Rare earth doped indium gallium zinc oxide powder as well as preparation method and application thereof

A technology of indium gallium zinc oxide and rare earth doping, applied in ion implantation plating, coating, metal material coating process and other directions, can solve the problem of uneven composition and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

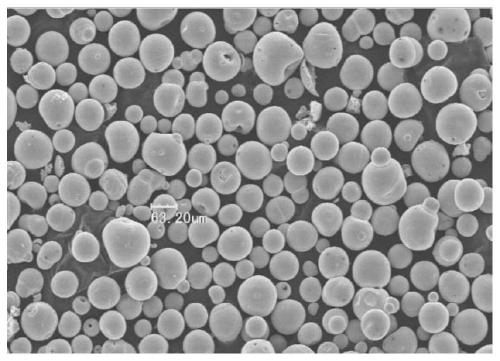

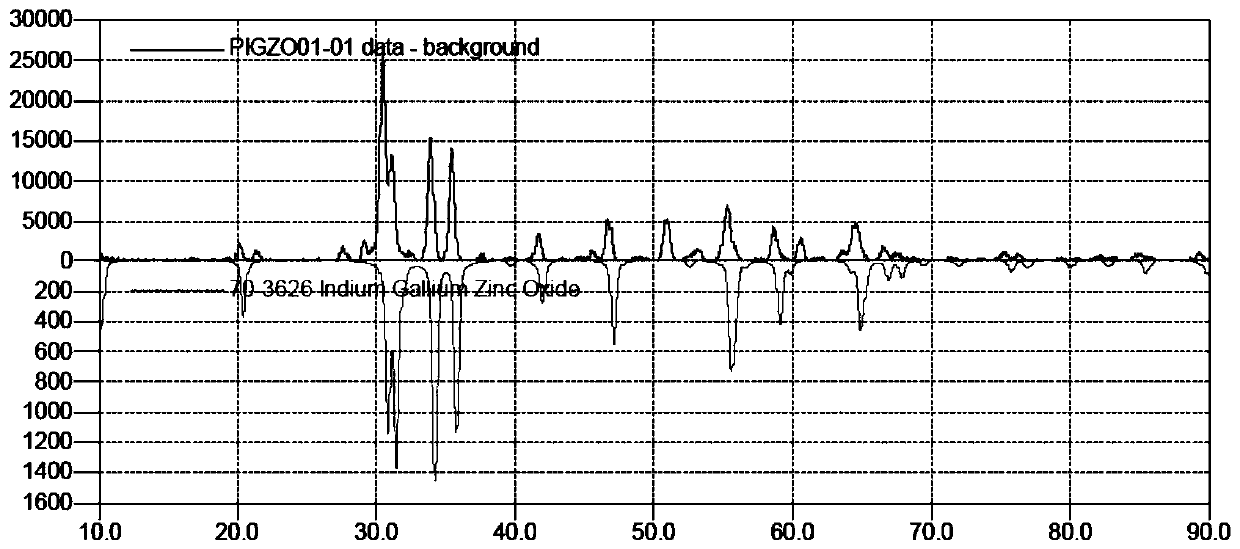

Image

Examples

preparation example Construction

[0027] According to the first aspect of the present invention, there is provided a method for preparing rare earth-doped indium gallium zinc oxide powder, which includes the following steps.

[0028] S1: Add water, first dispersant, gallium oxide powder, and rare earth oxide powder to the first mixing tank in sequence for pre-dispersion for the first preset time period to obtain the first mixed liquid, and grind the first mixed liquid for the second The first mixed slurry is obtained after a preset period of time.

[0029] In this example, due to the rare earth oxide (Re 2 o 3) and gallium oxide (Ga 2 o 3 ) The particles of these two oxide powders are relatively large, and the grinding requirements are relatively high, so they need to be ground first.

[0030] The first dispersant is one of polyvinyl pyrrolidone (PVP for short), sodium dodecyl benzene sulfonate (SDBS for short) or sodium hexadecyl benzene sulfonate. A dispersant is preferably polyvinylpyrrolidone, the dur...

Embodiment 1

[0054] With cerium oxide (CeO 2 ) powder and praseodymium oxide (Pr 6 o 11 ) powder is used as raw material to prepare rare earth doped indium gallium zinc oxide powder, and the preparation method includes the following steps.

[0055] (1) Add water, dispersant polyvinylpyrrolidone, gallium oxide (Ga 2 o 3 ) powder, cerium oxide powder (CeO 2 ) and praseodymium oxide (Pr 6 o 11 ) powder was pre-dispersed for 10 min, wherein the mass of dispersant accounted for dispersant, gallium oxide (Ga 2 o 3 ) powder, cerium oxide powder (CeO 2 ) and praseodymium oxide (Pr 6 o 11 ) 10% of the total mass of solids such as powder, and 35% of the total mass of solids and water. The pre-dispersed solution was pumped into a sand mill (using zirconium balls with a diameter of 0.2 mm), the grinding speed was 1800 r / min, and the grinding time was 8 hours to obtain the first mixed slurry.

[0056] (2) Add water, dispersant polyvinylpyrrolidone, and zinc oxide (ZnO) powder to the second ...

Embodiment 2

[0062] Lanthanum oxide (La 2 o 3 ) powder is used as raw material to prepare rare earth doped indium gallium zinc oxide powder, and the preparation method includes the following steps.

[0063] (1) Add water, dispersant polyvinylpyrrolidone, gallium oxide (Ga 2 o 3 ) powder and lanthanum oxide (La 2 o 3 ) powder was pre-dispersed for 15 min, where the mass of dispersant accounted for dispersant, gallium oxide (Ga 2 o 3 ) powder and lanthanum oxide (La 2 o 3 ) 1% of the total mass of solids such as powder, and the mass of solids accounts for 50% of the total mass of solids and water. The pre-dispersed solution was pumped into a sand mill (using zirconium balls with a diameter of 1.5 mm), the grinding speed was 800 r / min, and the grinding time was 5 hours to obtain the first mixed slurry.

[0064] (2) Add water, dispersant polyvinylpyrrolidone, and zinc oxide (ZnO) powder to the second mixing tank in sequence for pre-dispersion for 15 minutes, wherein the mass of the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com