Phase composition controllable indium gallium zinc oxide target material and preparation method thereof

A technology of indium gallium zinc oxide and gallium oxide, which is applied in the field of indium gallium zinc oxide target material and its preparation, can solve problems such as hindering the application of IGZO target material, affecting the performance of thin films, and affecting the performance of thin film devices, achieving high industrial utilization value, The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

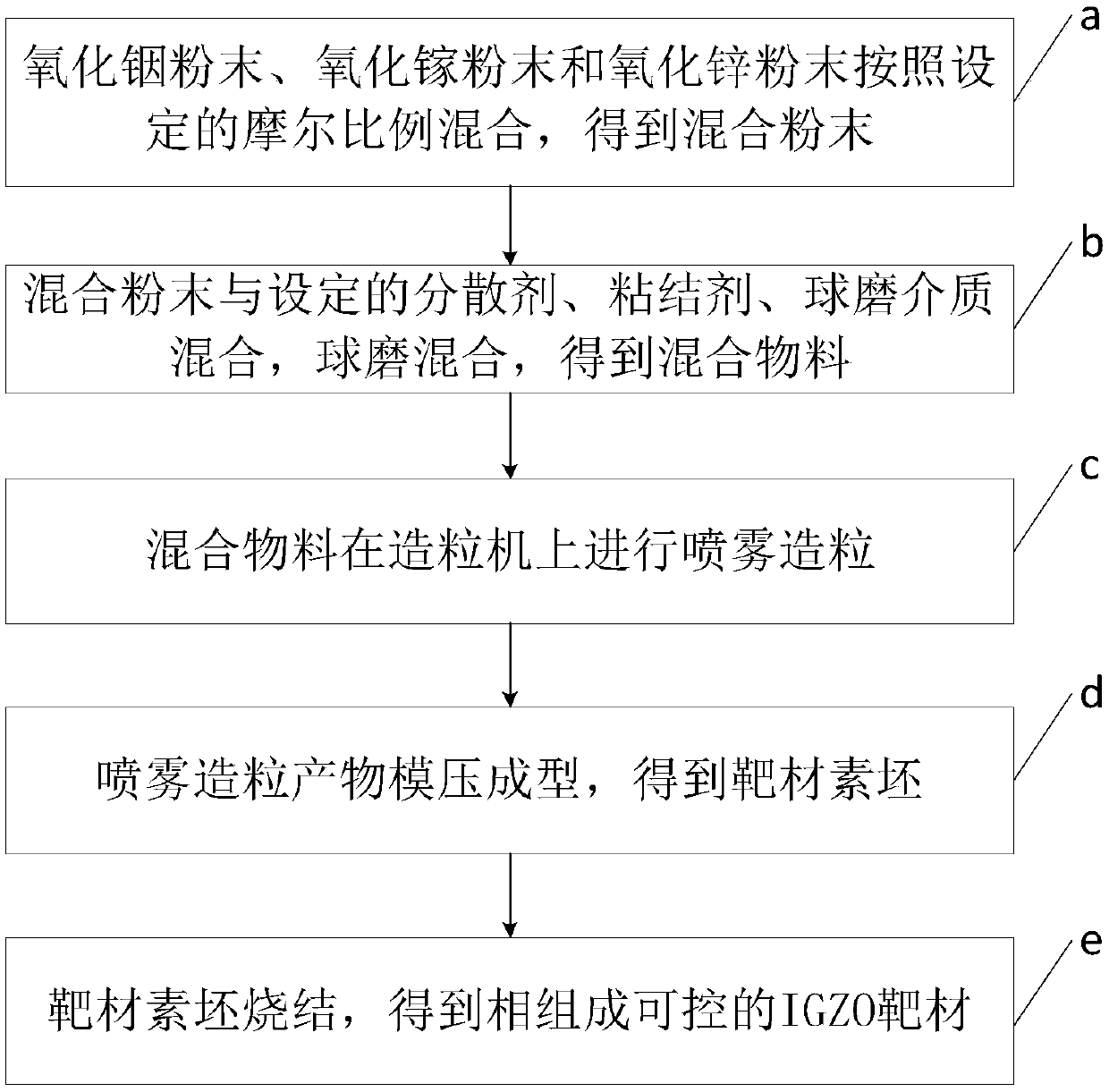

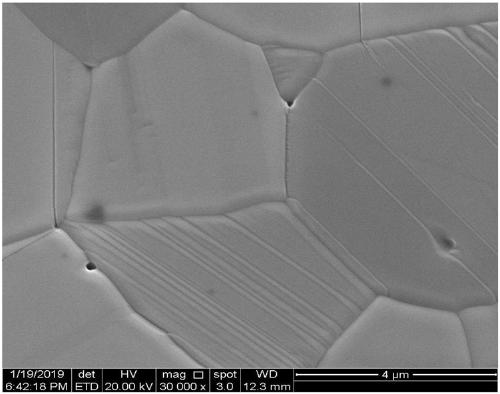

[0055] In Example 1, the preparation method of the IGZO (Indium Gallium Zinc Oxide) target material with controllable phase composition includes:

[0056] The three components of nano-level high-purity indium oxide powder, gallium oxide powder and zinc oxide powder are mixed in a molar ratio of 1:1:1, 0.5% ammonium polyacrylate is selected as the dispersant, and 0.8% polyvinyl alcohol is selected as the Binder, choose 50% pure water as ball milling medium;

[0057] Put the powder mixture composed of indium oxide powder, gallium oxide powder and zinc oxide powder, ammonium acrylate, pure water, and three specifications of zirconia grinding balls into a 1L zirconia ball mill jar, and mix the mixture on the ball mill Ball milling, add 0.1% dispersant again after 24 hours of ball milling, add 0.2% dispersant for the last time after 24 hours of ball milling, and ball mill again for 1 hour; add binder and continue ball milling for 1 hour, and the ball milling ends; the speed of the ball ...

Embodiment 2

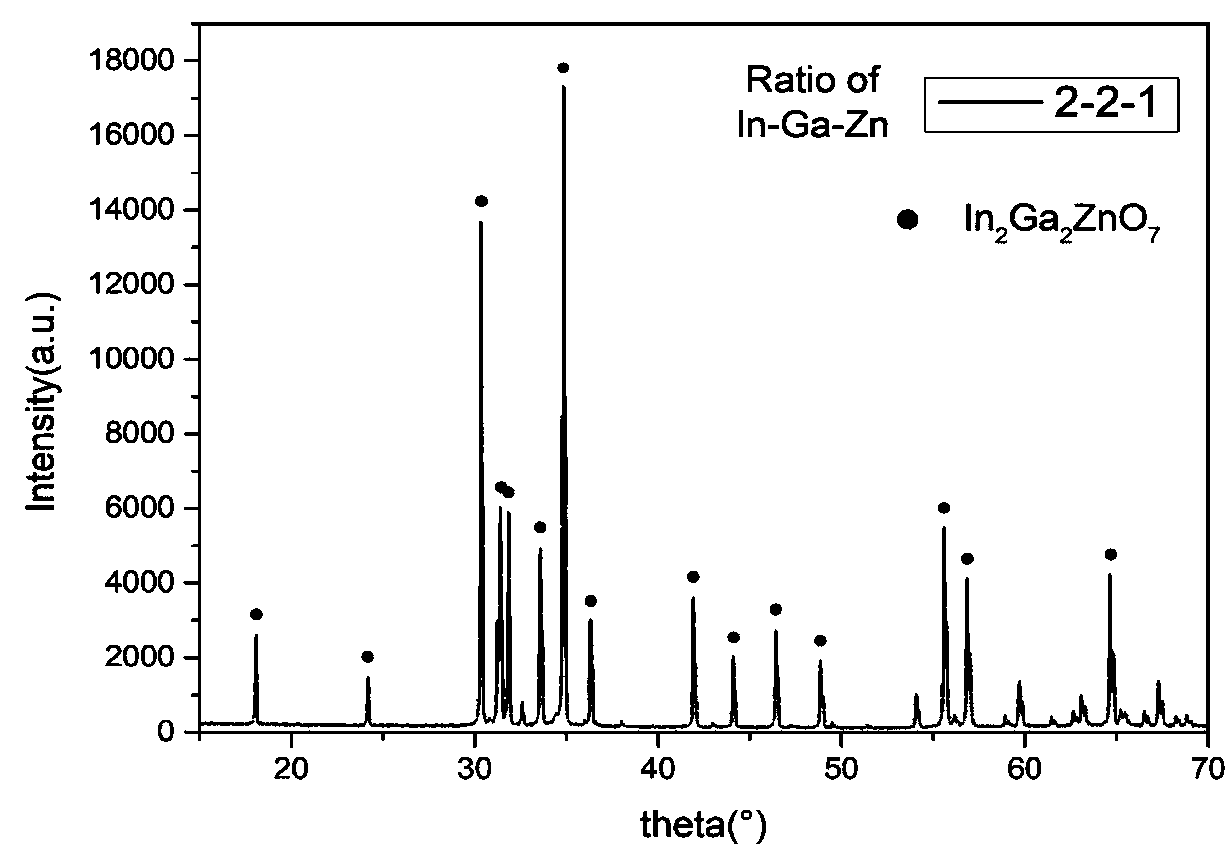

[0063] In Example 2, the preparation method of the indium gallium zinc oxide target material with controllable phase composition includes:

[0064] The three components of nano-level high-purity indium oxide powder, gallium oxide powder and zinc oxide powder are mixed in a molar ratio of 1:1:2, 0.4% ammonium polyacrylate is selected as the dispersant, and 0.8% polyvinyl alcohol is selected as the As the binder, 55% pure water is selected as the ball milling medium;

[0065] Put the powder mixture composed of indium oxide powder, gallium oxide powder and zinc oxide powder, ammonium acrylate, pure water, and three specifications of zirconia grinding balls into a 1L zirconia ball mill jar, and mix the mixture on the ball mill Ball milling, add 0.2% dispersant again after 24 hours of ball milling, add 0.2% dispersant for the last time after 24 hours of ball milling, and ball mill again for 1 hour; add binder and continue ball milling for 1 hour, and the ball milling ends; the speed of ...

Embodiment 3

[0071] In Example 3, the preparation method of the indium gallium zinc oxide target material with controllable phase composition includes:

[0072] The three components of nano-level high-purity indium oxide powder, gallium oxide powder and zinc oxide powder are mixed in a molar ratio of 1:1:8, 0.3% ammonium polyacrylate is selected as the dispersant, and 0.9% polyvinyl alcohol is selected as the Binder, choose 60% pure water as ball milling medium;

[0073] Put the powder mixture composed of indium oxide powder, gallium oxide powder and zinc oxide powder, ammonium acrylate, pure water, and three specifications of zirconia grinding balls into a 1L zirconia ball mill jar, and mix the mixture on the ball mill Ball milling, add 0.2% dispersant again after 24 hours of ball milling, add 0.3% dispersant for the last time after 24 hours of ball milling, and ball mill again for 1 hour; add binder and continue ball milling for 1 hour, and the ball milling ends; where the speed of the ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com