Low-temperature liquid-phase preparation method of indium gallium zinc oxide thin film transistor with high migration rate

A thin film transistor, indium gallium zinc oxide technology, used in semiconductor/solid state device manufacturing, semiconductor devices, electrical components and other directions, can solve the problems of increasing equipment complexity and increasing costs, avoiding high-temperature solution processes, low cost, and high performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

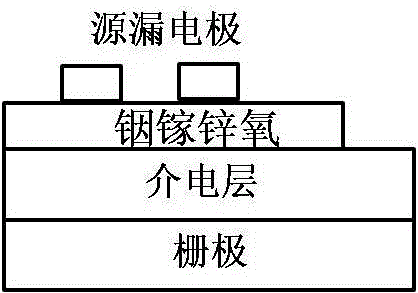

[0027] Weigh 1.106 g of indium chloride, 0.88 g of gallium chloride, and 0.682 g of zinc chloride, measure 10 ml of ethylene glycol methyl ether solution, and prepare an indium gallium zinc oxide precursor solution with a concentration of 0.5 mol / L. After 2 hours The magnetic stirring and ultrasonic dispersion formed a clear and transparent indium gallium zinc oxide precursor solution. The indium gallium zinc oxide precursor solution was coated on the indium tin oxide glass pre-coated with silicon oxide to form the indium gallium zinc oxide precursor thin film, which was preheated at 100 °C, and then subjected to a light wave of 300W, 60 minutes and 200 °C. After annealing, the indium gallium zinc oxide transparent semiconductor thin film is obtained. The source and drain electrodes are deposited on the indium gallium zinc oxide transparent semiconductor thin film to obtain the indium gallium zinc oxide thin film transistor.

Embodiment 2

[0029] Weigh 0.032 g of indium nitrate, 0.0256 g of gallium nitrate, and 0.0136 g of zinc chloride, measure 10 ml of ethanol solution, and prepare an indium gallium zinc oxide precursor solution with a concentration of 0.01 mol / L. After 0.5 hours of magnetic stirring and ultrasonic dispersion A clear and transparent indium gallium zinc oxide precursor solution is formed. The indium gallium zinc oxide precursor solution was coated on the indium tin oxide glass pre-coated with zirconia to form the indium gallium zinc oxide precursor thin film, which was preheated at 50 °C, and then subjected to a light wave of 700 W, 30 minutes and 280 °C. After annealing, the indium gallium zinc oxide transparent semiconductor thin film is obtained. The source and drain electrodes are deposited on the indium gallium zinc oxide transparent semiconductor thin film to obtain the indium gallium zinc oxide thin film transistor.

Embodiment 3

[0031] Weigh 0.146 g of indium acetate, 0.123 g of gallium acetate, and 0.1488 g of zinc nitrate, weigh 5 ml of aqueous solution, and prepare a solution of indium gallium zinc-oxygen precursor with a concentration of 0.1 mol / L. After 1 hour of magnetic stirring and ultrasonic dispersion, a clear solution was formed. Transparent indium gallium zinc oxide precursor solution. The indium gallium zinc oxide precursor solution was coated on a single crystal silicon substrate pre-coated with aluminum oxide to form an indium gallium zinc oxide precursor thin film, which was preheated at 90 ℃, and then subjected to 900 W, 5 minutes and 300 ℃ of temperature. Light wave annealing, that is, the indium gallium zinc oxide transparent semiconductor thin film is obtained. The source and drain electrodes are deposited on the indium gallium zinc oxide transparent semiconductor thin film to obtain the indium gallium zinc oxide thin film transistor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com