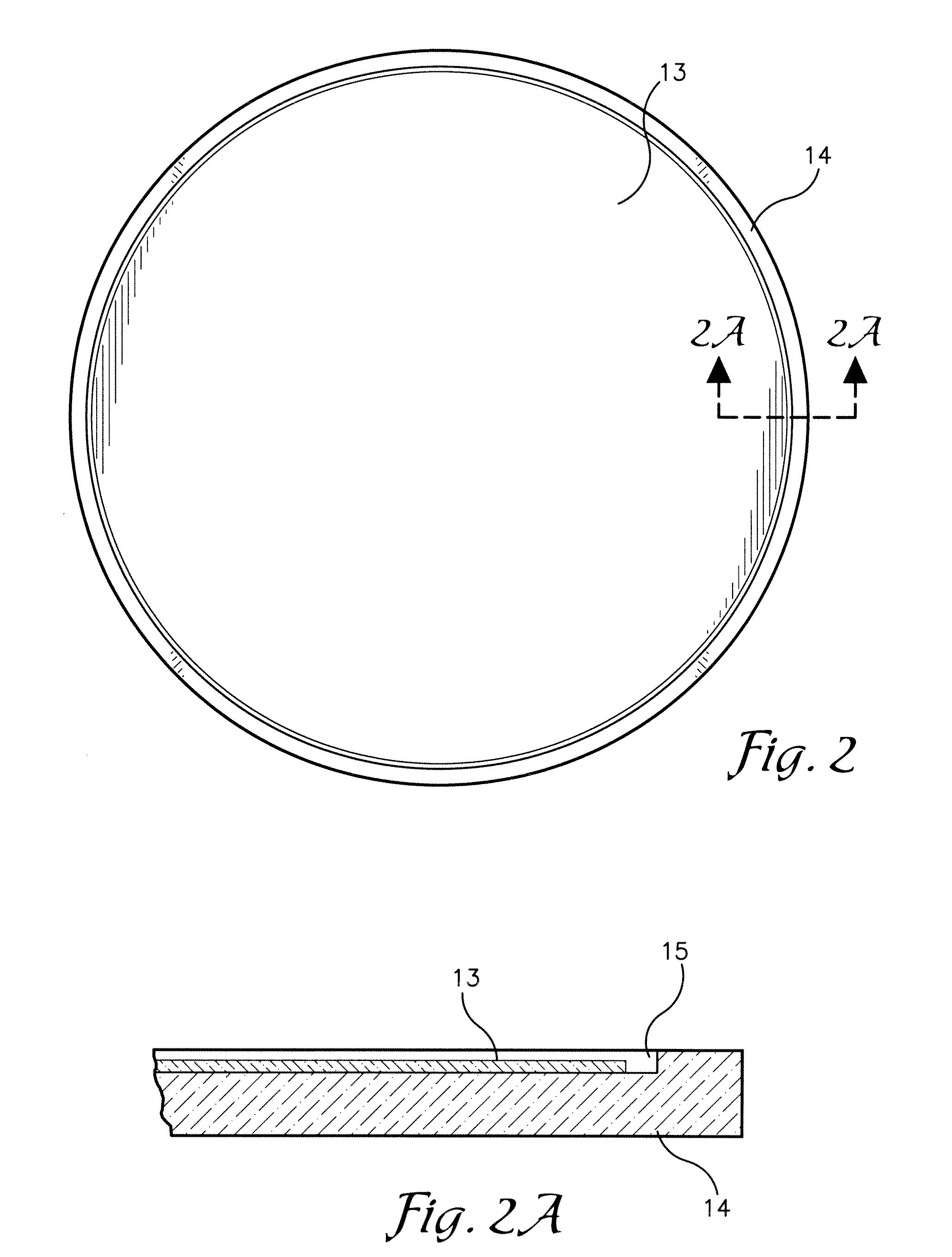

Systems and methods for microwave annealing are disclosed. In some embodiments, the system may comprise a microwave emitter configured to emit a microwave at a single frequency during an anneal time. In some embodiments, the system may further comprise an anneal unit to be annealed, the anneal unit having a top side, a bottom side, and one or more edge sides. In some embodiments, the system may further comprise a susceptor configured to absorb microwave energy, where the susceptor is adjacent to the edge side and at the bottom side of the anneal unit.

Owner:ARIZONA STATE UNIVERSITY

System for and method of microwave annealing semiconductor material

ActiveUS7928021B2Inhibited DiffusionLong heating timeSemiconductor/solid-state device manufacturingElectricityDopant

A system for and method of processing, i.e., annealing semiconductor materials. By controlling the time, frequency, variance of frequency, microwave power density, wafer boundary conditions, ambient conditions, and temperatures (including ramp rates), it is possible to repair localized damage lattices of the crystalline structure of a semiconductor material that may occur during the ion implantation of impurities into the material, electrically activate the implanted dopant, and substantially minimize further diffusion of the dopant into the silicon. The wafer boundary conditions may be controlled by utilizing susceptor plates (4) or a water chill plate (12). Ambient conditions may be controlled by gas injection (10) within the microwave chamber (3).

Owner:DSGI

Microwave Rapid Thermal Processing of Electrochemical Devices

InactiveUS20130266741A1Easy to manufactureHigh crystallinityFinal product manufactureVacuum evaporation coatingElectrical batteryEnergy absorption

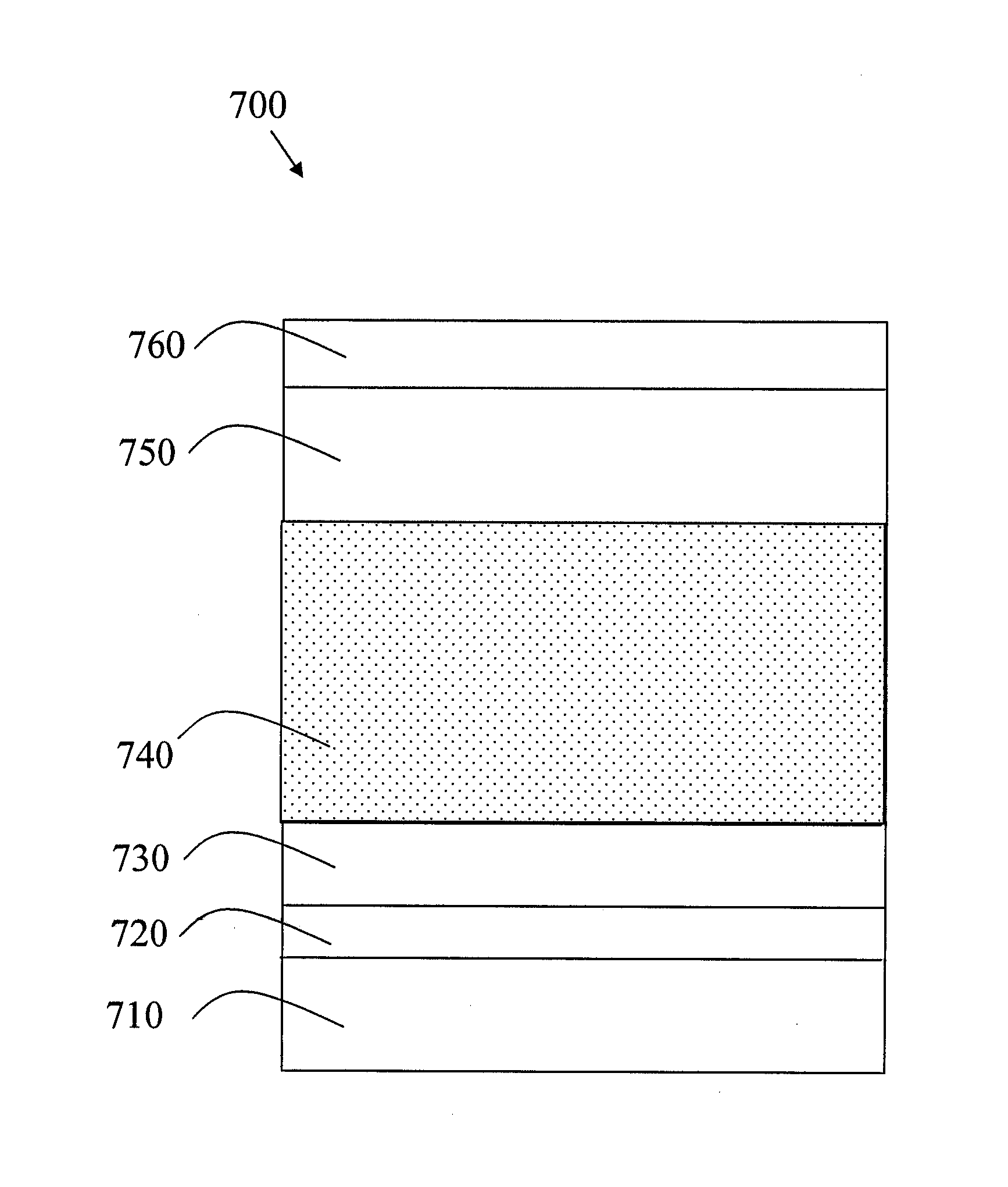

Microwave radiation may be applied to electrochemical devices for rapid thermal processing (RTP) (including annealing, crystallizing, densifying, forming, etc.) of individual layers of the electrochemical devices, as well as device stacks, including bulk and thin film batteries and thin film electrochromic devices. A method of manufacturing an electrochemical device may comprise: depositing a layer of the electrochemical device over a substrate; and microwave annealing the layer, wherein the microwave annealing includes selecting annealing conditions with preferential microwave energy absorption in the layer. An apparatus for forming an electrochemical device may comprise: a first system to deposit an electrochemical device layer over a substrate; and a second system to microwave anneal the layer, wherein the second system is configured to provide preferential microwave energy absorption in the device layer.

Owner:APPLIED MATERIALS INC

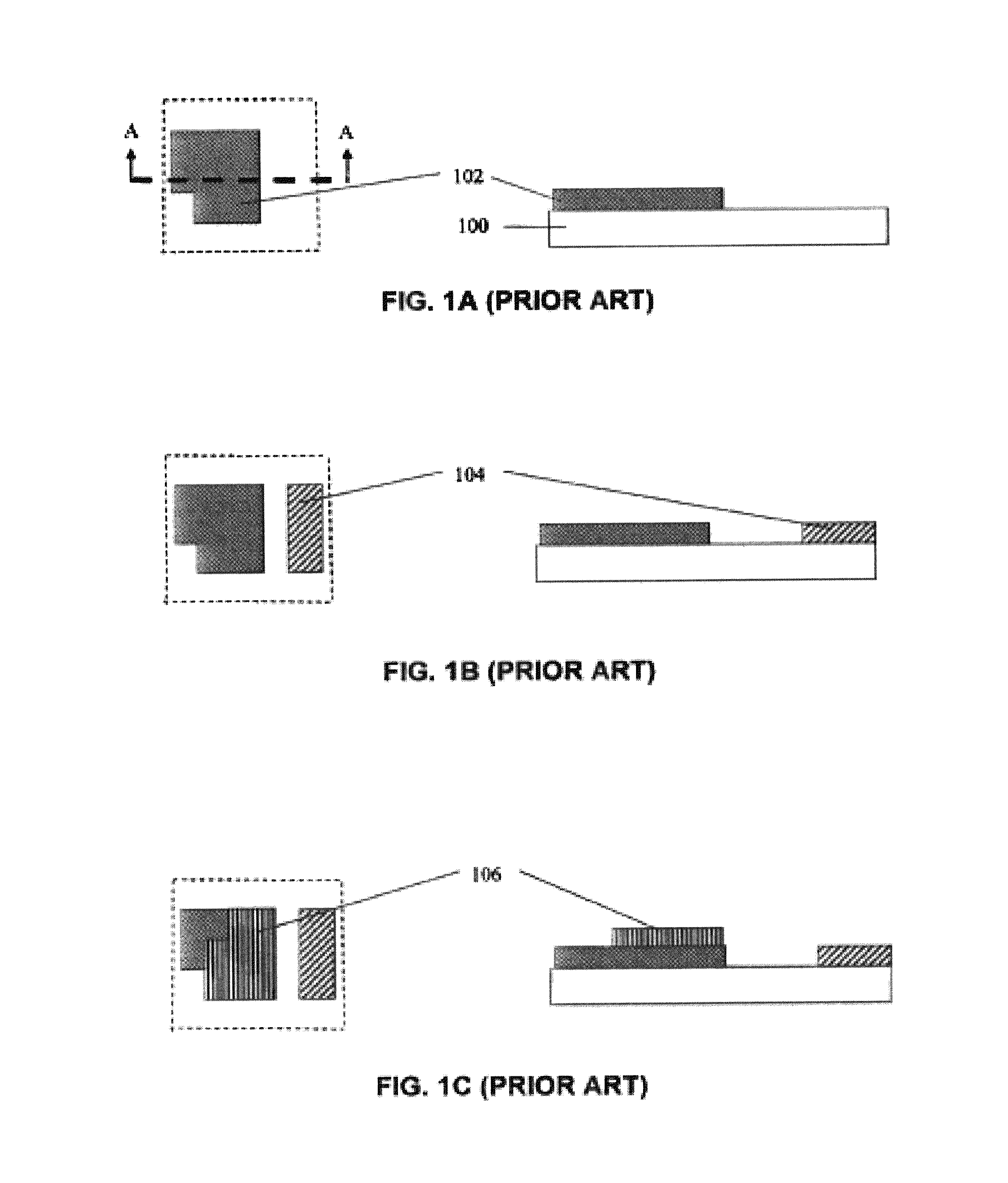

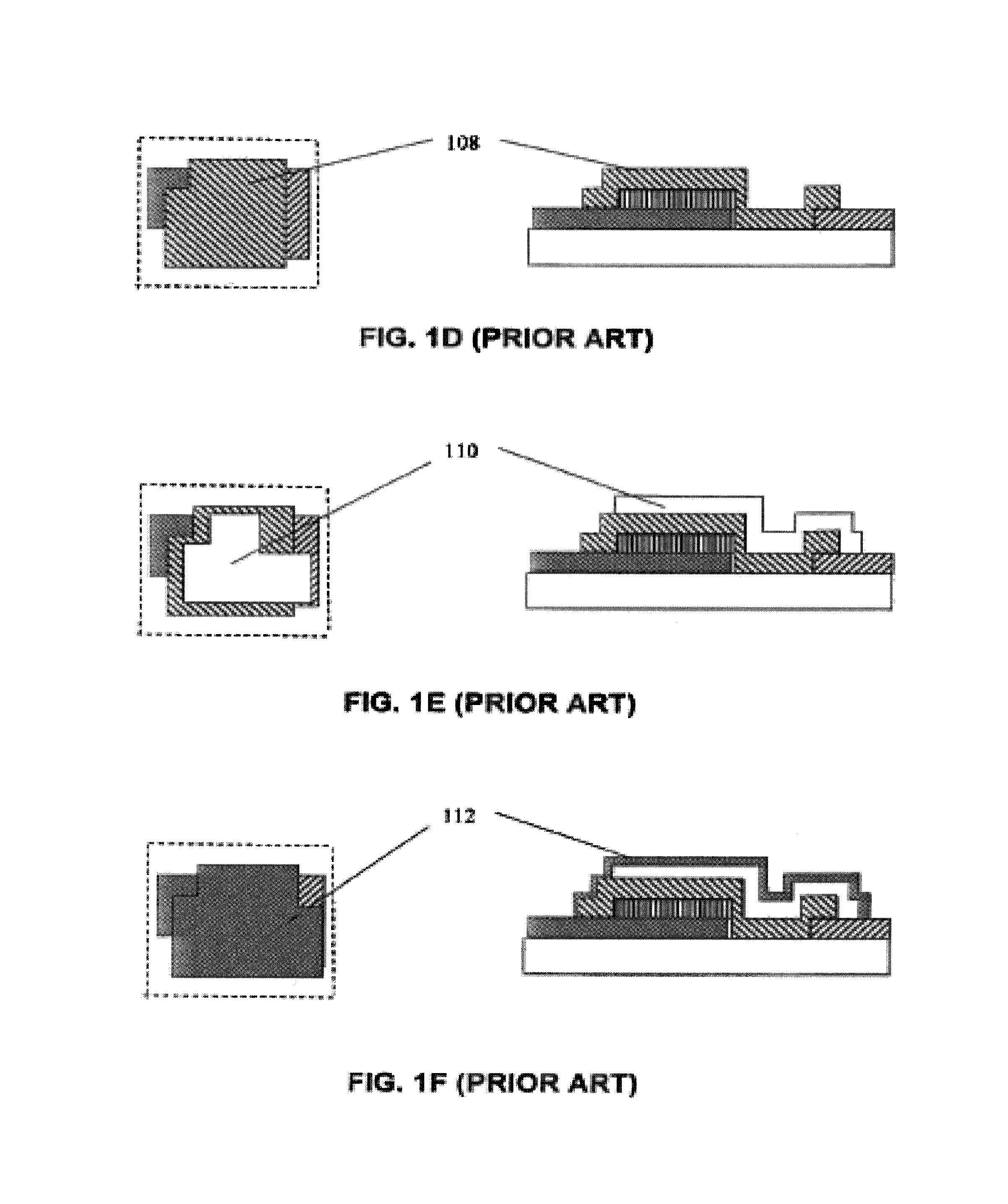

Methods for forming low resistivity, ultrashallow junctions with low damage

InactiveUS7135423B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSurface layer

Methods for forming ultrashallow junctions in semiconductor wafers include introducing into a shallow surface layer of a semiconductor wafer a dopant material that is selected to form charge carrier complexes which produce at least two charge carriers per complex, and short-time thermal processing of the doped surface layer to form the charge carrier complexes. The short-time thermal processing step may be implemented as flash rapid thermal processing of the doped surface layer, sub-melt laser processing of the doped surface layer, or RF or microwave annealing of the doped surface layer.

Owner:VARIAN SEMICON EQUIP ASSOC INC

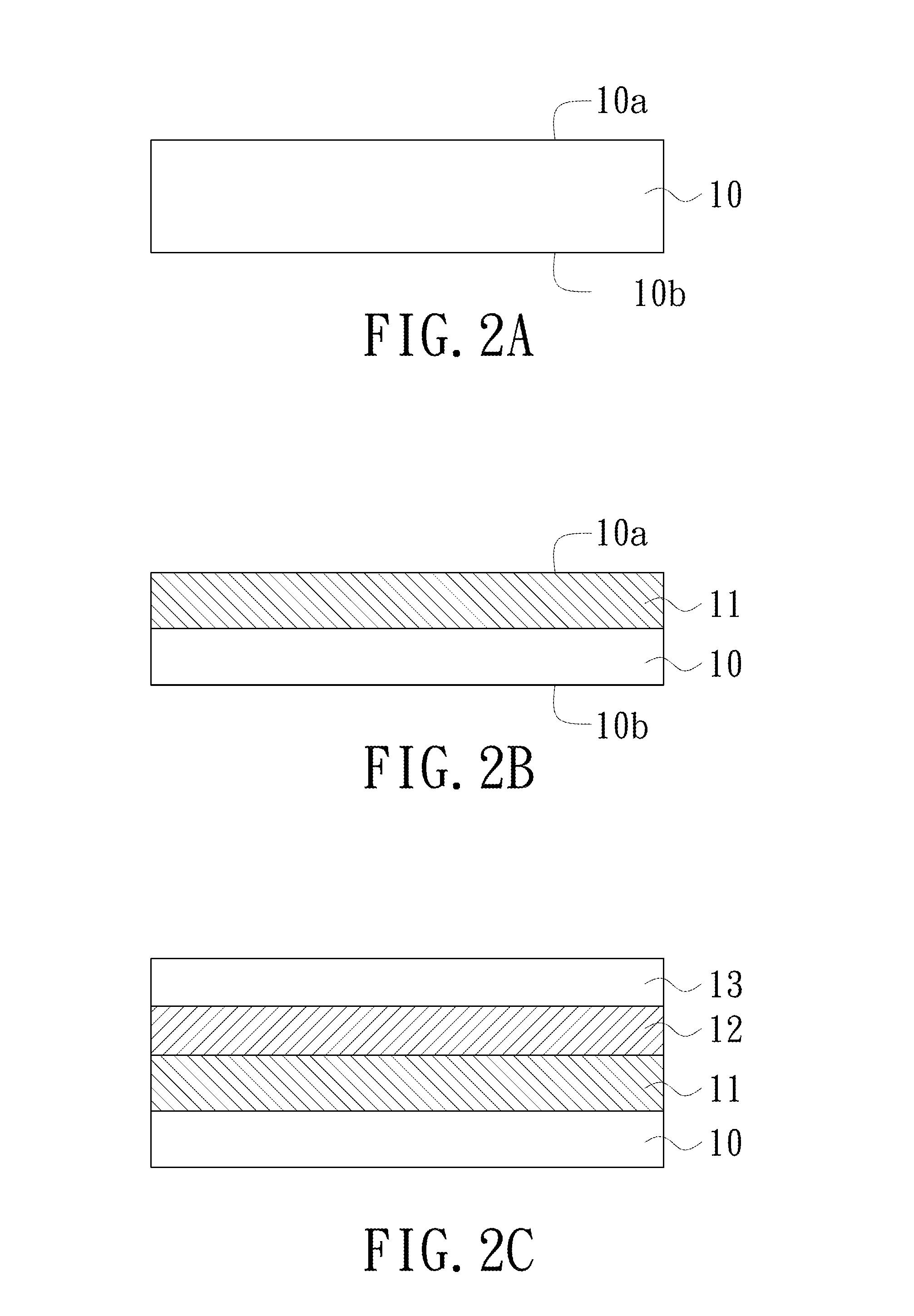

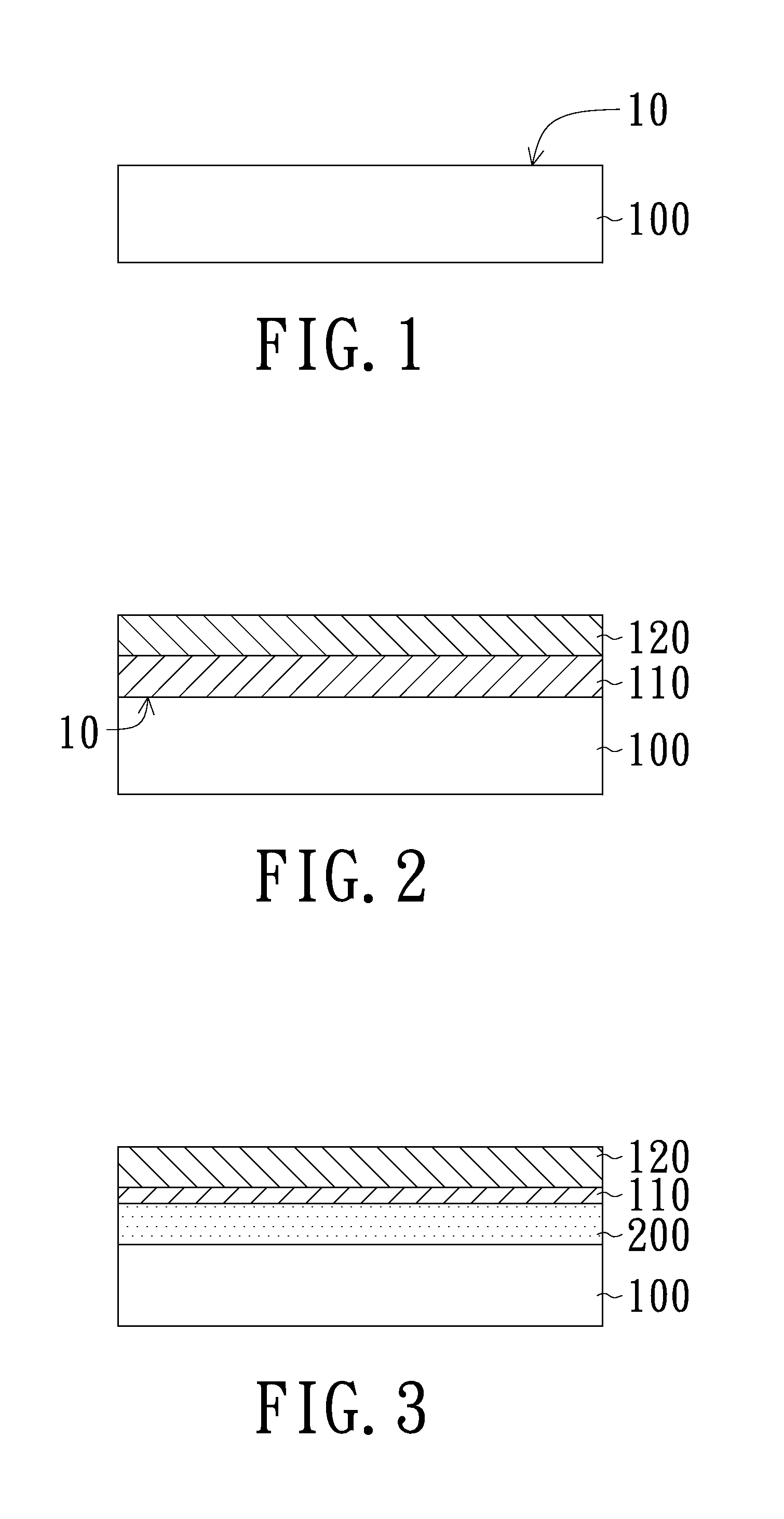

Fabricating method of semiconductor chip

InactiveUS20140094023A1Improve performanceSemiconductor/solid-state device manufacturingChemical reactionSemiconductor chip

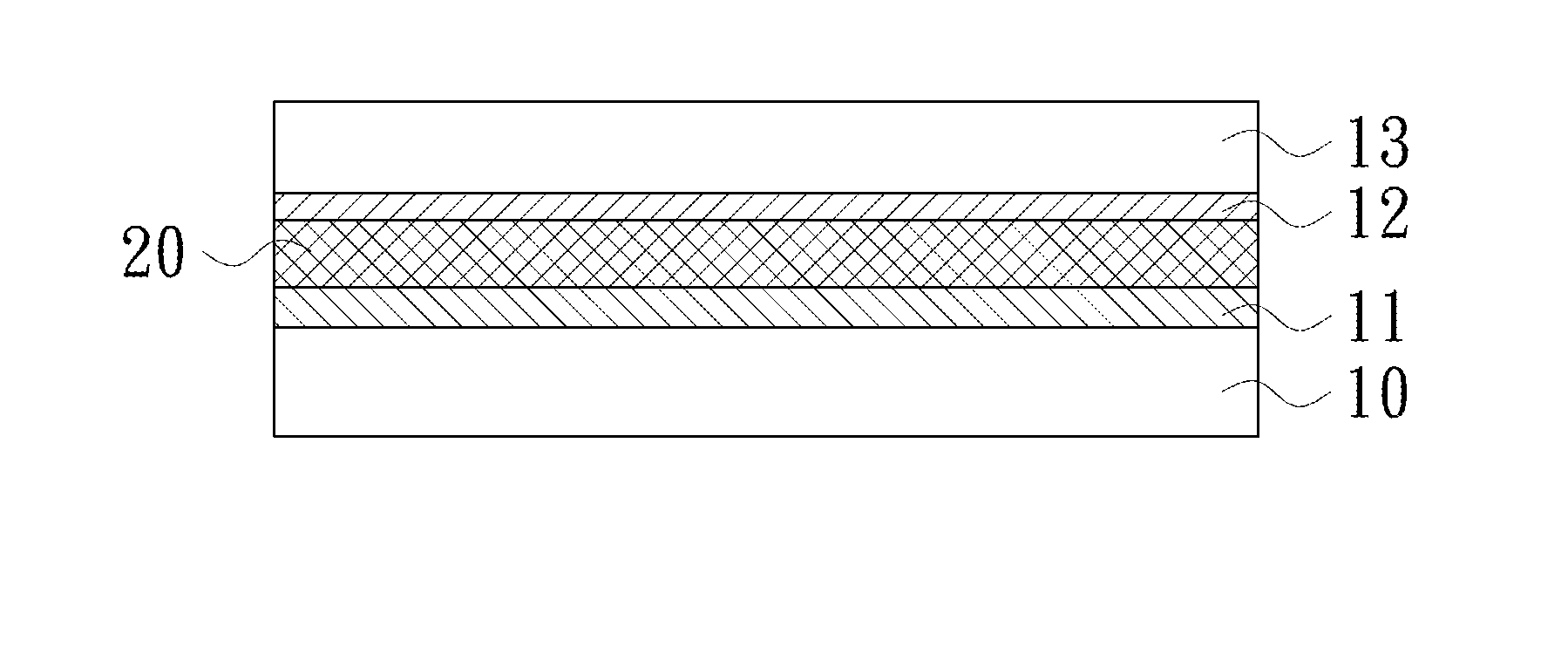

A fabricating method of a semiconductor chip includes the following steps. Firstly, a substrate is provided, wherein an amorphous semiconductor layer is formed in a first surface of the substrate. Then, a first metal layer is formed on the amorphous semiconductor layer. Then, a thermal-treating process is performed to result in a chemical reaction between the first metal layer and a part of the amorphous semiconductor layer, thereby producing an amorphous metal semiconductor compound layer. Afterwards, a microwave annealing process is performed to recrystallize the amorphous metal semiconductor compound layer as a polycrystalline metal semiconductor compound layer.

Owner:NAT APPLIED RES LAB

Microwave anneal of a thin lamina for use in a photovoltaic cell

InactiveUS8257995B2Final product manufactureSemiconductor/solid-state device manufacturingSemiconductor materialsCrystal structure

A cleave plane is defined in a semiconductor donor body by implanting ions into the wafer. A lamina is cleaved from the donor body, and a photovoltaic cell is formed which comprises the lamina. The implant may cause some damage to the crystal structure of the lamina. This damage can be repaired by annealing the lamina using microwave energy. If the lamina is bonded to a receiver element, the receiver element may be either transparent to microwaves, or may reflect microwaves, while the semiconductor material absorbs the microwaves. In this way the lamina can be annealed at high temperature while the receiver element remains cooler.

Owner:NEUTRON THERAPEUTICS LLC

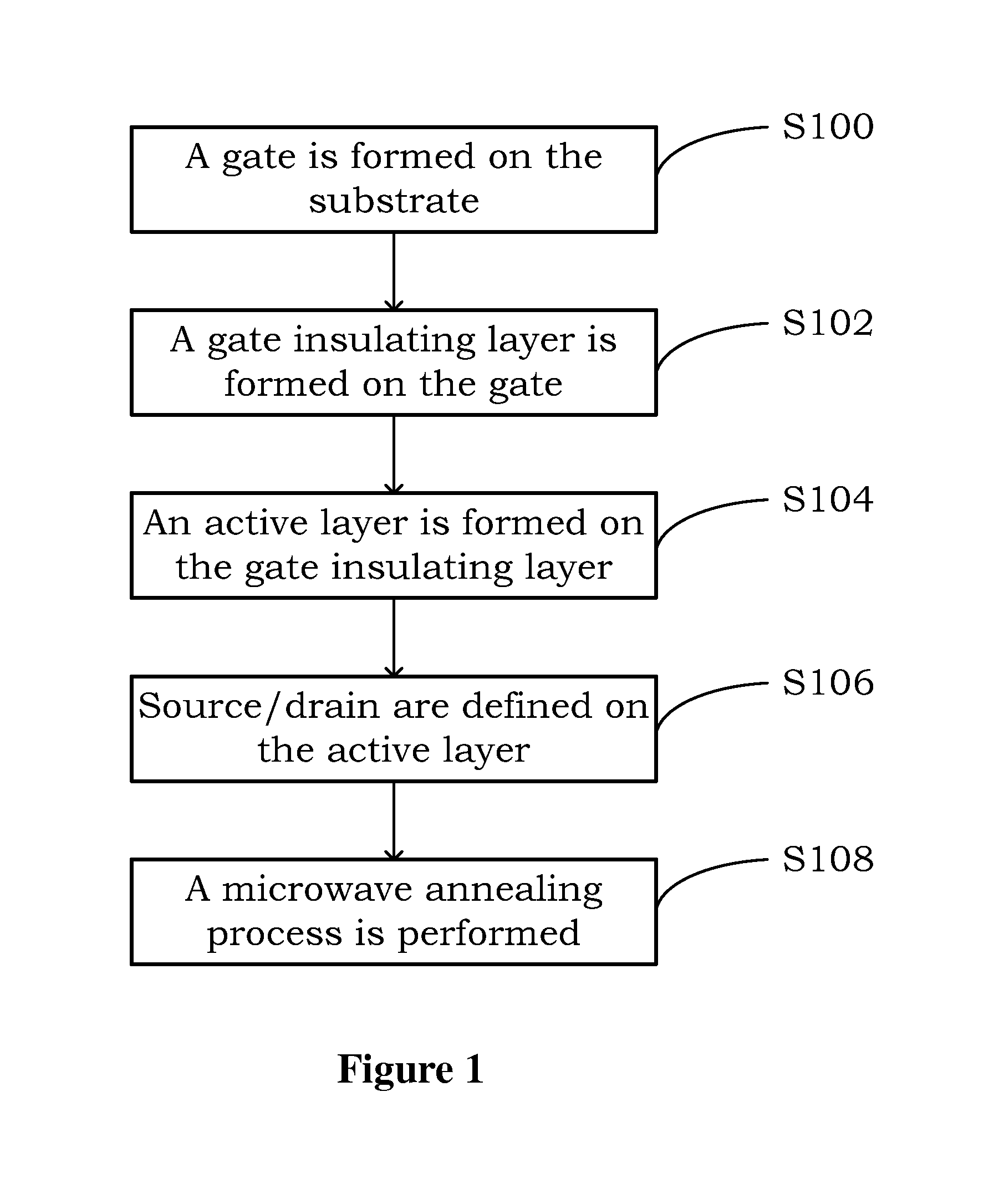

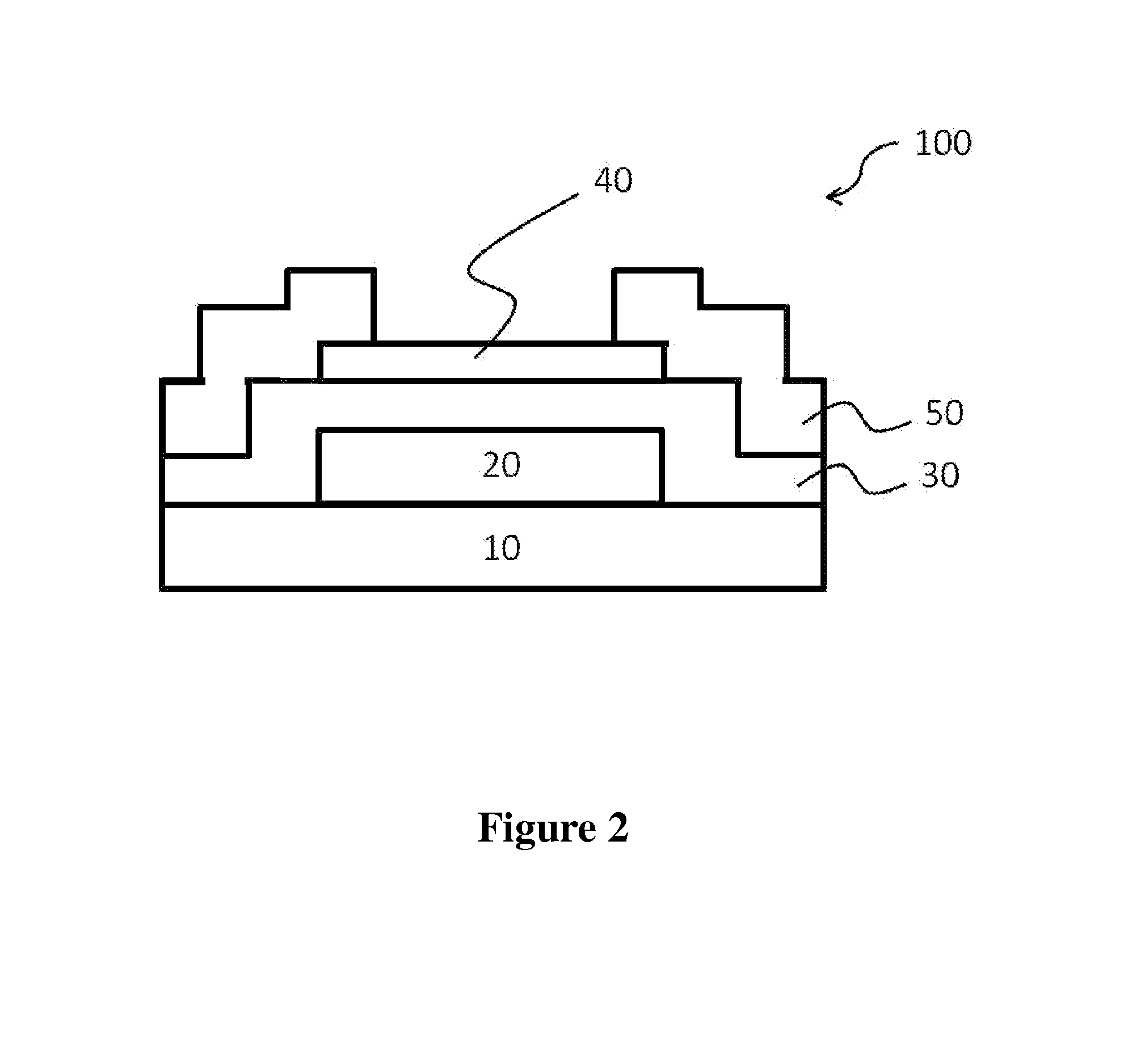

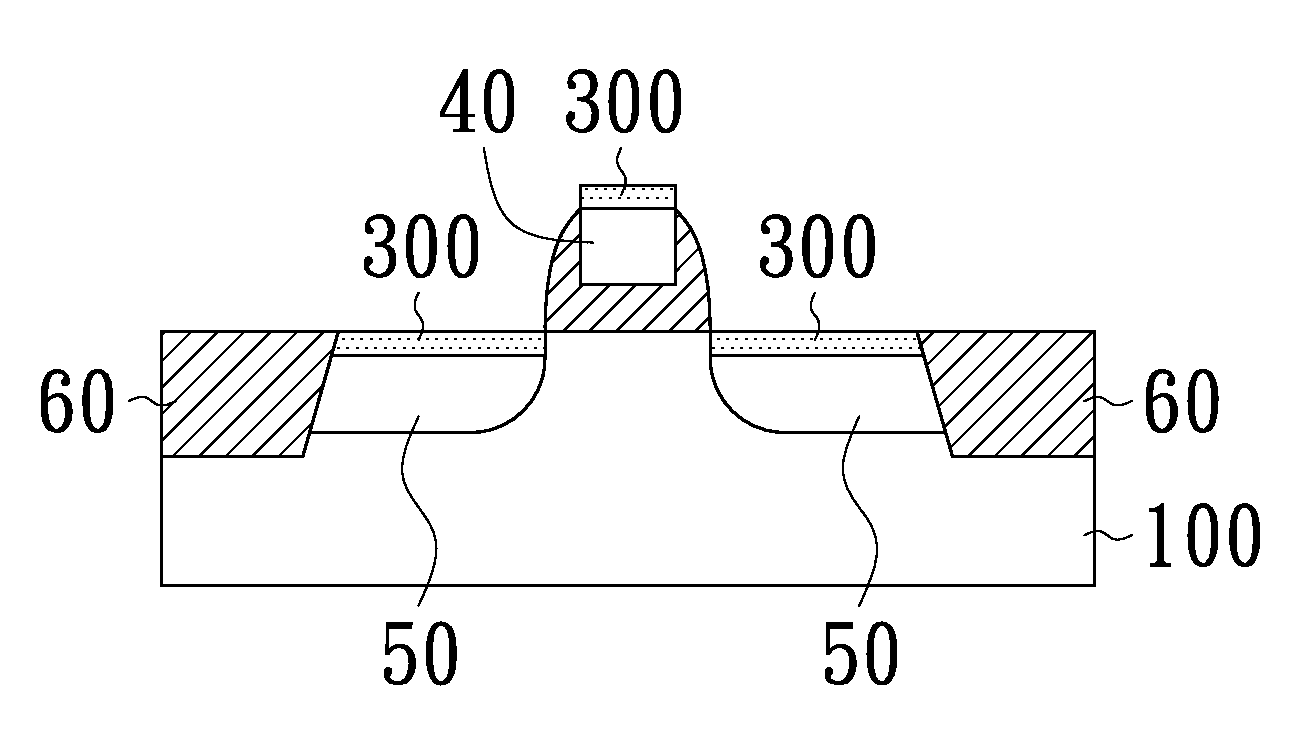

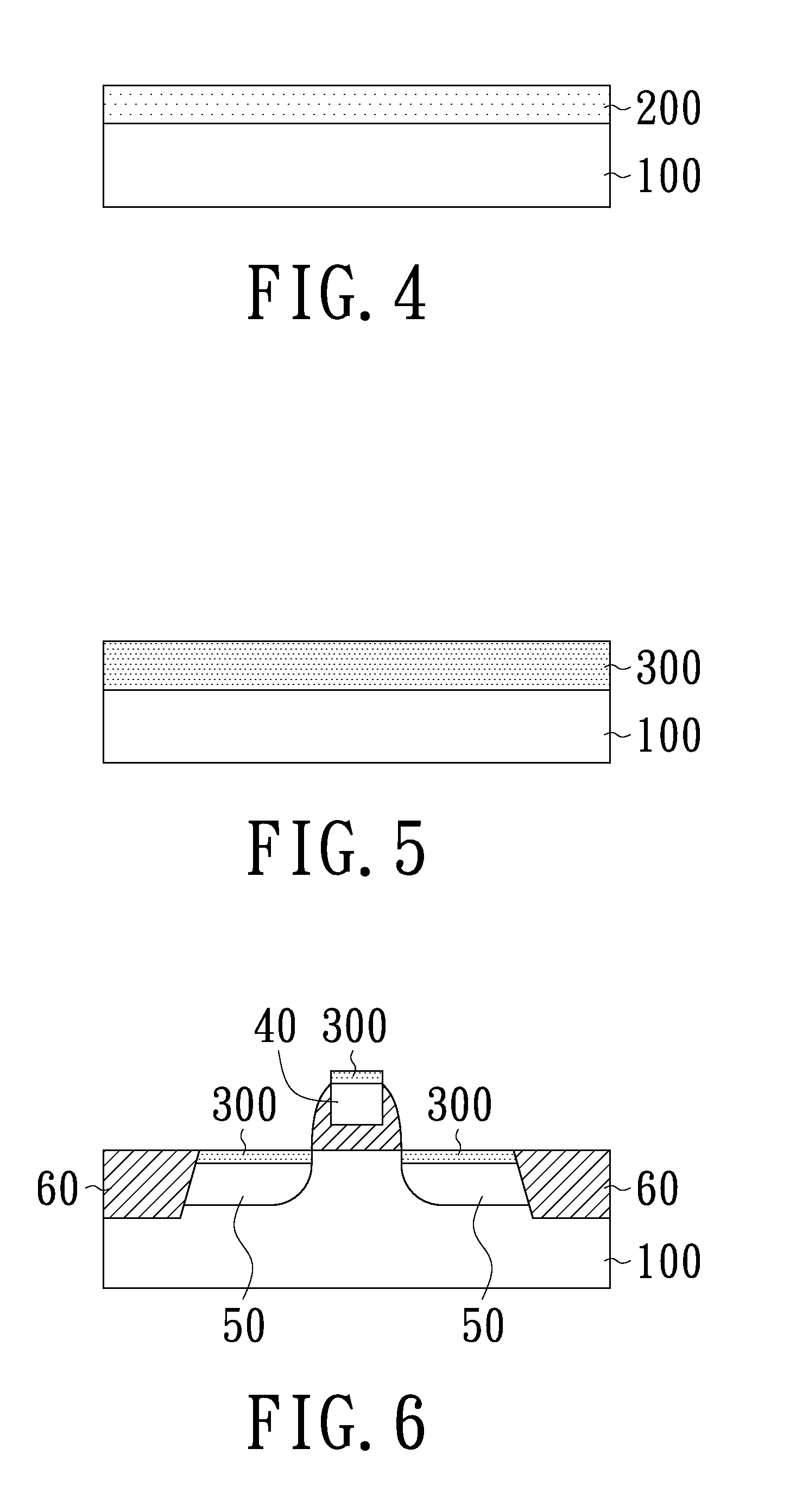

Method for fabricating semiconductor device

InactiveUS20140287561A1Improve efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceSemiconductor

A method for fabricating a semiconductor device is disclosed in the present invention. The abovementioned method comprises the following steps. Firstly, a gate is formed on a substrate. A gate insulating layer is then formed on the gate, and further an active layer is disposed on the gate insulating layer, wherein the active layer is composed of a microwave absorbing material. Source / drain is defined on the active layer to form the semiconductor device, and a microwave annealing process is finally performed thereon.

Owner:NAT CHIAO TUNG UNIV

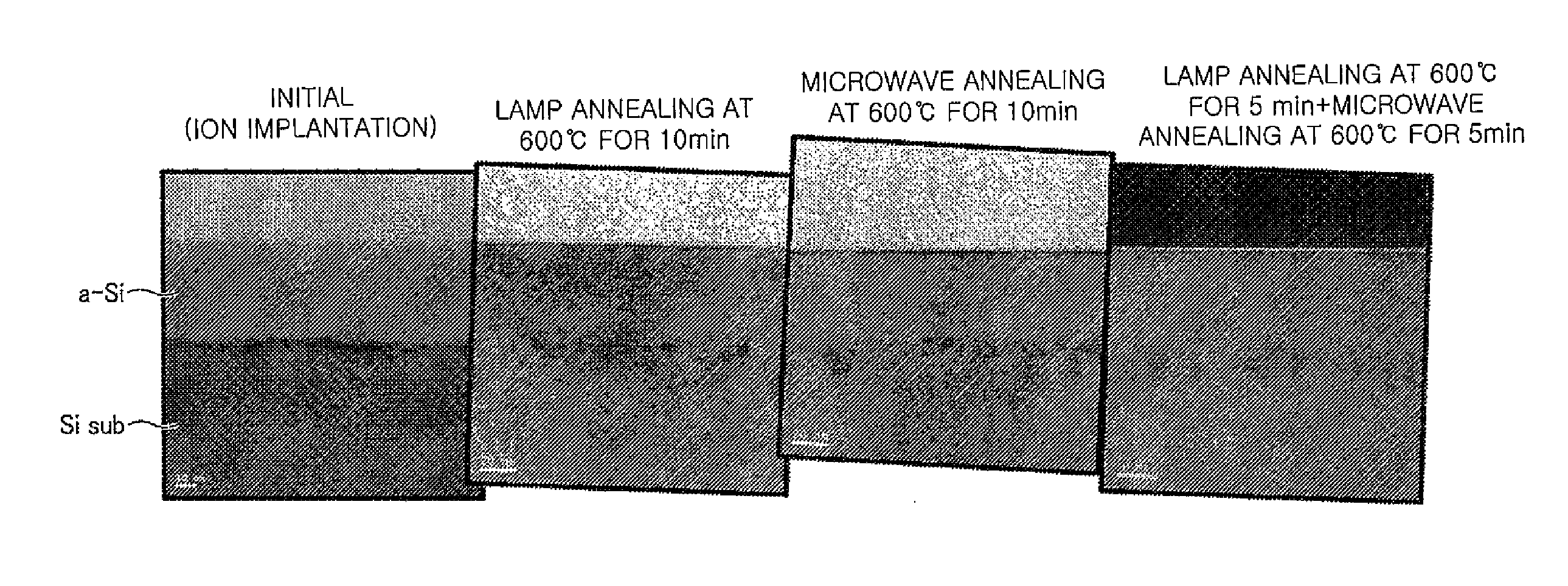

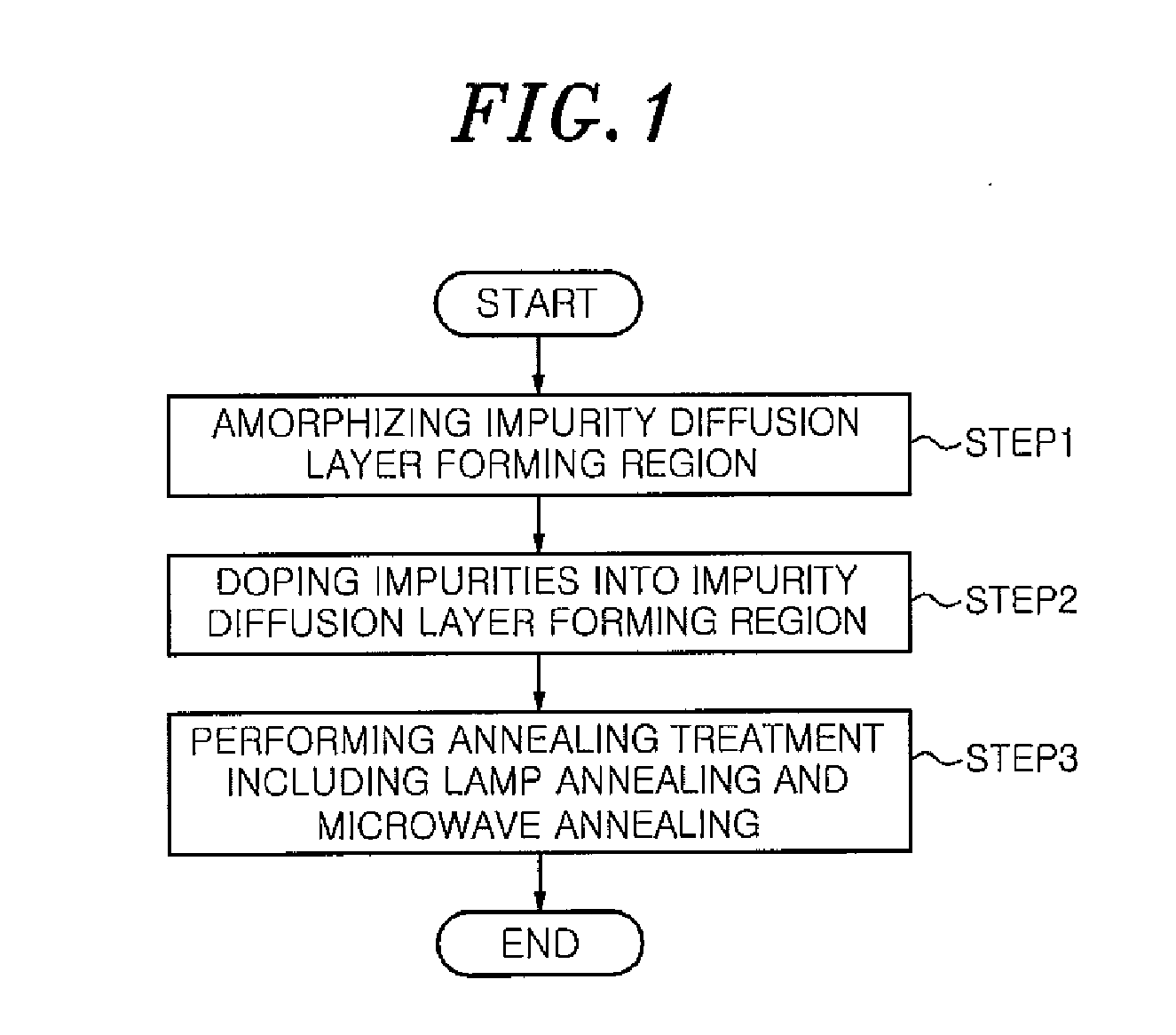

Method for manufacturing semiconductor device and annealing method

InactiveUS20150132930A1Fully removedSemiconductor/solid-state device manufacturingPower semiconductor deviceImpurity diffusion

A semiconductor device manufacturing method includes: amorphizing the impurity diffusion layer formation region; doping the impurity diffusion layer formation region of the semiconductor substrate with impurities; and performing an annealing treatment including lamp annealing in which a heating lamp is used and microwave annealing in which microwaves are irradiated, on the semiconductor substrate doped with the impurities, for activating the impurities. In addition to activation of the impurity, re-crystallization and removing of crystal defects also take place in the annealing treatment.

Owner:TOKYO ELECTRON LTD

Method for low-temperature preparation of two-dimensional flexible ion-sensitive field effect transistor

InactiveCN107238648AImprove interface propertiesShort preparation cycleMaterial analysis by electric/magnetic meansNanotechnologyNano structuringManufacturing technology

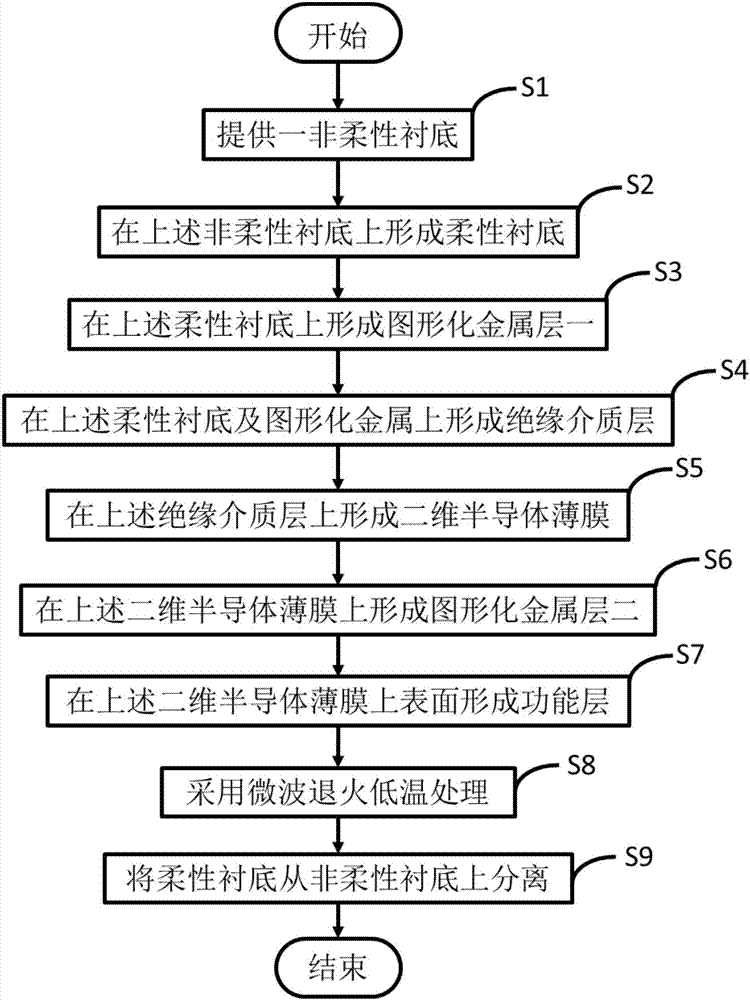

The invention belongs to the technical field of manufacturing of electrochemical sensor devices and particularly discloses a method for low-temperature preparation of a two-dimensional flexible ion-sensitive field effect transistor. The method includes: taking a flexible material as a substrate, depositing a graphic metal layer on the substrate to serve as a back electrode, growing an insulating oxide layer on the back electrode, and transferring a two-dimensional semiconductor film on the insulating medium layer to serve as a conductive channel of a device; forming graphic metal layers on the two-dimensional semiconductor film to serve as source and drain regions of the device; depositing a functional layer material above a channel area. By a microwave annealing process for low-temperature treatment, on the one hand, interface characteristics of layers of the device can be improved so as to eliminate delaying and drifting caused by interface defects; on the other hand, by the aid of the microwave absorption function of the functional layer material and a nano-structure functional layer at an interface of the two-dimensional semiconductor film, applicability to sensing detection in different scenes can be realized. The microwave annealing process has advantages of quickness, low thermal budget, short manufacturing period, low cost and the like.

Owner:FUDAN UNIV

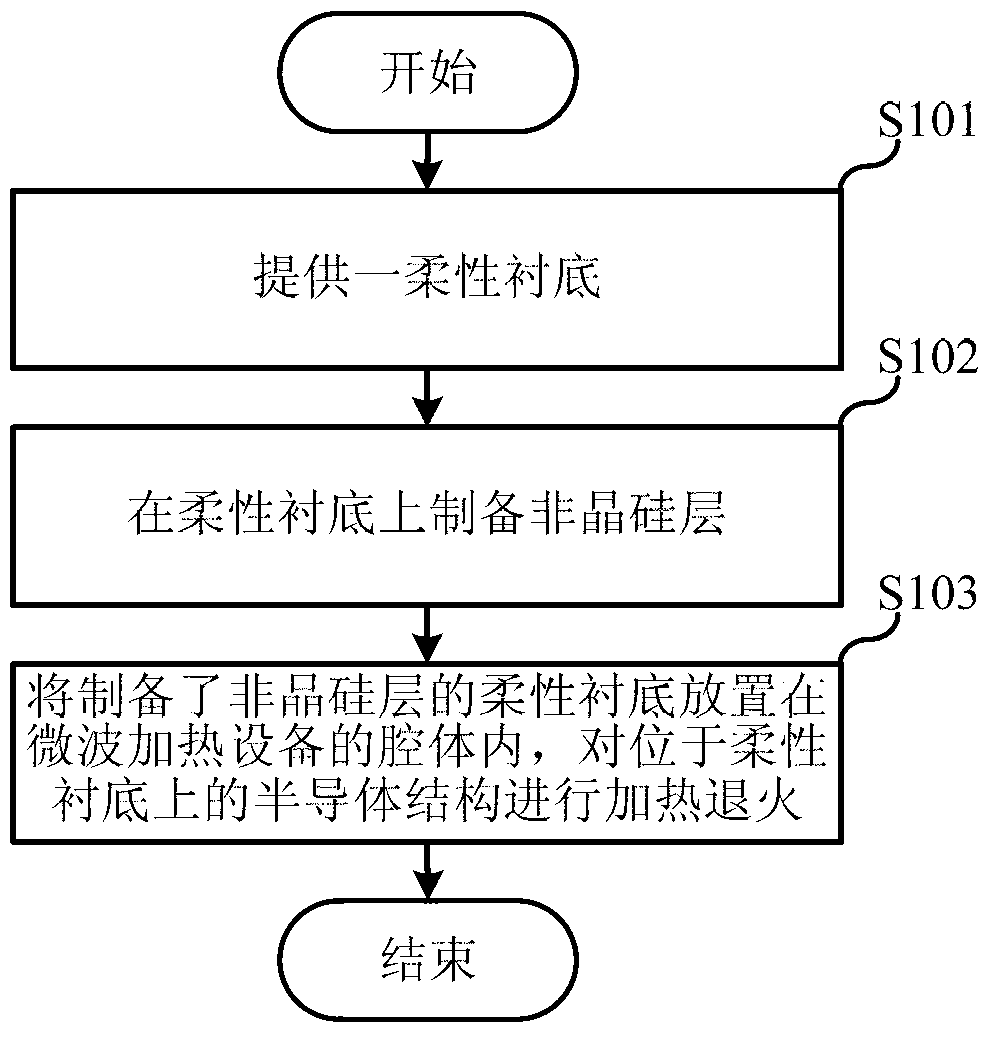

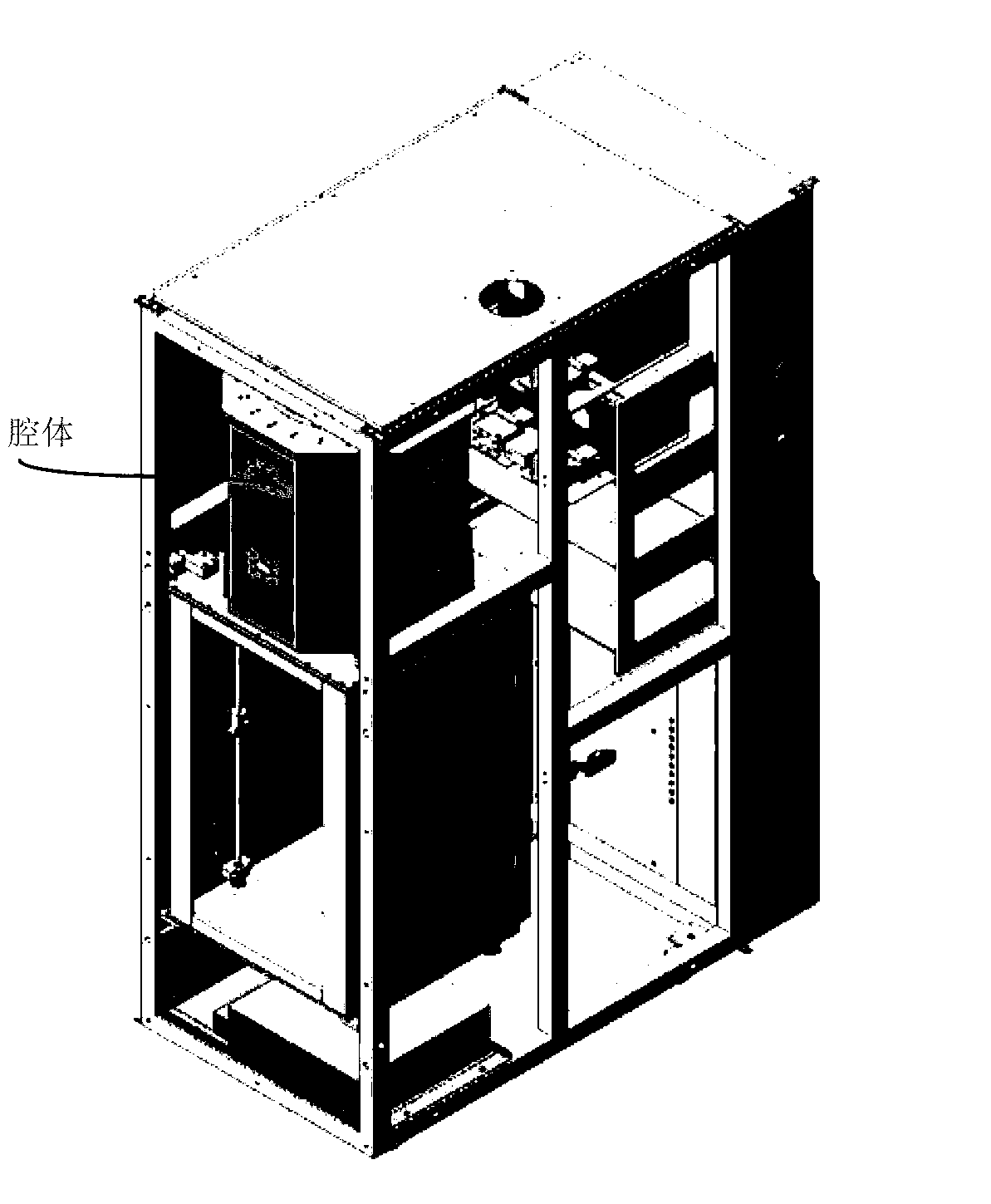

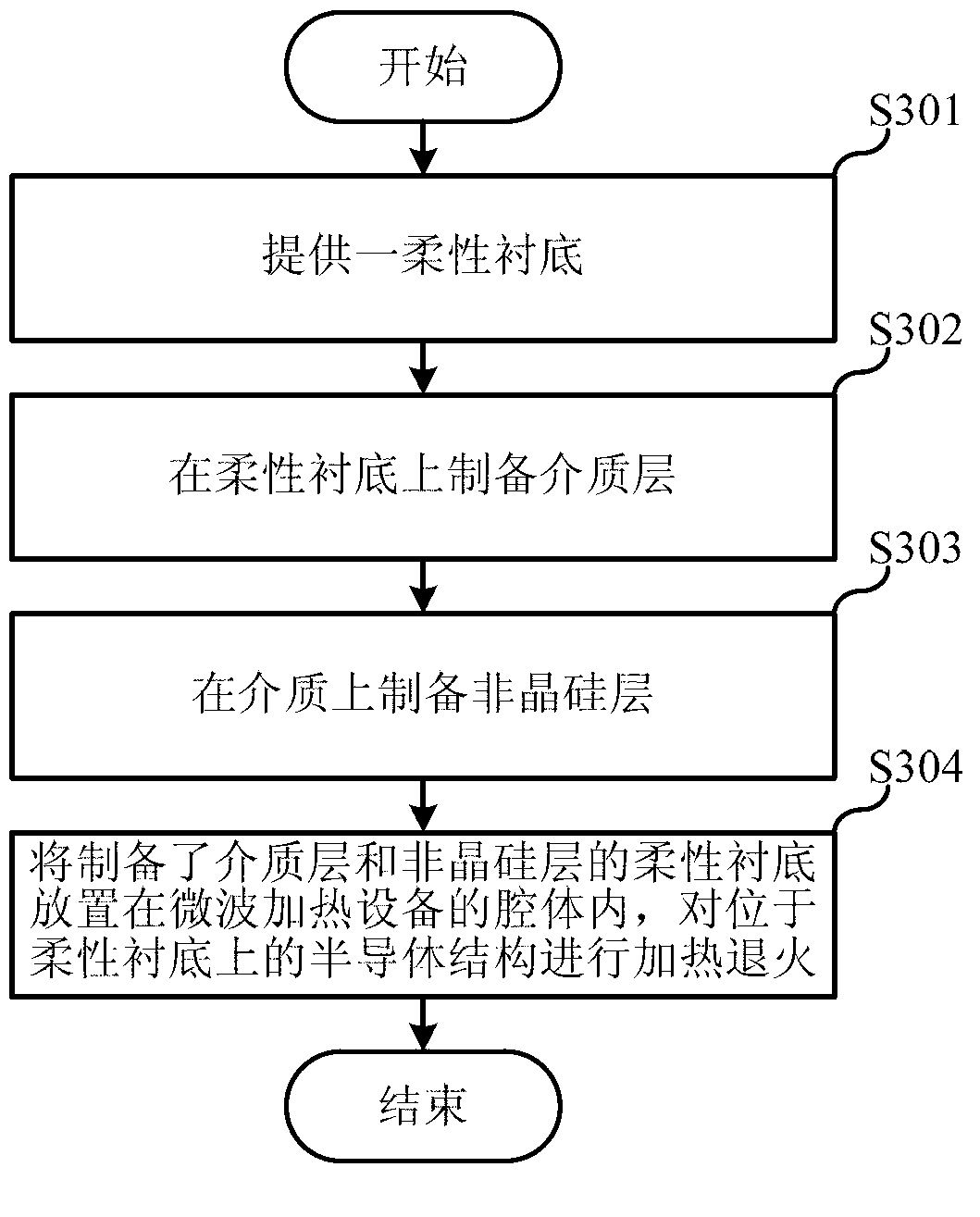

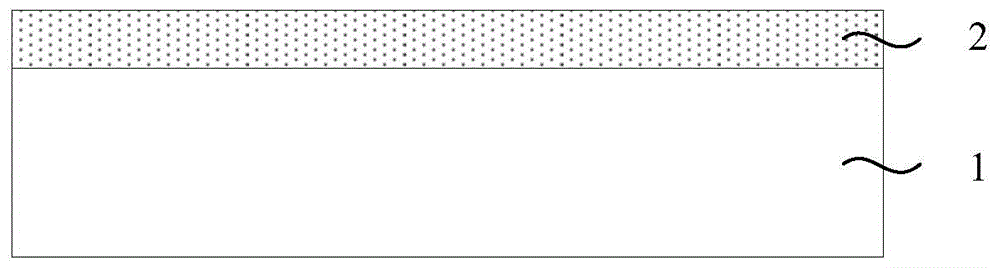

Metal or semiconductor structure on flexible substrate and annealing method of metal or semiconductor

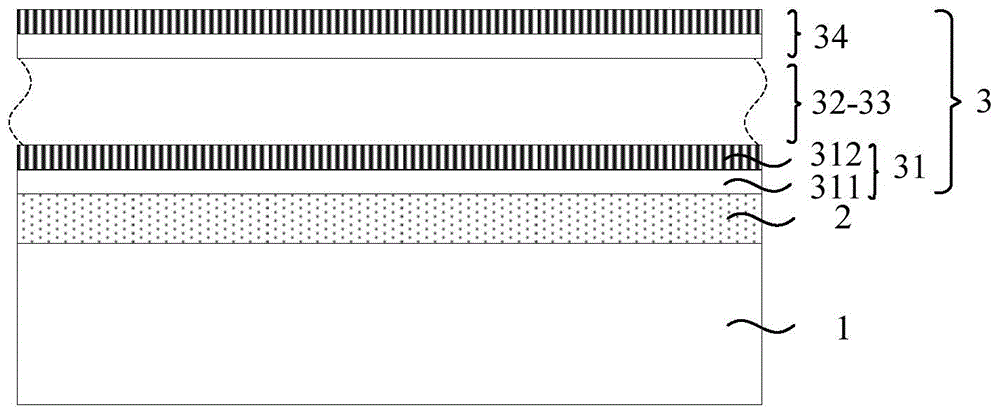

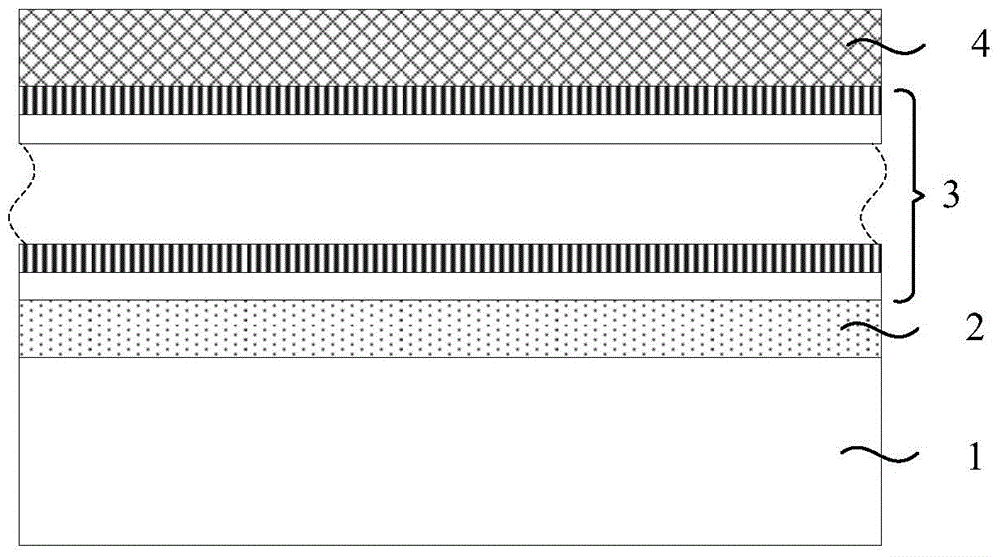

ActiveCN103021821AHigh heating energy consumption efficiencyHeating evenlySemiconductor/solid-state device manufacturingSemiconductor structureAmorphous silicon

The invention relates to the technical field of a semiconductor technology, and discloses a metal or semiconductor structure on a flexible substrate and an annealing method of the metal or semiconductor structure. According to the annealing method, the metal or semiconductor structure on the flexible substrate is annealed in a microwave heating manner; as microwave heating has the characteristic of selective heating on a material, when the metal or semiconductor structure on the flexible substrate is annealed, an amorphous silicon layer or a meta layer can be selectively heated, the flexible substrate does not absorb or basically does not absorb microwave energy, and therefore, the flexible substrate is not heated to a very high temperature during microwave annealing, thus the flexible substrate is prevented from being damaged; and the microwave heating can ensure that the interior and the exterior of the heated material are simultaneously heated, and the heating is uniform. Thus, according to the method, the metal or semiconductor structure on the flexible substrate can be annealed, the heating is uniform, and the efficiency of heating energy consumption is high.

Owner:FUDAN UNIV

Method for fabricating variable resistance memory device

InactiveUS20120289020A1Reduce processing timeImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingImpuritySemiconductor

A method for fabricating a variable resistance memory device includes forming a semiconductor pattern doped with impurities, forming a resistor over the semiconductor pattern, and forming a diode by performing microwave annealing to activate the impurities in the semiconductor pattern.

Owner:SK HYNIX INC

Method for forming nickel silicide with microwave annealing

InactiveCN102446730AHigh activityFacilitate rearrangementSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceSalicide

The invention discloses a method for forming nickel silicide with microwave annealing. The method comprises the following steps of: pre-cleaning the surface of exposed silicon for removing natural oxide; depositing nickel or nickel alloy and coating a layer of barrier layer on the surface of the nickel or nickel alloy; utilizing microwave radiation so that a part of the nickel or nickel alloy is reacted with the silicon to form high-resistance one-silication two-nickel in the process of heating a wafer to a first temperature at the same time; removing the barrier layer of the surface of the nickel or nickel alloy and unreacted nickel or nickel alloy; and utilizing microwave radiation so that the high-resistance one-silication two-nickel is changed to low-resistance nickle silicide in the process of heating the wafer to a second temperature at the same time. In the method, the surface of a silicon wafer is radiated by utilizing the microwave during heating at the same time, therefore, the activity of atomic motion is improved, and atomic realignment is promoted. The first temperature for heating is reduced so that the first step of diffusion of nickel is limited. The activity of the atomic motion is improved on the basis of the second temperature, therefore, the atomic realignment is promoted, the uniformity of the nickle silicide is helped to be improved, and the performance of devices is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

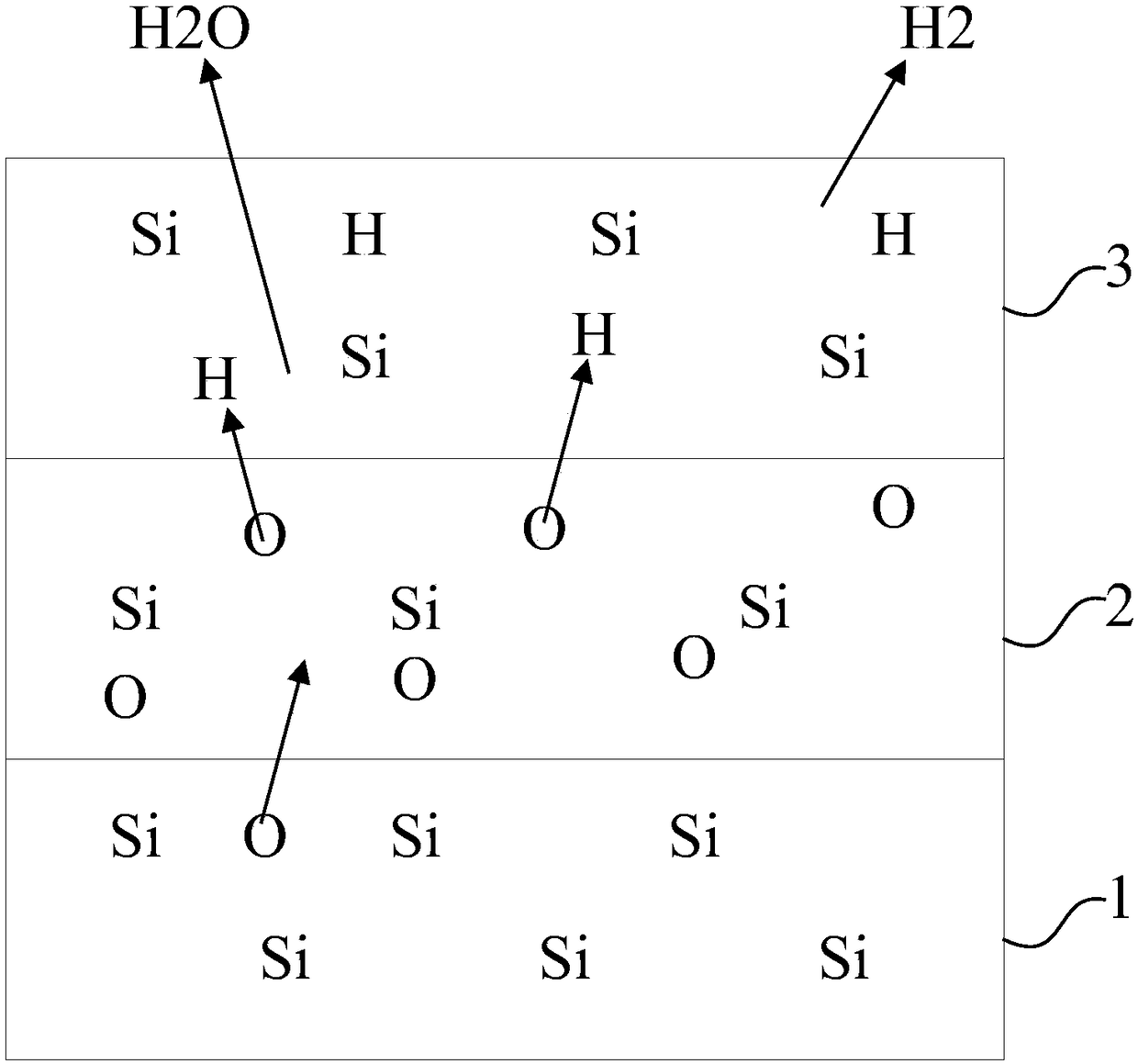

Method of preparing GOI at low temperature by microwave annealing technology

InactiveCN105428301AQuality improvementIncrease local temperatureSemiconductor/solid-state device manufacturingOptoelectronicsIon implantation

The invention provides a method of preparing GOI at low temperature by a microwave annealing technology. The method at least includes the following steps: providing a substrate and sequentially forming a doped layer and a first Ge layer on the substrate through an epitaxial mode; conducting ion implantation to enable ions to be implanted into the bottom surface of the doped layer below a preset depth; and providing a substrate with an insulating layer on the surface, making the substrate bond with the first Ge layer to form a bonding pad, conducting microwave annealing so that doped layer adsorption ions form micro-cracks and are separated from the bottom surface, and finally obtaining Germanium On Insulator. GOI is prepared through adsorption, peeling and bonding of the doped layer. Microwave annealing is performed on the bonding pad, and during the microwave annealing process, the local temperature of an interface between the doped layer and the substrate is high to cause peeling while the overall temperature of the bonding pad is low. Therefore, doped ions are not liable to be diffused in the first Ge layer, and the low temperature will not have an adverse influence on the first Ge layer and other layers. In this way, preparation of high-quality GOI is facilitated.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Preparation method of field effect transistor

InactiveCN102104006AReduce the impactTransistorSemiconductor/solid-state device manufacturingEngineeringField-effect transistor

The invention provides a preparation method of a field effect transistor, comprising the following steps of: supplying a first molded body substrate, forming a shallow groove by utilizing a photoetching and etching method, and growing to form a silicon dioxide shallow groove isolation structure in the shallow groove; depositing on the first molded body substrate and the silicon dioxide shallow groove isolation structure to form a high-K gate dielectric layer and a metal gate electrode layer; forming a grid electrode structure by utilizing a photoetching or corrosion process and the like; implanting second molded body foreign ions to form a source drain extension area; depositing an insulating layer to form a side wall attached to the edge of a grid electrode; implanting the second molded body foreign ions to form a source drain area of a second molded body field effect transistor and a PN (Performance Number) junction interface positioned between the source drain area and a silicon substrate; and carrying out microwave annealing to activate the implanted ions. The novel process of the field effect transistor can activate the impurities in the source drain area at lower temperature and reduce the influence of source drain annealing on a high-K gate dielectric / metal gate electrode.

Owner:FUDAN UNIV

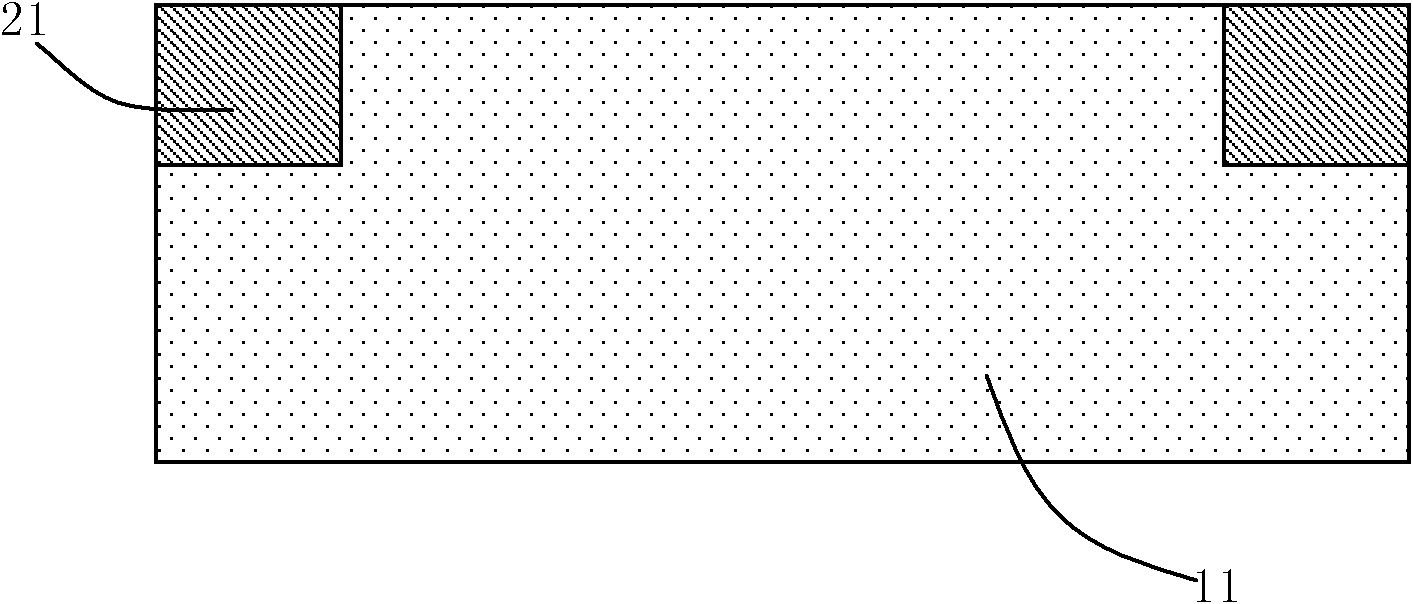

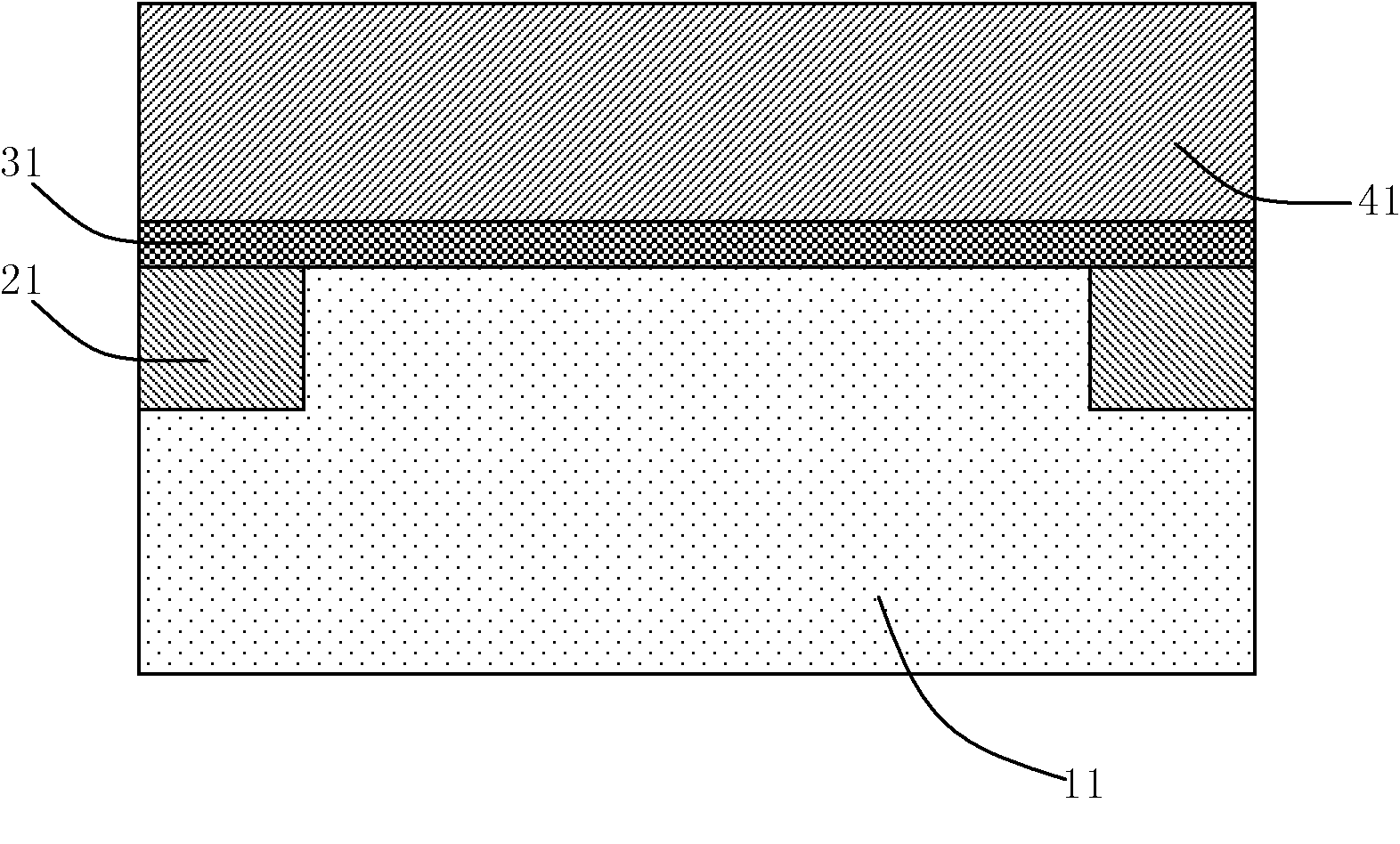

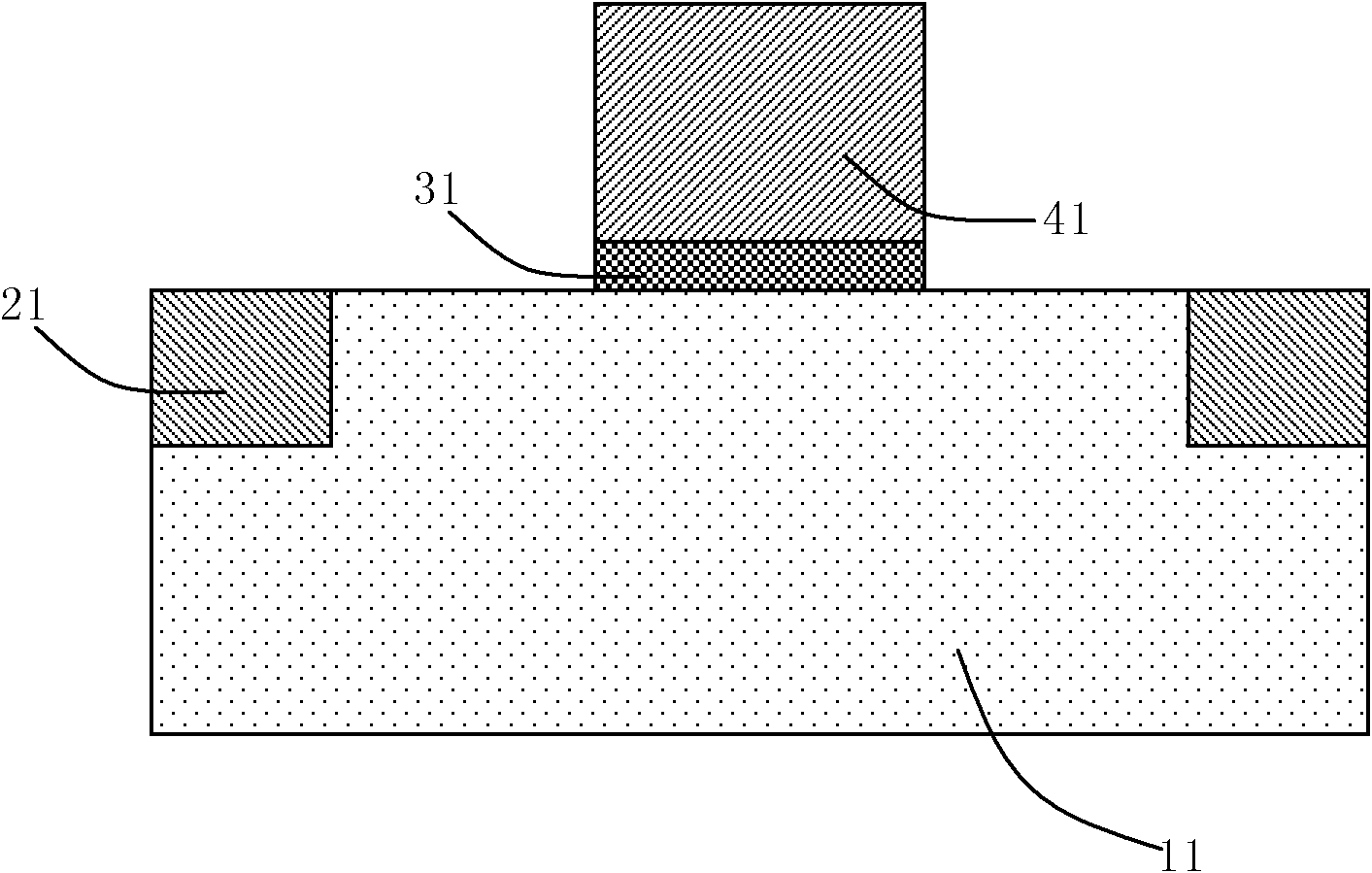

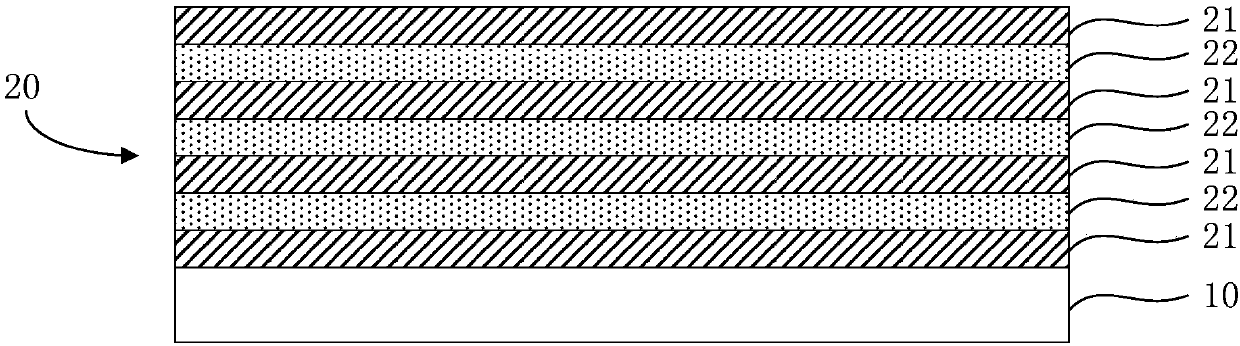

Method of preparing material-over-insulator through adsorption and peeling

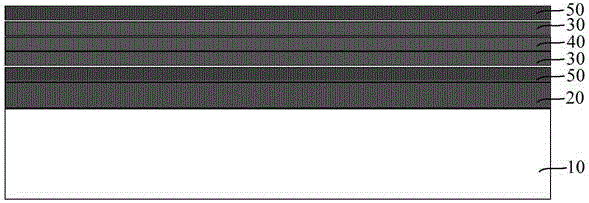

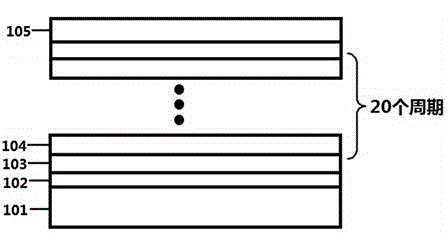

ActiveCN105428300AReduce spreadImprove adsorption capacitySemiconductor/solid-state device manufacturingNon dopedSingle crystal

The invention provides a method of preparing a material-over-insulator through adsorption and peeling. The method comprises the following steps: providing a substrate, and sequentially forming a doped single crystalline layer, a superlattice structural layer and a to-be-transferred layer on the substrate through an epitaxial mode; conducting ion implantation to enable ions to be implanted into the bottom surface of the doped single crystalline layer below a preset depth; and providing a substrate with an insulating layer on the surface, making the substrate bond with the to-be-transferred layer to form a bonding pad, conducting microwave annealing so that doped layer adsorption ions form micro-cracks and are separated from the bottom surface, and finally obtaining a material-over-insulator. The material-over-insulator is prepared through adsorption, peeling and bonding of a doped layer. The doped layer is formed by laminating a doped single crystalline layer and a non-doped or low-doped superlattice structural layer. The superlattice structural layer enhances the ion adsorption capability of the doped single crystalline layer to enable adsorption and peeling of the doped single crystalline layer with low-doped concentration, and the low-doped concentration enables the probability of diffusion of doped ions into the to-be-transferred layer to be reduced. In this way, the quality of the to-be-transferred layer is guaranteed.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

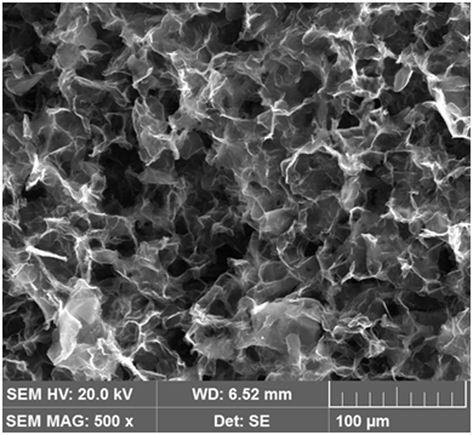

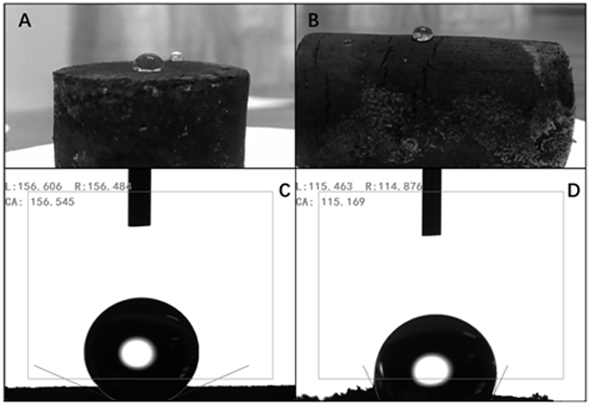

Preparation method and application of hydrophobic graphene aerogel

ActiveCN111994901AImprove structural strengthThe synthesis process is clearGas treatmentOther chemical processesTrimethylsilyl chlorideCross linker

The invention discloses a preparation method and application of hydrophobic graphene aerogel. The invention belongs to the field of graphene aerogel. The problems that an existing hydrophobic grapheneaerogel material is high in preparation cost, poor in structural strength and the like can be solved. A hydrothermal reaction method is adopted, a saccharide cross-linking agent which is low in priceand easy to obtain is adopted, an organic auxiliary agent and efficient and cheap modifiers such as trimethylchlorosilane are added, and the hydrophobic and oleophylic graphene aerogel material is obtained through a normal-pressure drying method and a microwave annealing method. It can be seen through scanning electron microscope imaging that the material is structurally a thin-wall porous material formed by three-dimensional crosslinking of thin-layer graphene. The material is definite in synthesis process, short in synthesis time, low in cost, free of heavy metal and organic pollutants, high in structural strength and capable of bearing the heavy pressure which is more than one hundred times of the mass of the material. The material has super-hydrophobicity, and the contact angle measured by experiments is as high as 150 degrees or above. The hydrophobic graphene aerogel can be used in the fields of protection and removal of volatile organic compounds in air and water, and other oil-water separation applications.

Owner:SHANXI DATONG UNIV +1

Microwave rapid thermal processing of electrochemical devices

InactiveUS9136569B2Easy to manufactureHigh crystallinityFinal product manufactureVacuum evaporation coatingEnergy absorptionSystem configuration

Owner:APPLIED MATERIALS INC

Method for forming thin metal compound film and semiconductor structure with thin metal compound film

InactiveUS20140027823A1Improve semiconductor device performanceReduce sheet resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesThin metalSemiconductor structure

A method for forming a metal compound film includes: providing a substrate structure; forming a first metal layer on the substrate structure; performing a first microwave annealing process to conduct a reaction between the first metal layer and the substrate structure so as to form a first polycrystalline film of a metal compound; and performing a second microwave annealing process to transform the first polycrystalline film into a second polycrystalline film of the metal compound with an enlarged grain size, wherein a microwave power output used in the second microwave annealing process is higher than that used in the first microwave annealing process.

Owner:NAT APPLIED RES LAB

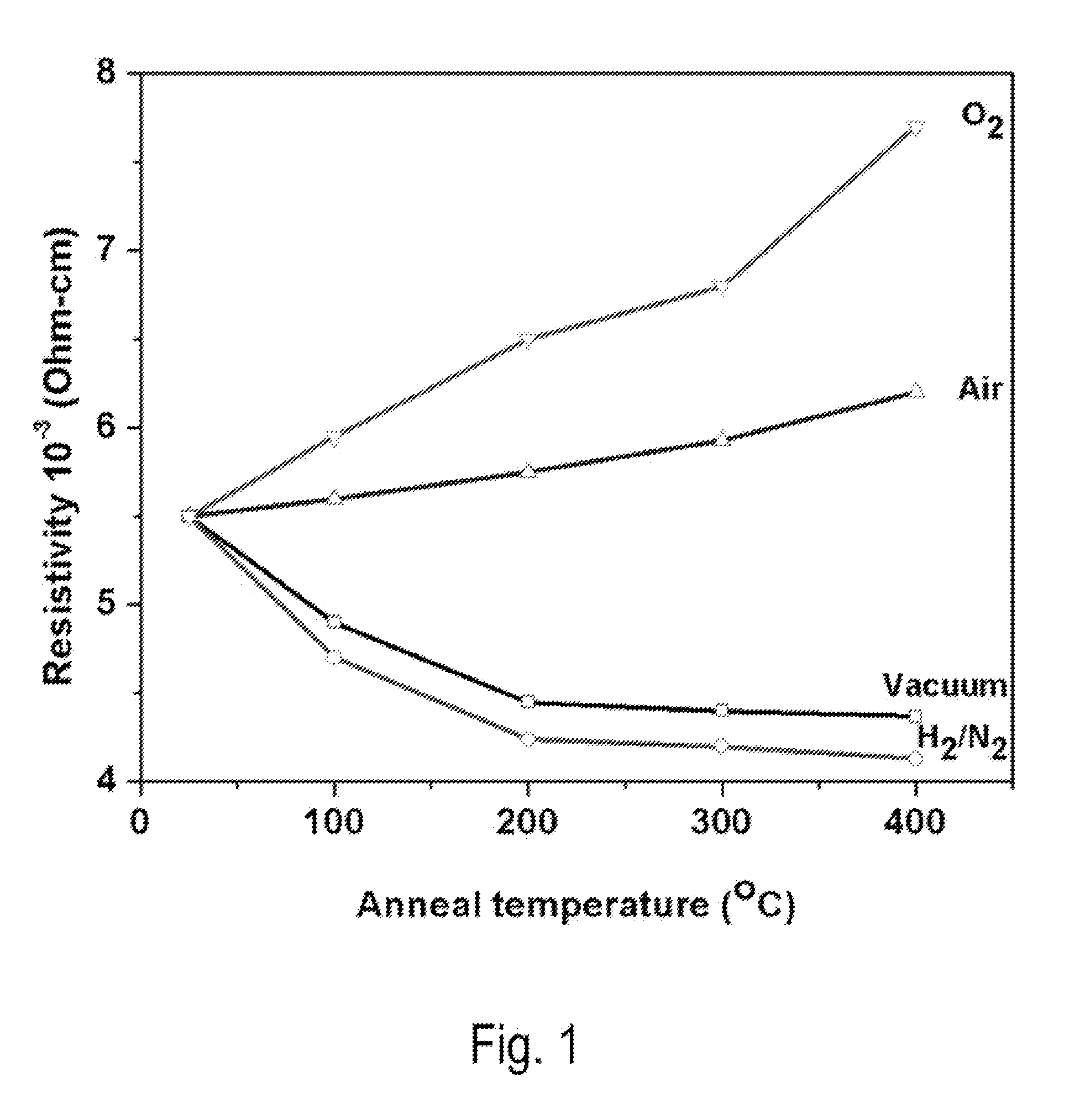

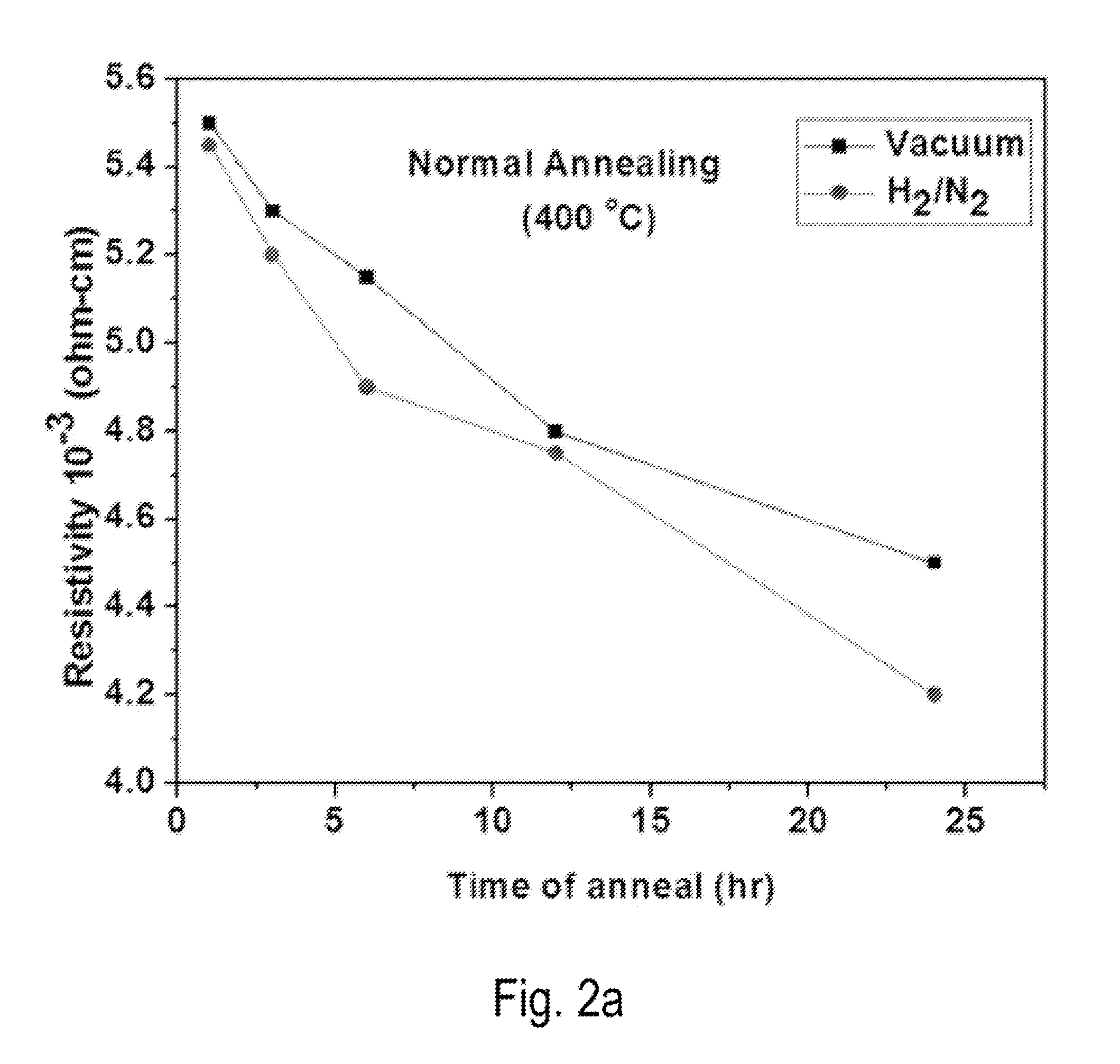

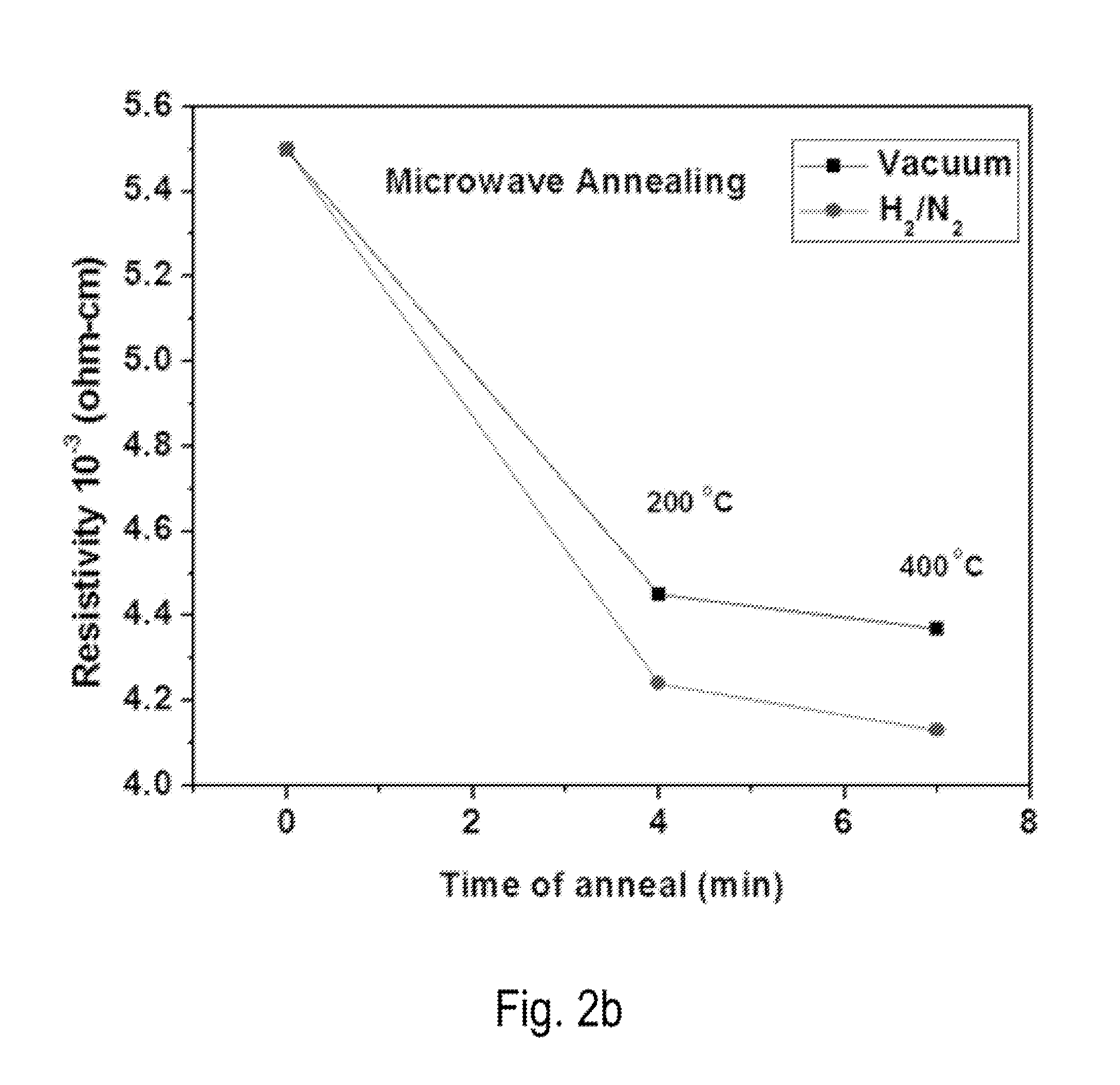

Microwave-Annealed Indium Gallium Zinc Oxide Films and Methods of Making the Same

ActiveUS20160027955A1Semiconductor/solid-state device testing/measurementFinal product manufactureIndium gallium zinc oxideOptoelectronics

Owner:ARIZONA STATE UNIVERSITY

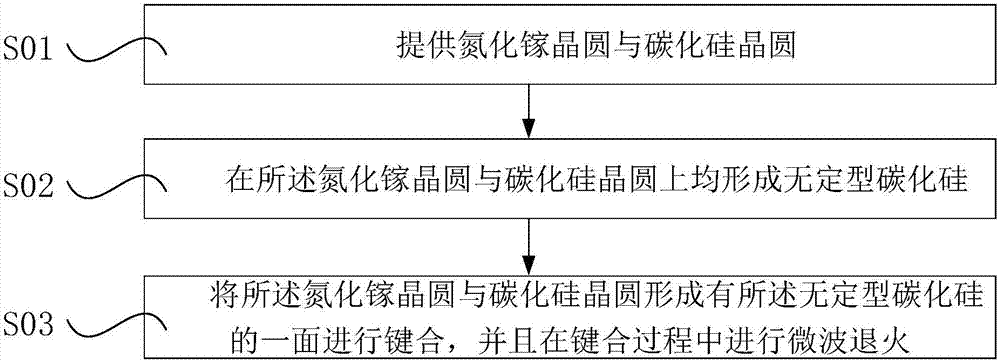

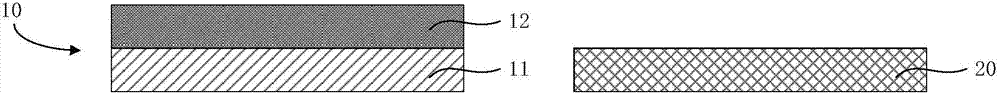

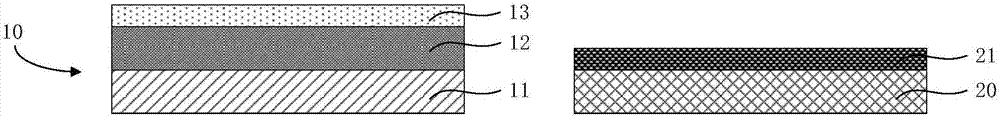

Wafer bonding method and bonding device thereof

ActiveCN107958839AImprove reliabilityImprove bonding efficiencySemiconductor/solid-state device manufacturingAmorphous siliconCarbide

The invention provides a wafer bonding method and a bonding device thereof. The wafer bonding method comprises the steps of: providing a gallium nitride wafer and a silicon carbide wafer; forming amorphous silicon carbide on the gallium nitride wafer and the silicon carbide wafer; and bonding the surfaces, on which the amorphous silicon carbide is formed, of the gallium nitride wafer and the silicon carbide wafer, and performing microwave annealing during the bonding process. According to the wafer bonding method, the amorphous silicon carbide on the gallium nitride wafer and the silicon carbide wafer is converted into crystalline silicon carbide through microwave annealing, thus the gallium nitride wafer and the silicon carbide wafer are bonded, the bonding efficiency is improved, and thereliability of gallium-nitride-based semiconductor device is improved.

Owner:ZING SEMICON CORP

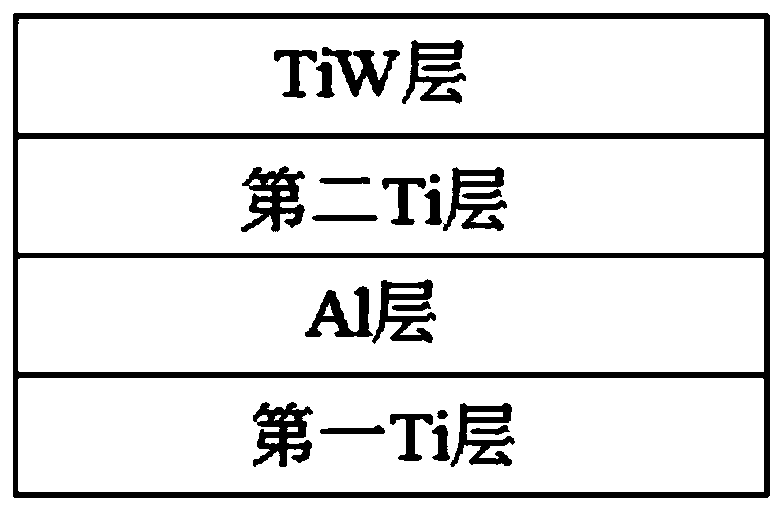

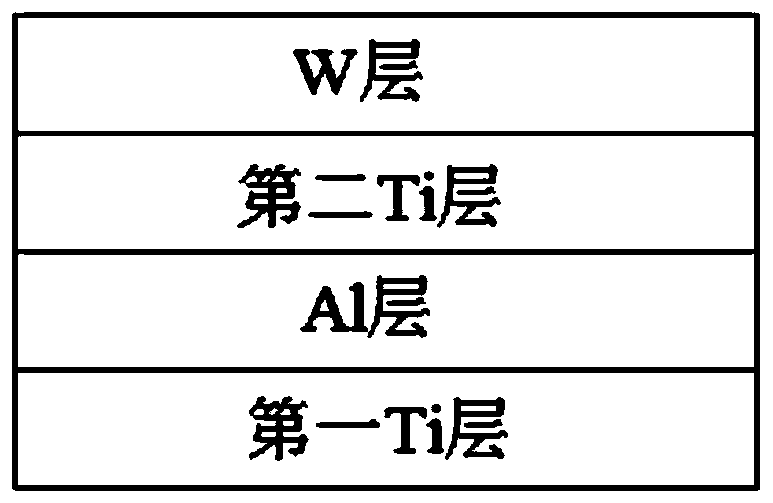

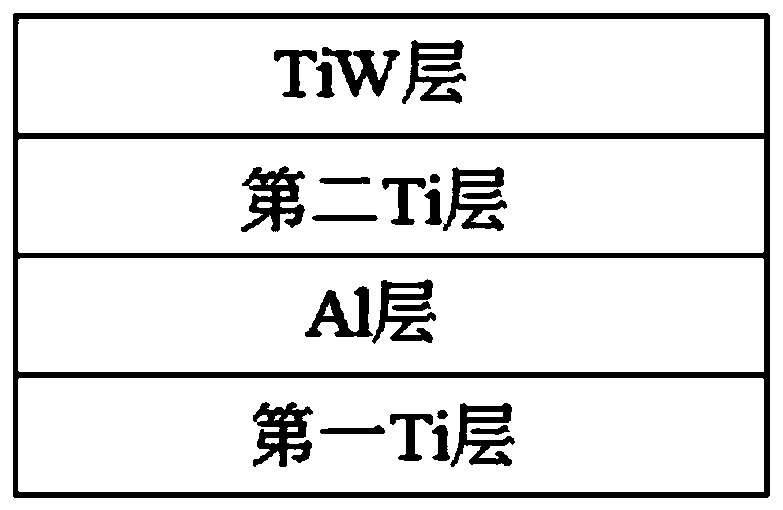

Ohmic contact electrode, HEMT device and preparation method

InactiveCN109712877AImprove contact uniformityReduce the formation temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactOptoelectronics

The invention provides an ohmic contact electrode, an HEMT device and a preparation method, and the preparation method comprises the following steps: S1, defining a source-drain ohmic contact window by photoetching; S2, etching an ohmic contact area of AlGaN to a certain thickness; S3, sequentially depositing metal layers in the source-drain region; S4, carrying out alloy annealing treatment by adopting a microwave radiation process after degumming and stripping to form the ohmic contact electrode provided by the invention. According to the preparation method of the ohmic contact electrode, the deposited metal layer is processed in a microwave annealing mode, the formation temperature of the GaN ohmic contact resistor can be reduced, the ohmic contact uniformity is improved, and the electrical parameters and the working reliability of a GaN power device are improved.

Owner:ZHANGJIAGANG EVER POWER SEMICON

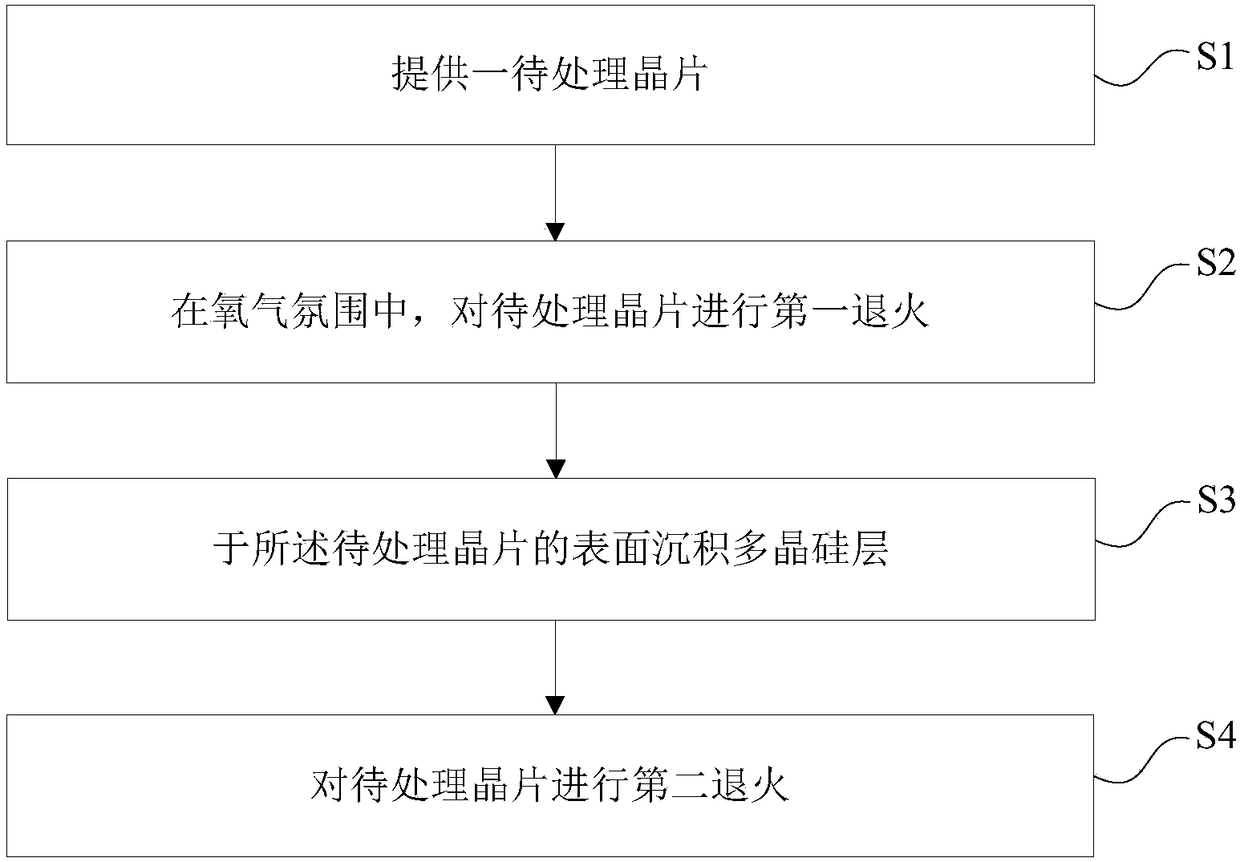

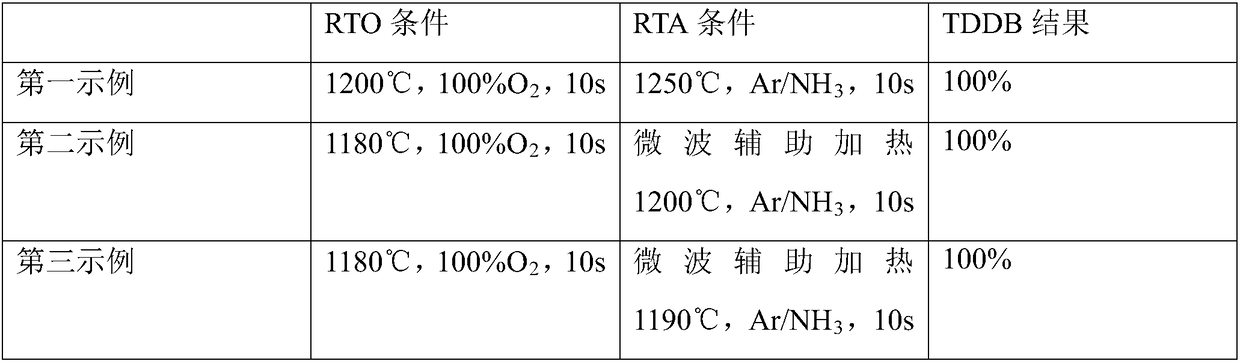

Wafer gettering method

ActiveCN108666215AReduce defectsAvoid warpingSemiconductor/solid-state device manufacturingWaferingMetallurgy

The present invention provides a wafer gettering method. The method comprises: performing a first annealing on a to-be-treated wafer, wherein the first annealing is performed under an oxygen atmosphere and a first temperature condition for a first time; depositing a polysilicon layer on a surface of the to-be-treated wafer; performing a second annealing on the to-be-treated wafer, wherein the second annealing is performed under an inert gas atmosphere and a second temperature condition for a second time which is greater than or equal to the first temperature. According to the wafer gettering method, the polysilicon layer can effectively adsorb oxygen atoms in the vacancies, thereby removing wafer defects; the two annealing processes can promote atom rearrangement and further eliminate defects in the to-be-treated wafer; the second annealing can uniformly heat the to-be-treated wafer in a short time by microwave annealing, thereby improving the activity of atomic motion and further improving the annealing efficiency; and the two annealings are performed at lower temperatures, which can avoid wafer warpage caused by high annealing temperature and improve wafer quality.

Owner:ZING SEMICON CORP

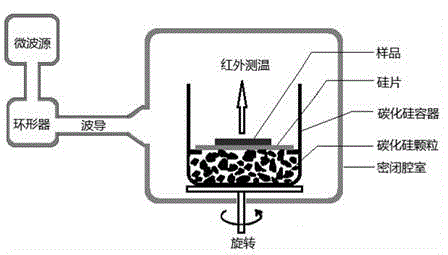

Microwave annealing process

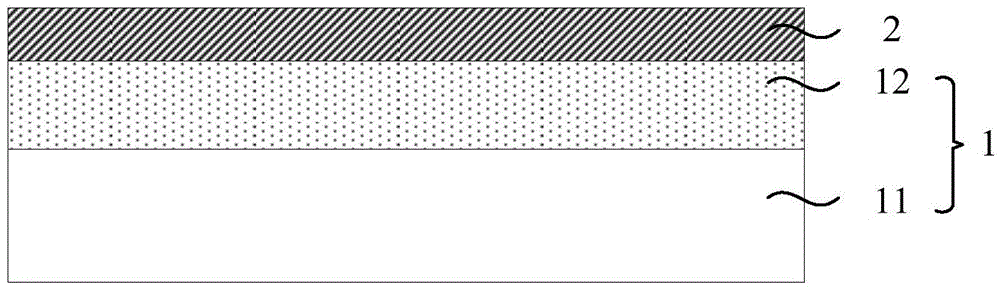

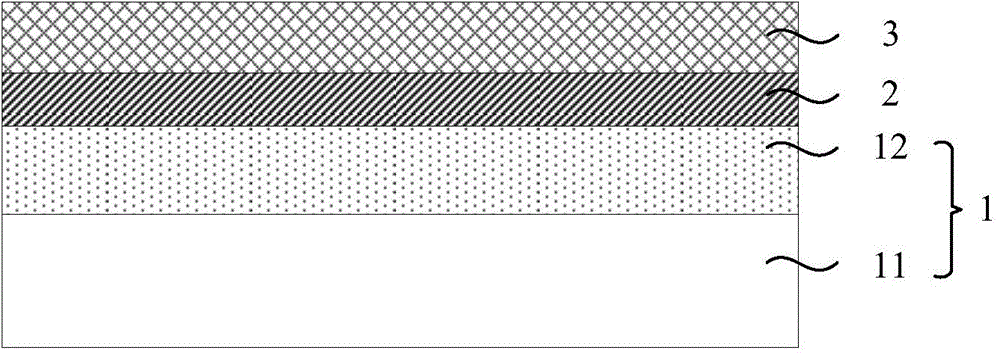

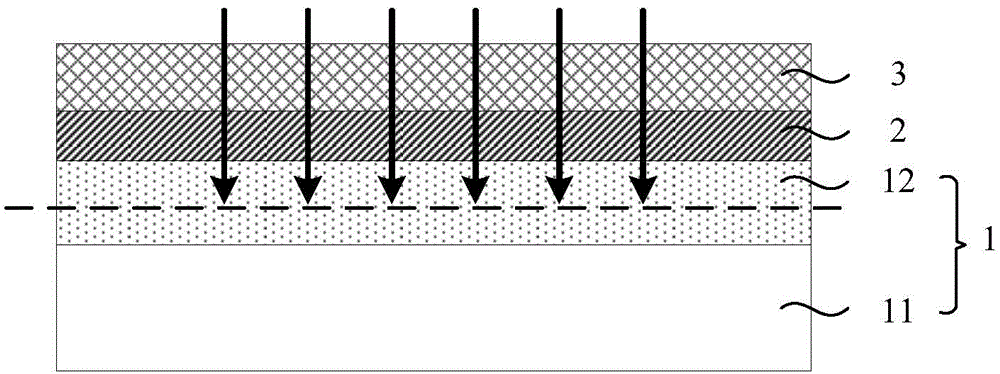

InactiveCN105047560AUniform heat conductionReduce the total massSemiconductor/solid-state device manufacturingHigh absorptionSemiconductor

The invention relates to the field of semiconductor manufacturing, and discloses a microwave annealing process. A uniform-covering high absorption layer is formed on a first surface and / or a second surface of a function layer. With the help of high microwave absorption by the high absorption layer, on one hand, uniform heat conduction on the function layer is ensured, and the problem of low non-contact efficiency is overcome; and on the other hand, as the high absorption layer is corresponding to the function layer, the high absorption layer has a tiny mass itself, and the consumed microwave energy is greatly reduced compared with former modes, the energy utilization efficiency is improved.

Owner:FUDAN UNIV

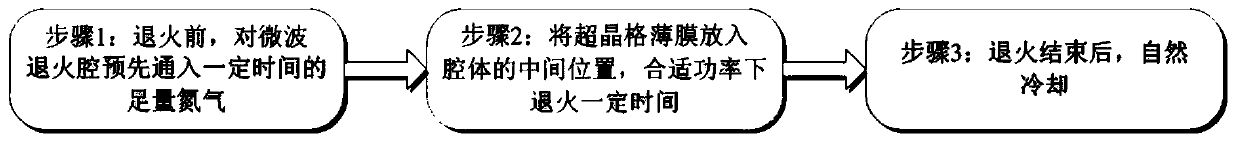

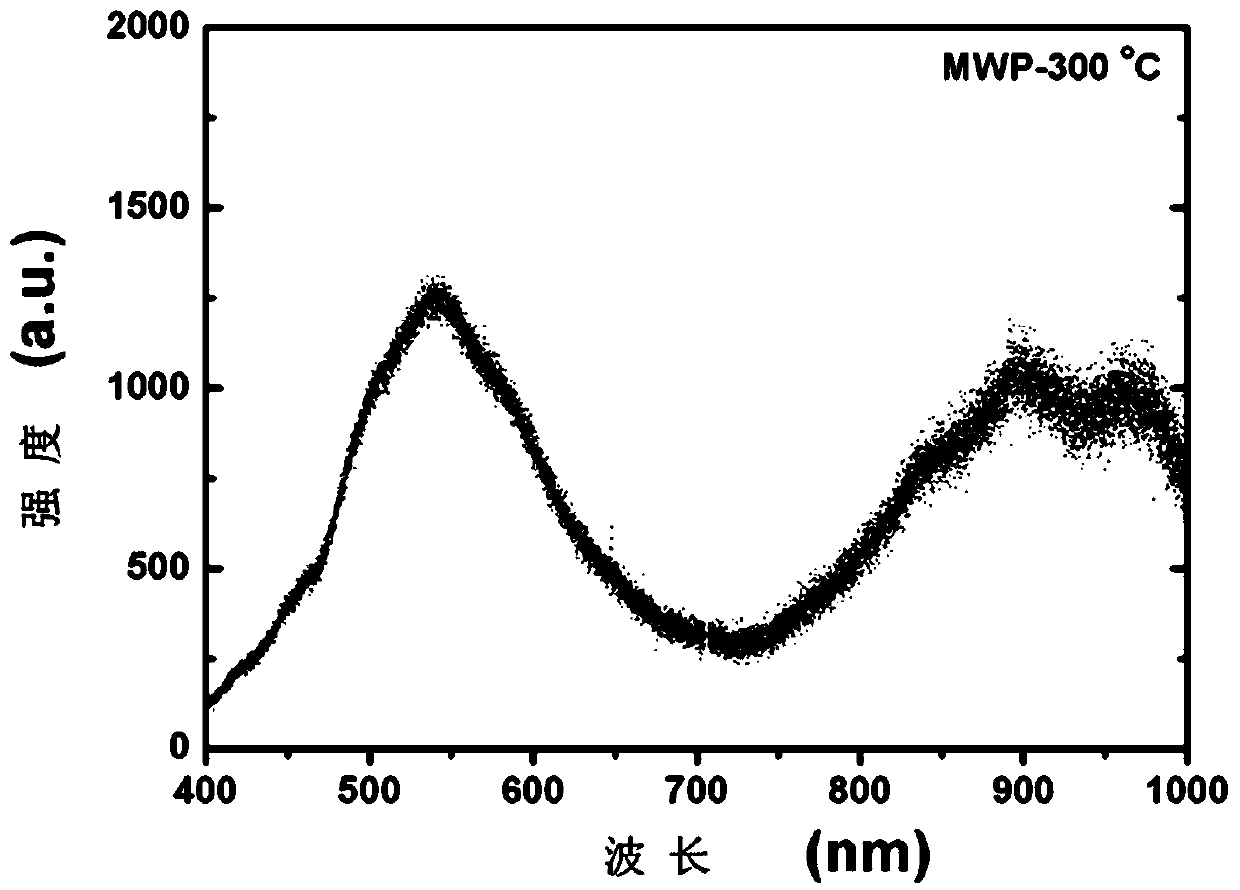

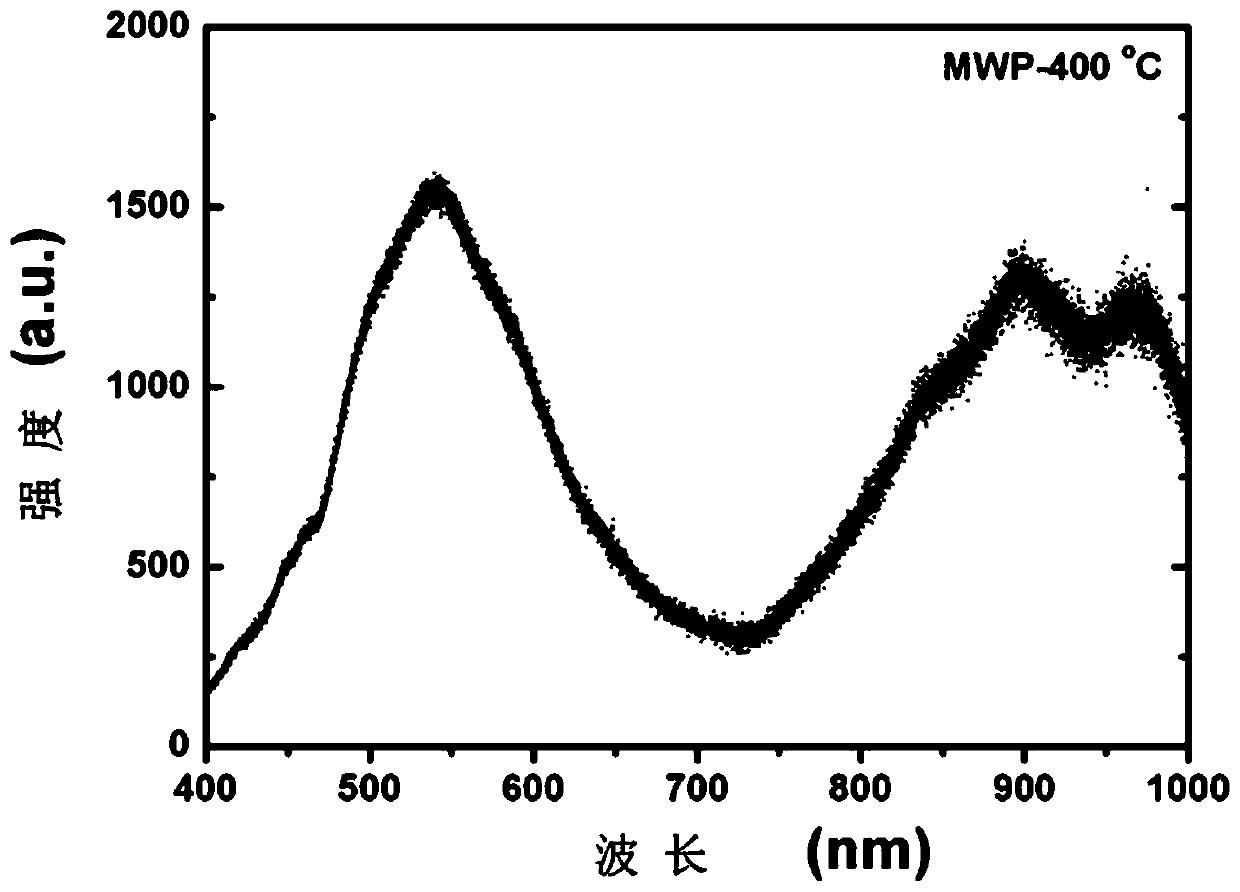

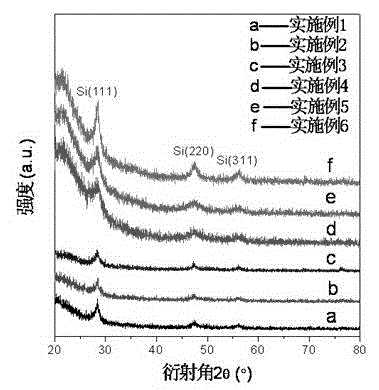

Low-temperature microwave annealing method for improving optical-electrical characteristic of silicon superlattice film

ActiveCN109742012ALow annealing temperatureLower thermal budgetFinal product manufactureSemiconductor/solid-state device manufacturingFree coolingRepeatability

The invention discloses a low-temperature microwave annealing method for improving the optical-electrical characteristic of a silicon superlattice film. The low-temperature microwave annealing methodcomprises the specific steps that 1, before annealing, inertia gas is introduced into a microwave annealing cavity in advance, so that a pure inertia atmosphere is formed in the cavity; 2, the inertiagas continues being introduced to serve as an annealing atmosphere, the silicon superlattice film is put into the middle of the microwave annealing cavity, the annealing power and the maximum temperature in the annealing process are set, the annealing time with the corresponding duration is set, and microwave annealing is started, wherein the maximum temperature in the annealing process is 300-500 DEG C; and 3, after microwave annealing and after natural cooling of the temperature in the cavity, the modified and optimized silicon superlattice film is obtained. The low-temperature microwave annealing method is high in reliability and repeatability, the finished product rate of the modified and optimized silicon superlattice film prepared through the low-temperature microwave annealing method is high, and the method with guiding significance is provided for low-temperature annealing of the silicon superlattice film.

Owner:FUDAN UNIV

Method for preparing silicon quantum dot films through microwave annealing

InactiveCN104952981AEasy to separateLower crystallization temperatureFinal product manufacturePhotovoltaic energy generationArgon atmosphereSolar cell

The invention relates to a method for preparing silicon quantum dot films through microwave annealing. Specifically, magnetron-sputtering-deposited silicon-rich silicide films are placed in a microwave annealing furnace for annealing at the lower temperature, and the uniform silicon quantum dot films are prepared. The method is good in controllability, high in repeatability, simple, effective and high in operability due to adoption of reliable magnetron co-sputtering and microwave annealing technologies. According to the main technical scheme, the method comprises steps as follows: firstly, magnetron co-sputtering is performed on Si targets and SiO2 (or Si3N4 or SiC) targets through Ar ions, sputtering power of all the targets is optimized, and silicon-rich silicide films are deposited on monocrystalline silicon and quartz substrates; then silicon quantum dots are formed through annealing treatment at the temperature of 700-900 DEG C in a nitrogen atmosphere or an argon atmosphere by the aid of microwave annealing equipment. Compared with traditional methods for growing silicon quantum dots through tube furnace annealing or rapid photo-thermal annealing, the method has the advantages that the annealing temperature is decreased, the process is simple and the cost is low. The method is applicable to the field of a new generation of high-efficiency solar cells.

Owner:YUNNAN NORMAL UNIV

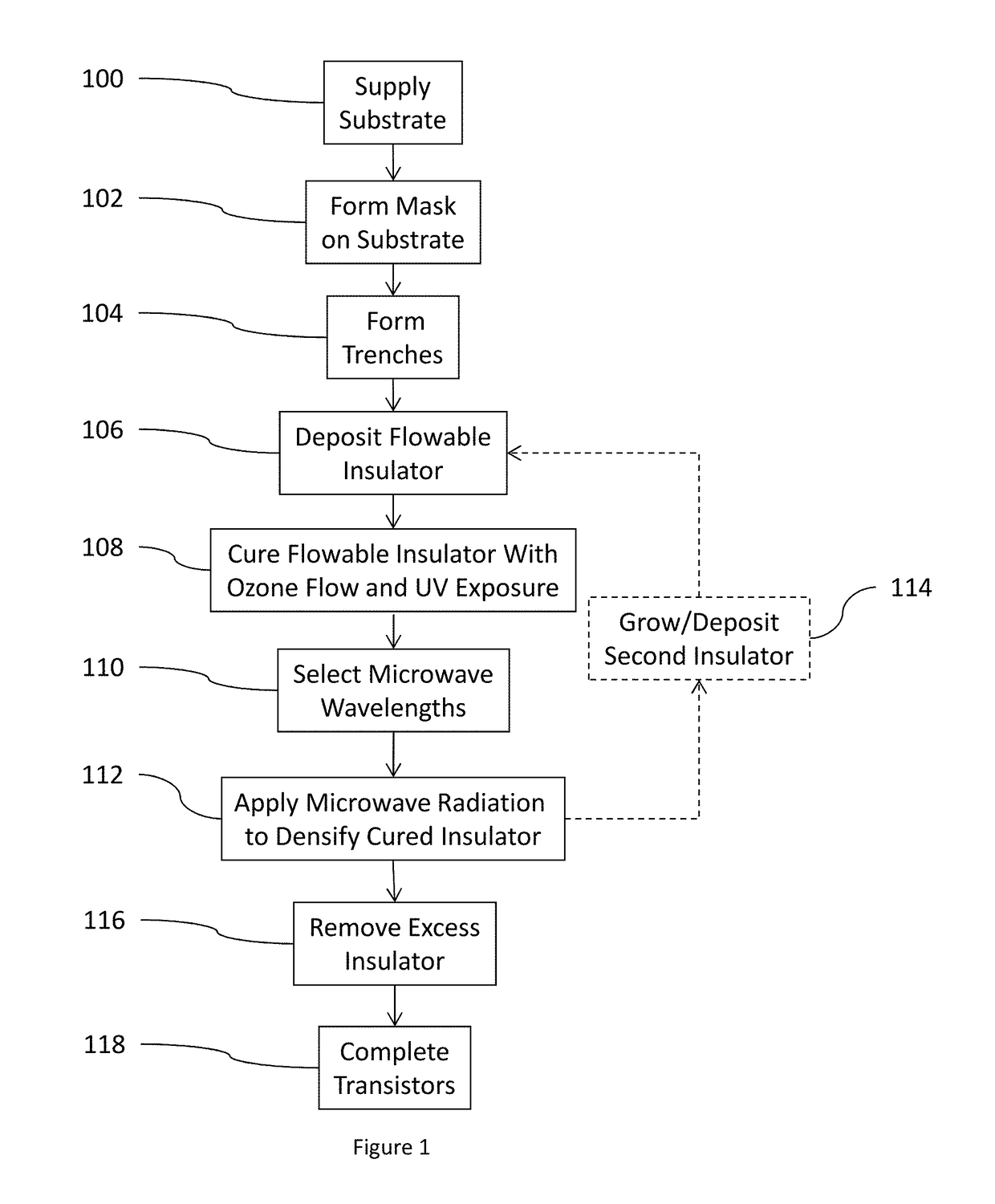

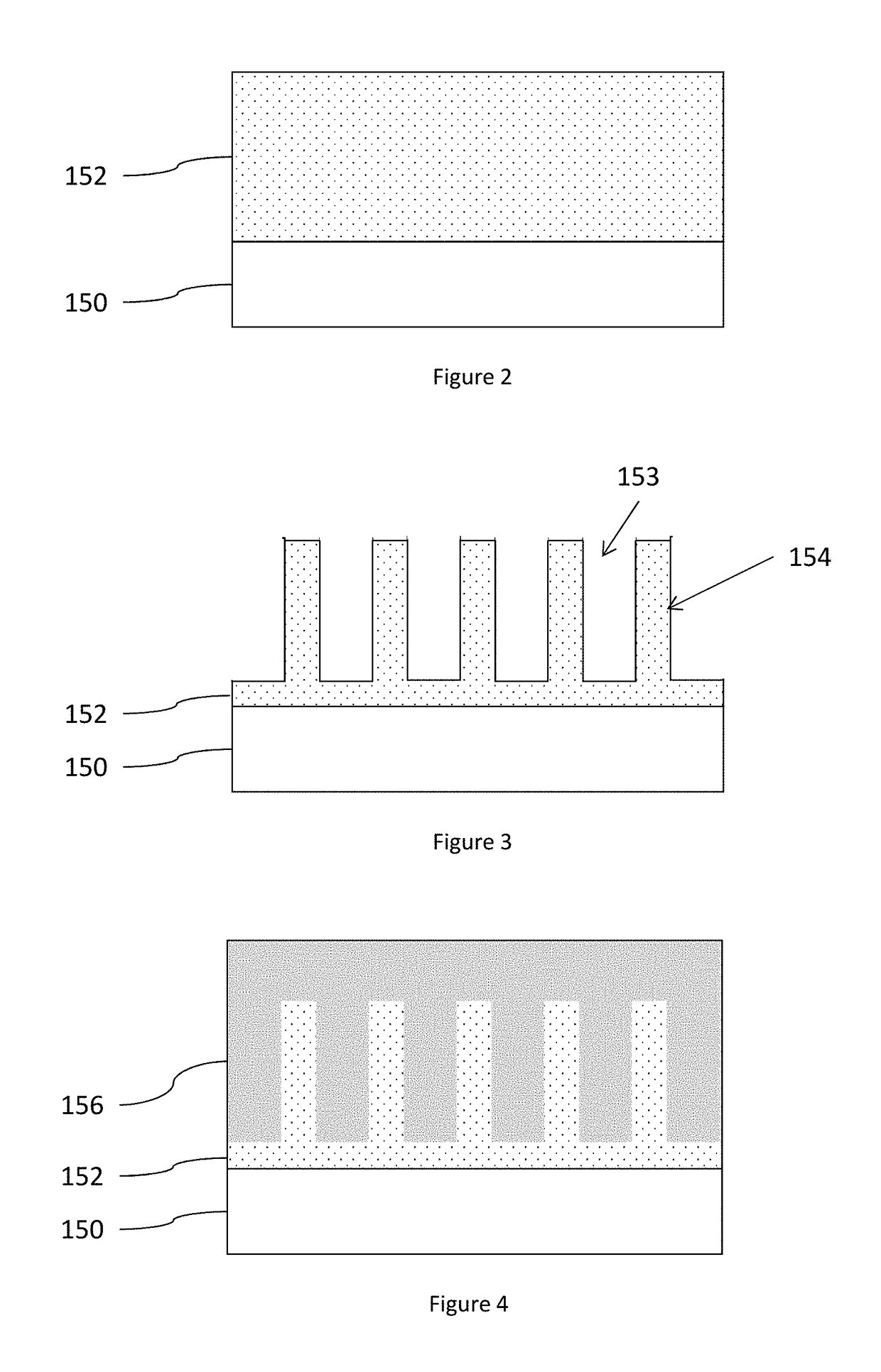

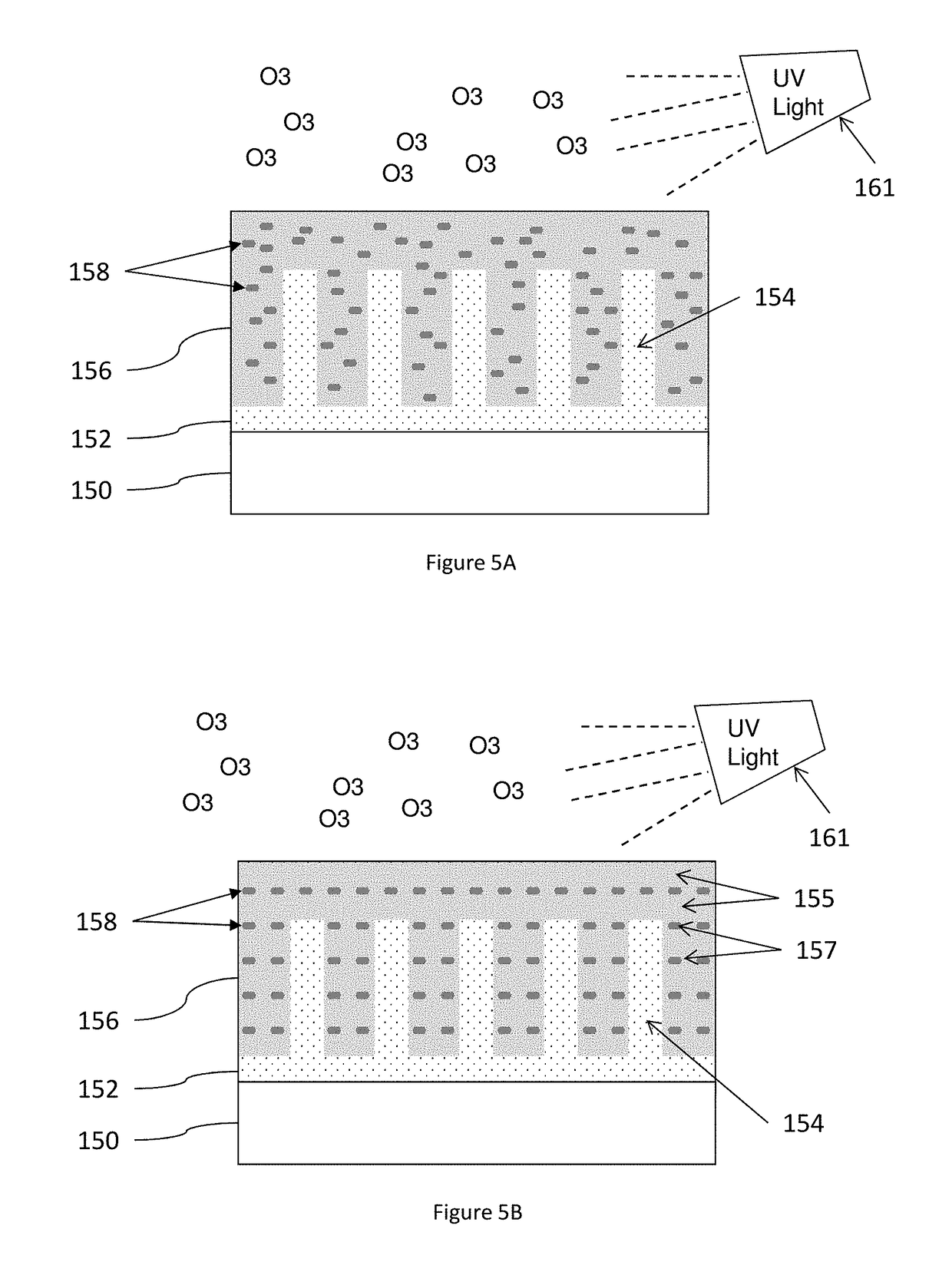

Microwave annealing of flowable oxides with trap layers

An insulator is formed by flowable chemical vapor deposition (FCVD) process. The insulator is cured by exposing the insulator to ultraviolet light while flowing ozone over the insulator to produce a cured insulator. The curing process forms nitrogen, hydrogen, nitrogen monohydride, or hydroxyl-rich atomic clusters in the insulator. Following the curing process, these methods select wavelengths of microwave radiation (that will be subsequently used during annealing) so that such wavelengths excite the nitrogen, hydrogen, nitrogen monohydride, or hydroxyl-rich atomic clusters. Then, these methods anneal the cured insulator by exposing the cured insulator to microwave radiation in an inert (e.g., non-oxidizing) ambient atmosphere, at a temperature below 500° C., so as to increase the density of the cured insulator.

Owner:GLOBALFOUNDRIES US INC

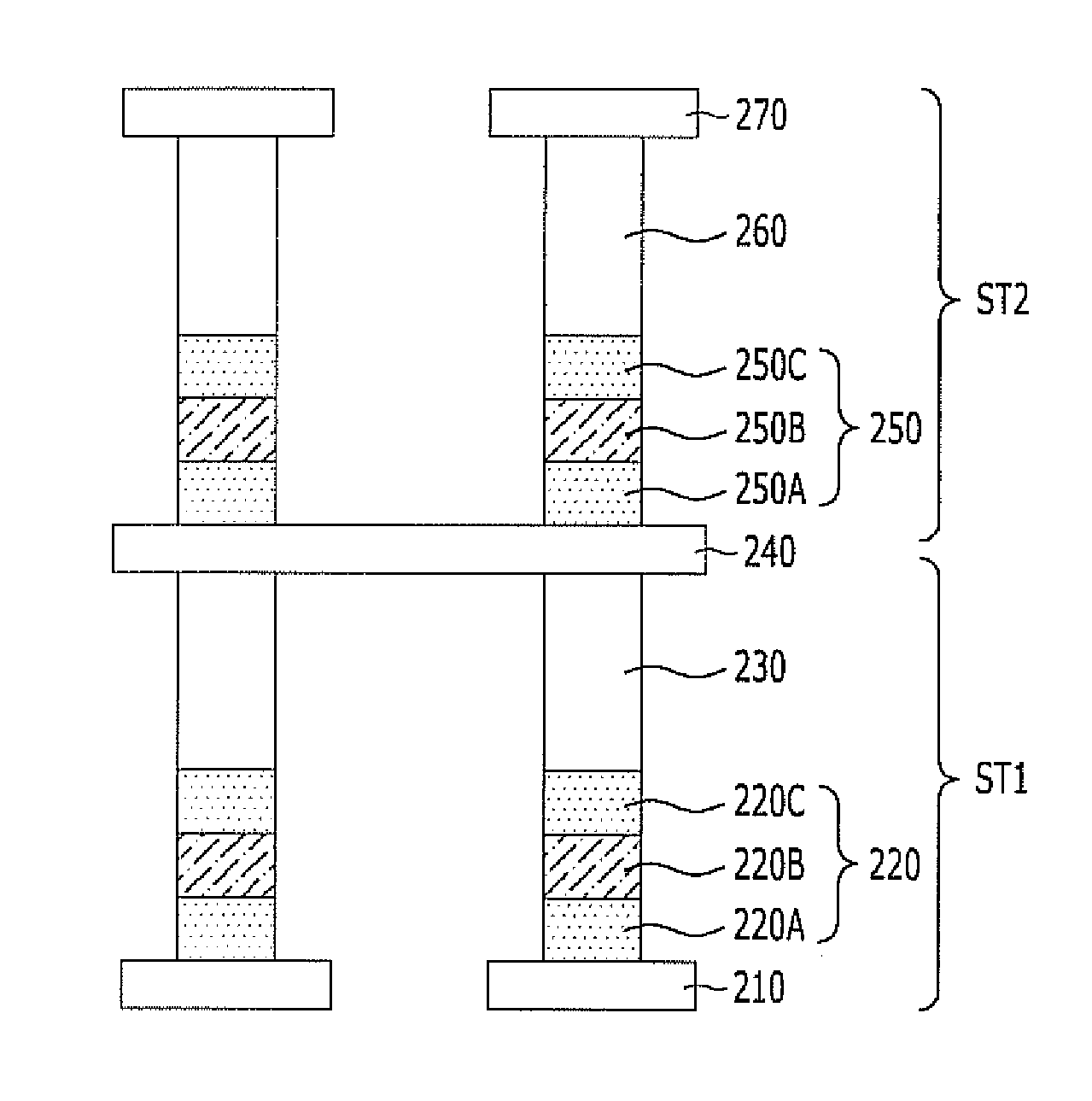

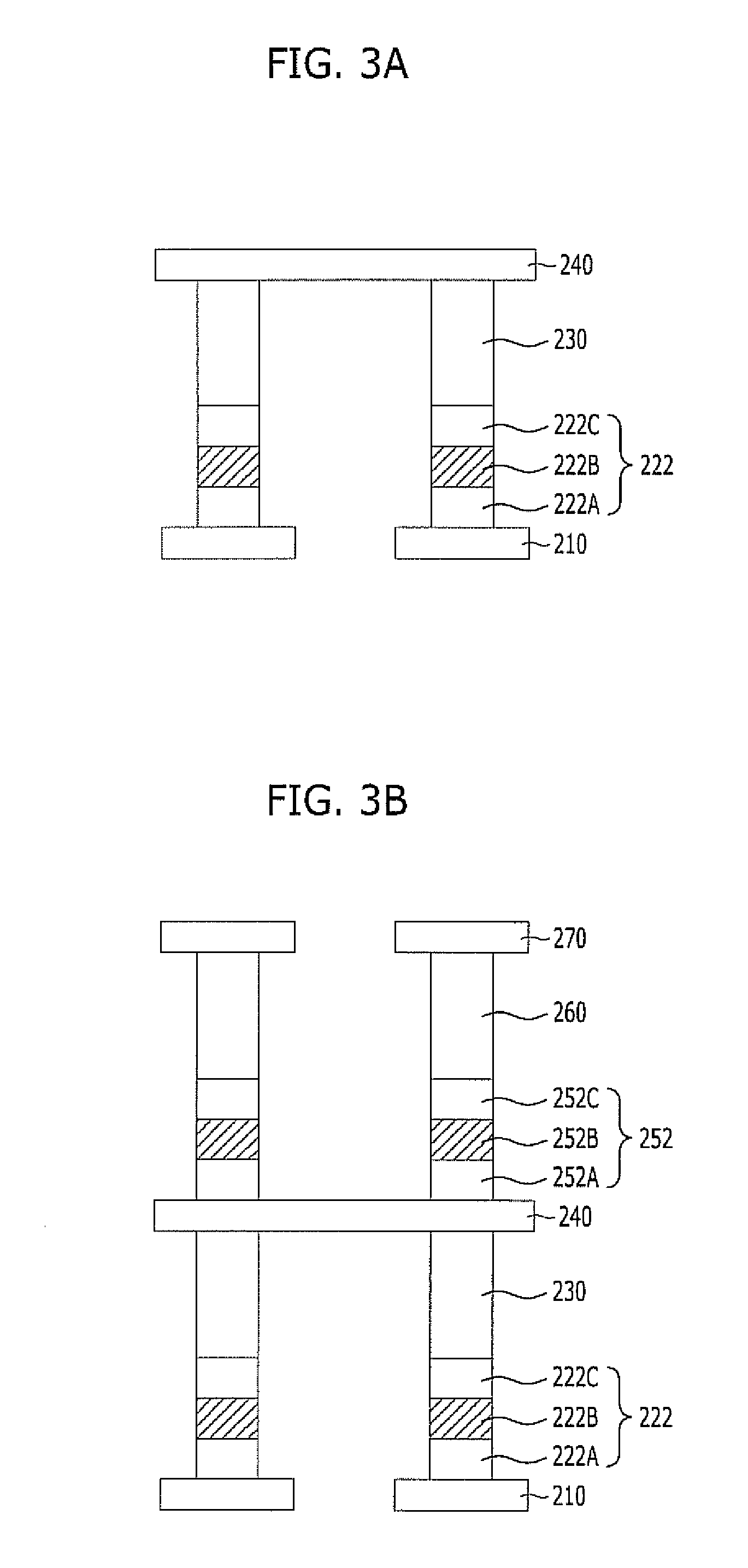

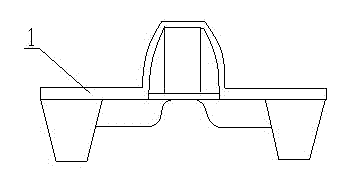

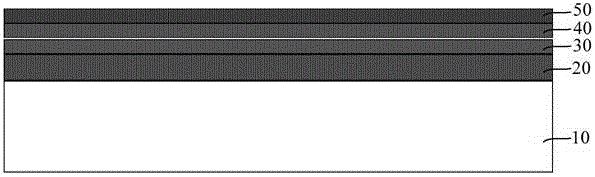

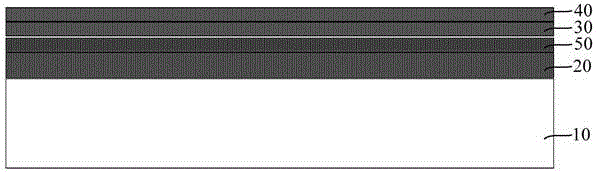

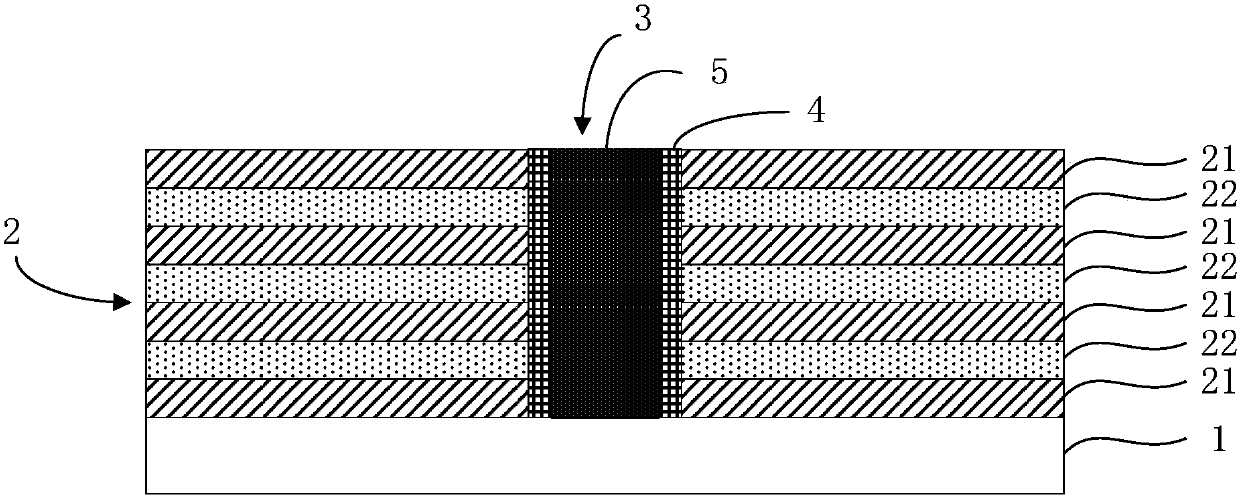

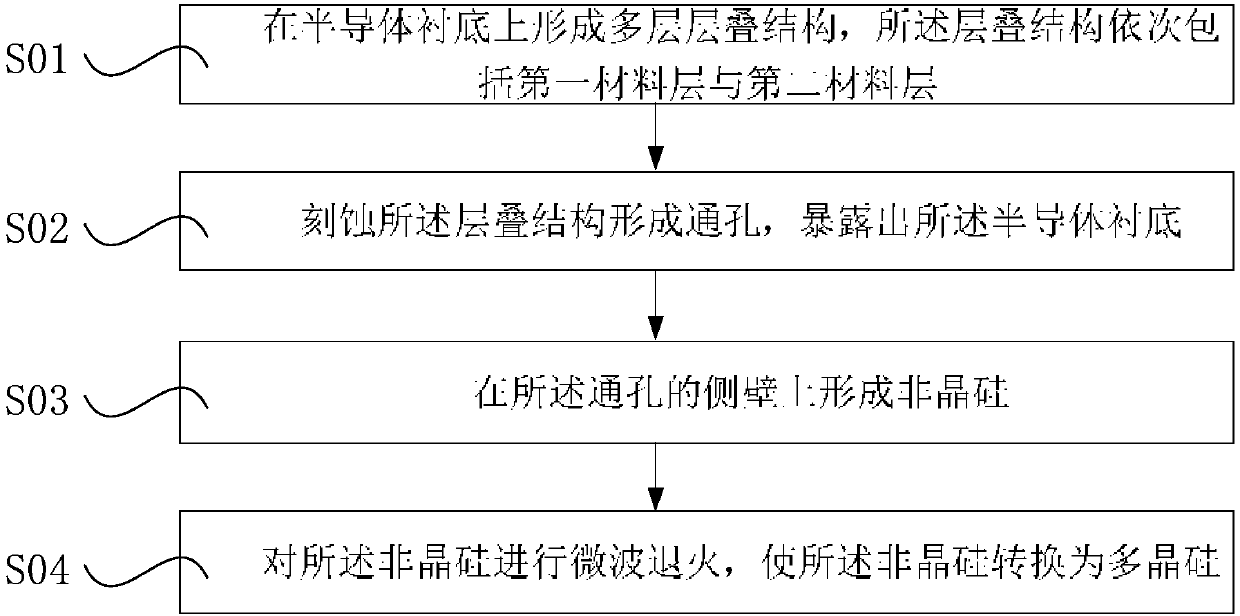

Method of manufacturing 3D NAND through microwave annealing

ActiveCN107863347AImprove the quality of crystallizationImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconSemiconductor

The invention provides a method of manufacturing 3D NAND through microwave annealing. The method comprises the following steps of forming a multilayer stacked structure on a semiconductor substrate, wherein the stacked structure successively includes a first material layer and a second material layer; etching the stacked structure and forming a through hole so as to expose the semiconductor substrate; forming amorphous silicon on a side wall of the through hole; and carrying out microwave annealing on the amorphous silicon so that the amorphous silicon is converted into polycrystalline silicon. After the amorphous silicon is formed on the side wall of the through hole, the microwave annealing is performed on the amorphous silicon so that the amorphous silicon is converted into the polycrystalline silicon. Crystallization quality of the polycrystalline silicon is increased and performance of a semiconductor device is improved.

Owner:ZING SEMICON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com