Patents

Literature

200 results about "Indium gallium zinc oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indium gallium zinc oxide (IGZO) is a semiconducting material, consisting of indium (In), gallium (Ga), zinc (Zn) and oxygen (O). IGZO thin-film transistor (TFT) is used in the TFT backplane of flat-panel displays (FPDs). IGZO-TFT was developed by Hideo Hosono's group at Tokyo Institute of Technology and Japan Science and Technology Agency (JST) in 2003 (crystalline IGZO-TFT) and in 2004 (amorphous IGZO-TFT). IGZO-TFT has 20–50 times the electron mobility of amorphous silicon, which has often been used in liquid-crystal displays (LCDs) and e-papers. As a result, IGZO-TFT can improve the speed, resolution and size of flat-panel displays. It is currently used as the thin-film transistors for use in organic light-emitting diode (OLED) TV displays.

Apparatus and method of forming an indium gallium zinc oxide layer

ActiveUS9214340B2TransistorSemiconductor/solid-state device manufacturingGas phaseIndium gallium zinc oxide

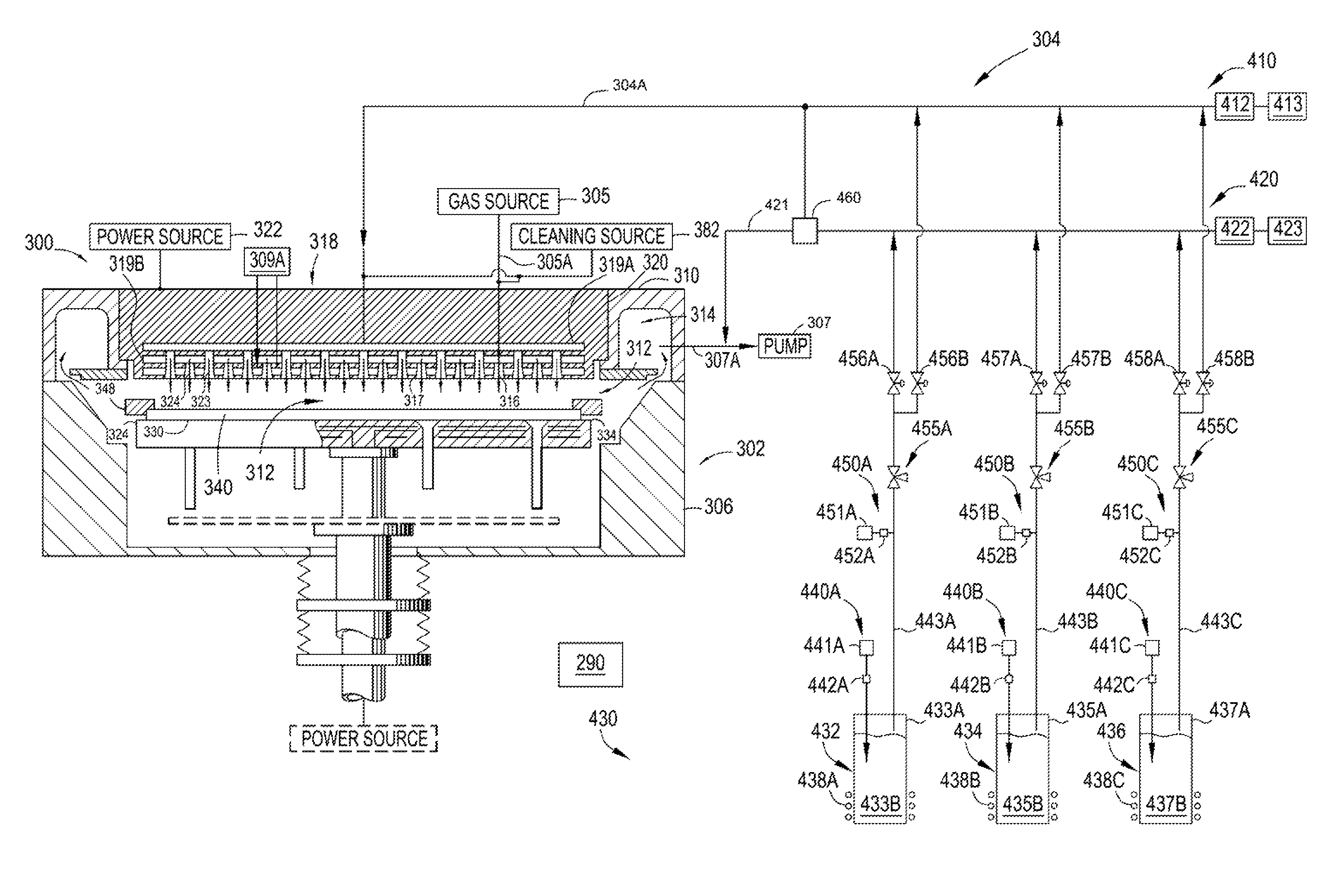

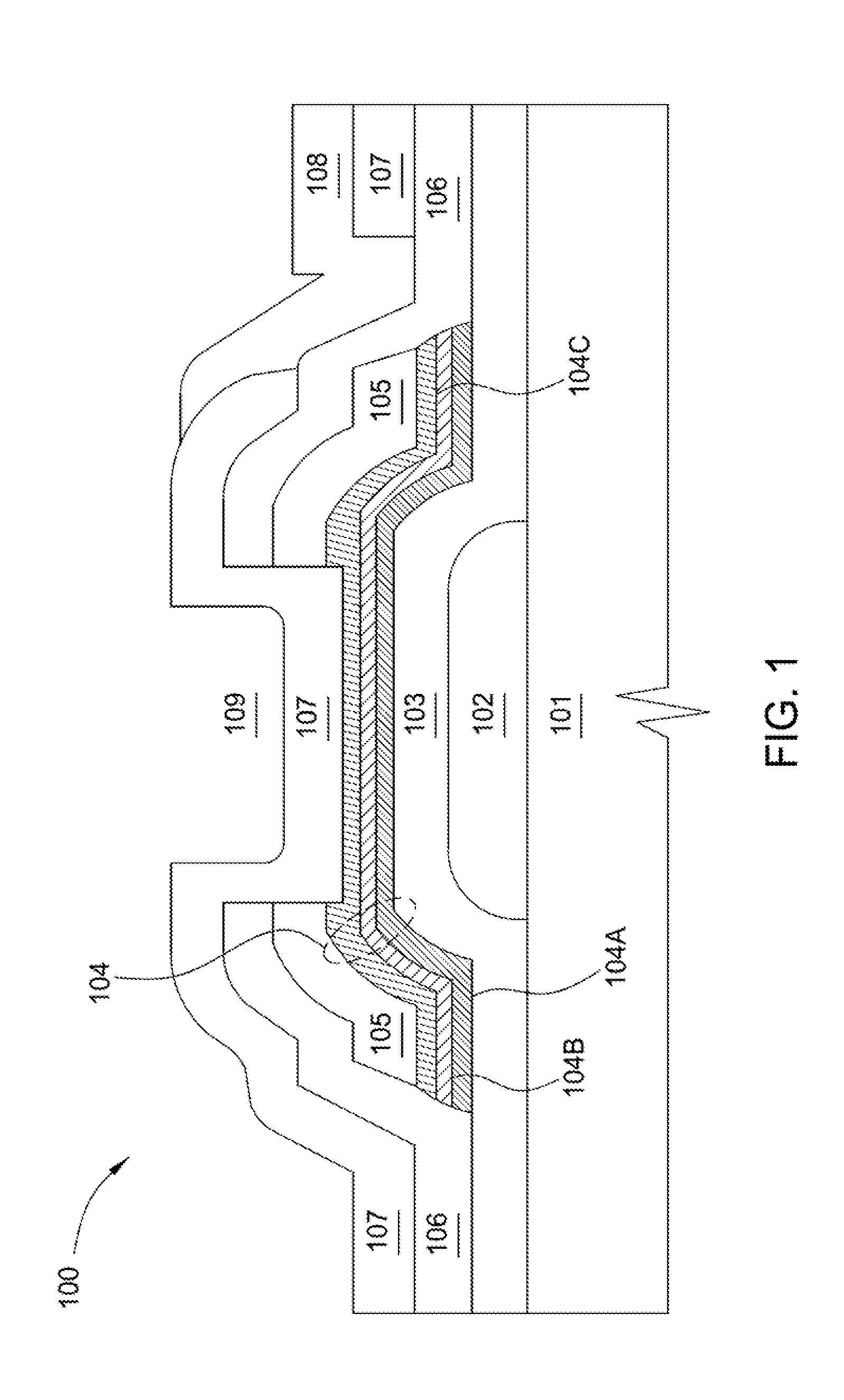

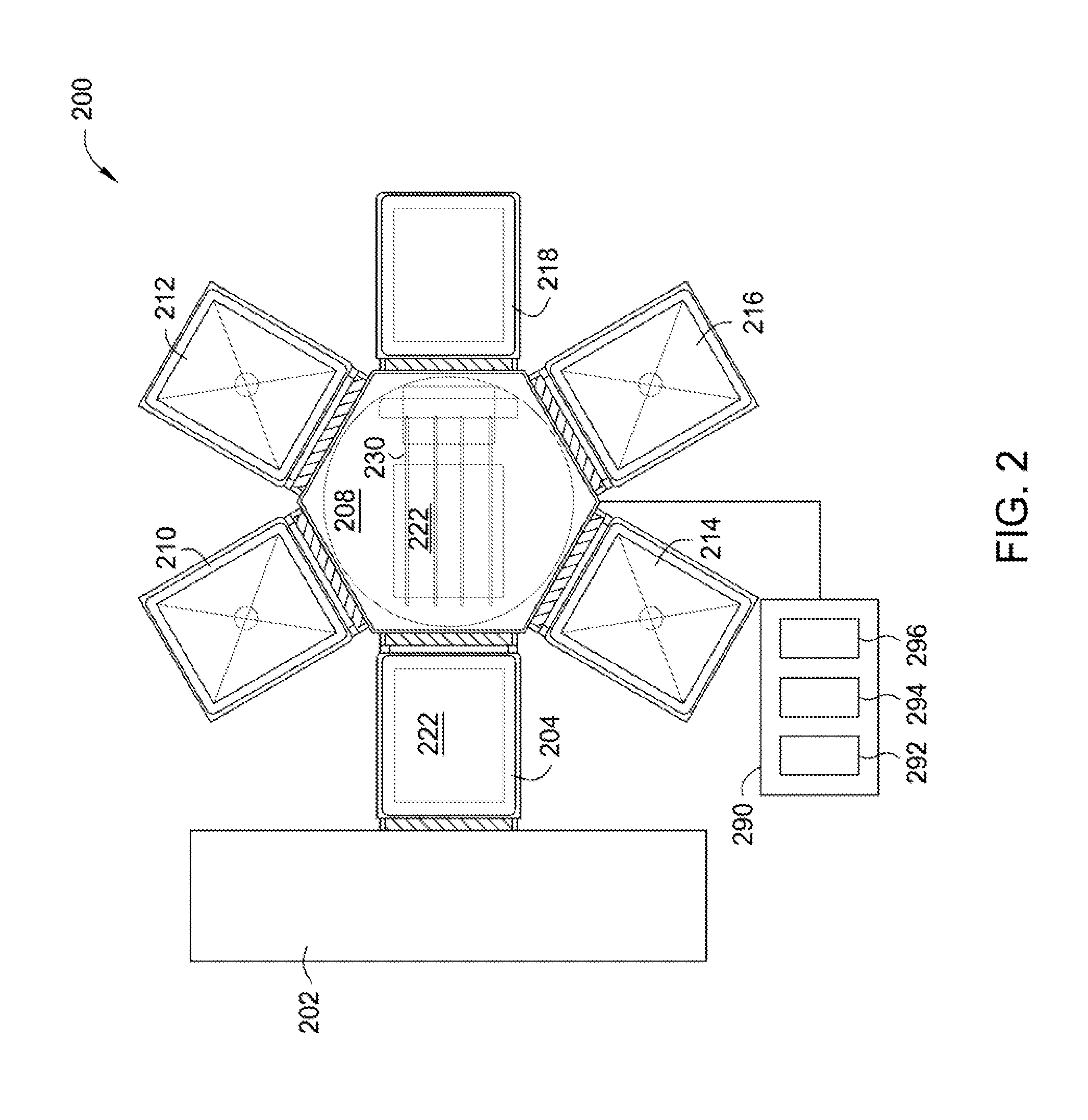

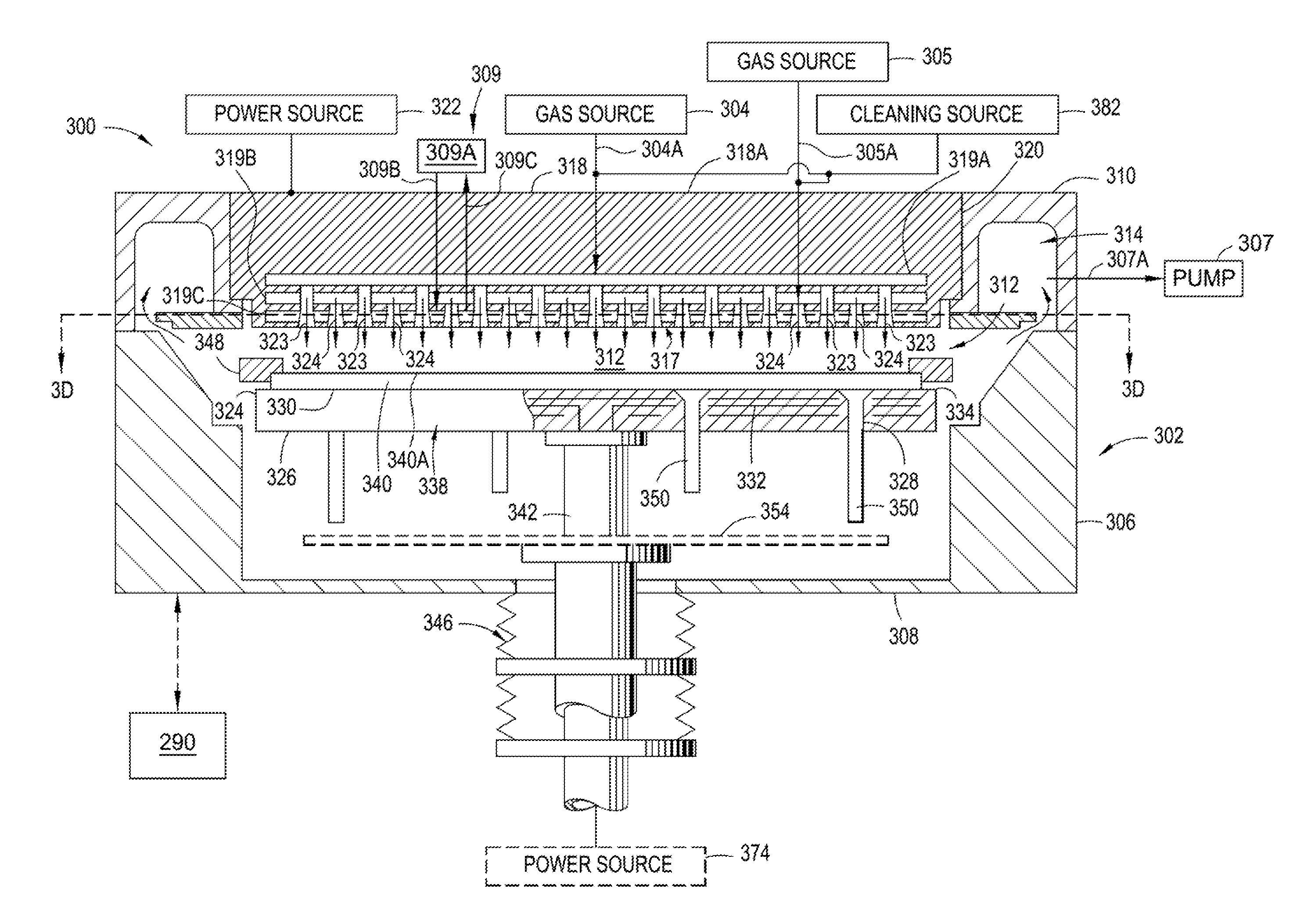

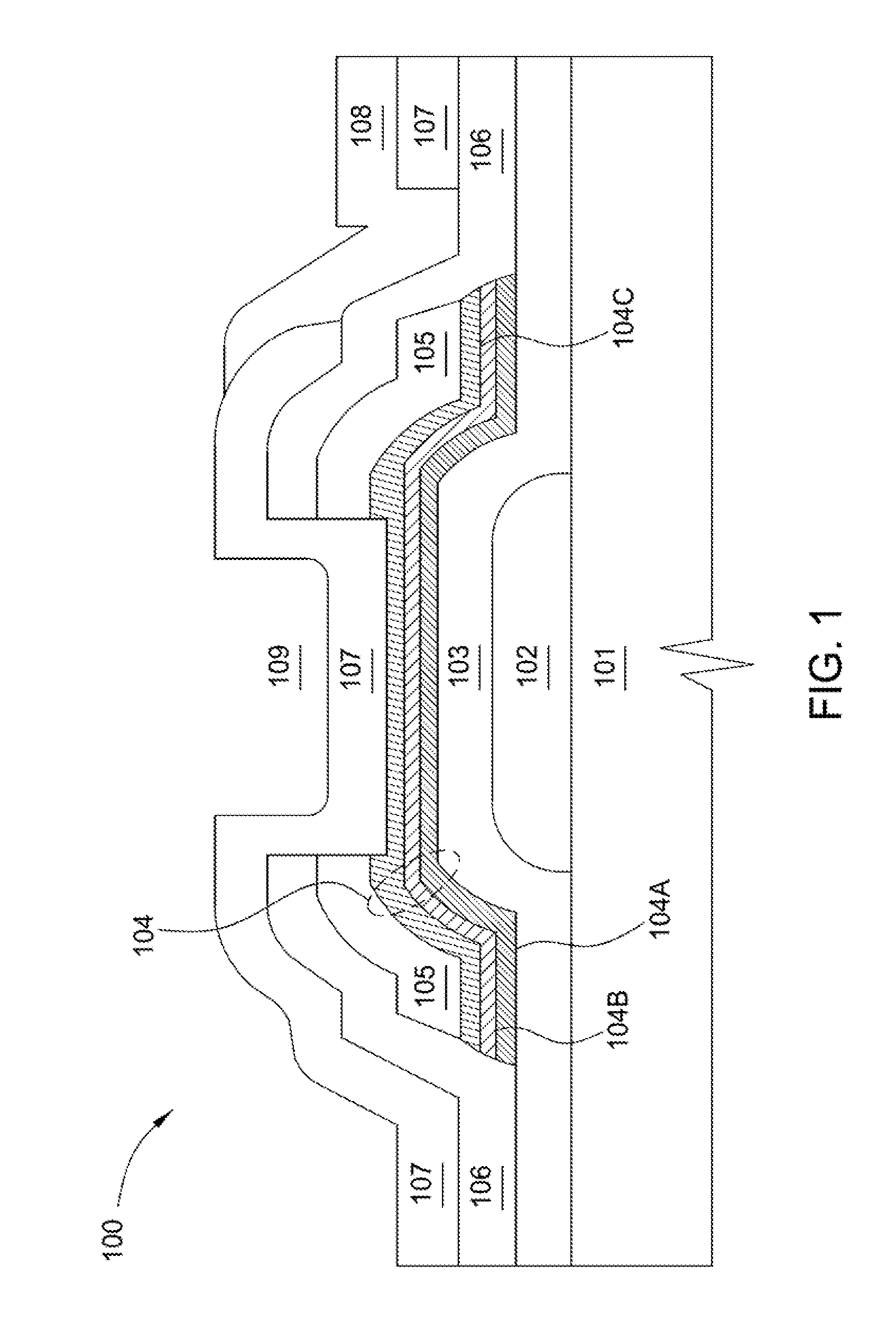

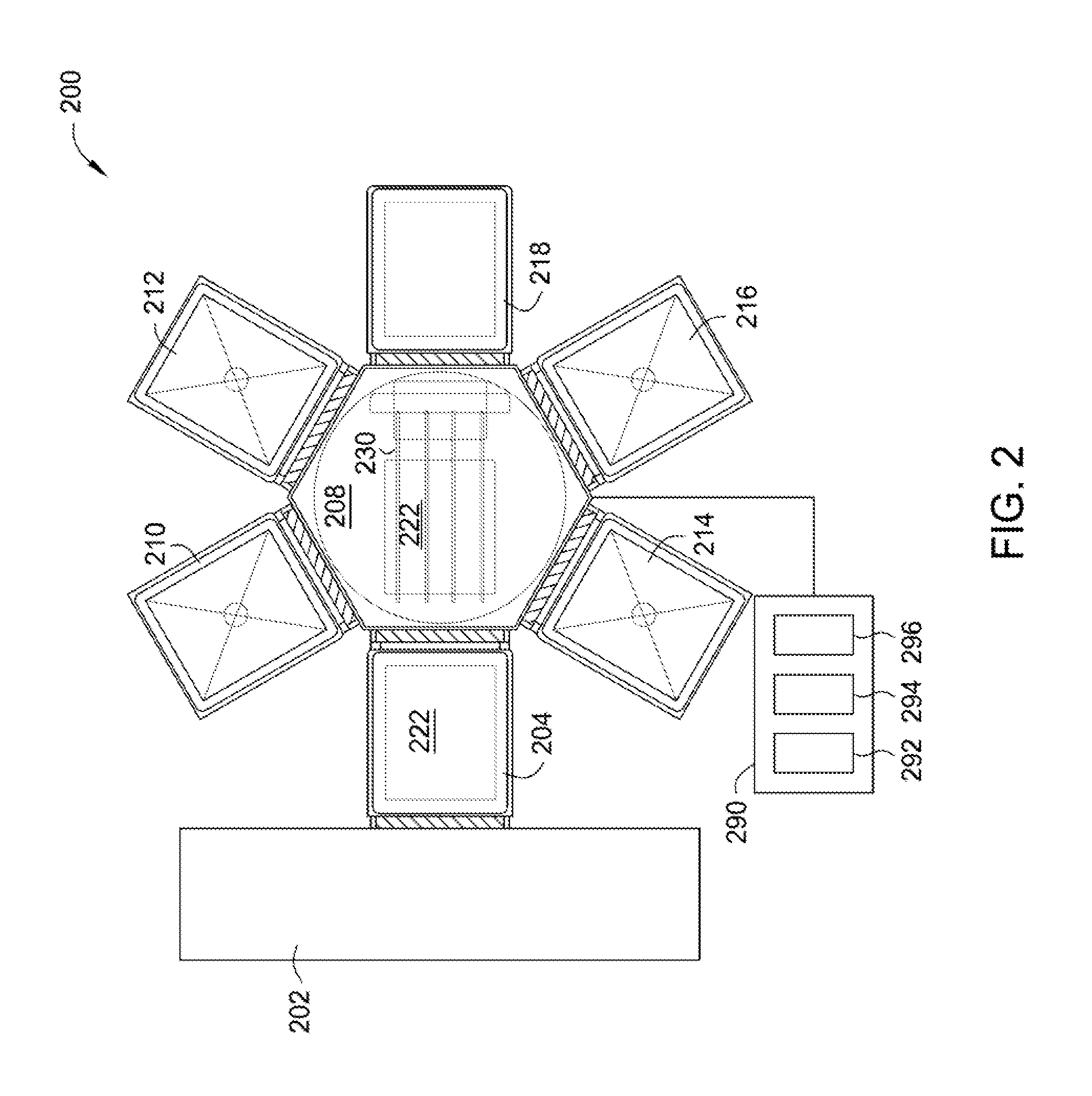

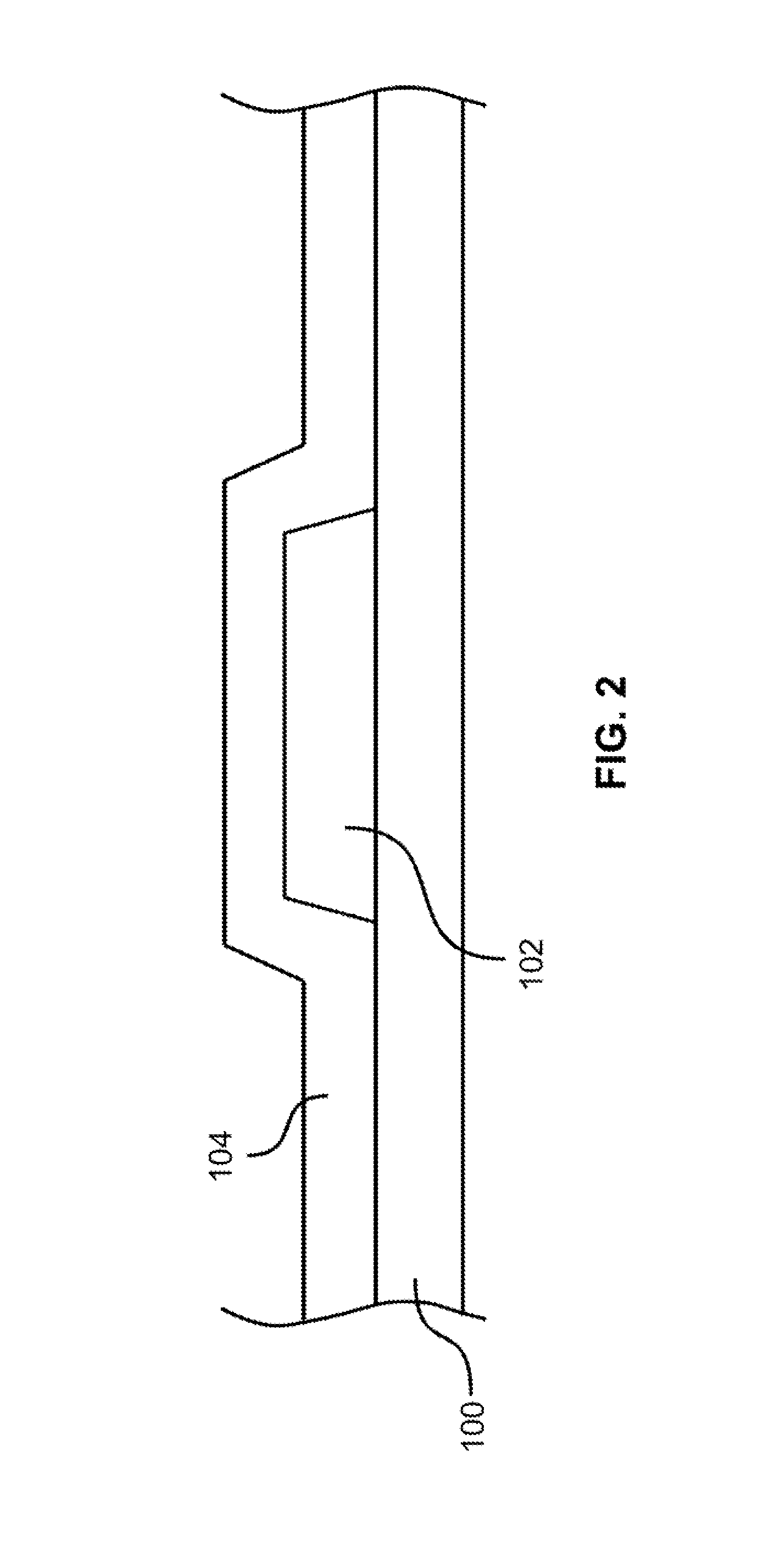

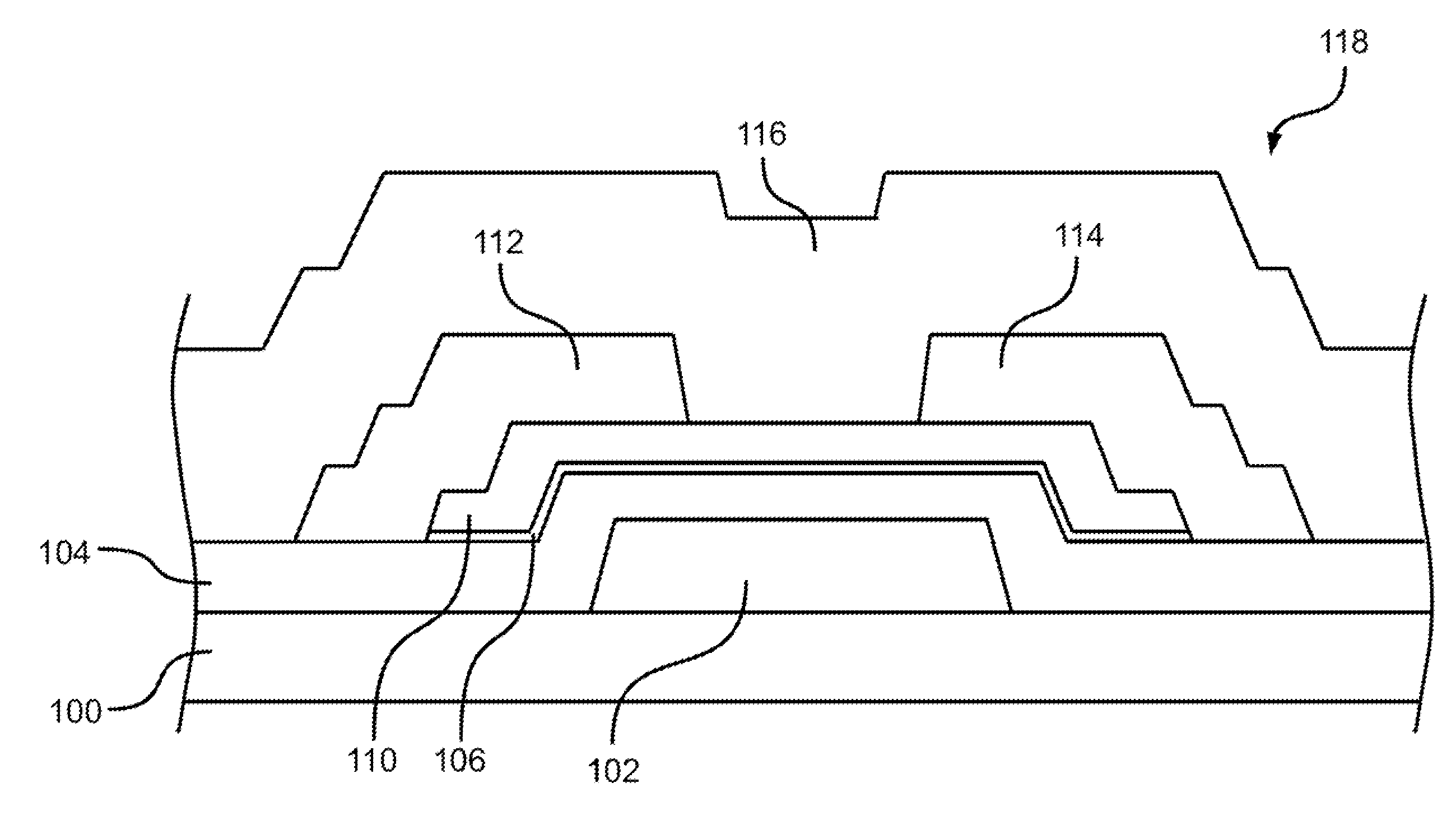

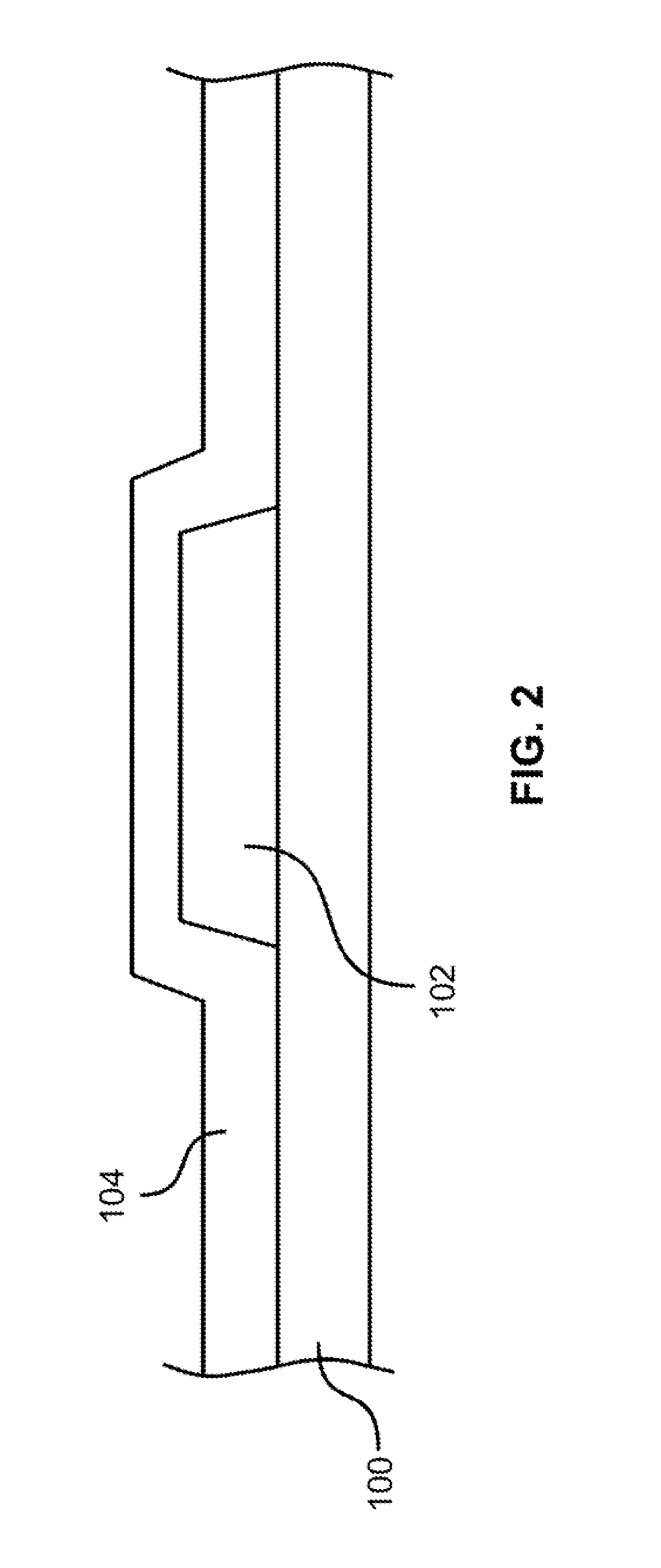

The embodiments of the disclosure may generally provide a method and apparatus for forming thin film transistor device that includes an indium gallium zinc oxide (IGZO) layer using a multi-component precursor gas. The embodiments of the disclosure may provide a plasma enhanced chemical vapor deposition system configured to form an IGZO layer on large area substrates. However, it should be understood that the disclosure has utility in other system configurations such other types of chemical vapor deposition systems and any other system in which distributing a multi-component precursor gas to and within a process chamber is desired.

Owner:APPLIED MATERIALS INC

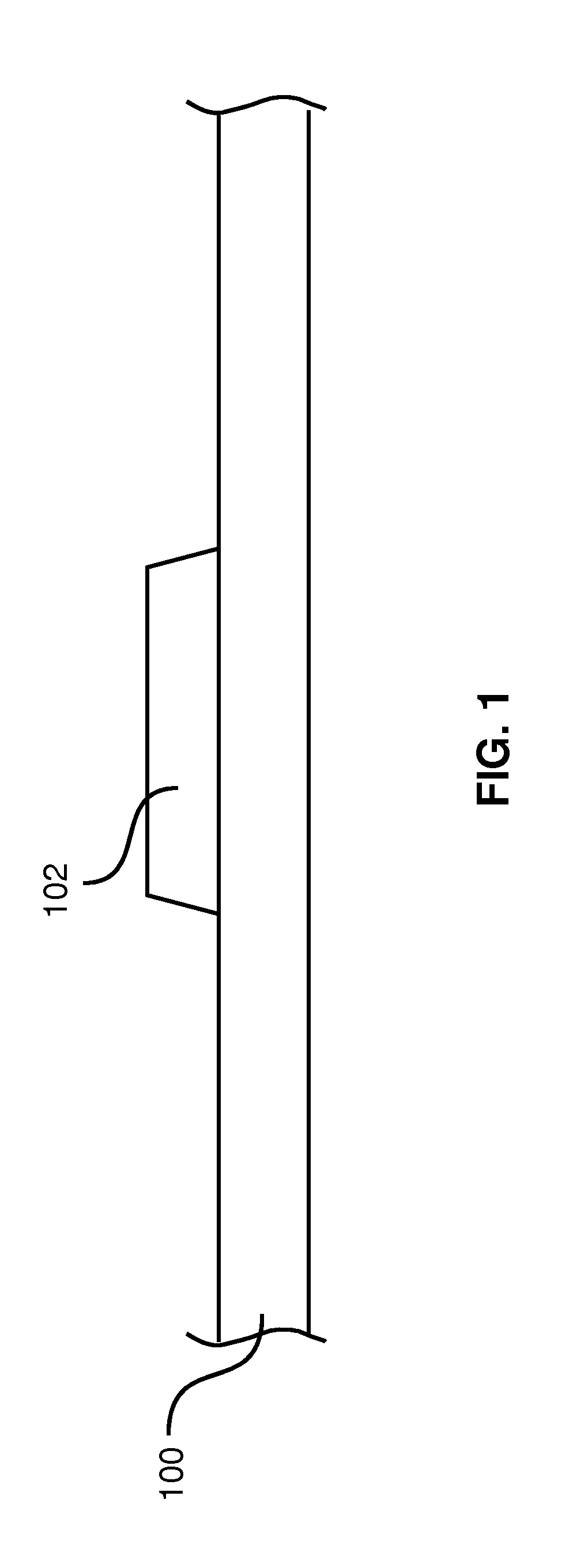

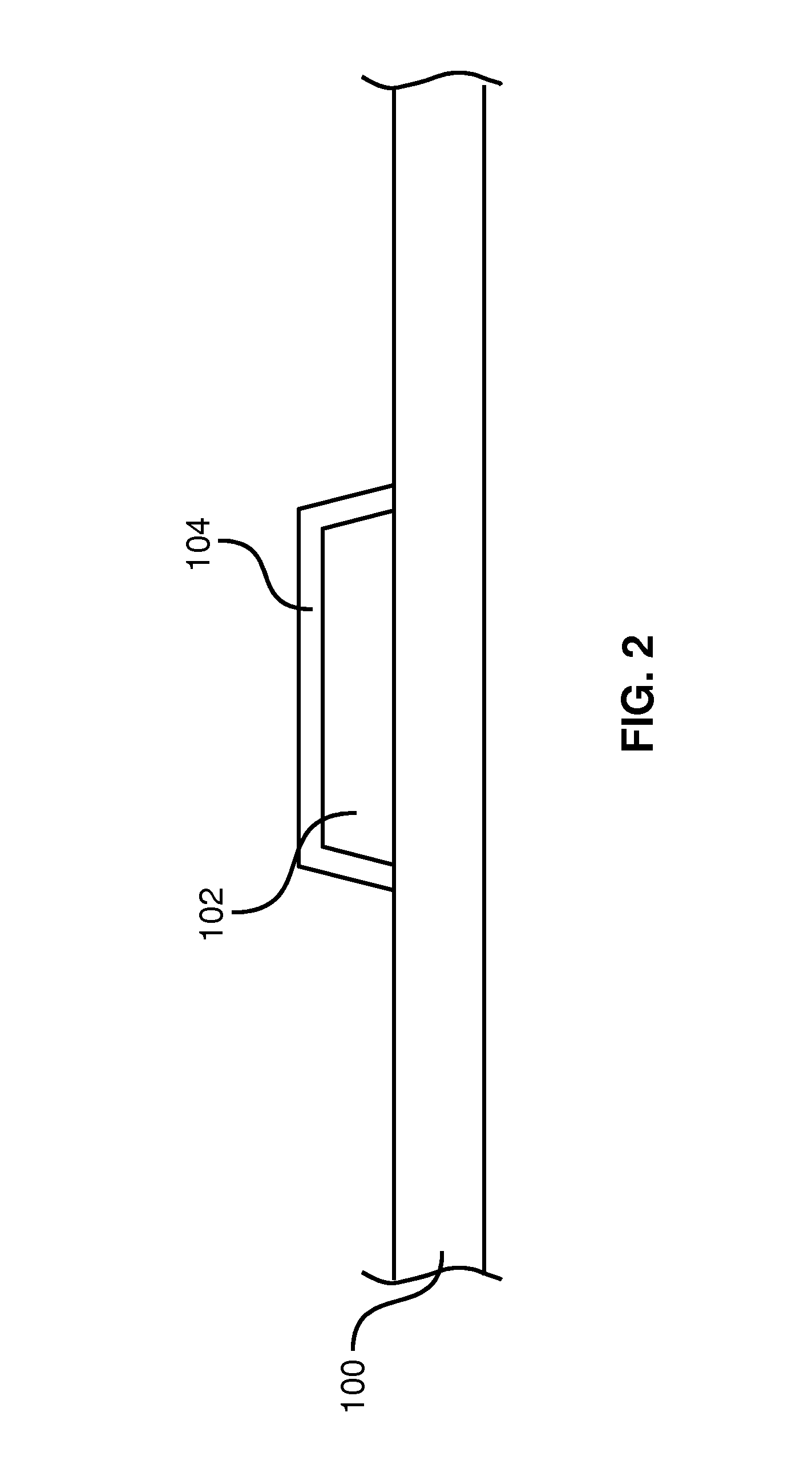

Oxide semiconductor device and method of manufacturing the same and active matrix substrate

InactiveUS20100140614A1High content ratioImprove contact effectTransistorSolid-state devicesActive matrixThreshold potential

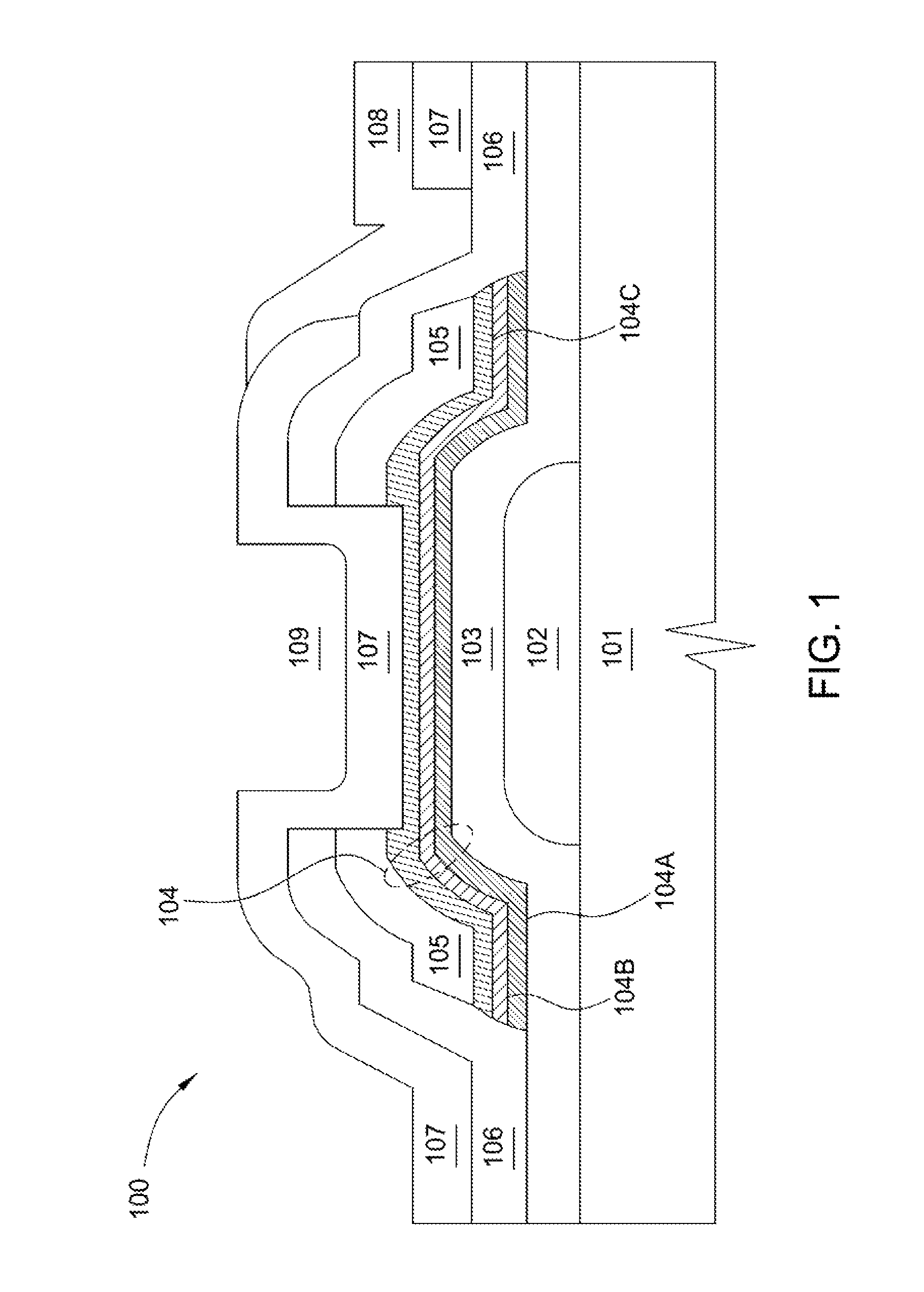

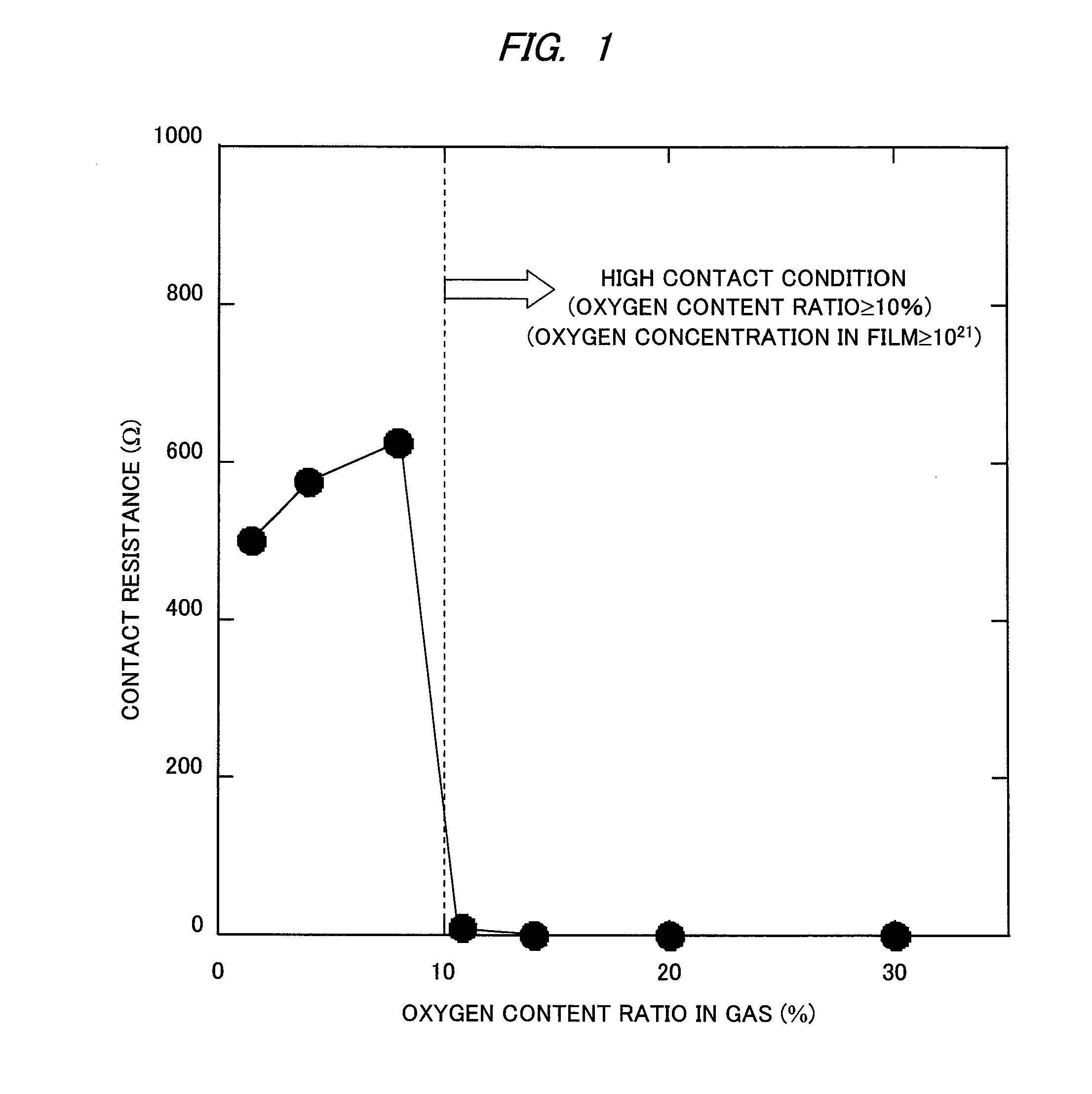

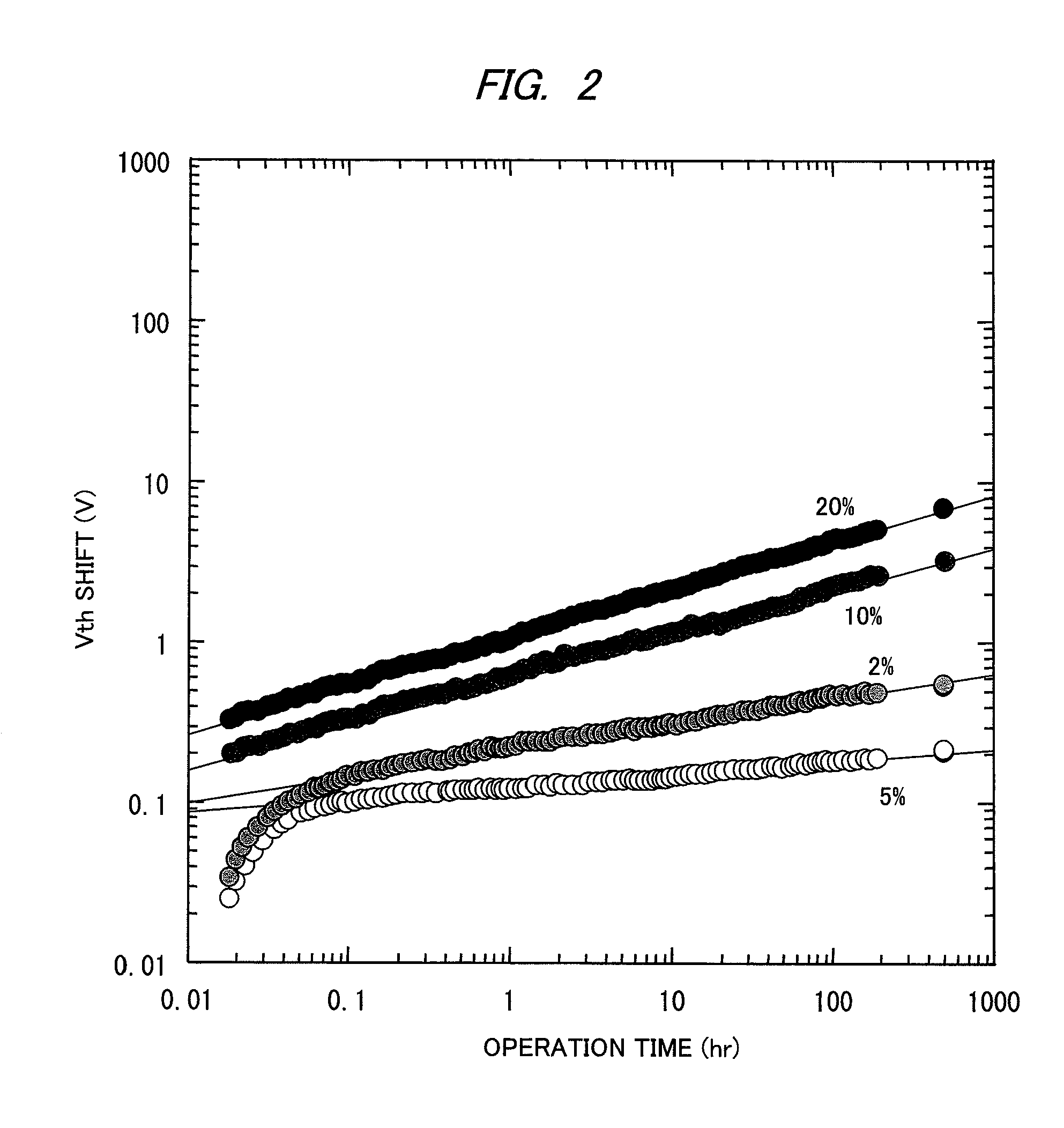

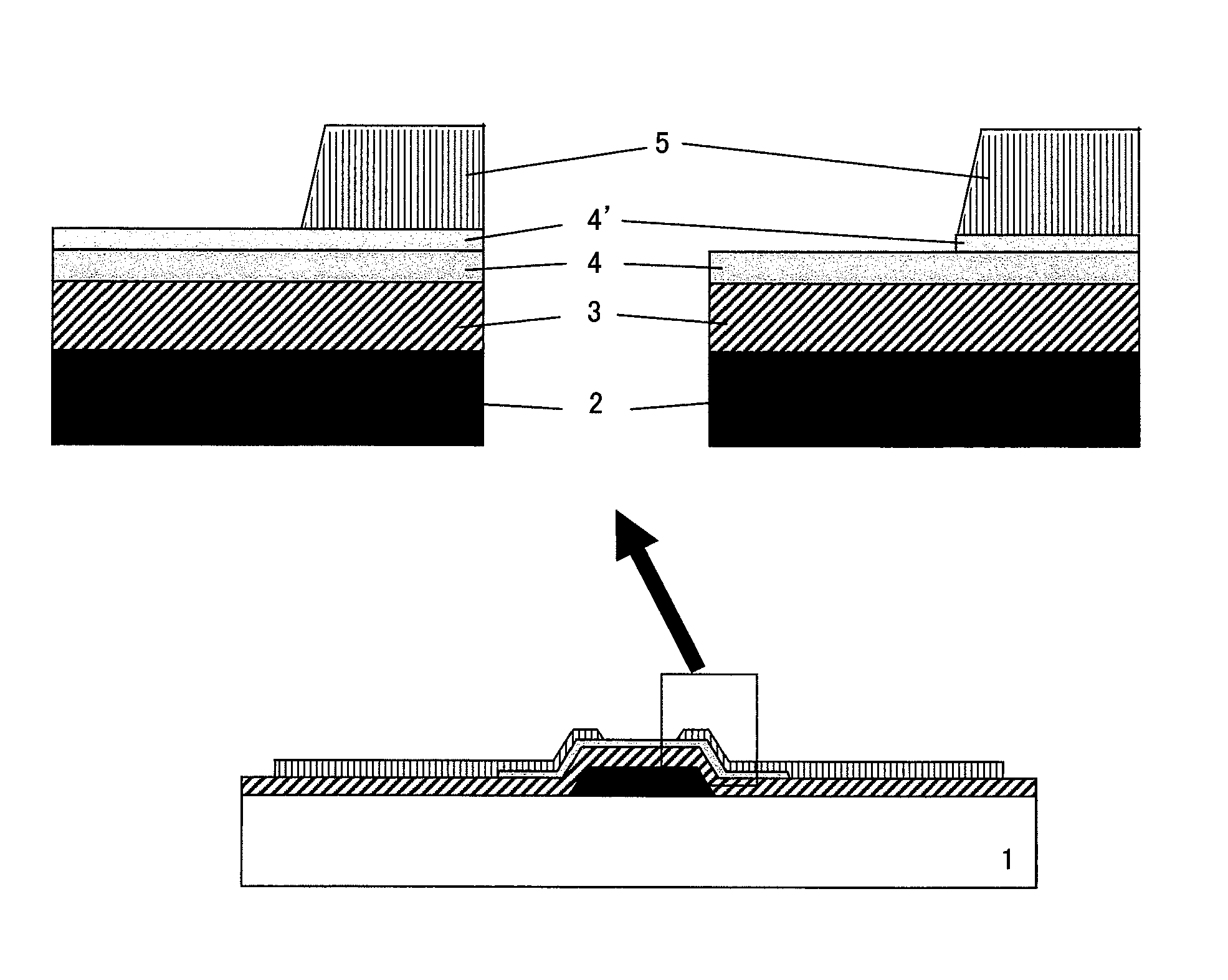

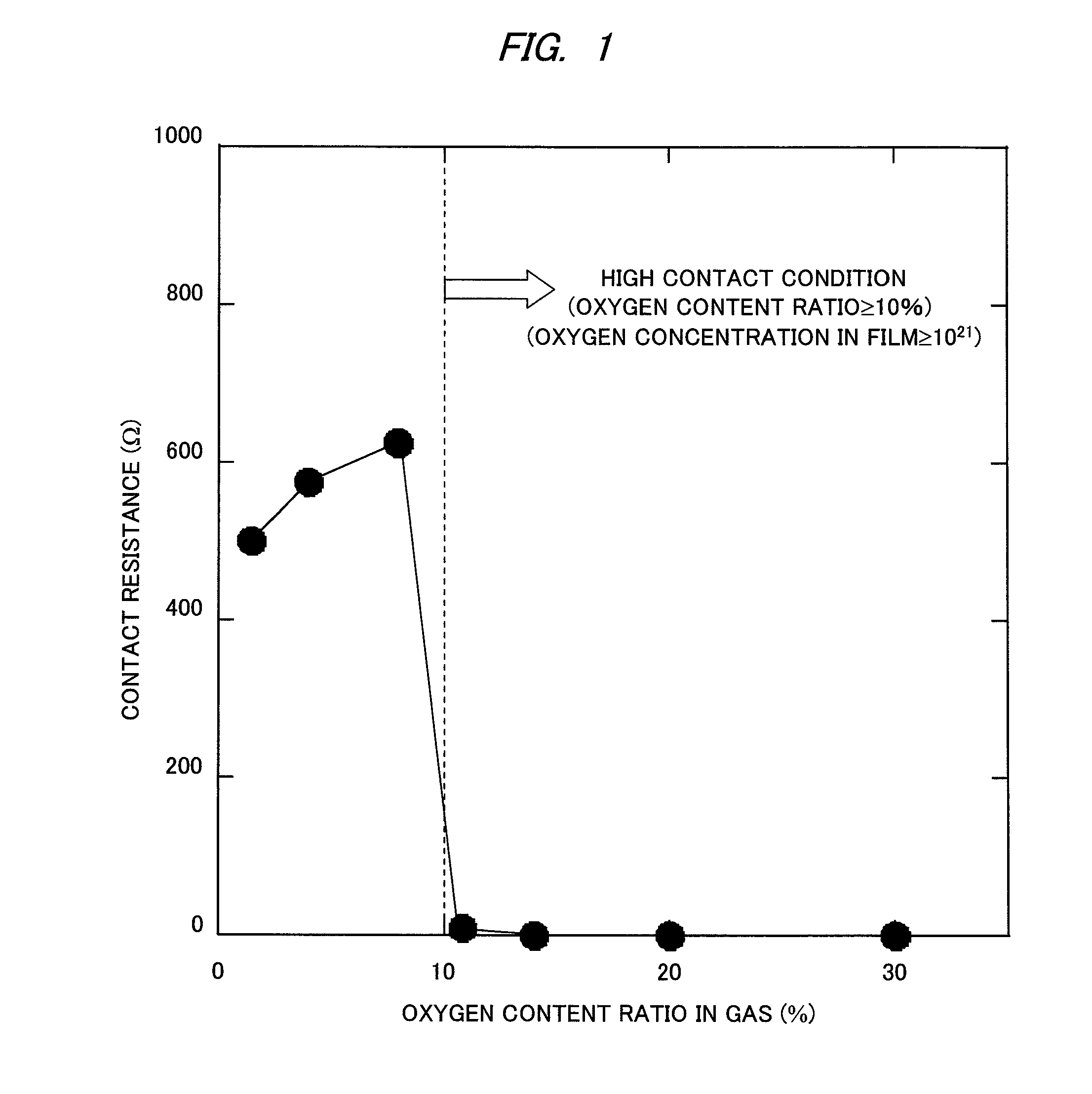

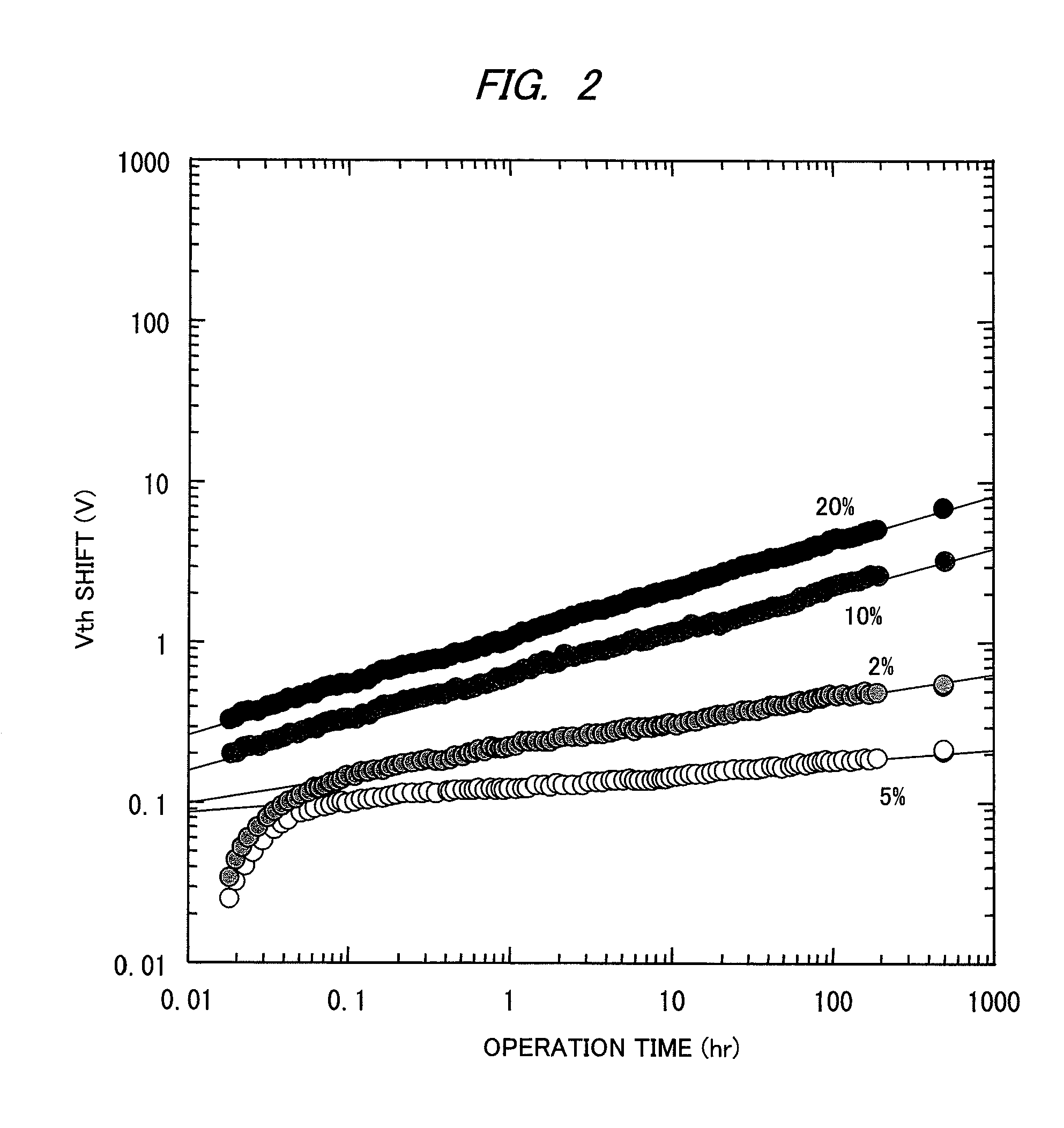

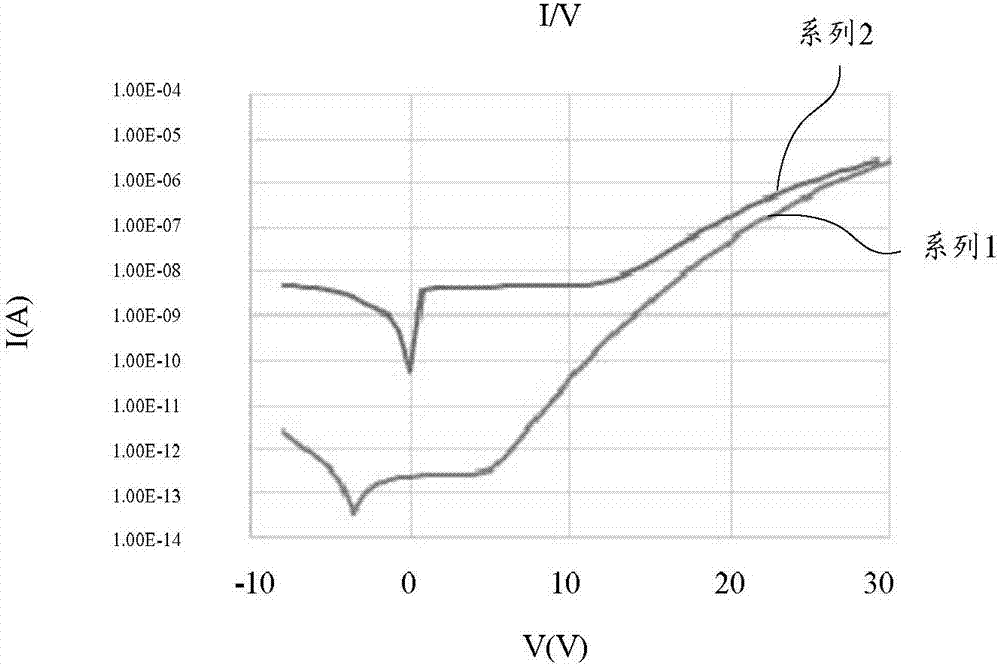

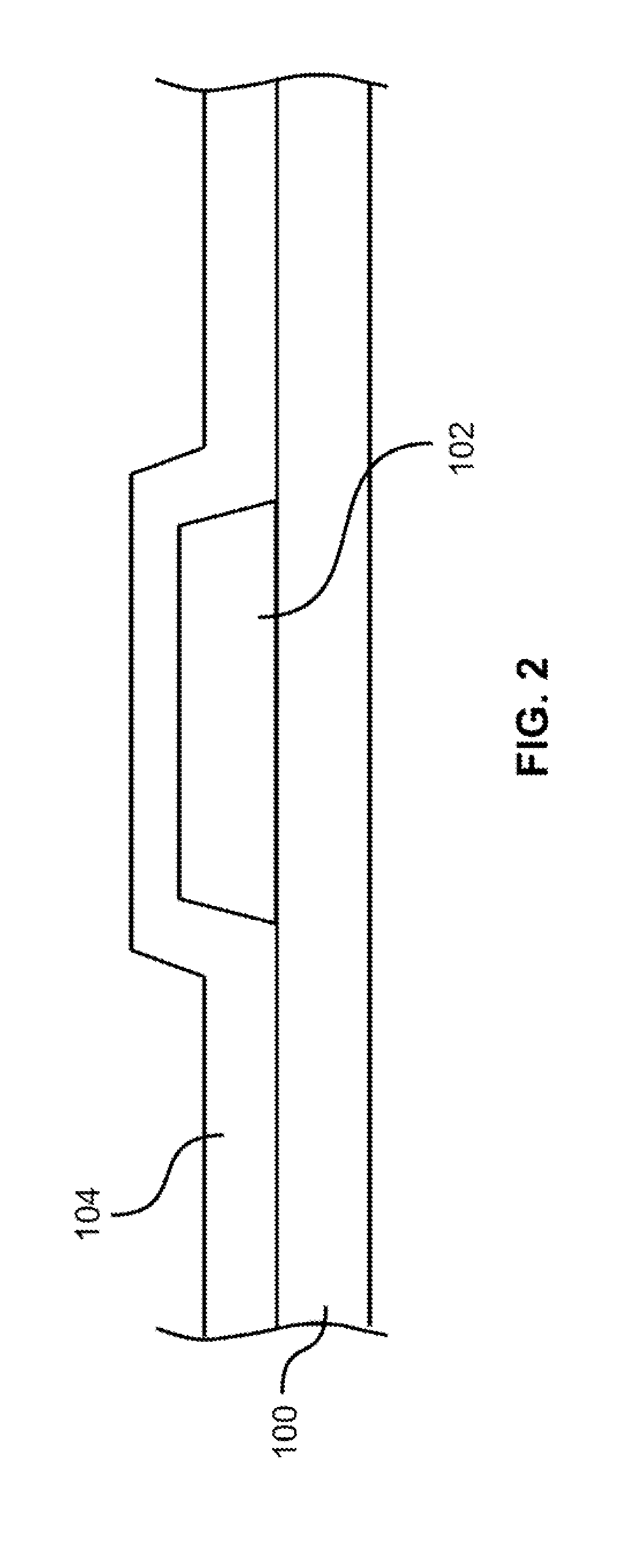

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

Oxide semiconductor device with oxide semiconductor layers of different oxygen concentrations and method of manufacturing the same

InactiveUS8368067B2Easiness of flexibilityImprove the level ofTransistorSolid-state devicesThreshold potentialMain channel

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

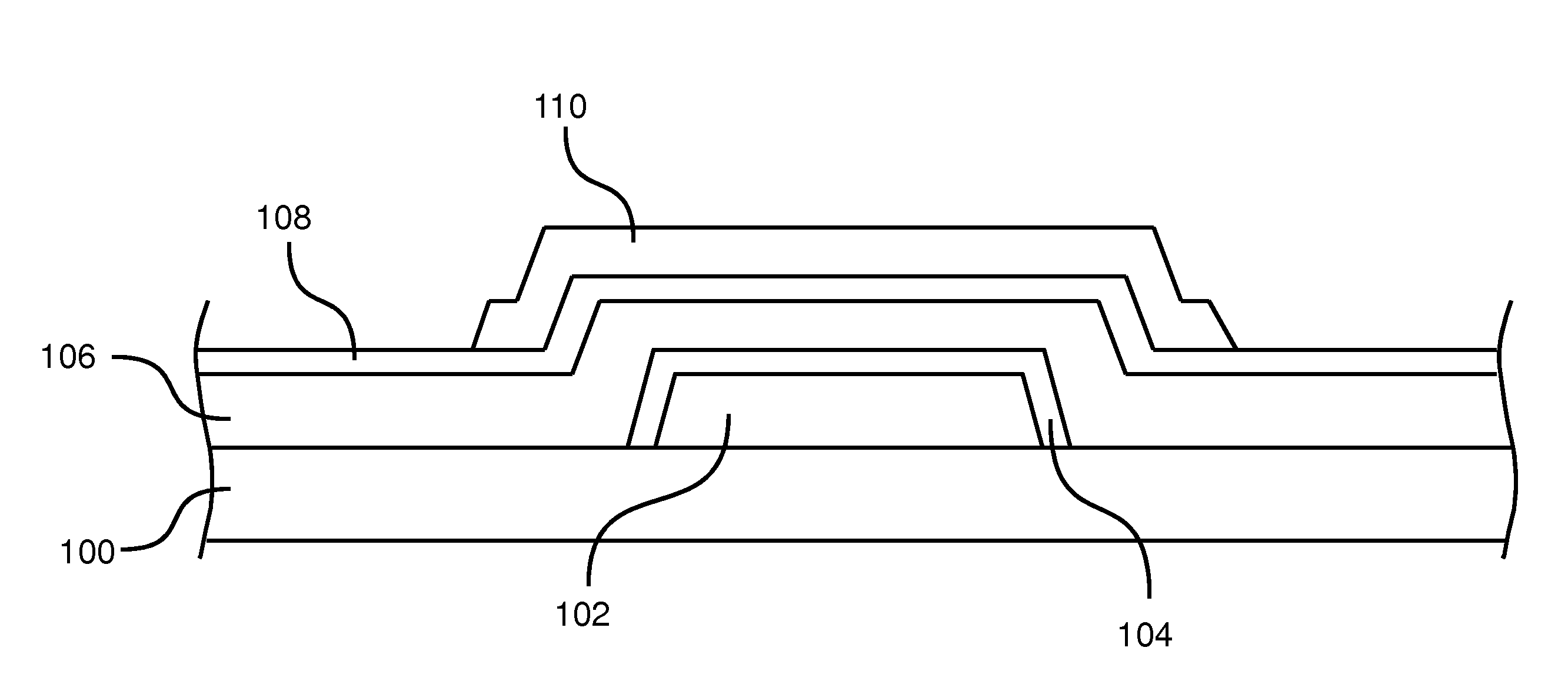

Indium gallium zinc oxide layers for thin film transistors

InactiveUS20150221507A1Improve throughputIncrease productionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectric surfaceIndium gallium zinc oxide

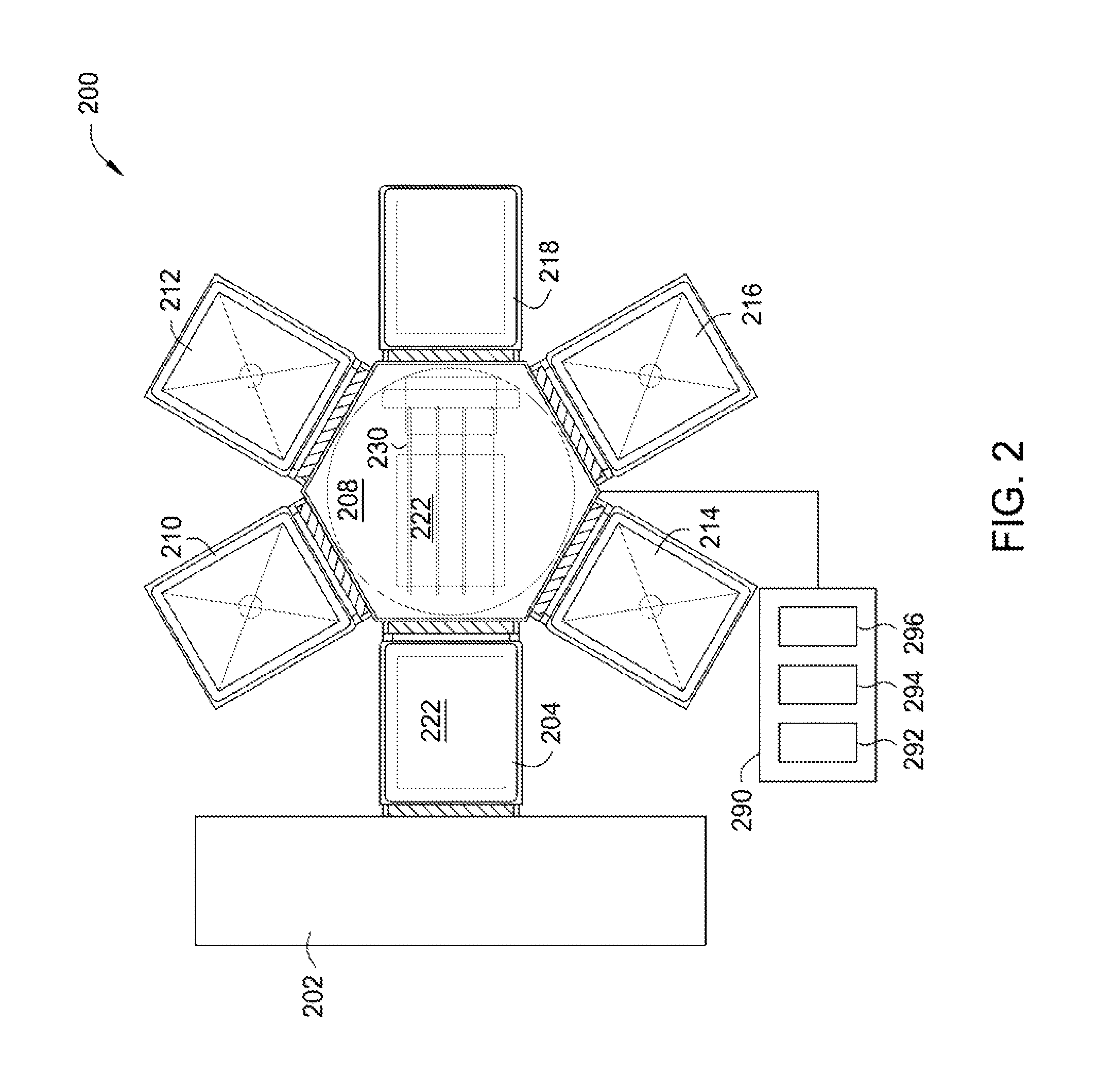

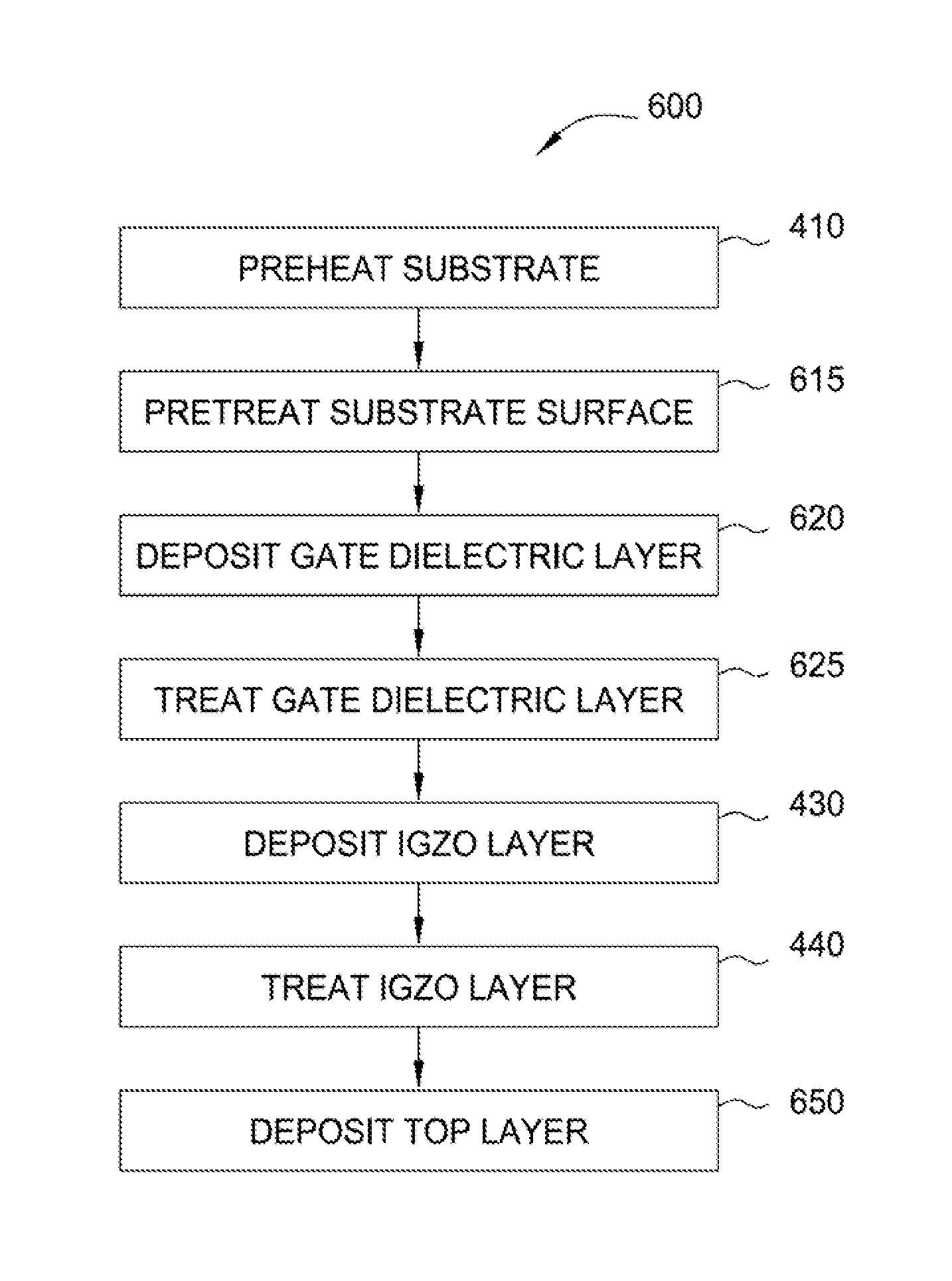

Embodiments of the present disclosure generally provide a method and apparatus for forming an IGZO active layer within a thin film transistor (TFT) device. In one embodiment, a method is provided for forming an IGZO active layer on a dielectric surface using a PECVD deposition process. In one embodiment, a method is provided for pretreating and passivating the dielectric surface for receiving the PECVD formed IGZO layer. In another embodiment, a method is provided for treating a PECVD formed IGZO layer after depositing said layer. In another embodiment, a method is provided for forming a multi-layer or complex layering structure of IGZO, within a PECVD processing chamber, for optimizing TFT electrical characteristics such as carrier density, contact resistance, and gate dielectric interfacial properties. In yet another embodiment, a method is provided for forming integrated layers for a TFT including IGZO within an in-situ environment of a cluster tool.

Owner:APPLIED MATERIALS INC

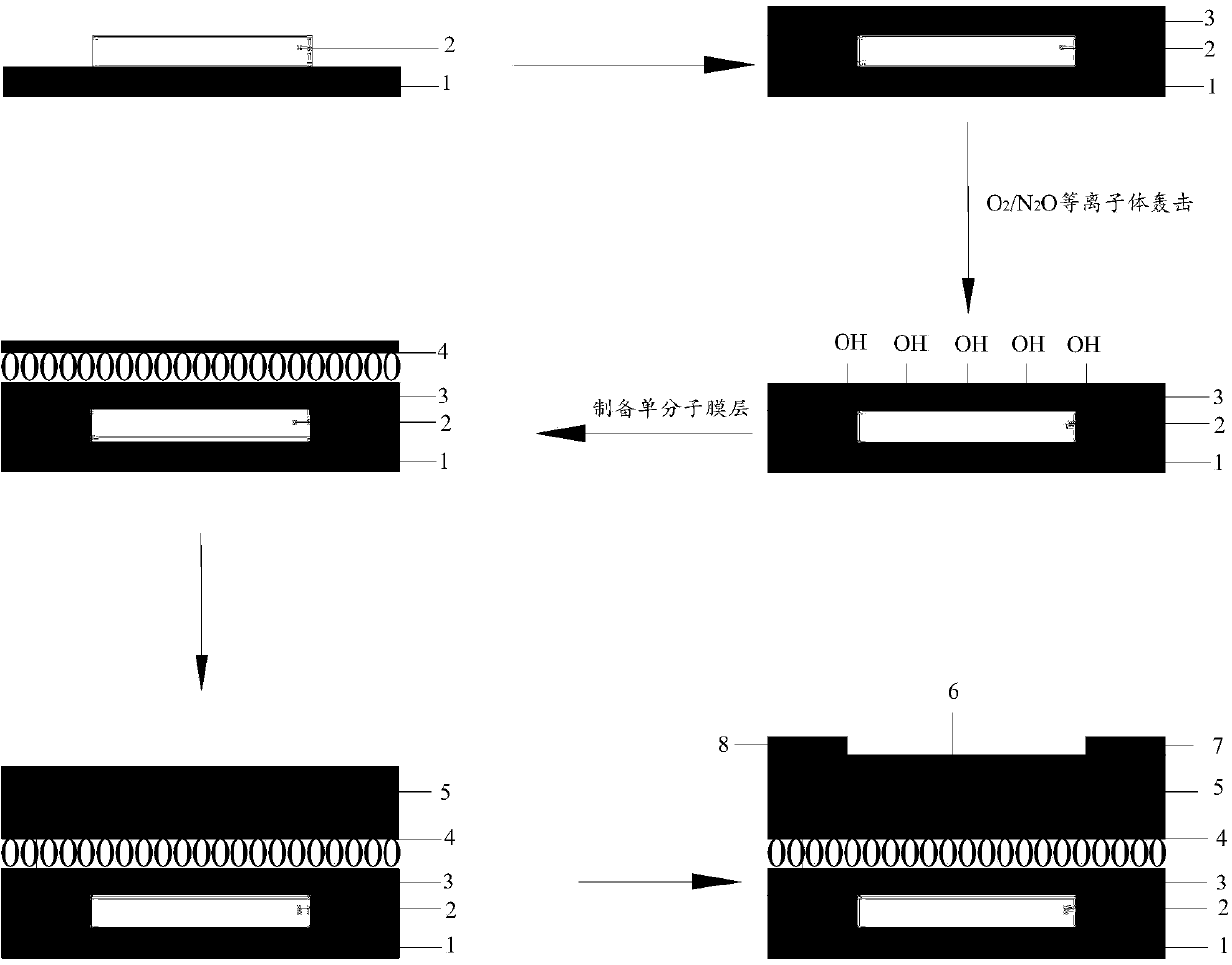

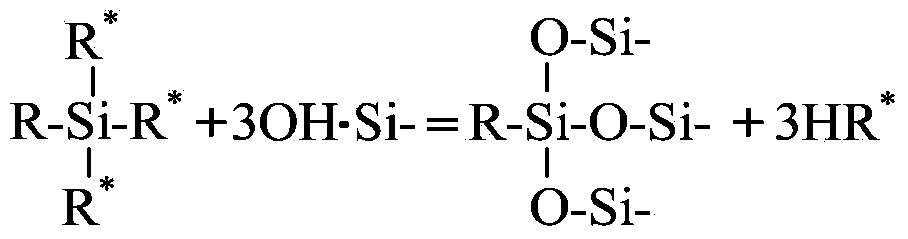

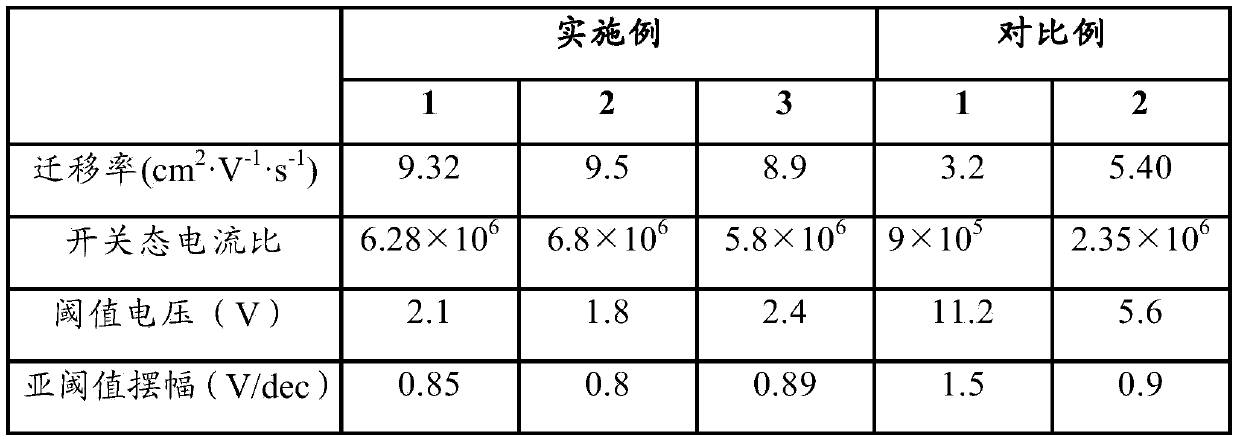

IGZO (indium gallium zinc oxide) thin film transistor and preparing method thereof

ActiveCN103700710AImprove mobilityImprove performanceTransistorSemiconductor/solid-state device manufacturingInsulation layerIndium gallium zinc oxide

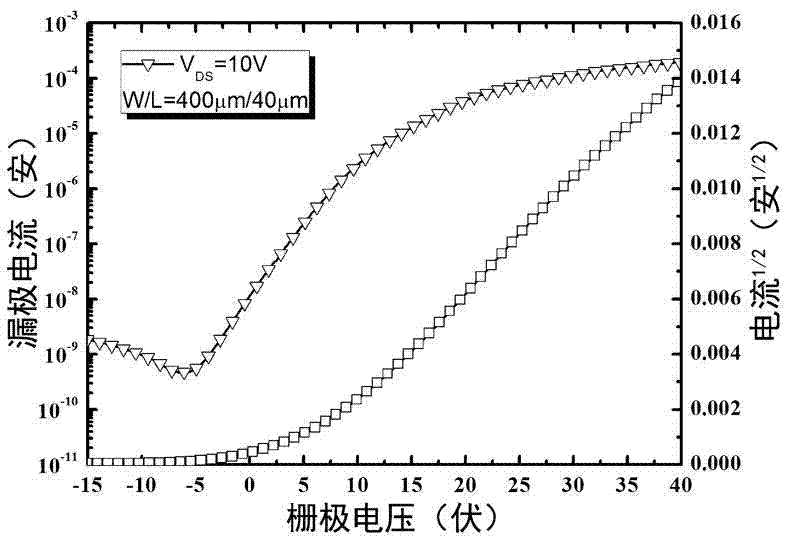

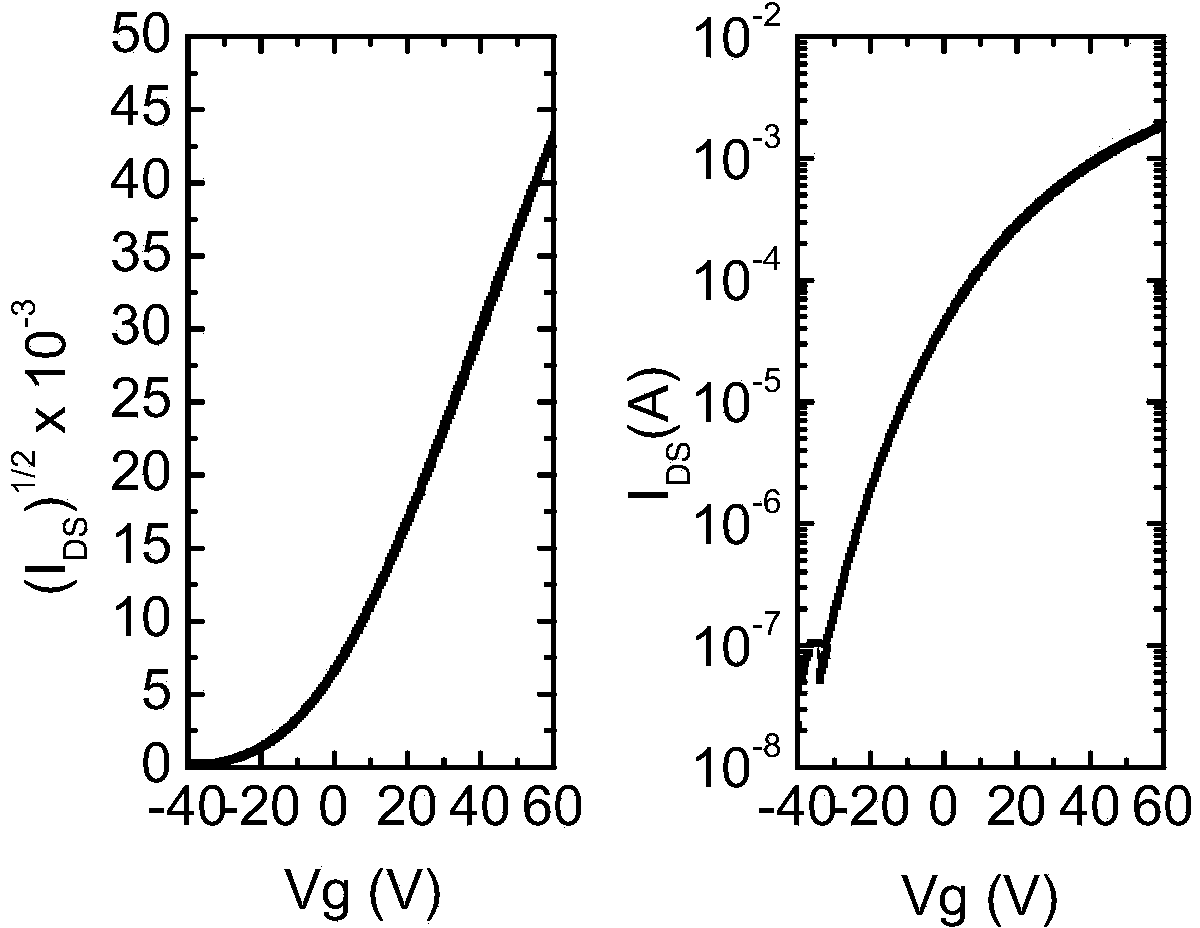

The invention discloses an IGZO (indium gallium zinc oxide) thin film transistor and a preparing method thereof, wherein the IGZO thin film transistor comprises a substrate, a grid combined on the substrate surface and a silicide grid insulation layer covering the outer surfaces of the substrate and the grid, wherein the surface of the silicide grid insulation layer is subjected to O2 / N2O plasma bombardment processing; the surface of the silicide grid insulation layer subjected to the O2 / N2O plasma bombardment processing is also combined with a self-assembly single-molecule film layer in a laminating mode, so the film defect state of the silicide grid insulation layer can be reduced after the O2 / N2O plasma bombardment, the charge trap action is inhibited, the roughness of the surface of the insulation layer is reduced by the self-assembly single-molecule film layer, the interface property between the insulation layer and an active layer is well improved, charges are prevented from being captured by an interface defect, the carrier mobility of a device is reduced, the threshold voltage is reduced, leak current is reduced and the performance of the device is more stable.

Owner:TCL CORPORATION

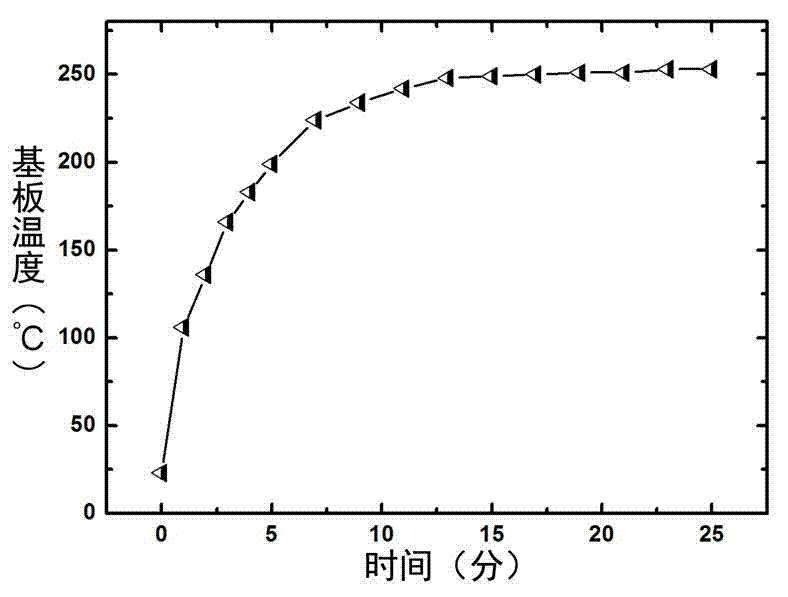

Method for producing indium gallium zinc oxide semiconductor thin film by using sol-gel method

InactiveCN102768945ASimple processReduce the temperatureSemiconductor/solid-state device manufacturingOptical propertySwitched current

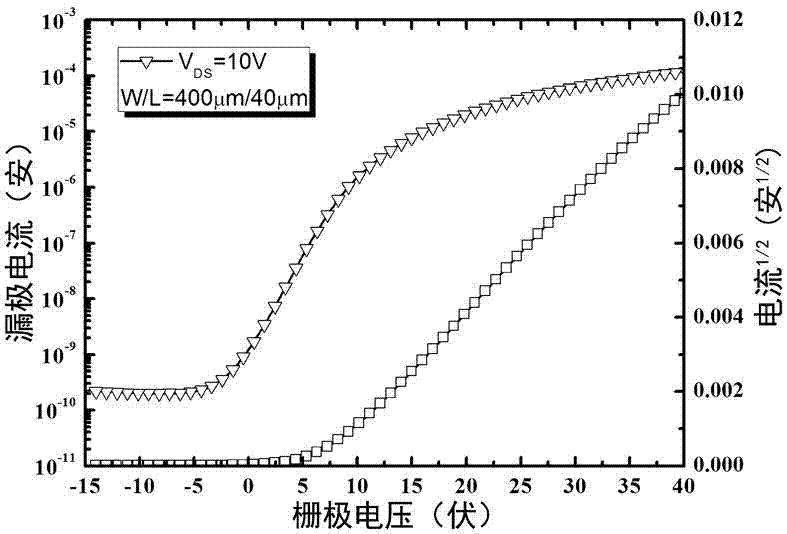

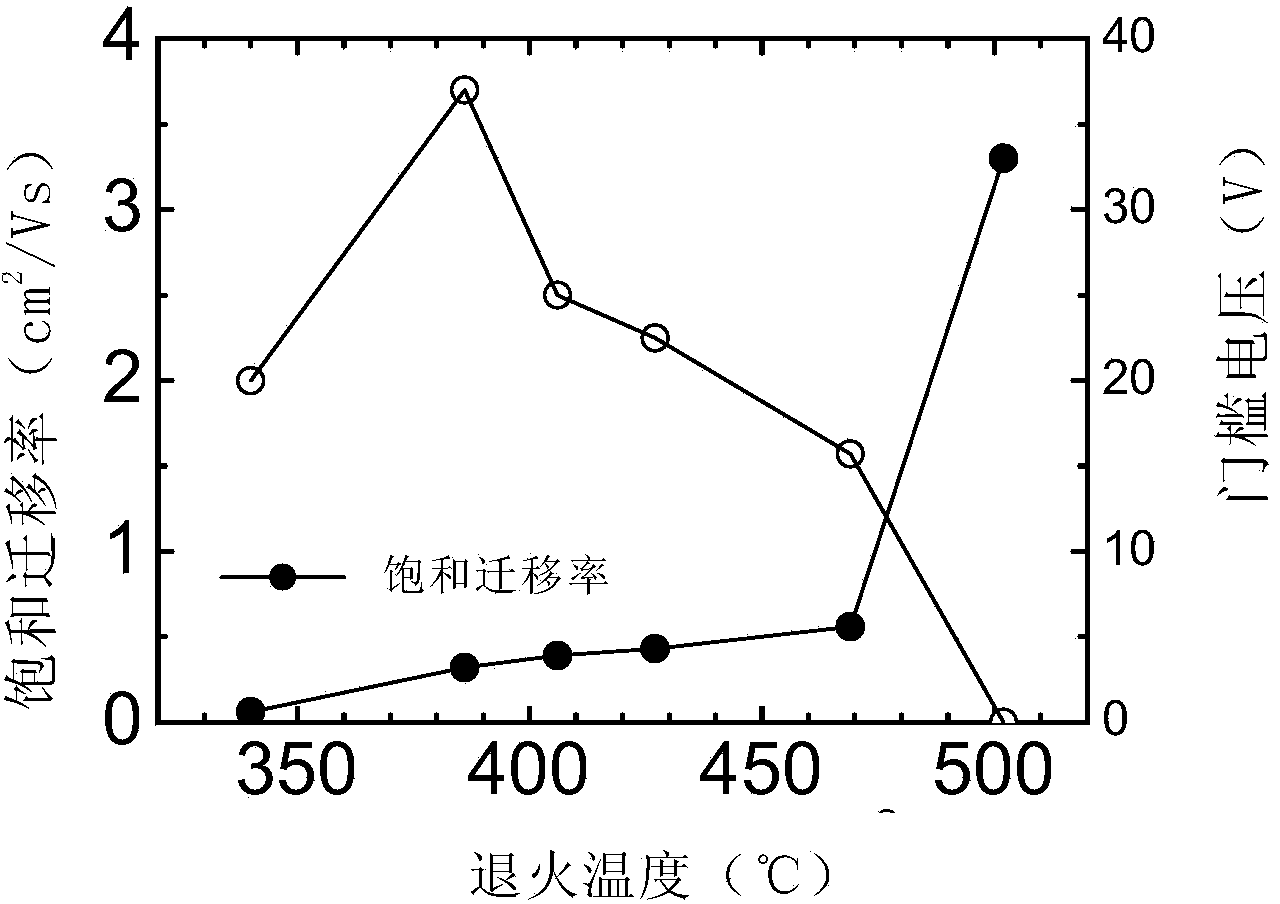

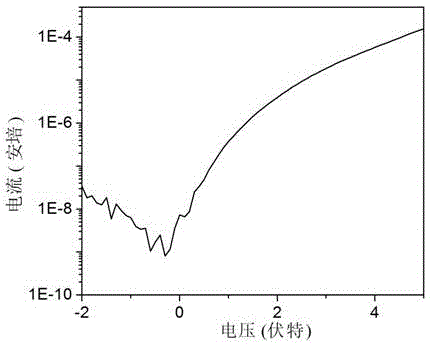

The invention belongs to the technical field of preparation of semiconductor thin films, and particularly relates to a low-temperature treatment method for producing an indium gallium zinc oxide (IGZO) semiconductor thin film by using a sol-gel method. The method comprises the following steps of: dissolving In(NO3)3.4*5H2O, Ga(NO3)3.4*5H2O and Zn(C2H3O2)2*5H2O into ethylene glycol monomethyl ether serving as a solvent and monoethanolamine serving as a stabilization agent to form a clear stable precursor solution; and coating the precursor solution on a glass substrate in a rotatable manner, and irradiating by using an infrared heating lamp to obtain the flat and transparent IGZO semiconductor thin film. Compared with the conventional method for preparing the IGZO thin film through annealing of a heat plate by using the sol-gel method, the method has the advantages that the IGZO thin film irradiated by the infrared heating lamp is relatively high in semiconductor and optical properties, and the process temperature is relatively low and lower than 250 DEG C; the IGZO thin film is used as a thin film transistor with a trench layer material; the switch current ratio is more than 5*10<6>; the saturated migration rate is more than 1.8 cm<2> / Vs; and the subthreshold amplitude is less than 2.2 V / dec.

Owner:FUDAN UNIV

Preparing method for indium gallium zinc oxide semi-conductor film

InactiveCN103779425AImprove stabilityImprove performanceTransistorSemiconductor/solid-state device manufacturingIndium gallium zinc oxideIndium acetylacetonate

The invention discloses a preparing method for an indium gallium zinc oxide semi-conductor film. The preparing method comprises the following steps: a) preparing an ethanol solution of gallium acetylacetonate, an ethanol solution of zinc acetylacetonate hydrate, and a tetrahydrofuran solution of indium acetylacetonate; b) mixing and stirring the three solutions well, thereby obtaining a polymeric precursor solution of indium gallium zinc oxide; c) depositing the polymeric precursor solution on a substrate material, then carrying out annealing treatment, thereby obtaining the indium gallium zinc oxide semi-conductor film. According to the method, the preparing process is simple and controllable, the cost is low, and the photoelectric property is excellent.

Owner:SHANGHAI JIAO TONG UNIV

Methods for Forming Back-Channel-Etch Devices with Copper-Based Electrodes

InactiveUS20140273341A1Solid-state devicesSemiconductor/solid-state device manufacturingMalonic acidIndium gallium zinc oxide

Embodiments described herein provide methods for forming indium-gallium-zinc oxide (IGZO) devices. A substrate is provided. An IGZO layer is formed above the substrate. A copper-containing layer is formed above the IGZO layer. A wet etch process is performed on the copper-containing layer to form a source region and a drain region above the IGZO layer. The performing of the wet etch process on the copper-containing layer includes exposing the copper-containing layer to an etching solution including a peroxide compound and one of citric acid, formic acid, malonic acid, lactic acid, etidronic acid, phosphonic acid, or a combination thereof.

Owner:INTERMOLECULAR

Thin film transistor, gate driver including the same, and display device including the gate driver

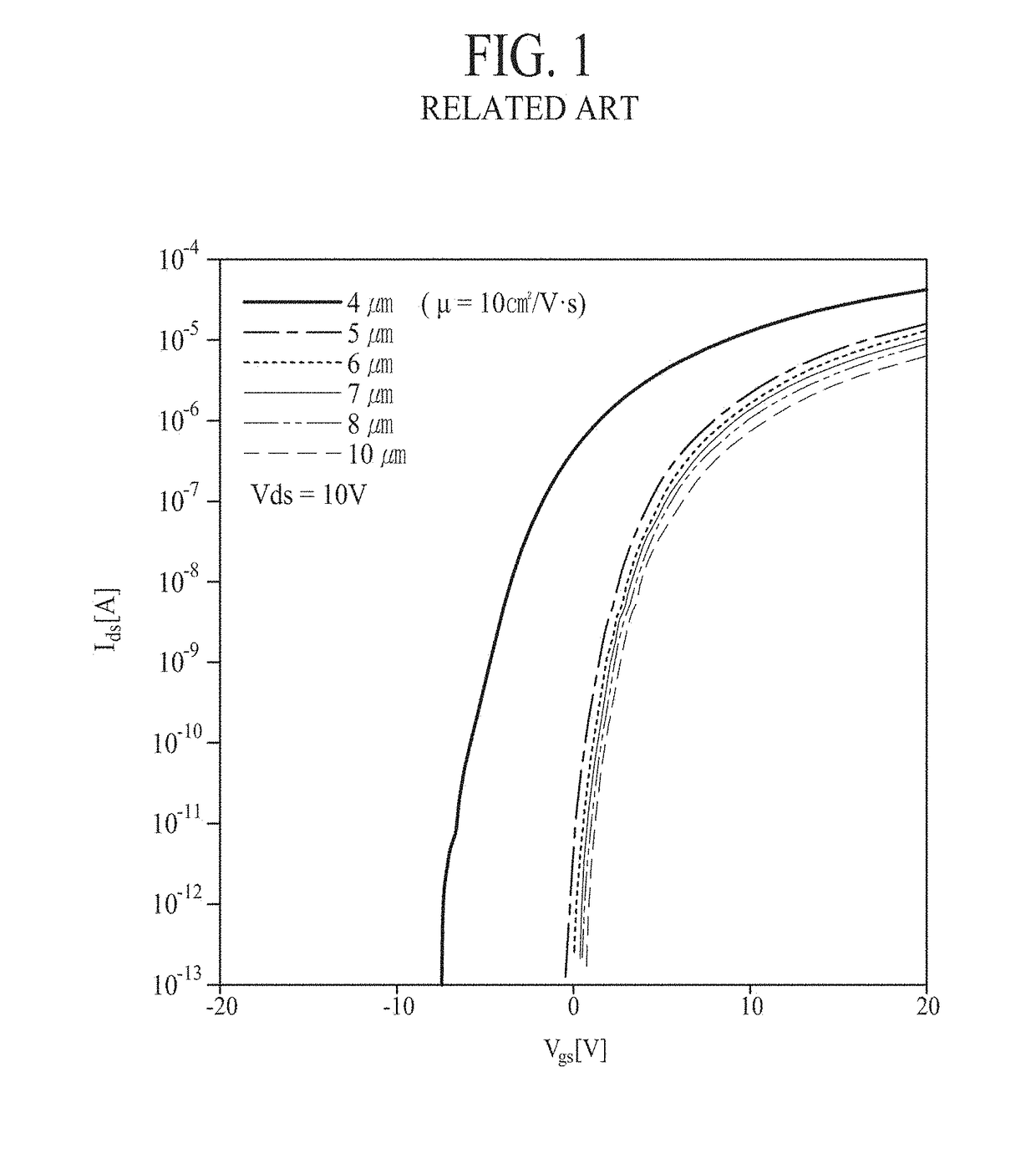

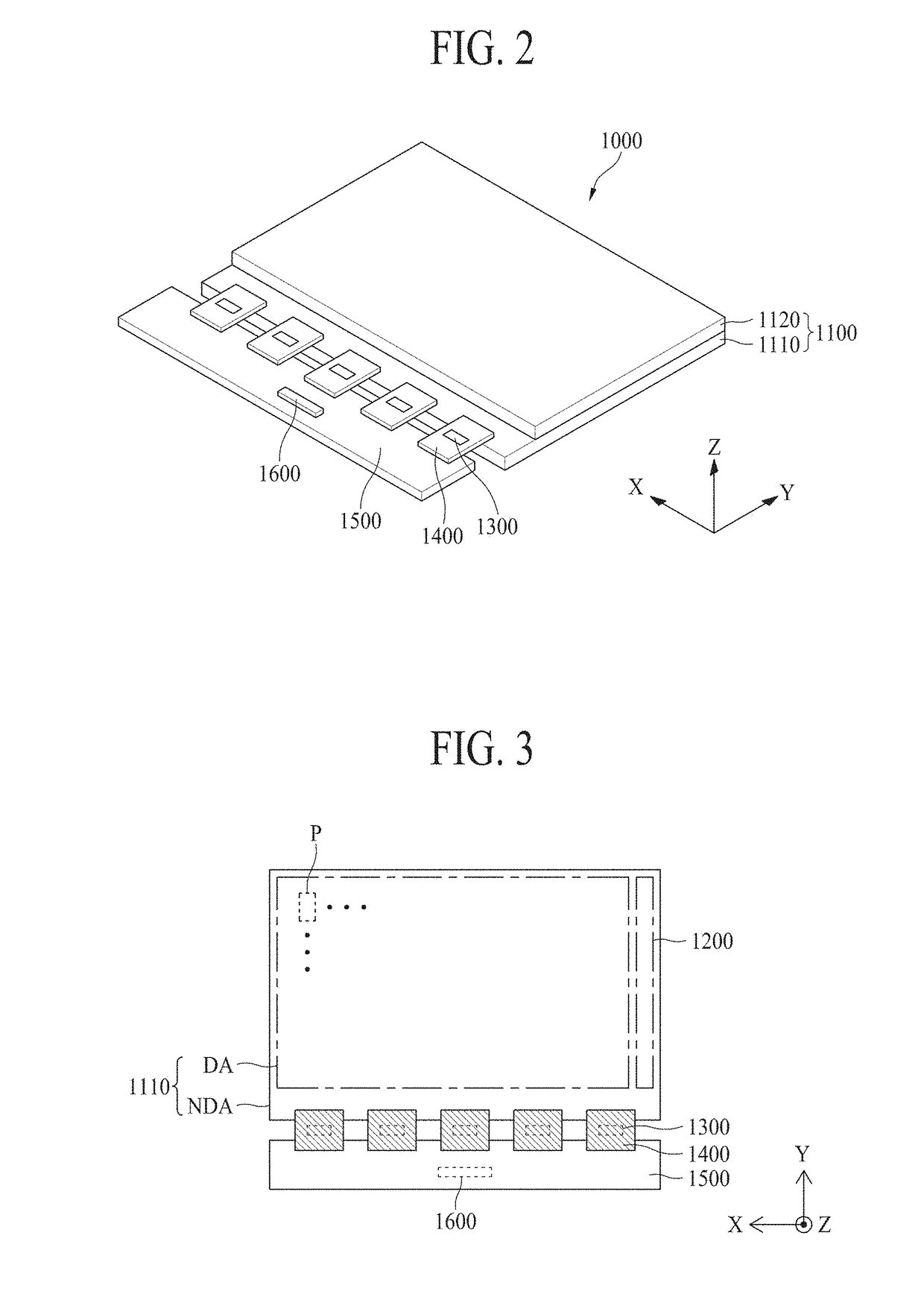

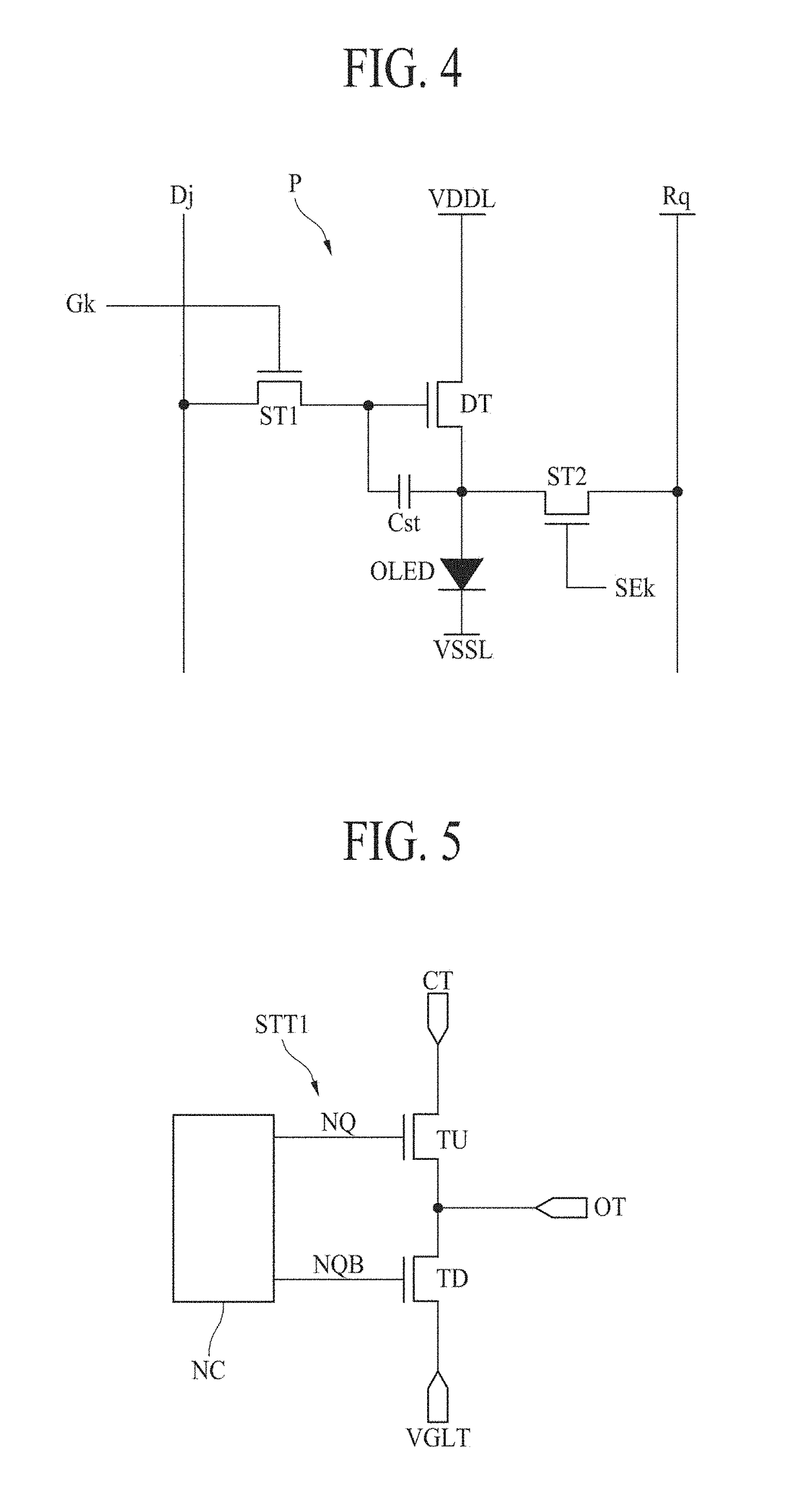

Disclosed are a thin film transistor (TFT) including an oxide semiconductor layer capable of being applied to high-resolution flat panel display devices requiring high-speed driving, a gate driver including the TFT, and a display device including the gate driver. The TFT includes first oxide semiconductor layer consisting of indium-gallium-zinc-tin oxide (IGZTO) and a second oxide semiconductor layer including indium-gallium-zinc oxide (IGZO). A content ratio (Ga / In) of gallium (Ga) to indium (In) of the second oxide semiconductor layer is higher than a content (Ga / In) of Ga to In of the first oxide semiconductor layer, and a content ratio (Zn / In) of zinc (Zn) to In of the second oxide semiconductor layer is higher than a content (Zn / In) of Zn to In of the first oxide semiconductor layer.

Owner:LG DISPLAY CO LTD

Apparatus and method of forming an indium gallium zinc oxide layer

ActiveUS20150221508A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseIndium gallium zinc oxide

The embodiments of the disclosure may generally provide a method and apparatus for forming thin film transistor device that includes an indium gallium zinc oxide (IGZO) layer using a multi-component precursor gas. The embodiments of the disclosure may provide a plasma enhanced chemical vapor deposition system configured to form an IGZO layer on large area substrates. However, it should be understood that the disclosure has utility in other system configurations such other types of chemical vapor deposition systems and any other system in which distributing a multi-component precursor gas to and within a process chamber is desired.

Owner:APPLIED MATERIALS INC

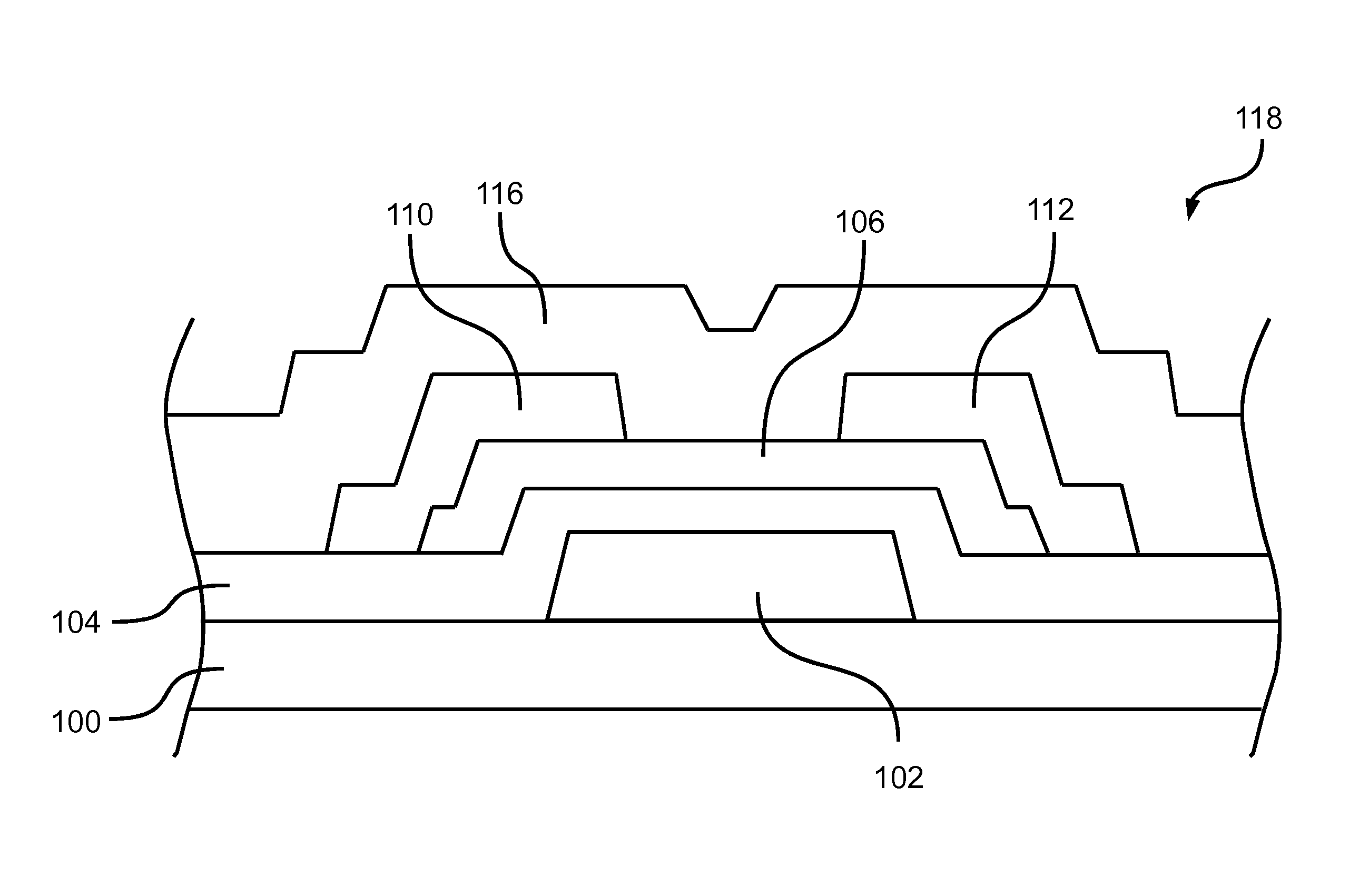

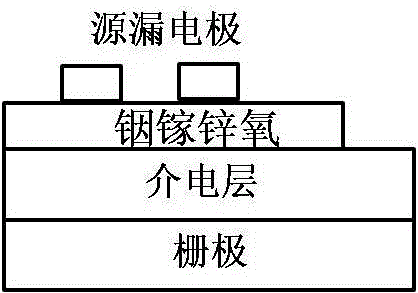

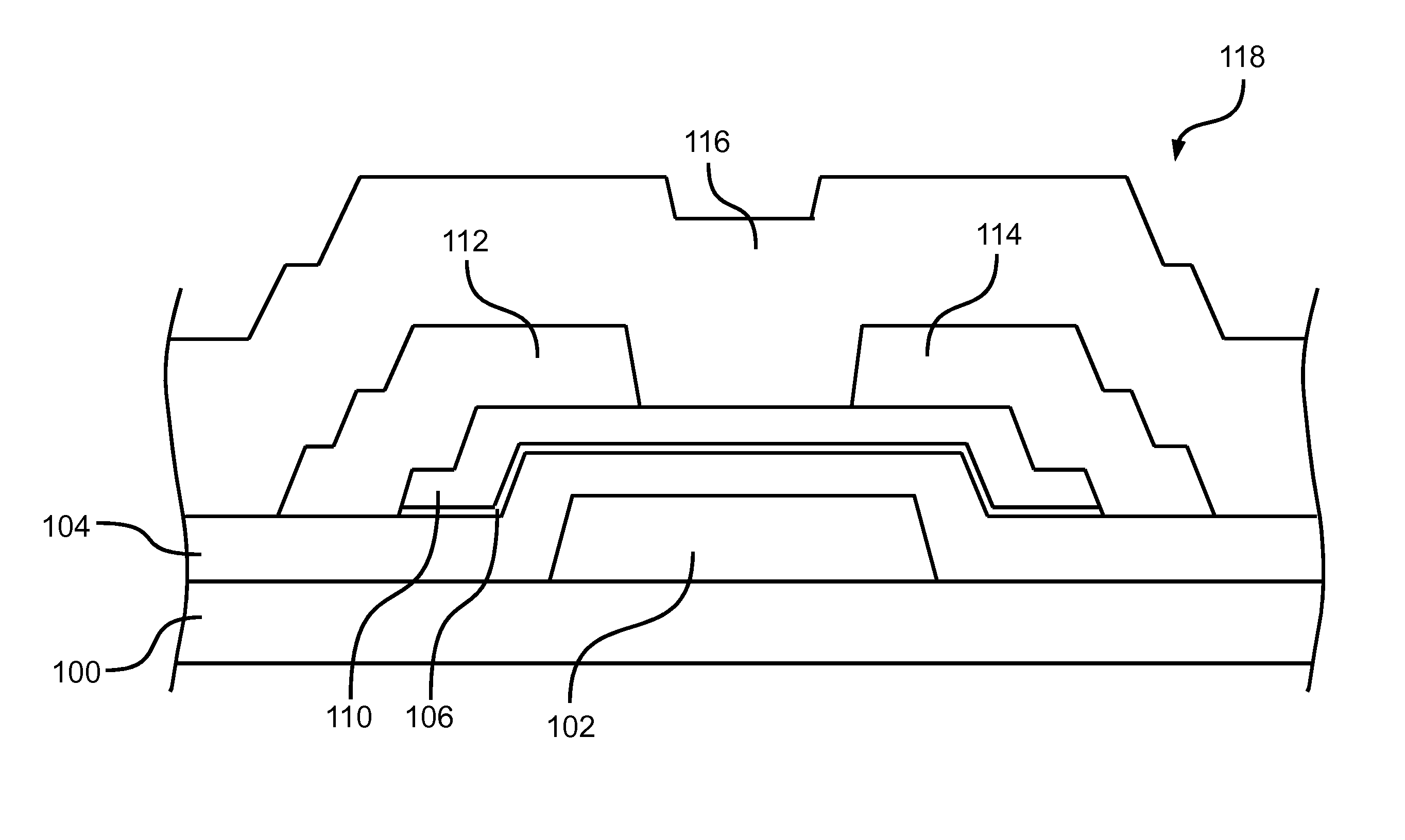

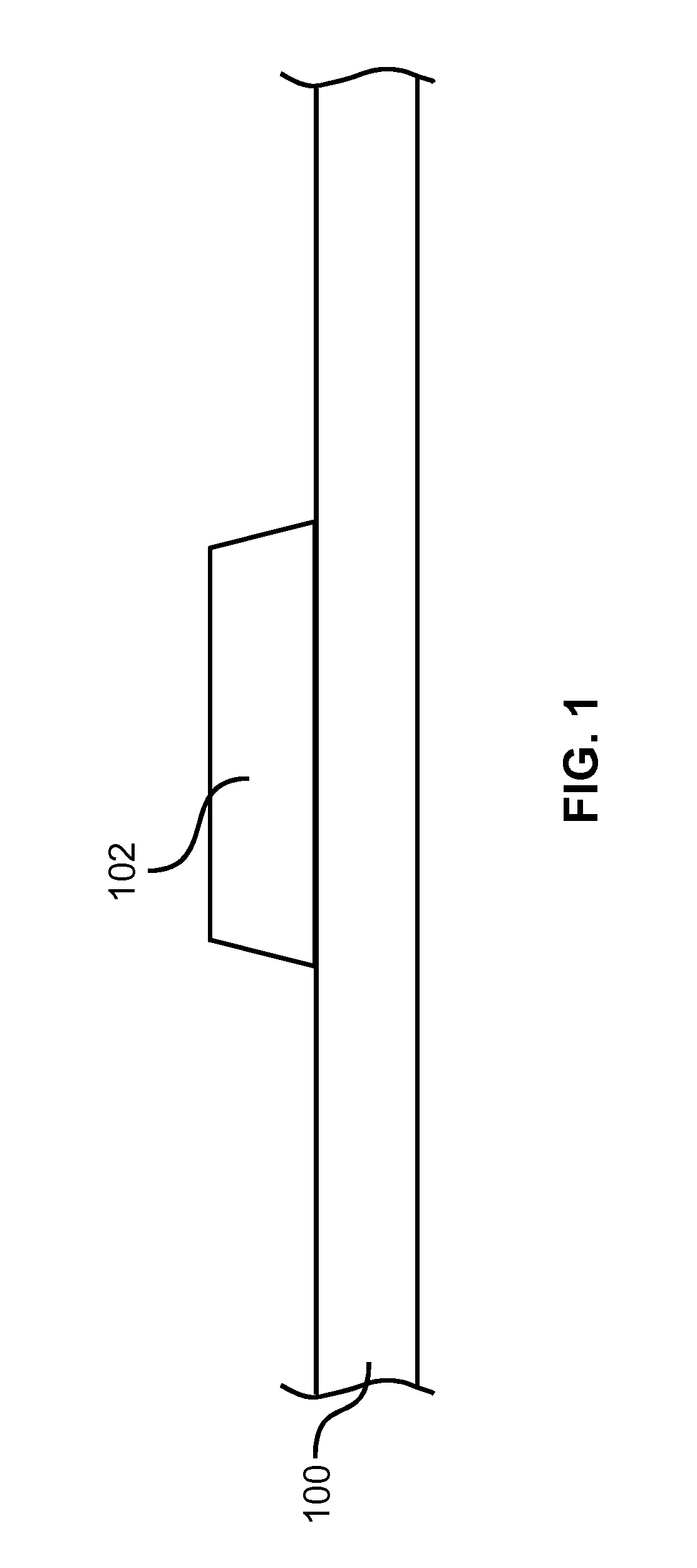

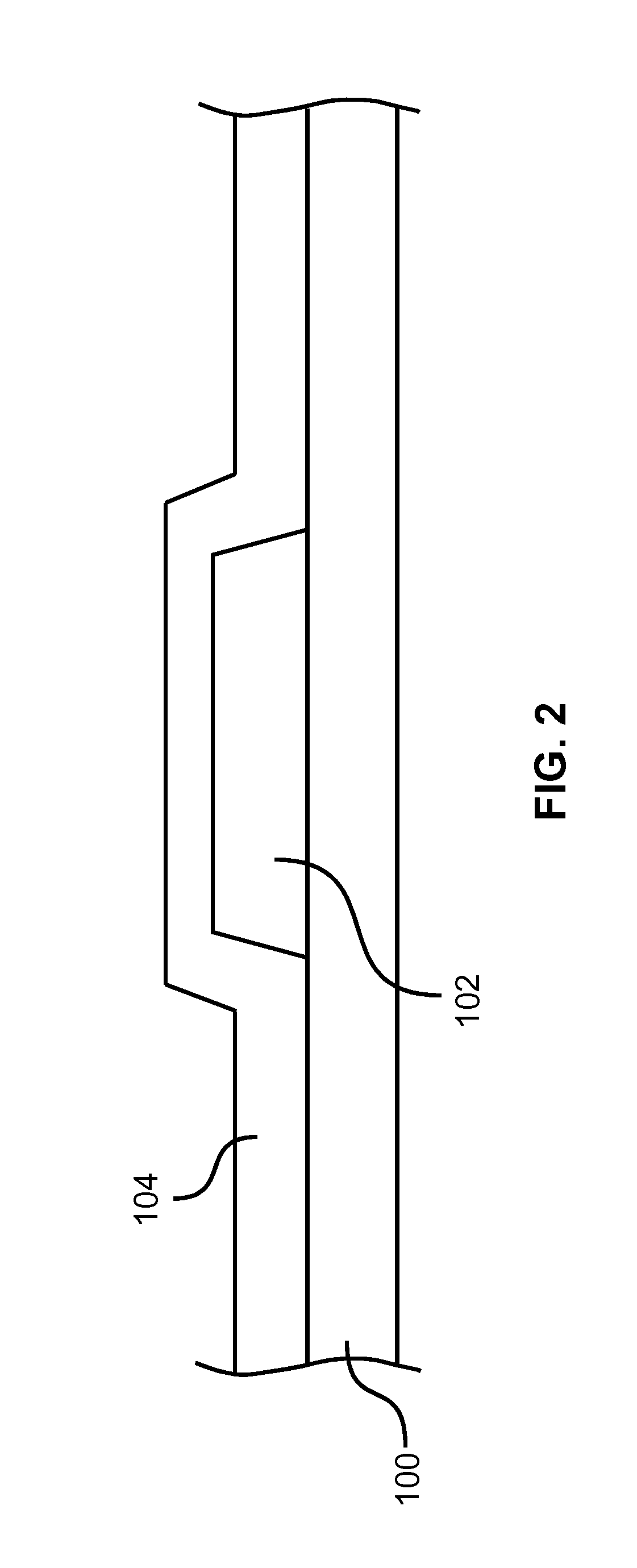

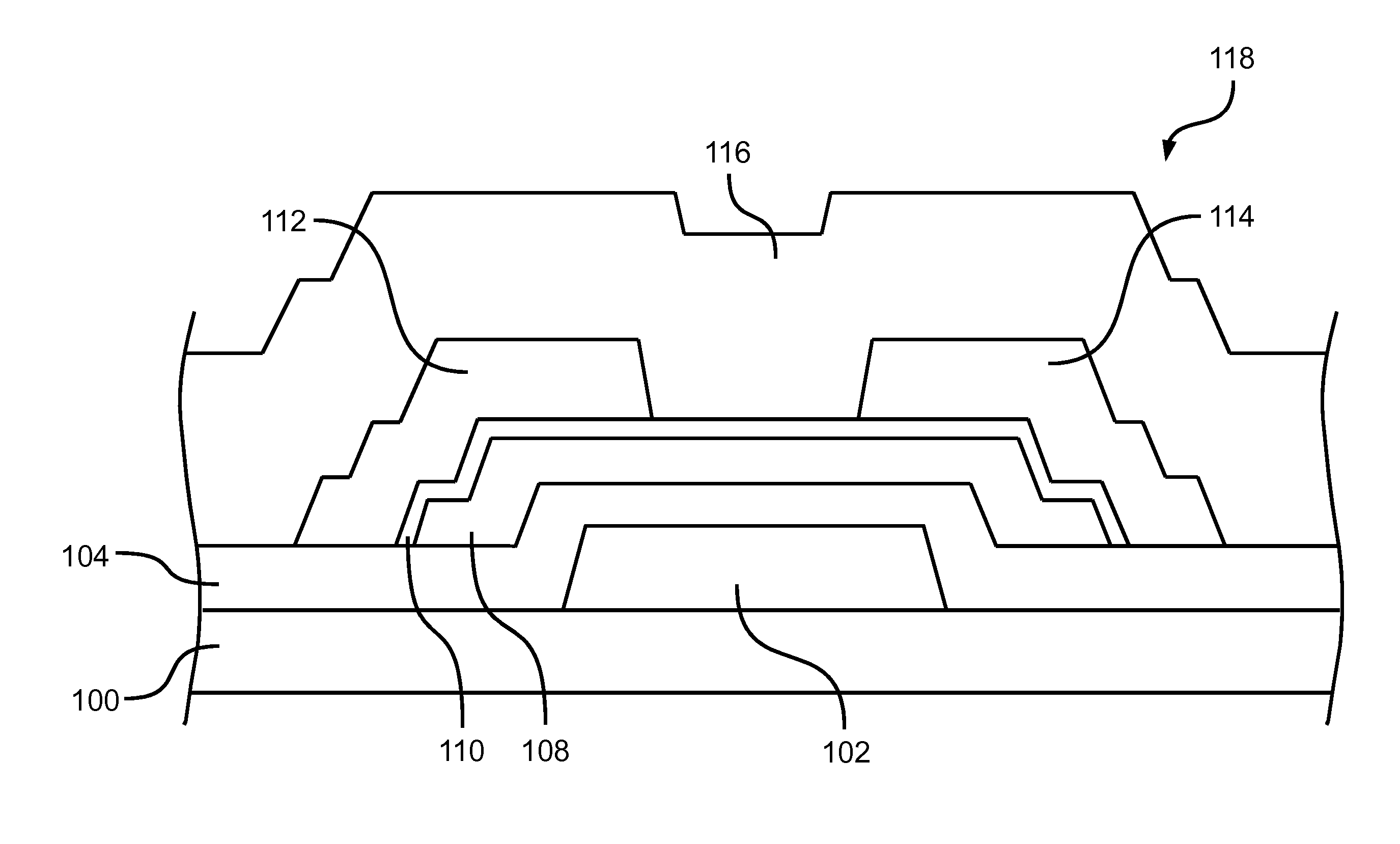

IGZO devices with composite channel layers and methods for forming the same

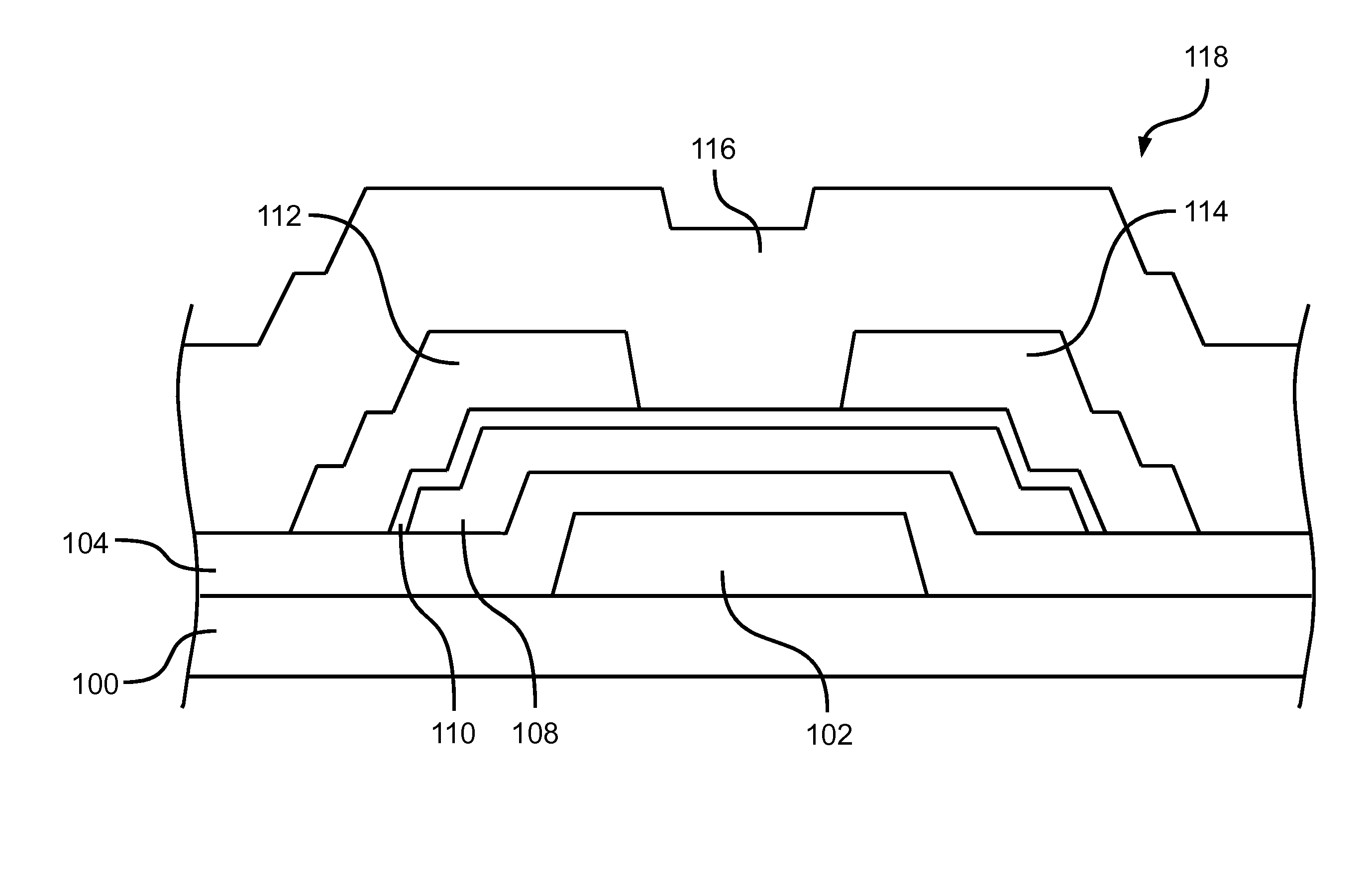

InactiveUS9246013B2TransistorSemiconductor/solid-state device manufacturingComposite channelIndium gallium zinc oxide

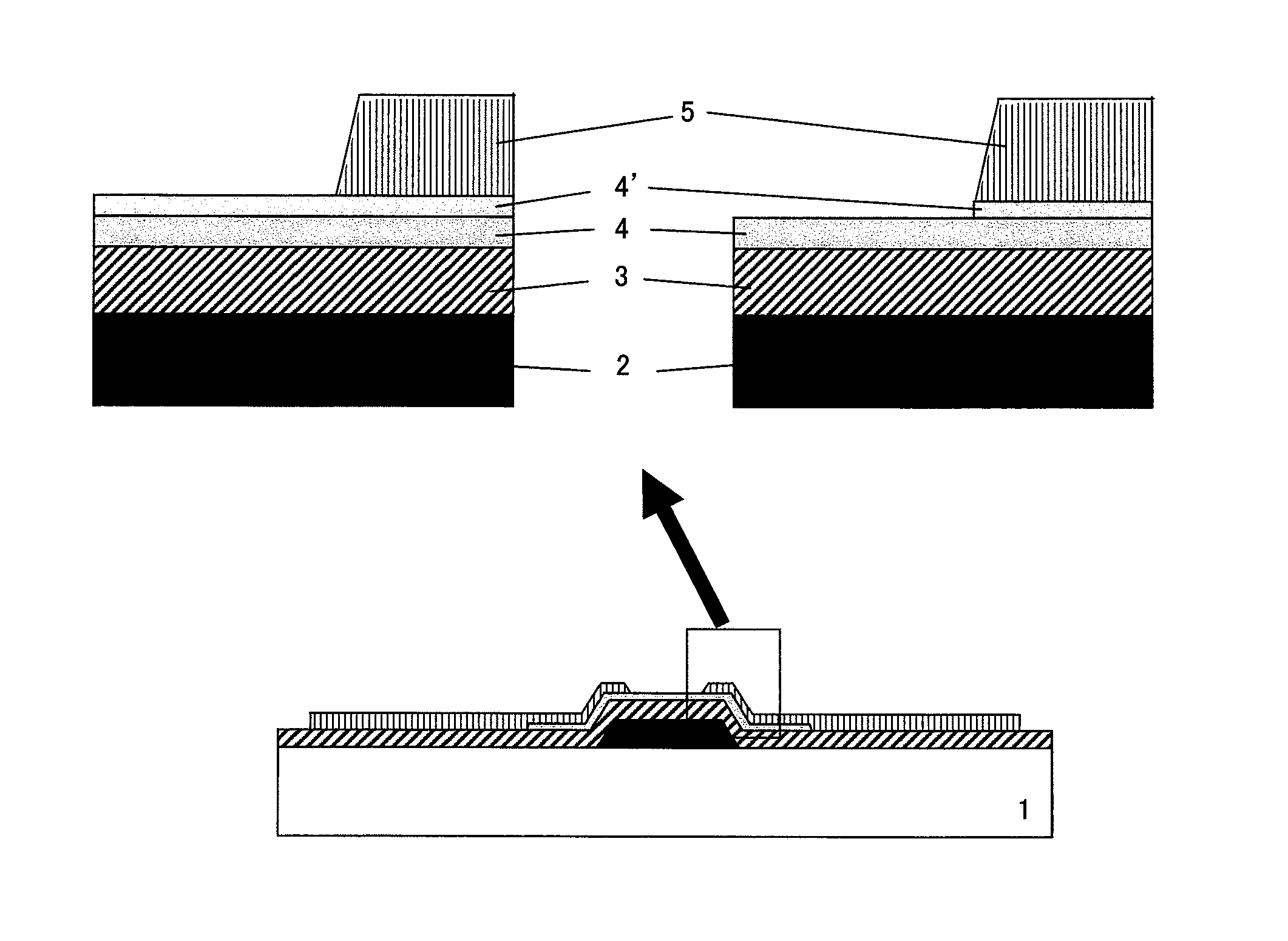

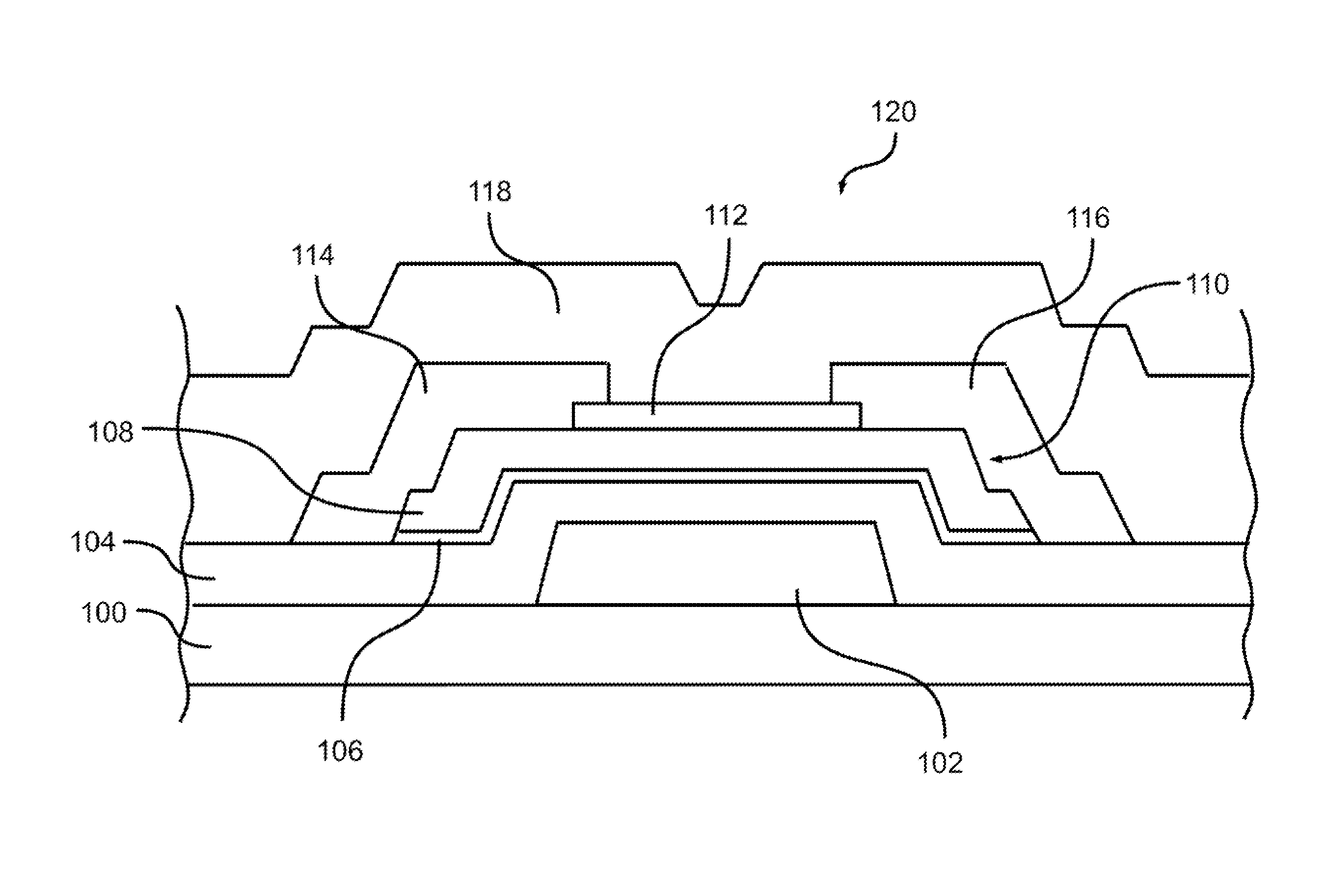

Embodiments described herein provide indium-gallium-zinc oxide (IGZO) devices, such as IGZO thin-film transistors (TFTs), and methods for forming such devices. A substrate is provided. A gate electrode is formed above the substrate. An IGZO channel layer is formed above the gate electrode. The IGZO channel layer has a first sub-layer including c-IGZO and a second sub-layer including a-IGZO. A source electrode and a drain electrode are formed above the IGZO channel layer.

Owner:INTERMOLECULAR

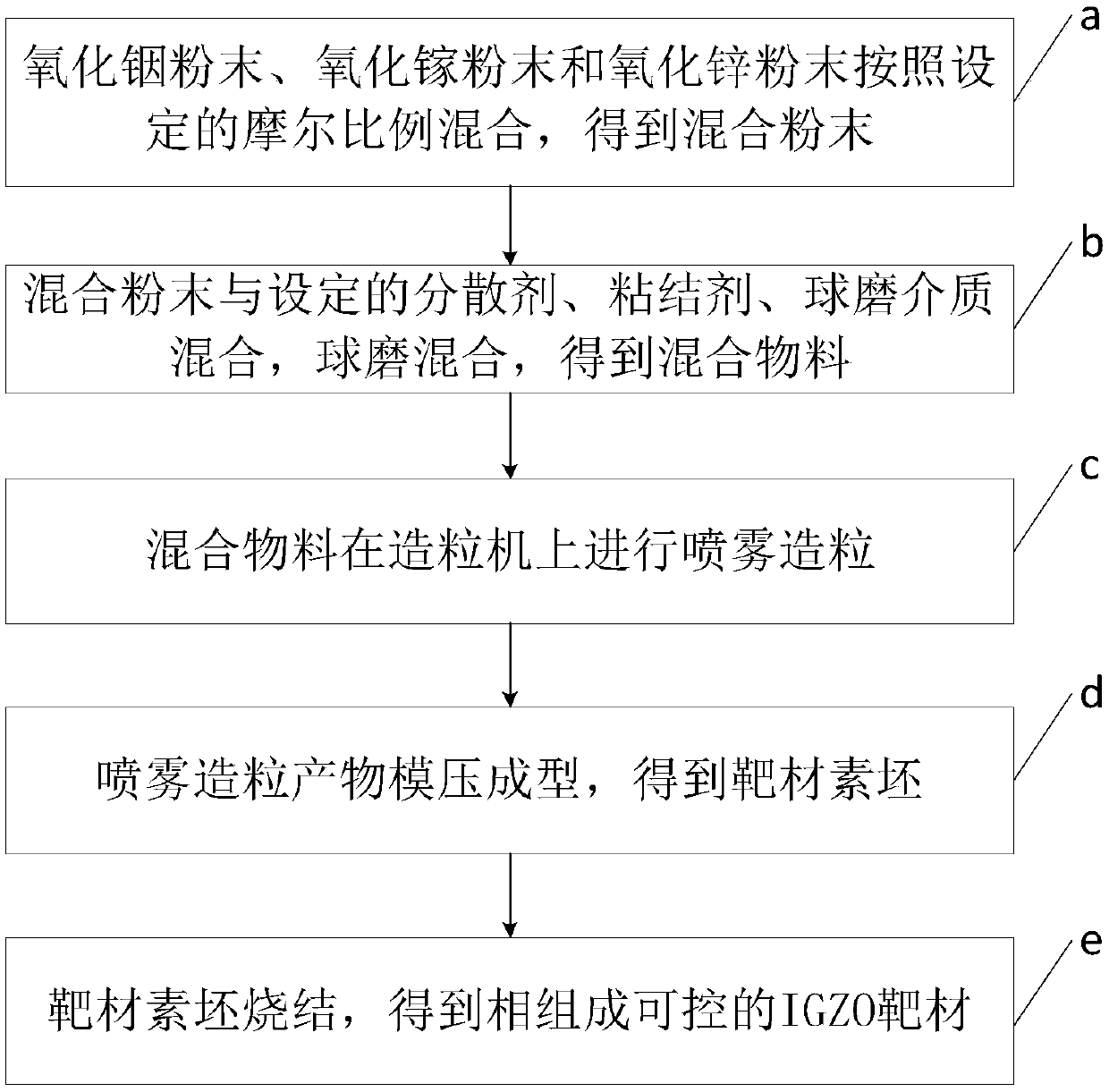

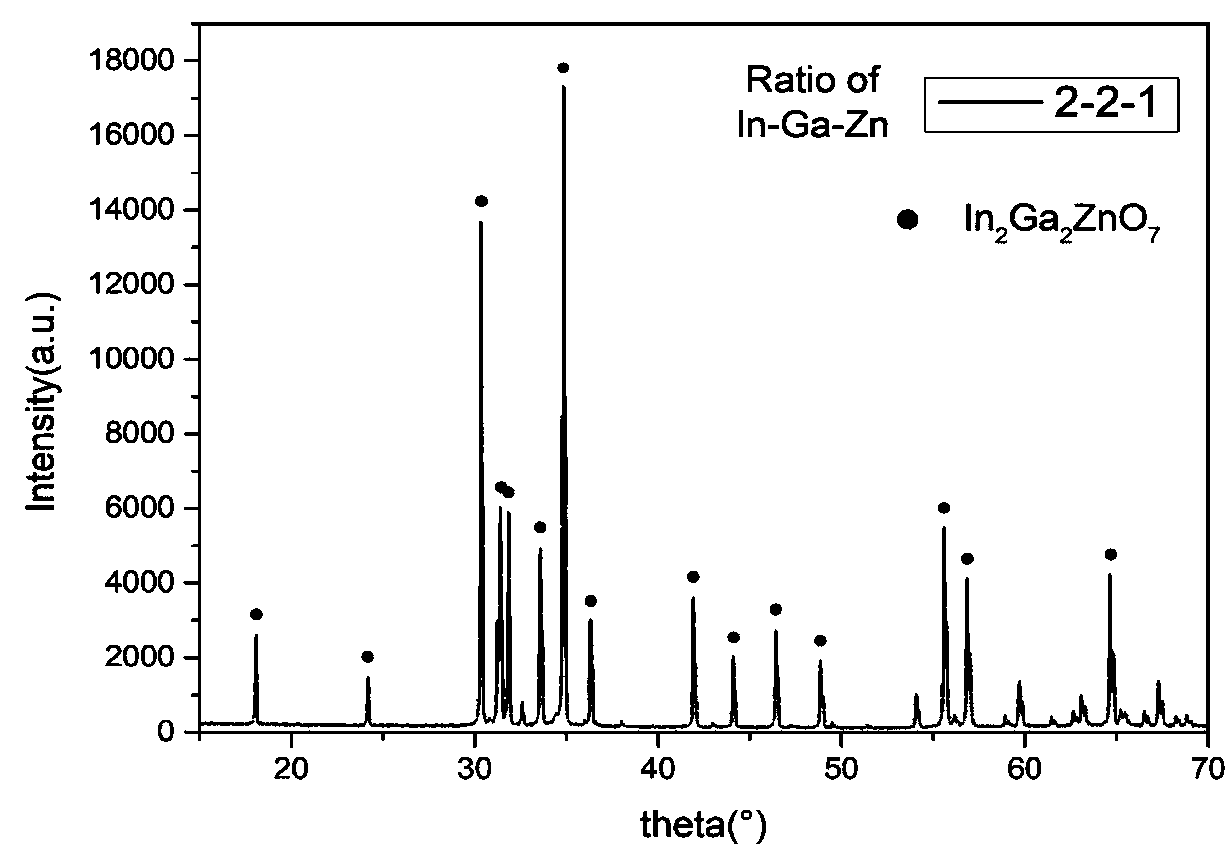

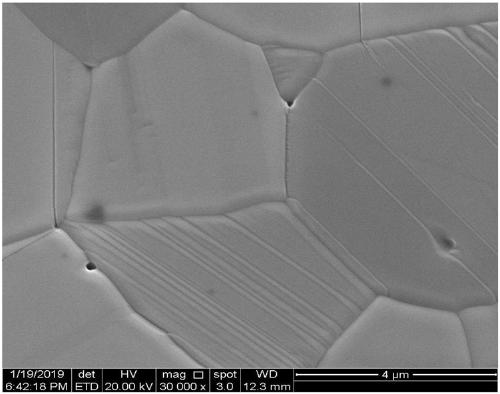

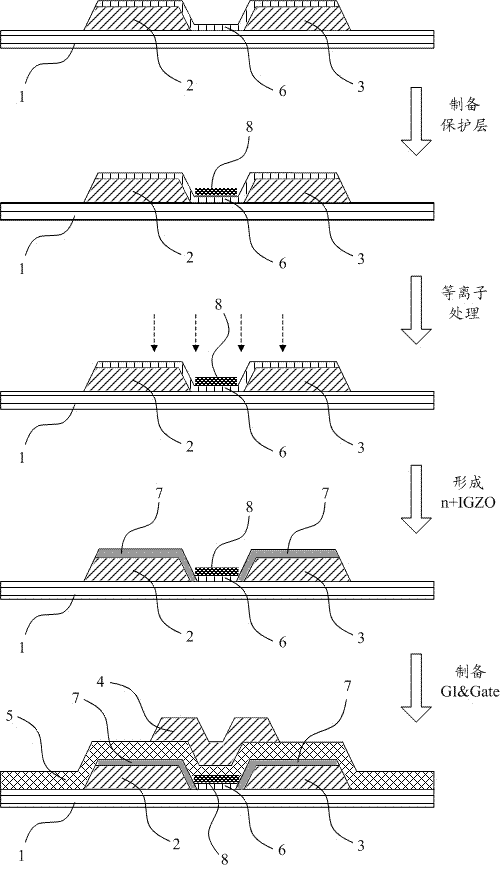

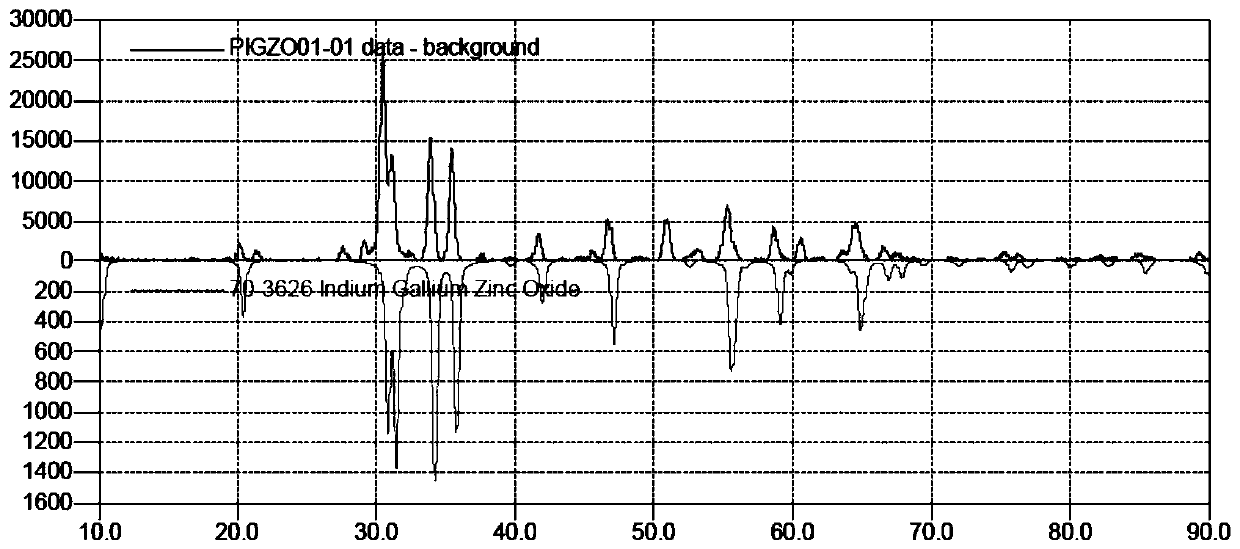

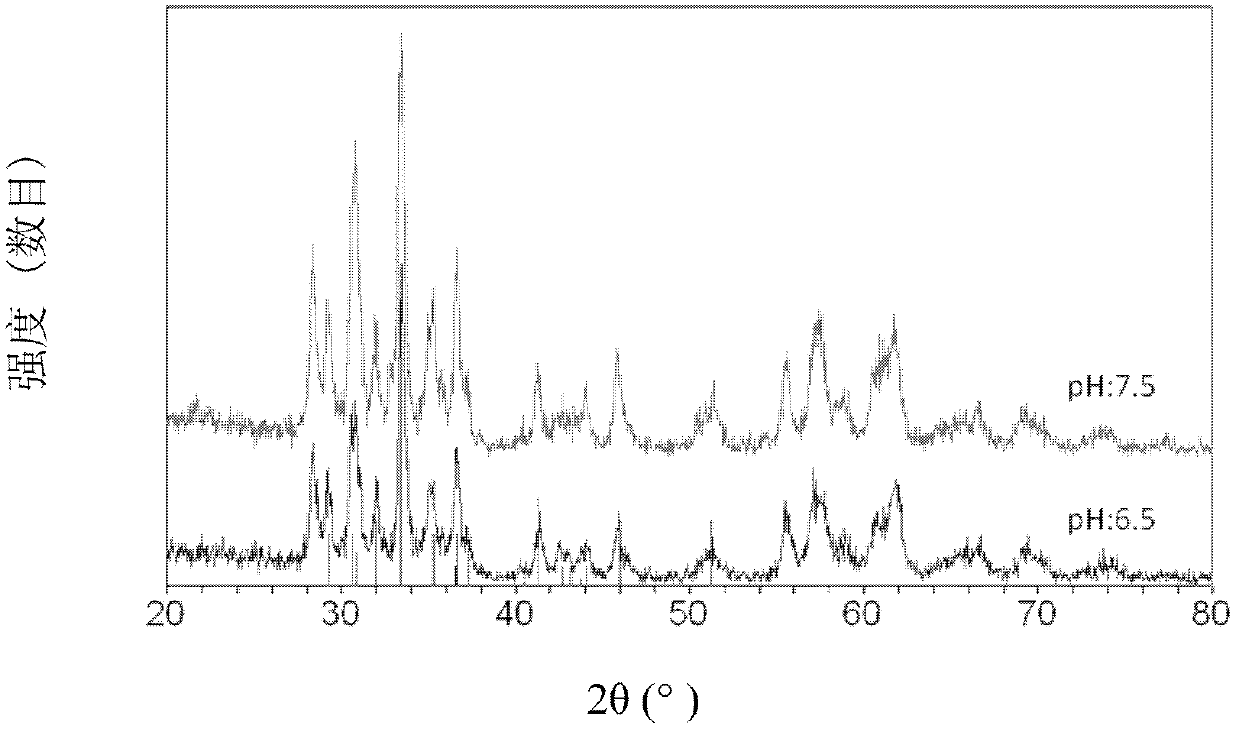

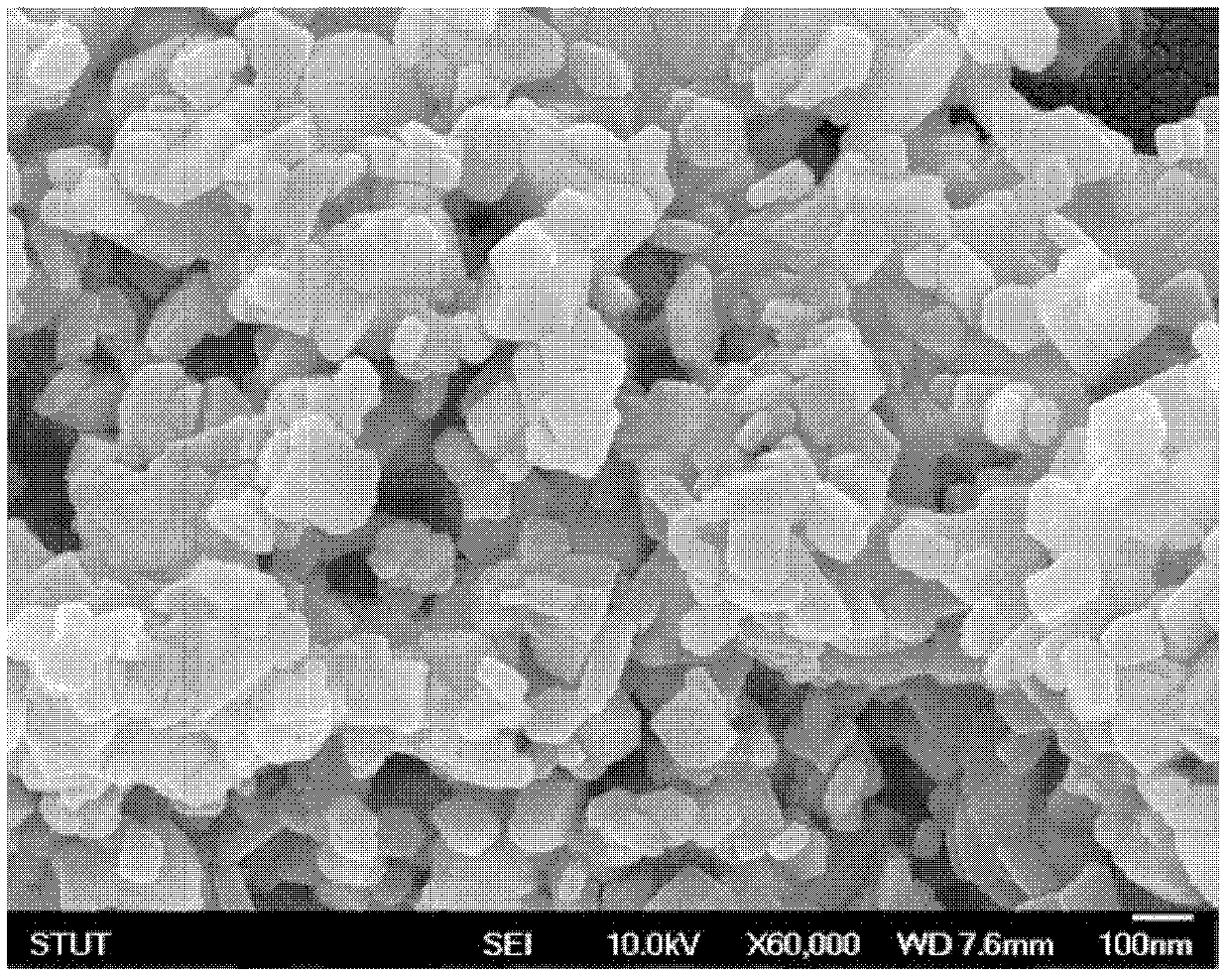

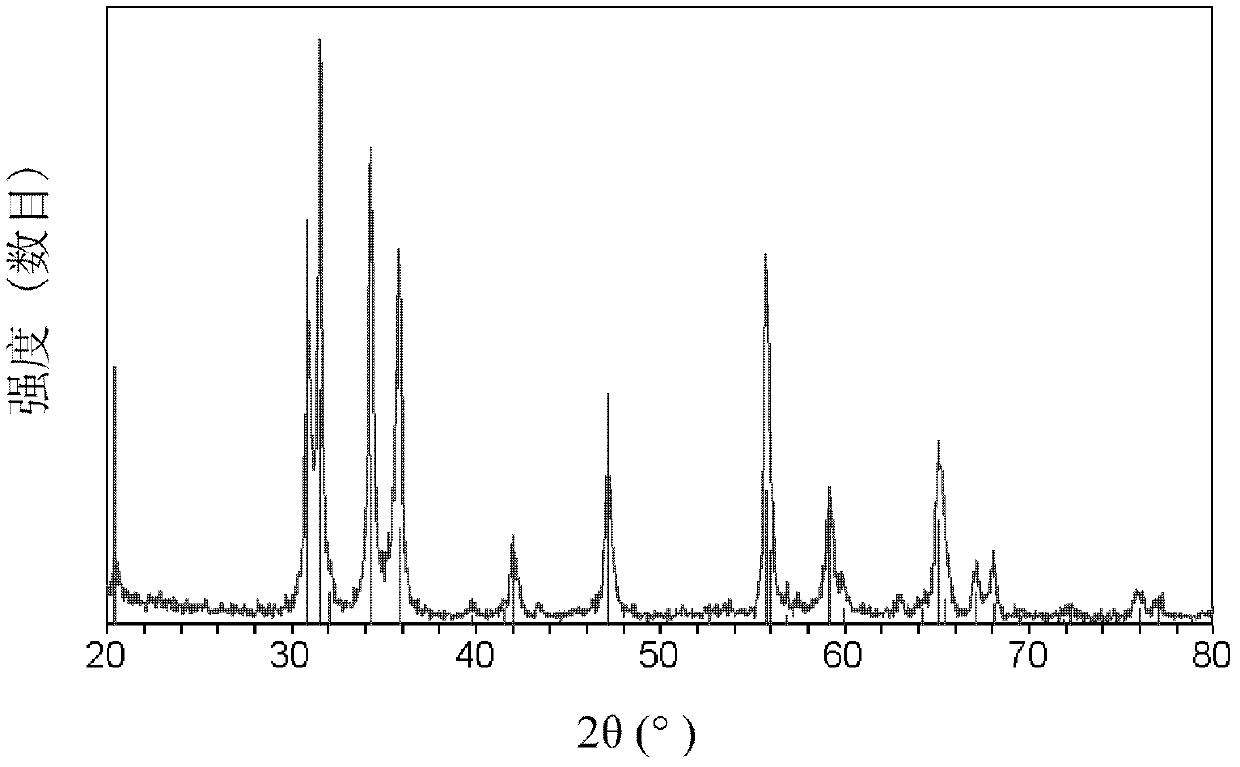

Phase composition controllable indium gallium zinc oxide target material and preparation method thereof

The invention discloses a phase composition controllable indium gallium zinc oxide target material and a preparation method thereof. The preparation method includes that indium oxide powder, gallium oxide powder and zinc oxide powder are mixed according to the set molar ratio to obtain a mixed powder; the mixed powder is mixed with the set amount of dispersant, binder and ball milling medium; a ball milling device is applied to control the ball milling parameters, and the ball milling mixing is carried out to obtain a mixed material; the mixed material is sprayed and granulated on a granulator, the product obtained by spray granulation is molded and a target blank is obtained; and the target blank is sintered to obtain the IGZO target material with controllable phase composition. A high quality IGZO target material with single phase and controllable phase is obtained by controlling the process parameters effectively in the preparation process according to the molar ratio of the raw materials. Other mixed phase composition is not contained in the target material, no secondary phase structure is existed between grains and inside, the bonding between grains is compact, and the targetmaterial has high density and has high industrial utilization value.

Owner:ZHENGZHOU UNIV

Oxide rotating target material and preparation method thereof

InactiveCN113831141AImprove mobilityImprove use valueVacuum evaporation coatingSputtering coatingIndiumIndium gallium zinc oxide

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

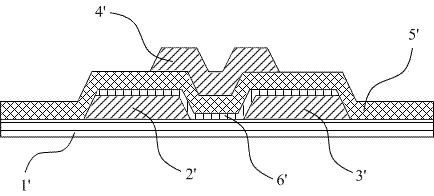

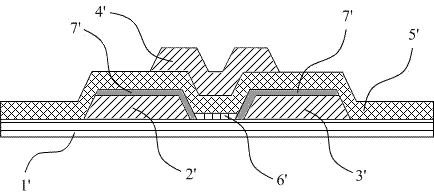

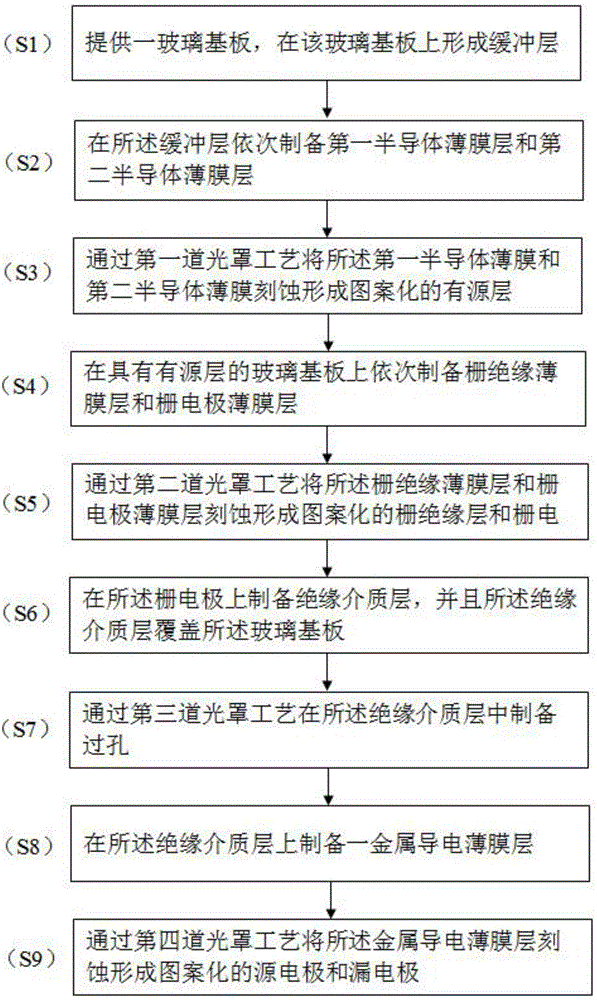

IGZO (Indium Gallium Zinc Oxide) transistor structure, manufacture method and display panel thereof

ActiveCN103700705AAvoid damageIncrease contactTransistorSolid-state devicesInsulation layerOhmic contact

The invention provides an IGZO (Indium Gallium Zinc Oxide)transistor, a manufacture method and a display panel thereof, wherein the manufacture method of the IGZO transistor comprises the following steps: preparing a source / drain electrode pattern layer and an IGZO pattern layer on a substrate; preparing a protective layer on an IGZO channel; performing N-shaped mix on the region where source / drain electrodes are in contact with an IGZO via plasma treatments to form an n+IGZO region; preparing a gate insulation layer and a gate pattern layer. Via the IGZO transistor, the manufacture method and the display panel, the problem of damaging the IGZO channel in the process of performing the N-shaped mix on the IGZO via the plasma treatments can be solved, and the method is helpful to improve ohmic contact and increase element characteristics.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of IGZO (Indium Gallium Zinc Oxide) target

The invention relates to a preparation method of a target, in particular to a preparation method of a high-performance IGZO (Indium Gallium Zinc Oxide) target. The method comprises the following steps of: (1) uniformly ball-milling and mixing Ga2O3 nano-powder, ZnO nano-powder and In2O3 nano-powder at an atomic ratio In:Ga:Zn of 1:(1-5):(1-5) to form IGZO powder, adding PVA (Polyvinyl Acetate) accounting for 1-5% of the mass of the IGZO powder for granulation, (2) loading the IGZO powder into a mold for compression molding at 40-80MPa, performing secondary moulding on a biscuit moulded for the first time at 200-300 MPa, releasing pressure at 4-8MPa / min to the ordinary pressure, then taking out a moulded biscuit, and (3) putting the biscuit in a sintering furnace for sintering: heating to 1300-1550 DEG C at a heating rate of less than 1 DEG C / min, holding, and sintering for 4-10h, then cooling to 950-1050 DEG C at a cooling rate of 0.5-1 DEG C / min, then naturally cooling, and obtaining the IGZO target. The method can prepare the high-performance IGZO target (high density, relative density greater than 98%, and high conductivity), and fills in the blank of producing and fabricating the high-performance IGZO target domestically.

Owner:洛阳晶联光电材料有限责任公司

Rare earth doped indium gallium zinc oxide powder as well as preparation method and application thereof

InactiveCN111574217AHigh densityUniform tissueVacuum evaporation coatingSputtering coatingRare-earth elementIndium

The invention relates to a preparation method of rare earth doped indium gallium zinc oxide powder. The method comprises the following steps of: sequentially adding water, a dispersing agent, galliumoxide powder and rare earth oxide powder into a first mixing barrel to perform pre-dispersion on the added raw materials, and grinding an obtained pre-dispersed solution to obtain first mixed slurry;sequentially adding water, a dispersing agent and zinc oxide powder into a second mixing barrel to perform pre-dispersion on the added raw materials, adding an obtained pre-dispersed solution into thefirst mixed slurry to perform grinding so as to obtain second mixed slurry; sequentially adding water, a dispersing agent and indium oxide powder into a third mixing barrel for pre-dispersing, and adding an obtained pre-dispersed solution into the second mixed slurry so as to perform grinding to obtain third mixed slurry; adding an adhesive into the third mixed slurry, and performing grinding toobtain fourth mixed slurry; and granulating, mixing and screening the fourth mixed slurry to finally obtain the rare earth doped indium gallium zinc oxide powder. According to the preparation method of the invention, the problem of non-uniform components caused by doping of large-particle-size rare earth elements into IGZO powder can be solved.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

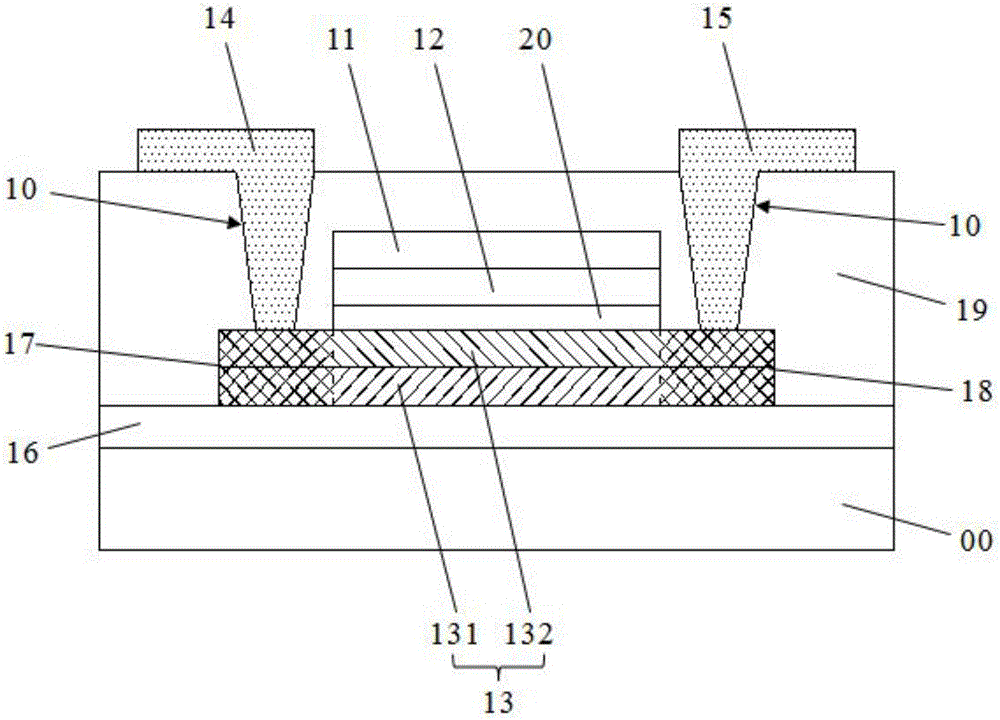

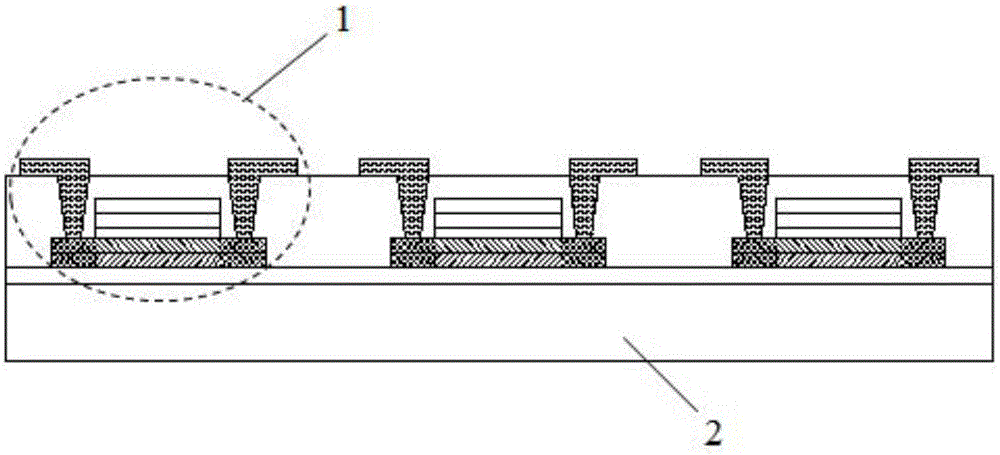

Thin-film transistor, array substrate and preparation method thereof

ActiveCN106158978AMeet the characteristic requirementsAvoid damageTransistorSemiconductor/solid-state device detailsSemiconductor materialsIndium

The invention discloses a thin-film transistor which comprises an active layer formed on a substrate, wherein the active layer comprises a first semiconductor layer and a second semiconductor layer which are arranged in a lamination way; the material of the first semiconductor layer is indium gallium zinc oxide of which atomic ratio In / (Ga+Zn) is less than 50%, and the material of the second semiconductor layer is indium gallium zinc oxide of which atomic ratio In / (Ga+Zn) is more than 55%. The invention also discloses an array substrate containing the above thin-film transistor and a preparation method thereof, the array substrate can be applied to a liquid crystal display (LCD) or an organic light-emitting diode (OLED). If the above provided thin-film transistor adopts two-layer IGZO semiconductor materials as an active layer semiconductor, the characteristic requirements of the thin-film transistor can be satisfied, and the carrier mobility of the IGZO active layer semiconductor can be further improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

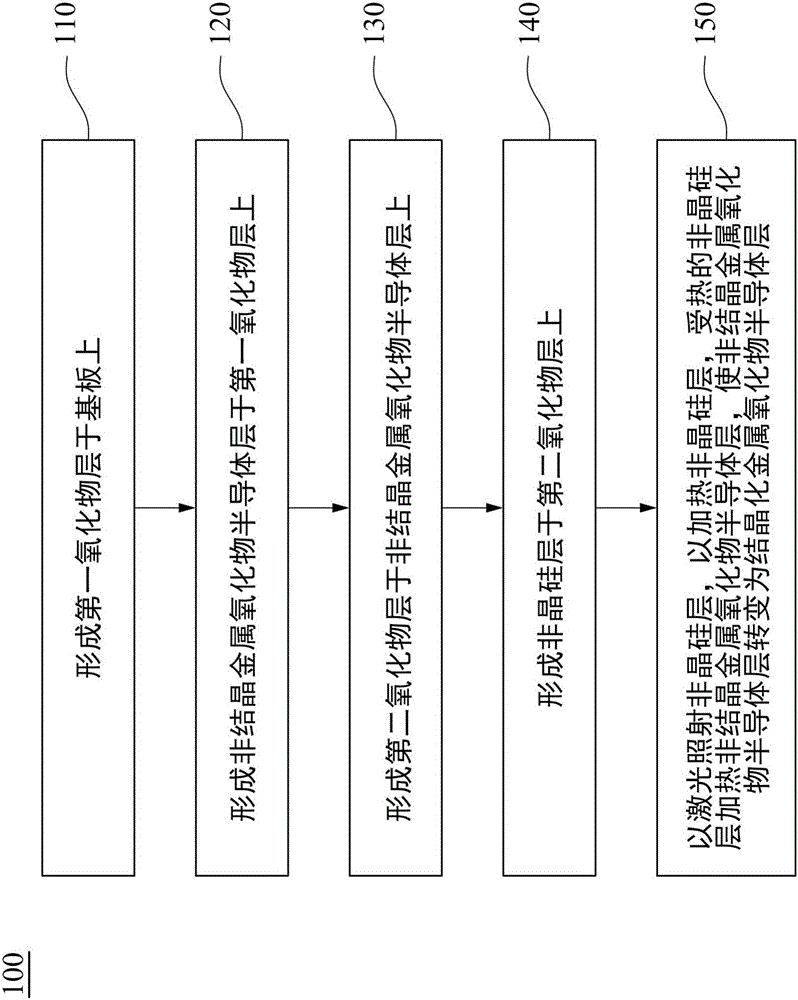

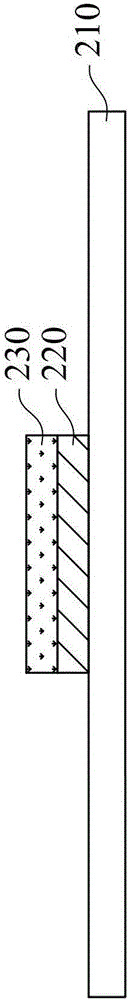

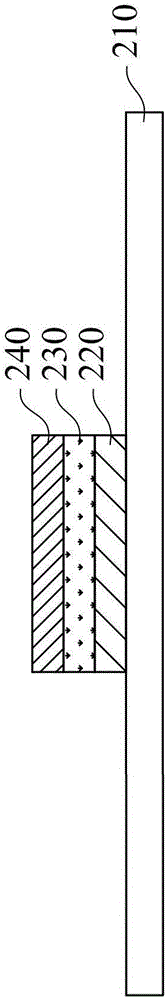

Crystallization method of metal oxide semiconductor layer, semiconductor structure, active array substrate, and indium gallium zinc oxide crystal

ActiveCN106783627AEasy to understandTransistorSolid-state devicesSemiconductor structureIndium gallium zinc oxide

The present invention provides a method for crystallizing a metal oxide semiconductor layer, a semiconductor structure, a method for fabricating the semiconductor structure, an active array substrate, and an indium gallium zinc oxide crystal. The crystallization method comprises the steps of: forming an amorphous metal oxide semiconductor layer over a substrate; forming an oxide layer on the non-crystalline metal oxide semiconductor layer; forming an amorphous silicon layer on the oxide layer; irradiating an amorphous silicon layer with a laser to heat the amorphous silicon layer and heating the amorphous metal oxide semiconductor layer with the heated amorphous silicon layer to convert the non-crystalline metal oxide semiconductor layer into a crystalline metal oxide semiconductor layer.

Owner:AU OPTRONICS CORP

Array substrate and manufacturing method therefor

ActiveCN105679714AReasonable structureReduce the number of photolithography processesSolid-state devicesSemiconductor/solid-state device manufacturingIndium gallium zinc oxideOptoelectronics

The invention provides an array substrate and a manufacturing method therefor. According to the manufacturing method for the array substrate, a halftone photomask and a one-time photoetching process are adopted to perform patterning processing for a passivation layer and an etching stop layer; a first via hole corresponding to the upward side of a source electrode is formed in the passivation layer; a second via hole and a third via hole positioned between the source electrode and the drain electrode are formed in the etching stop layer; then a pixel electrode connected with the source electrode through the first via hole, a first connecting layer connected with the source electrode and the active layer through the second via hole, and a second connecting layer connected with the drain electrode and the active layer through the third via hole are formed above the passivating layer, the source electrode, the drain electrode and the etching stop layer through the one-time photoetching process. By adoption of the processes, the number of the photoetching processes of an IGZO (indium gallium zinc oxide) array substrate with the etching stop layer structure is reduced; the six times of photoetching process in the prior art are reduced to five times, so that one time of photoetching process is saved, the use of the light-shading cover is reduced, and the production cost of the IGZO array substrate is lowered consequently.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

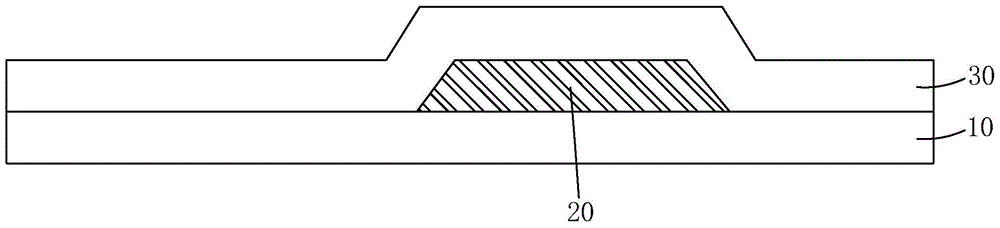

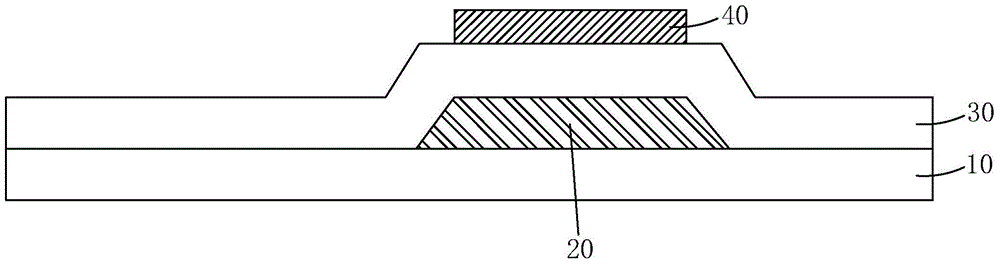

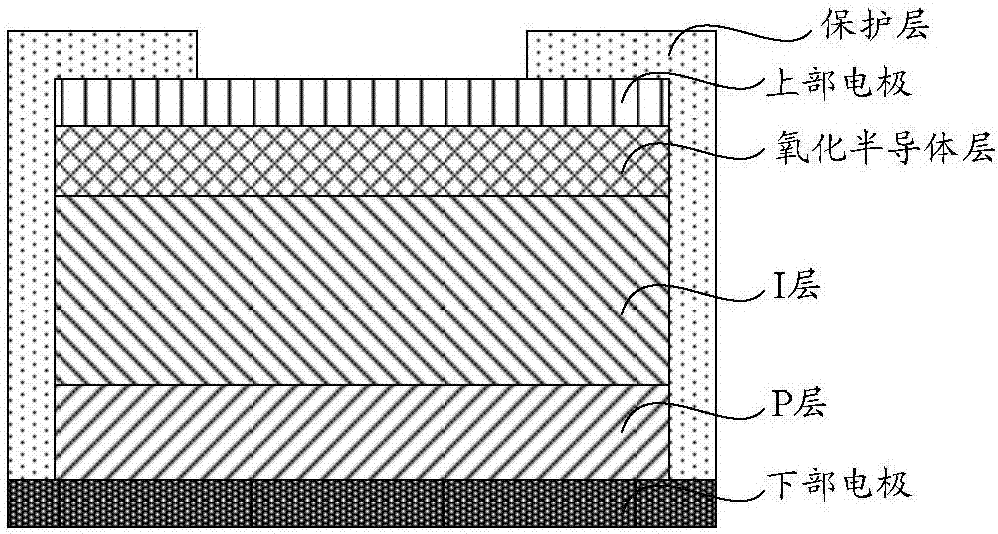

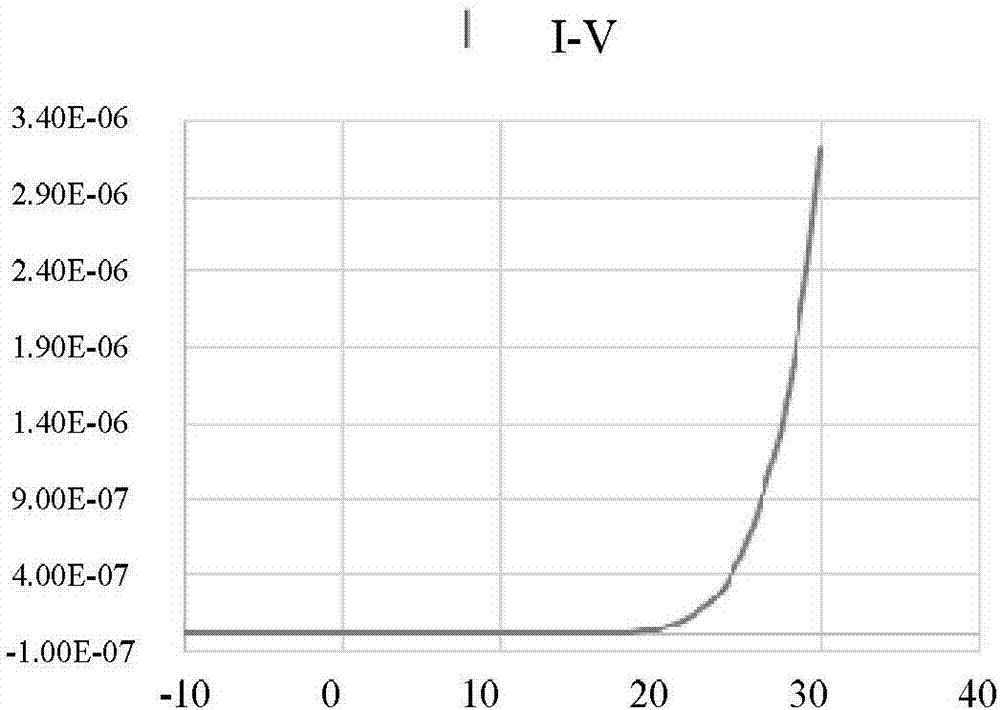

PIN unit device and preparation method thereof, and fingerprint recognition sensor and preparation method thereof

ActiveCN107017268AImprove photoresponse characteristicsFinal product manufactureSolid-state devicesUnit deviceIndium gallium zinc oxide

The invention discloses a PIN unit device and a preparation method thereof, and a fingerprint recognition sensor and a preparation method thereof. The PIN unit device provided by the invention comprises a lower electrode, a PI layer, an oxide semiconductor layer, an upper electrode, and a protective layer. The oxide semiconductor layer can be indium gallium zinc oxide (IGZO) or the like. According to the PIN unit device of the invention, an oxide semiconductor instead of A-Si is used as an N+ layer. The oxide semiconductor, such as IGZO, has a wide band gap, and is completely transparent to visible light. Therefore, more light can reach an intrinsic layer, and the light response characteristic of the PIN device is improved.

Owner:BOE TECH GRP CO LTD

IGZO with Intra-Layer Variations and Methods for Forming the Same

InactiveUS20150187574A1Semiconductor/solid-state device manufacturingSemiconductor devicesIndium gallium zinc oxideOptoelectronics

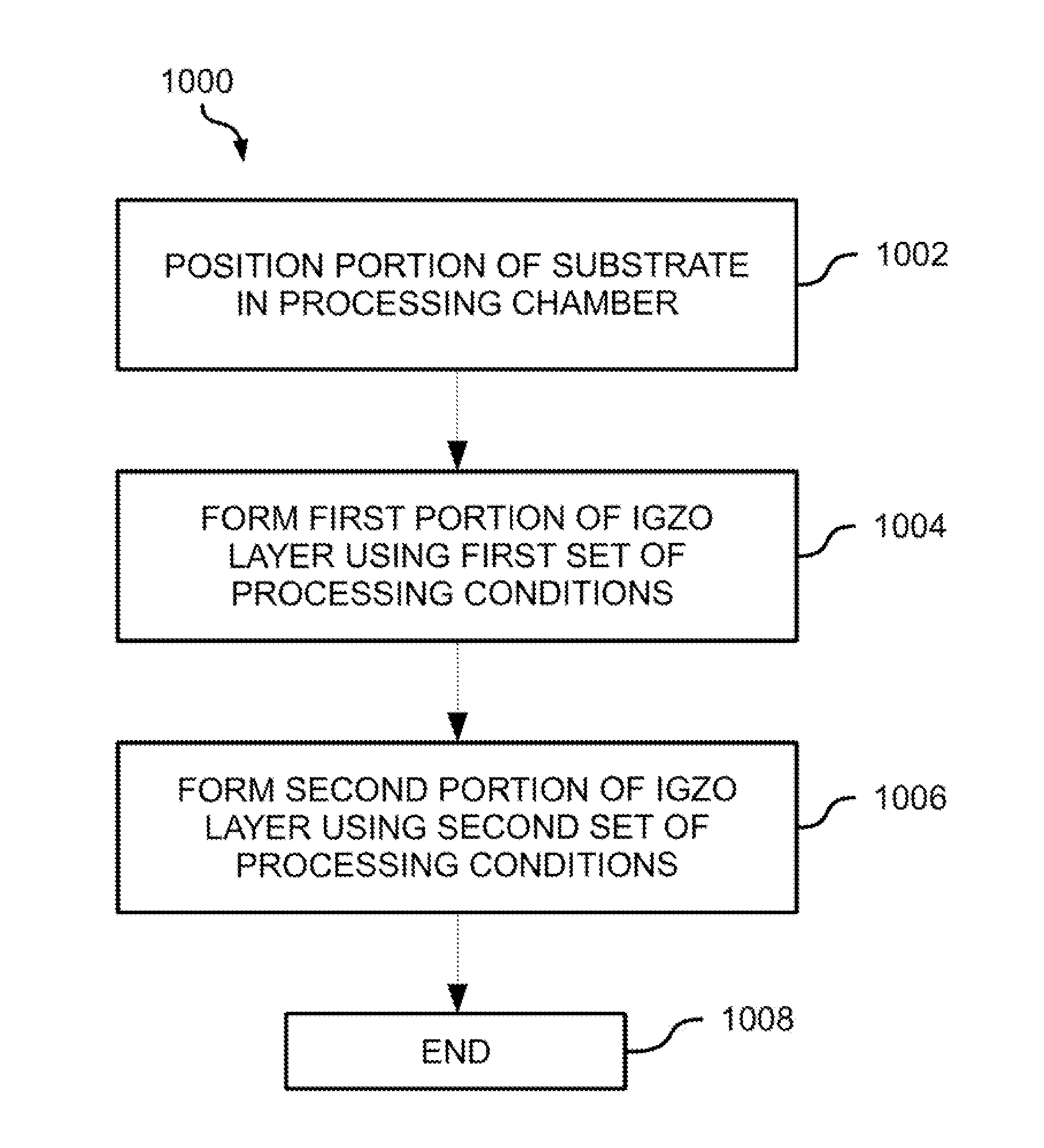

Embodiments described herein provide method for forming crystalline indium-gallium-zinc oxide (IGZO) with intra-layer variations and methods for forming such IGZO. At least a portion of a substrate is positioned in a processing chamber. A first sub-layer of an IGZO layer is formed above the at least a portion of the substrate while the at least a portion of the substrate is in the processing chamber. The first sub-layer of the IGZO layer is formed using a first set of processing conditions. A second sub-layer of the IGZO layer is formed above the first sub-layer of the IGZO layer while the at least a portion of the substrate is in the processing chamber. The second sub-layer of the IGZO layer is formed using a second set of processing conditions. The second set of processing conditions is different than the first set of processing conditions.

Owner:LG DISPLAY CO LTD +1

IGZO Devices with Increased Drive Current and Methods for Forming the Same

InactiveUS20150187956A1TransistorSemiconductor/solid-state device manufacturingDriving currentGate dielectric

Embodiments described herein provide indium-gallium-zinc oxide (IGZO) devices, such as IGZO thin-film transistors (TFTs), and methods for forming such devices. A substrate is provided. A gate electrode is formed above the substrate. A gate dielectric layer is formed above the gate electrode. The gate dielectric layer includes titanium. An interface layer is formed above the gate dielectric layer. The interface layer includes silicon. An IGZO channel layer is formed above the interface layer. A source electrode and a drain electrode are formed above the IGZO channel layer.

Owner:INTERMOLECULAR

Indium gallium zinc oxide as well as preparation method and application thereof

The invention provides a preparation method of an indium gallium zinc oxide. The preparation method comprises the following steps of: firstly mixing raw materials containing indium, gallium and zinc, and then drying, carrying out calcination and the like to prepare the indium gallium zinc oxide with evenness and high purity. In addition, the invention also provides a component for preparing an indium gallium zinc oxide target material; the component is a mixture containing multielement metallic oxides, especially comprises the indium gallium zinc oxide prepared by using the preparation method of the invention. Furthermore, the invention also provides a method for preparing the indium gallium zinc oxide target material by using the indium gallium zinc oxide and a finished product thereof, the indium gallium zinc oxide target material mainly contains InGaZnO4, but does not contain ZnGa2O4. According to the invention, the IGZO is taken as a raw material for preparing IGZO target material, so that the uneven mixing of the raw materials is reduced, and the IGZO target material with high quality and relative density is prepared.

Owner:SOLAR APPLIED MATERIALS TECHNOLOGY CORPORATION

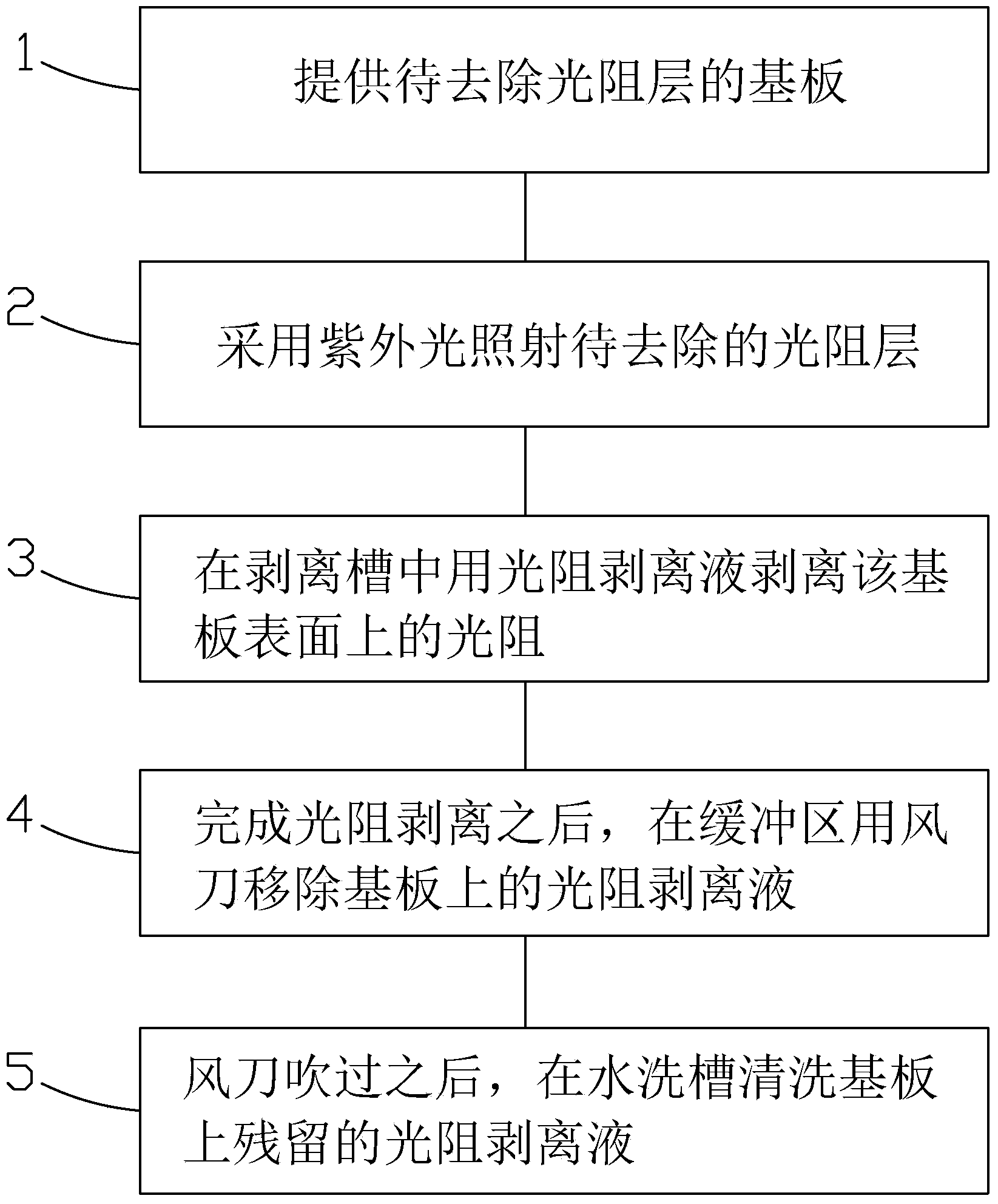

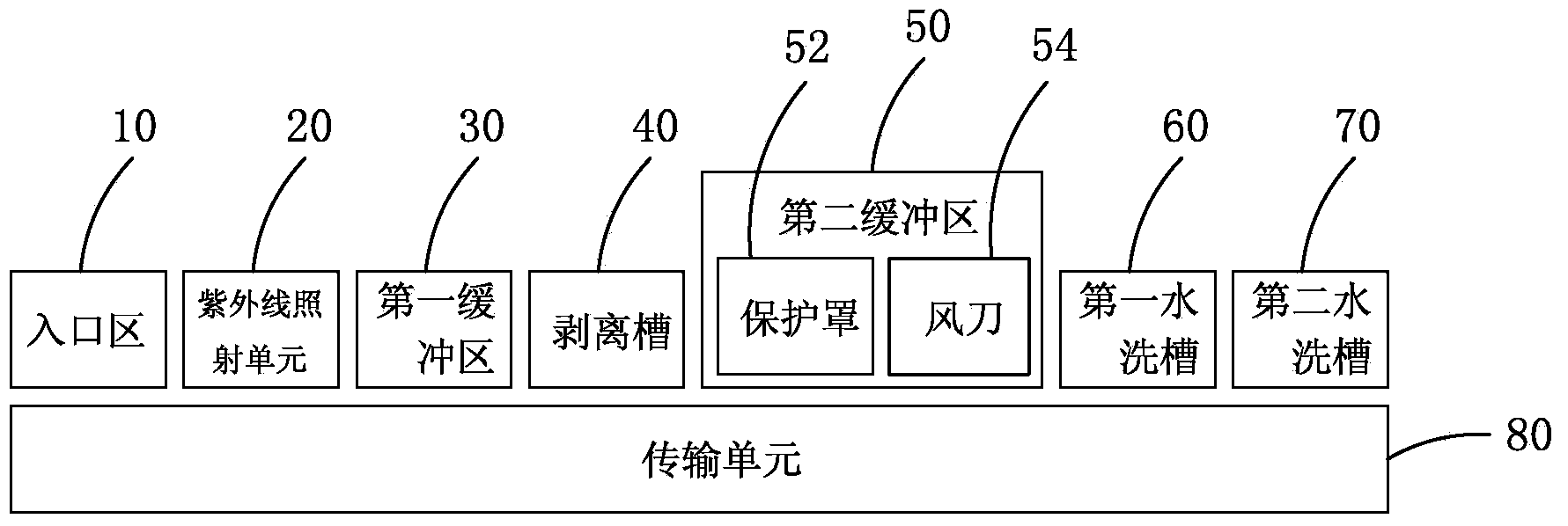

Light resistance stripping method and light resistance stripping device

ActiveCN103995441ASimple processSimple structureNon-surface-active detergent compositionsDetergent mixture composition preparationPhoto irradiationUltraviolet lights

The invention provides a light resistance stripping method and a light resistance stripping device. The light resistance stripping method comprises the steps: 1, providing a substrate of a to-be-removed light resistance layer; 2, irradiating the to-be-removed light resistance layer by adopting ultraviolet light; 3, stripping light resistance on the surface of the substrate by using a light resistance stripping solution in a stripping groove; 4, after the light resistance stripping is completed, removing the light resistance stripping solution on the substrate by using an air knife on a buffer region; and 5, after the air knife blows, cleaning the light resistance stripping solution remained on the substrate on a washing tank. According to the light resistance stripping method, the aluminum corrosion and IGZO (Indium Gallium Zinc Oxide) corrosion in the light resistance stripping process can be maximally reduced, and the quality of a flat panel display is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Amorphous IGZO Devices and Methods for Forming the Same

InactiveUS20150079727A1Semiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricIndium gallium zinc oxide

Embodiments described herein provide improvements to indium-gallium-zinc oxide devices, such as amorphous IGZO thin film transistors, and methods for forming such devices. A relatively thin a-IGZO channel may be utilized. A plasma treatment chemical precursor passivation may be provided to the front-side a-IGZO interface. High-k dielectric materials may be used in the etch-stop layer at the back-side a-IGZO interface. A barrier layer may be formed above the gate electrode before the gate dielectric layer is deposited. The conventional etch-stop layer, typically formed before the source and drain regions are defined, may be replaced by a pre-passivation layer that is formed after the source and drain regions are defined and may include multiple sub-layers.

Owner:INTERMOLECULAR

Low-temperature liquid-phase preparation method of indium gallium zinc oxide thin film transistor with high migration rate

InactiveCN106206292AImprove performanceSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesIndium gallium zinc oxideIndium zinc oxide

The invention belongs to the field of semiconductors and microelectronic devices, and particularly relates to a low-temperature liquid-phase preparation method of an indium gallium zinc oxide thin film transistor with the high migration rate. The method comprises the following steps that soluble zinc salt and tin salt are weighed, a solvent is measured, an indium gallium zinc oxide precursor solution with the concentration of 0.01-0.5 mol / L is prepared, and a clear and transparent indium gallium zinc oxide precursor solution is formed through 0.1-2 hour of magnetic stirring and ultrasonic dispersing; an indium gallium zinc oxide thin film is prepared; the indium gallium zinc oxide precursor solution is applied to a substrate precoated with a dielectric layer-grid thin film, preheating treatment at the temperature of 50 DEG C to 150 DEG C is conducted, light wave annealing at certain power, time and temperature is conducted, the indium gallium zinc oxide precursor solution is applied multiple times and annealing treatment is conducted according to the thickness requirement of the indium gallium zinc oxide thin film, and then an indium gallium zinc oxide transparent semiconductor thin film is obtained; source electrode and drain electrodes are deposited on the indium gallium zinc oxide transparent semiconductor thin film, and then the indium gallium zinc oxide thin film transistor is obtained. The indium gallium zinc oxide thin film transistor obtained through the method is high in performance and has an important application prospect in the electronic information field. Through a process of the method, the problems of a general high-temperature solution process, the long process cycle or expensive equipment and the like can be avoided, the cost is low, and the method is suitable for industrialized large-scale production.

Owner:QILU UNIV OF TECH

Methods for Forming Crystalline IGZO with a Seed Layer

InactiveUS20150179442A1Semiconductor/solid-state device manufacturingSemiconductor devicesIndium gallium zinc oxideCrystal structure

Embodiments described herein provide method for forming crystalline indium-gallium-zinc oxide (IGZO). A substrate is provided. A seed layer is formed above the substrate. The seed layer has a crystalline structure that is substantially dominant along the c-axis. An IGZO layer is formed above the seed layer. The seed layer may include zinc oxide. A stack of alternating seed layers and IGZO layers may be formed.

Owner:INTERMOLECULAR +1

IGZO devices with reduced threshhold voltage shift and methods for forming the same

Embodiments described herein provide indium-gallium-zinc oxide (IGZO) devices, such as IGZO thin-film transistors (TFTs), and methods for forming such devices. A substrate is provided. A gate electrode is formed above the substrate. A gate dielectric layer is formed above the gate electrode. An interface layer is formed above the gate dielectric material. An IGZO channel layer is formed above the interface layer. A source electrode and a drain electrode are formed above the IGZO channel layer. The interface layer includes a material different than that of the gate dielectric layer and the IGZO channel layer.

Owner:INTERMOLECULAR

IGZO Devices with Composite Channel Layers and Methods for Forming the Same

InactiveUS20150171227A1TransistorSemiconductor/solid-state device manufacturingComposite channelIndium gallium zinc oxide

Embodiments described herein provide indium-gallium-zinc oxide (IGZO) devices, such as IGZO thin-film transistors (TFTs), and methods for forming such devices. A substrate is provided. A gate electrode is formed above the substrate. An IGZO channel layer is formed above the gate electrode. The IGZO channel layer has a first sub-layer including c-IGZO and a second sub-layer including a-IGZO. A source electrode and a drain electrode are formed above the IGZO channel layer.

Owner:INTERMOLECULAR

Method for preparing high-conductivity indium gallium zinc oxide (IGZO) sputtering target material and product of high-conductivity IGZO sputtering target material

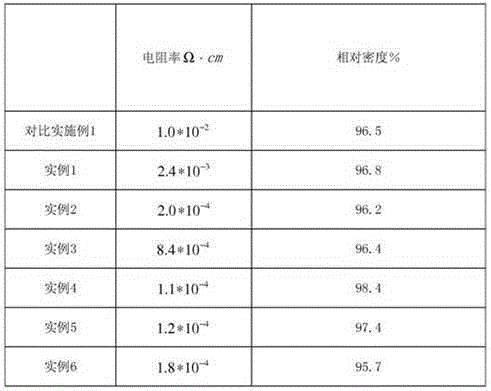

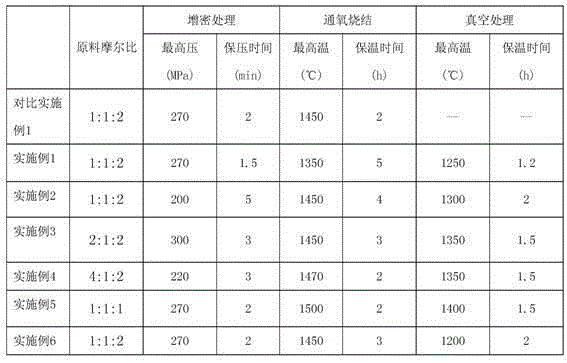

The invention discloses a method for preparing a high-conductivity indium gallium zinc oxide (IGZO) sputtering target material. The high-conductivity IGZO sputtering target material is prepared from indium oxide powder, gallium oxide powder and zinc oxide powder, wherein the molar ratio of the indium oxide powder to gallium oxide powder and zinc oxide powder is 1:(0-1):(0.5-2). The method for preparing the high-conductivity IGZO sputtering target material comprises the steps of preparation of a blank, oxygen introduction for sintering and vacuum heat treatment. According to the method for preparing the high-conductivity IGZO sputtering target material, the vacuum treatment step is added after the traditional step of oxygen introduction for sintering for the IGZO sputtering target material, component defects of the target material are overcome by conducting reduction of the target material, so that semi-conductivity is promoted, and accordingly the conductivity is improved; meanwhile, it is guaranteed that the density of a finished product meets the requirement, and the performance and the yield of the IGZO sputtering target material are improved.

Owner:福建省诺希科技园发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com