Method for preparing high-conductivity indium gallium zinc oxide (IGZO) sputtering target material and product of high-conductivity IGZO sputtering target material

A sputtering target and high conductivity technology, which is applied in the field of preparation of high conductivity IGZO sputtering targets, can solve the problems of large difference in measured values, poor uniformity of target electrical properties, and reduced target conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a high-conductivity IGZO sputtering target, which uses indium oxide, gallium oxide, and zinc oxide powders with a molar ratio of 1:1:2 as raw materials, and the preparation process includes the following steps:

[0026] 1) Made from raw embryos, specifically including:

[0027] 1.1) Mixing: mix the three raw materials evenly;

[0028] 1.2) Grouting;

[0029] 1.3) Densification treatment: After drying the grouted blanks, cold isostatic pressing is performed to obtain green embryos. The maximum pressure of cold isostatic pressing is 270MPa, and the holding time is 2 minutes;

[0030] 2) Oxygen sintering: place the prepared green body in an environment with an oxygen concentration of more than 95% for heating and sintering, raise the temperature to 1360°C at a rate of 40-100°C / h, hold for 2 hours and then anneal.

[0031] 3) Vacuum heat treatment: put the high-density target material obtained by oxygen-passing sintering under vacuum conditions, rai...

example 2-6

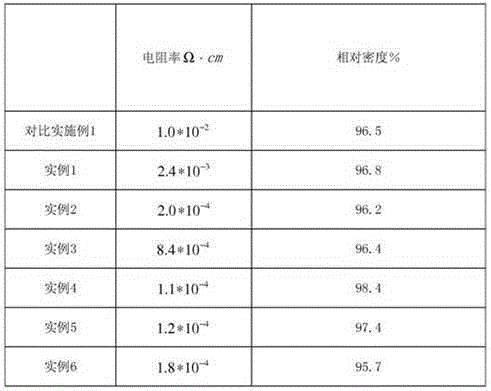

[0033] Embodiment 2-6 adopts the manufacturing method identical with embodiment 1, and difference is to use different raw material molar ratio, reaction pressure, time, temperature value in each step listed in table 1 to replace the adopted one of embodiment 1 respectively corresponding value.

[0034] Table 1

[0035]

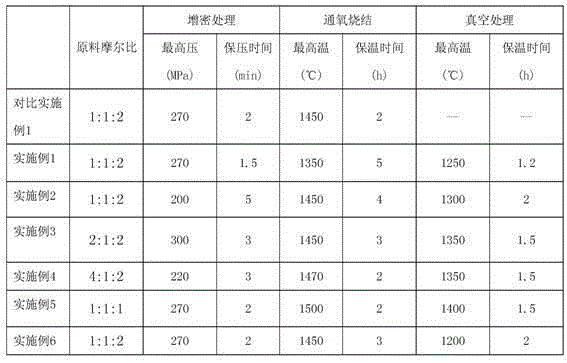

[0036] The resistivity and relative density of the finished products of each embodiment are shown in Table 2.

[0037] Table 2

[0038]

[0039] It can be seen from Table 2 that the resistivity of the IGZO sputtering target prepared by the scheme of Examples 1-6 is much higher than that of Comparative Example 1 without vacuum treatment, and the relative density is not significantly affected by the vacuum treatment. changes are even better. The present invention adds vacuum heat treatment on the basis of oxygen-passing sintering, and successfully obtains an IGZO target material with deepened and uniform color and greatly improved electrical conductivit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com