Method for producing indium gallium zinc oxide semiconductor thin film by using sol-gel method

A technology of indium gallium zinc oxide and sol-gel method is applied in the field of preparing oxide semiconductor thin films by sol-gel method, which can solve the problems of high cost, low price of precursors, explosion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation steps of the present invention are specifically set forth below by specific examples:

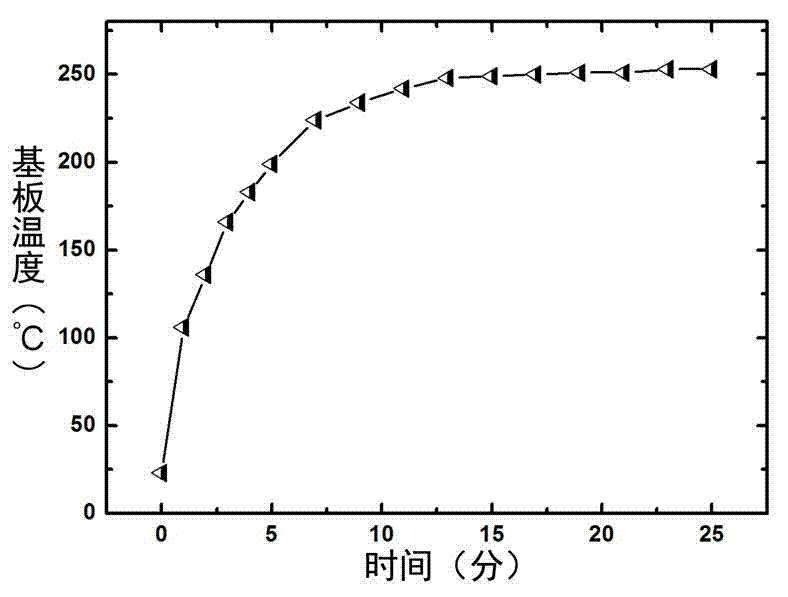

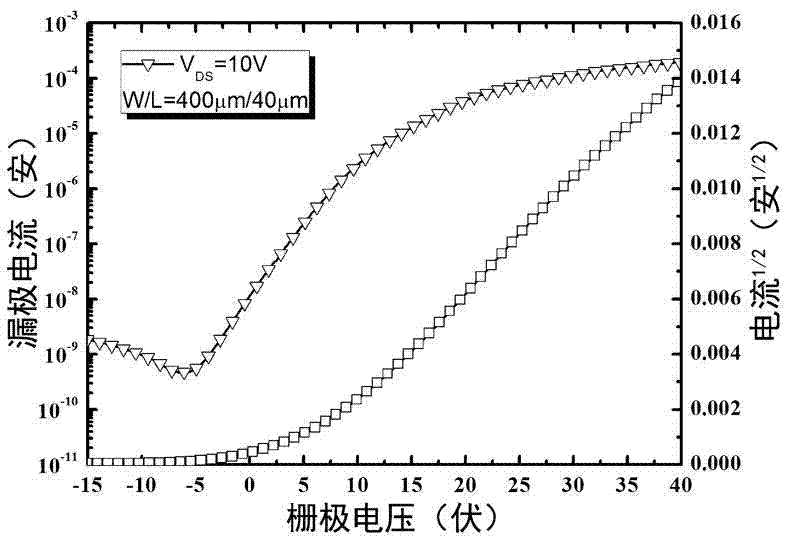

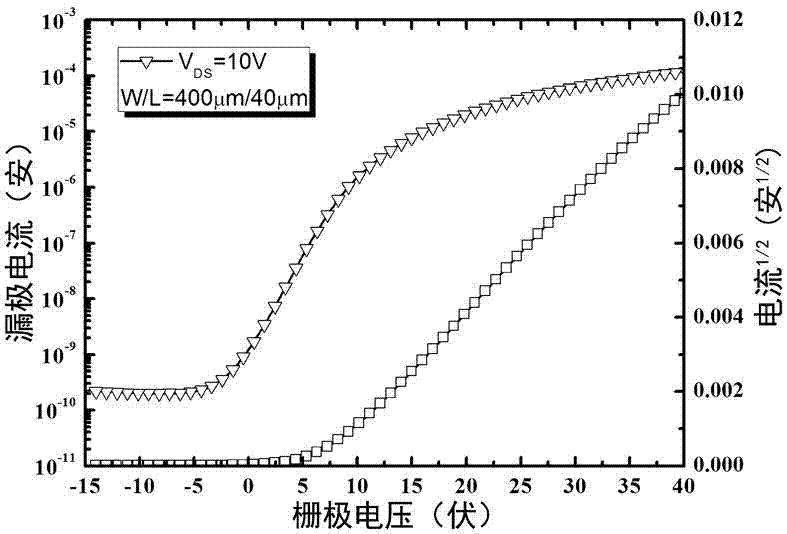

[0024] With ethylene glycol monomethyl ether as solvent and monoethanolamine as stabilizer, In(NO 3 ) 3 4.5H 2 O, Ga(NO 3 ) 3 4.5H 2 O, Zn(C 2 h 3 o 2 ) 2 ·5H 2 O was dissolved in it, and left to stand for 48 hours after ultrasonic oscillation for 1 hour to form a clear and stable precursor solution, wherein the volume ratio of ethylene glycol monomethyl ether to monoethanolamine was 10:1, and In ions, Ga ions, and Zn ions in the solution The molar ratio of Zn ions is 2:1:1, and the molar concentration of Zn ions is 0.3M; the precursor solution is spin-coated on a common glass substrate, and irradiated under an infrared heating lamp to obtain a 40 nm IGZO semiconductor film, and the spin-coating speed is 5500 rpm, the power of the infrared heating lamp is 275W, and the distance between the light source and the film is 10 mm during irradiation (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com