Patents

Literature

198 results about "Aluminum corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum is actually very prone to corrosion. However, aluminum corrosion is aluminum oxide, a very hard material that actually protects the aluminum from further corrosion. Aluminum oxide corrosion also looks a lot more like aluminum (dull gray to powdery white in color), so it isn't as easy to notice as rusted iron.

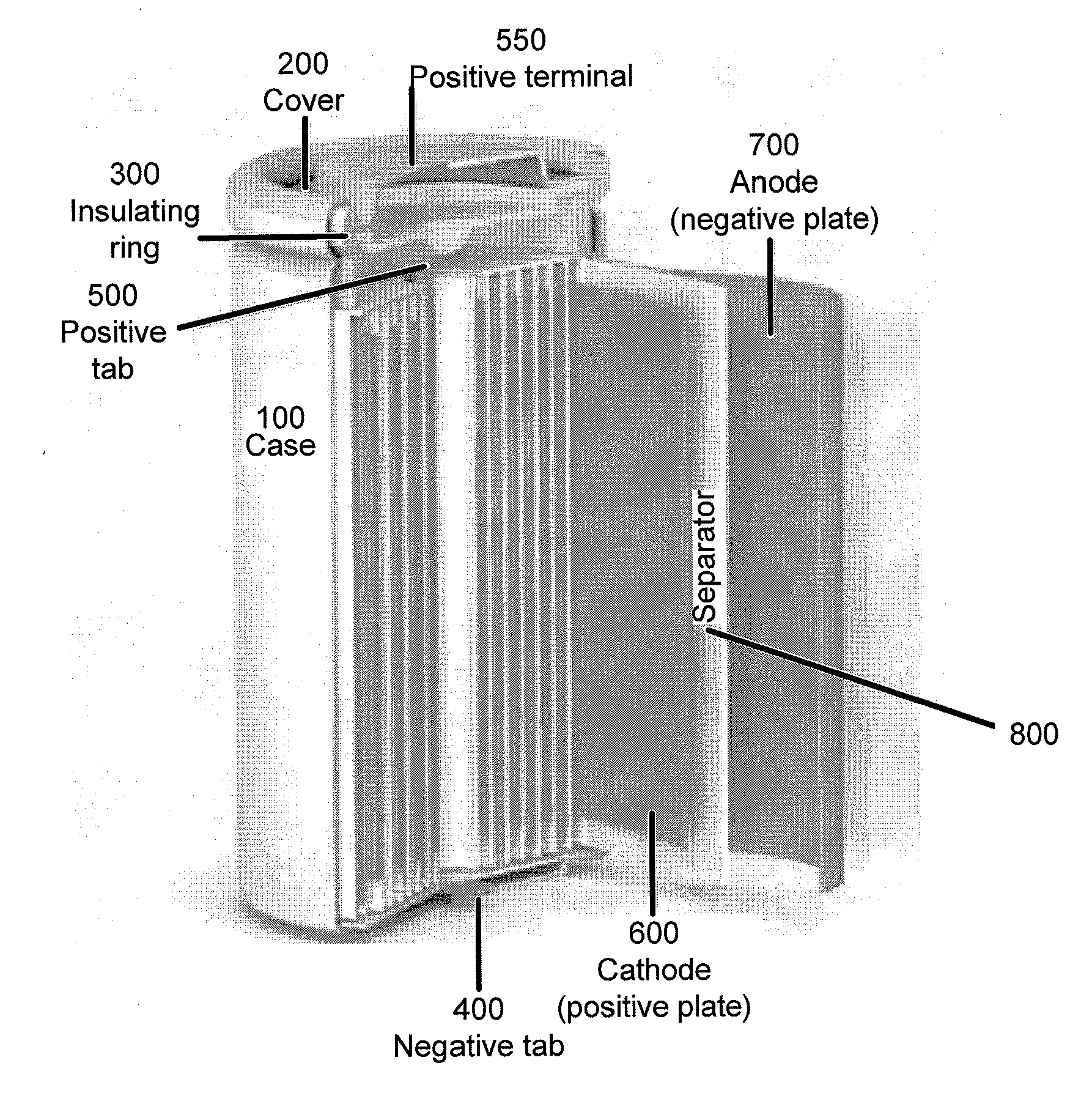

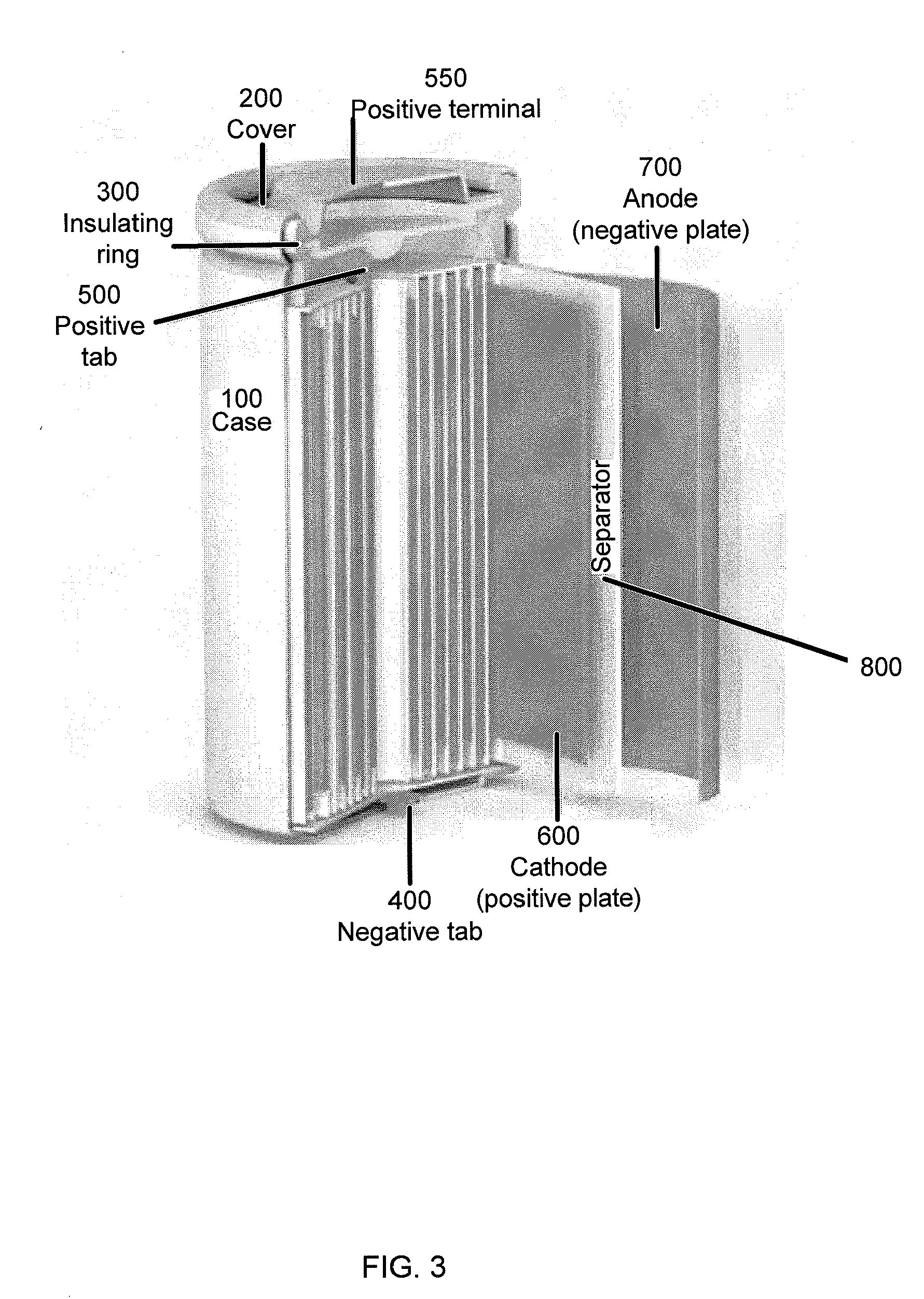

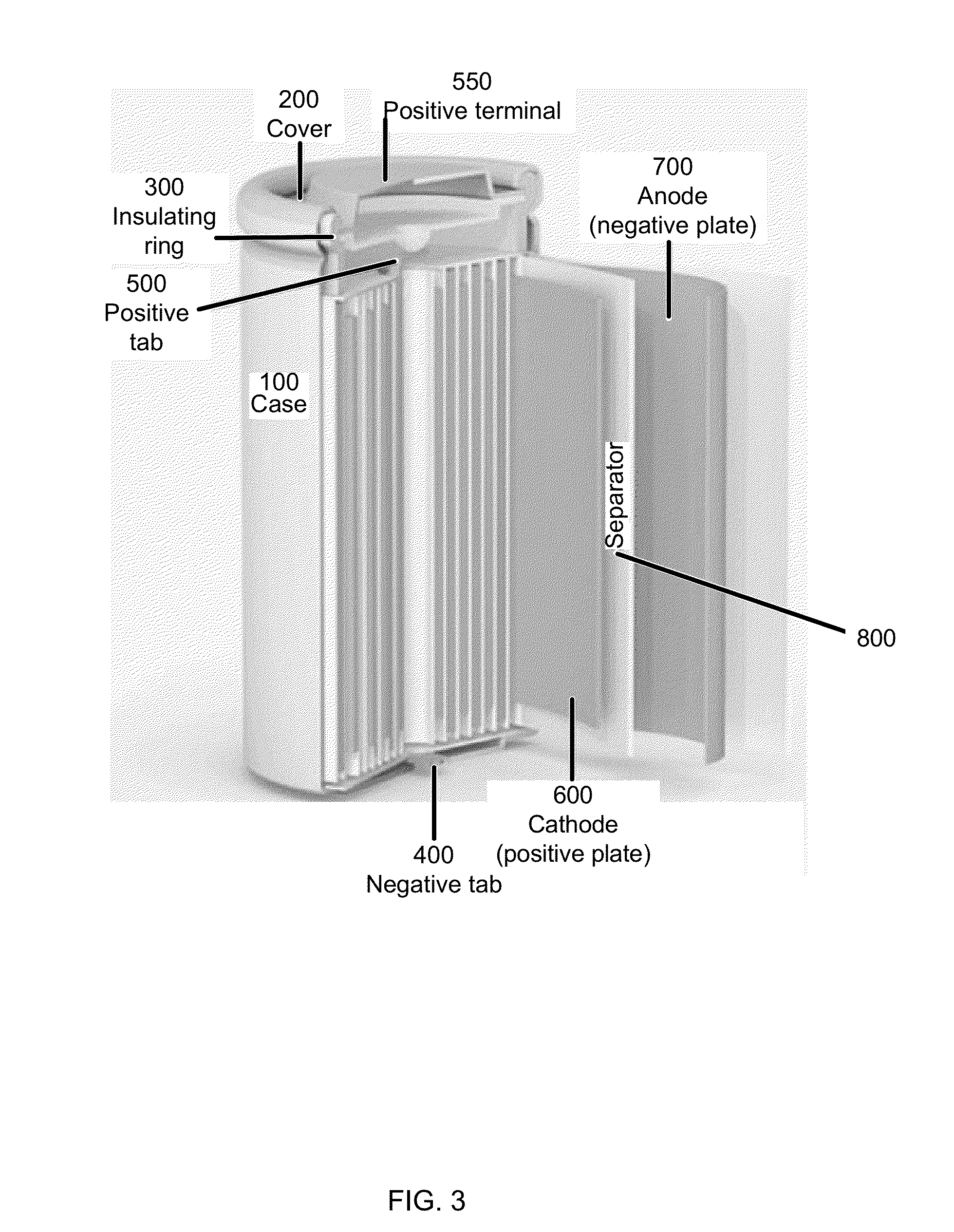

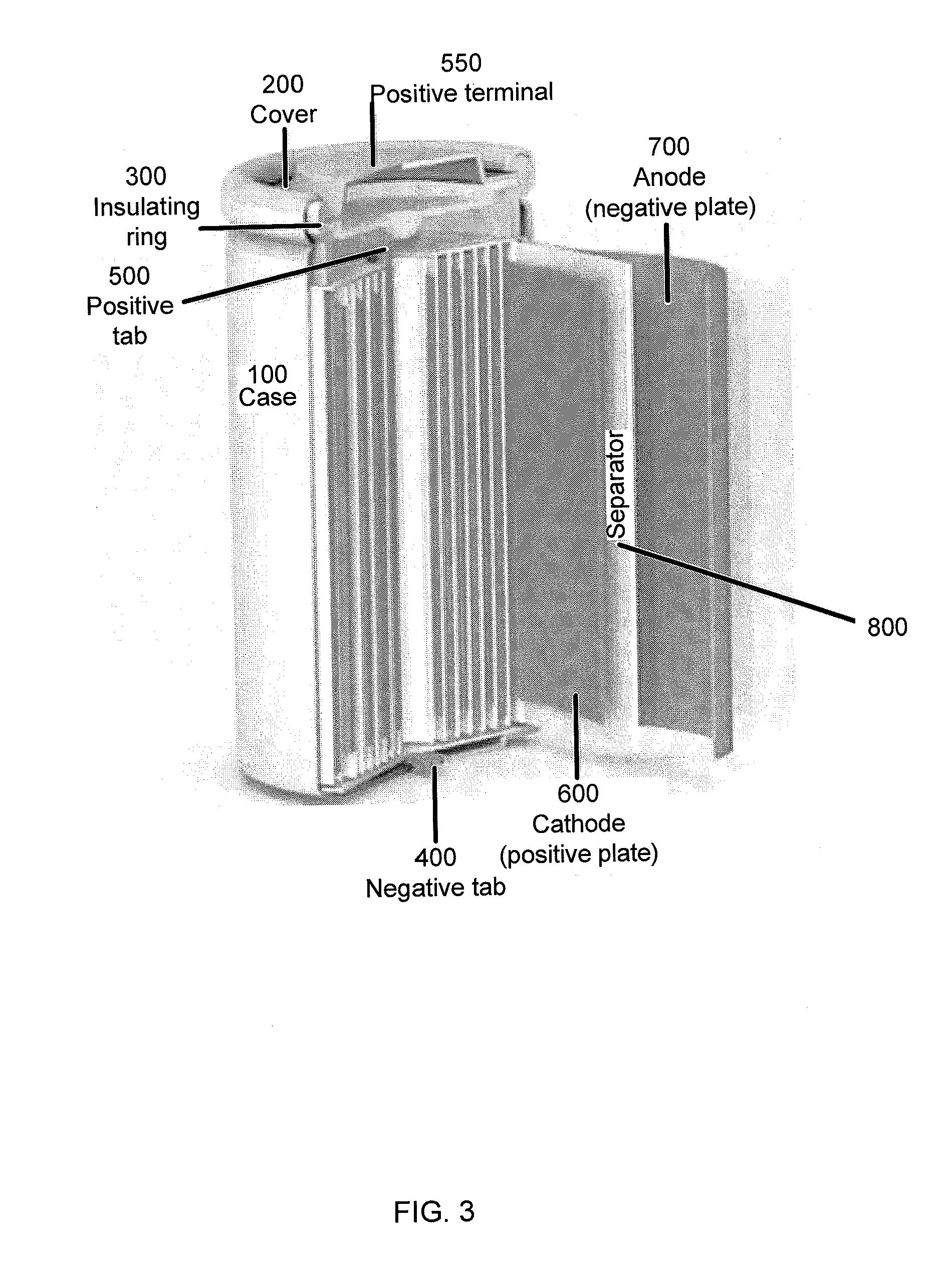

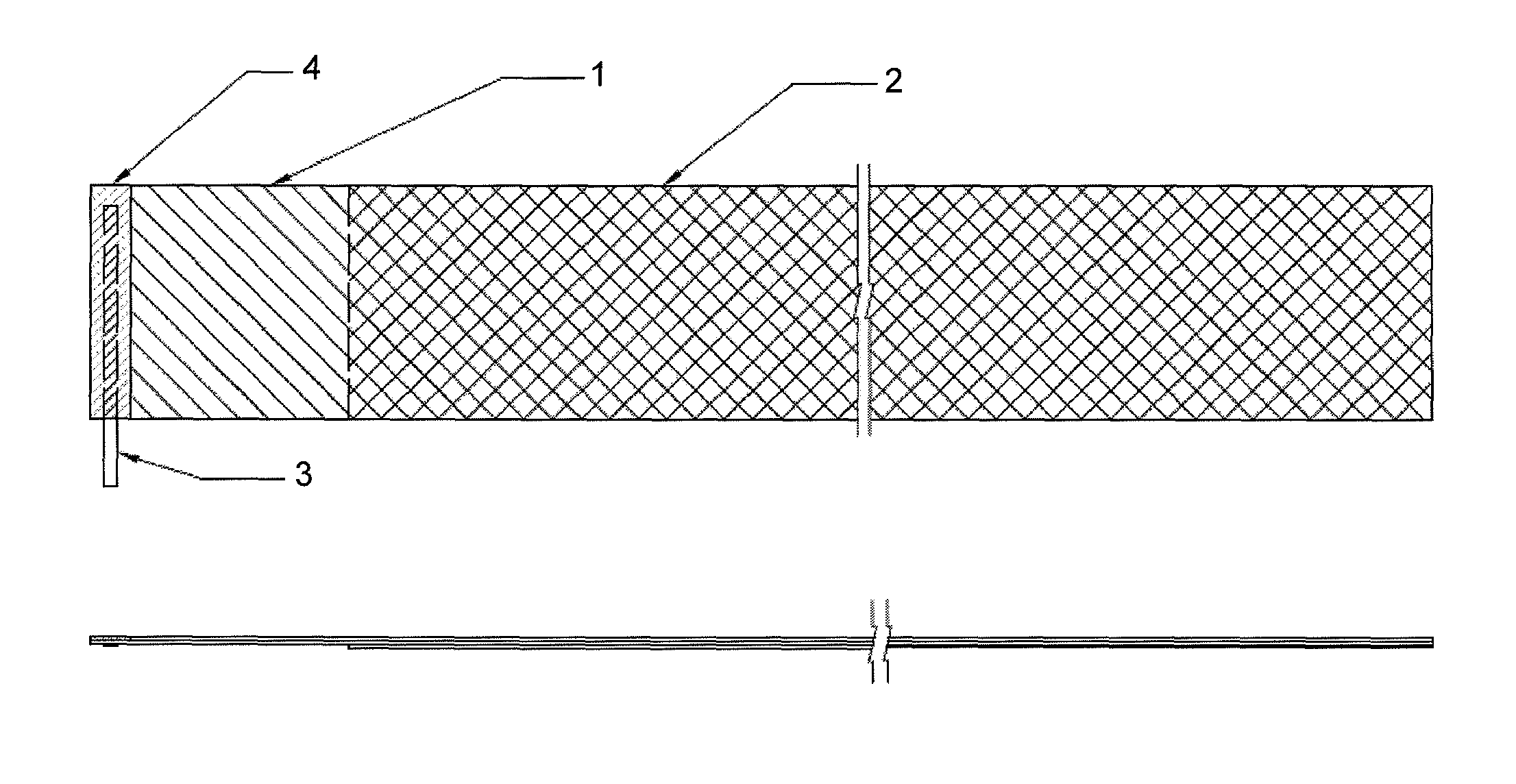

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

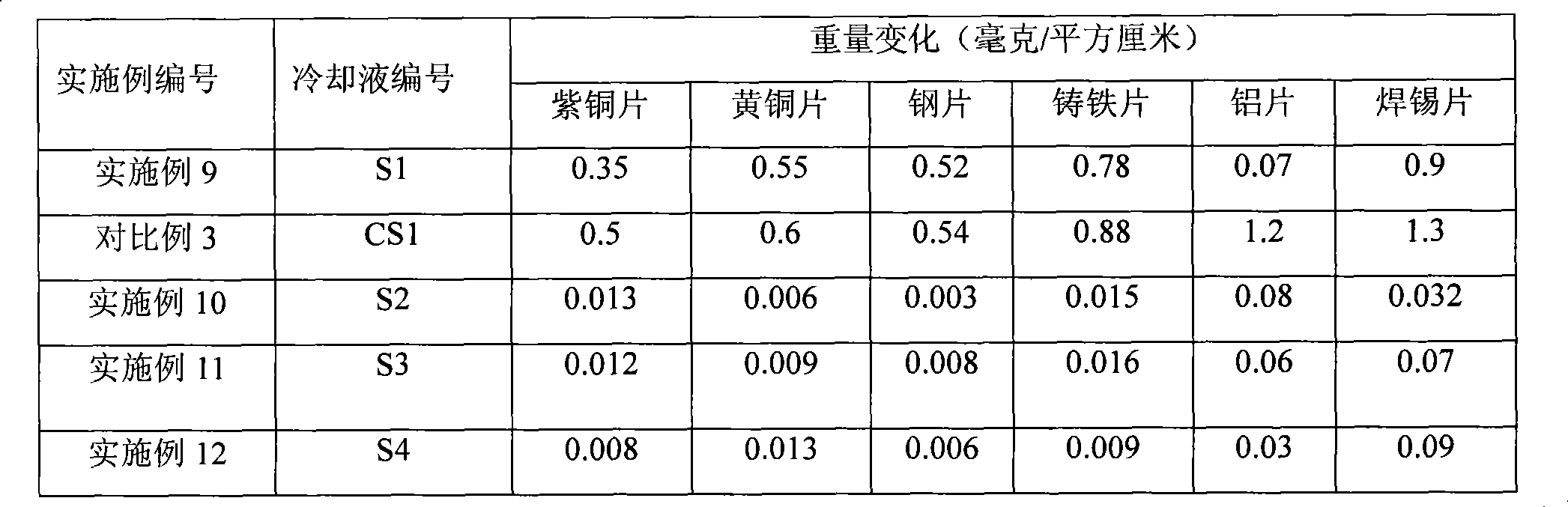

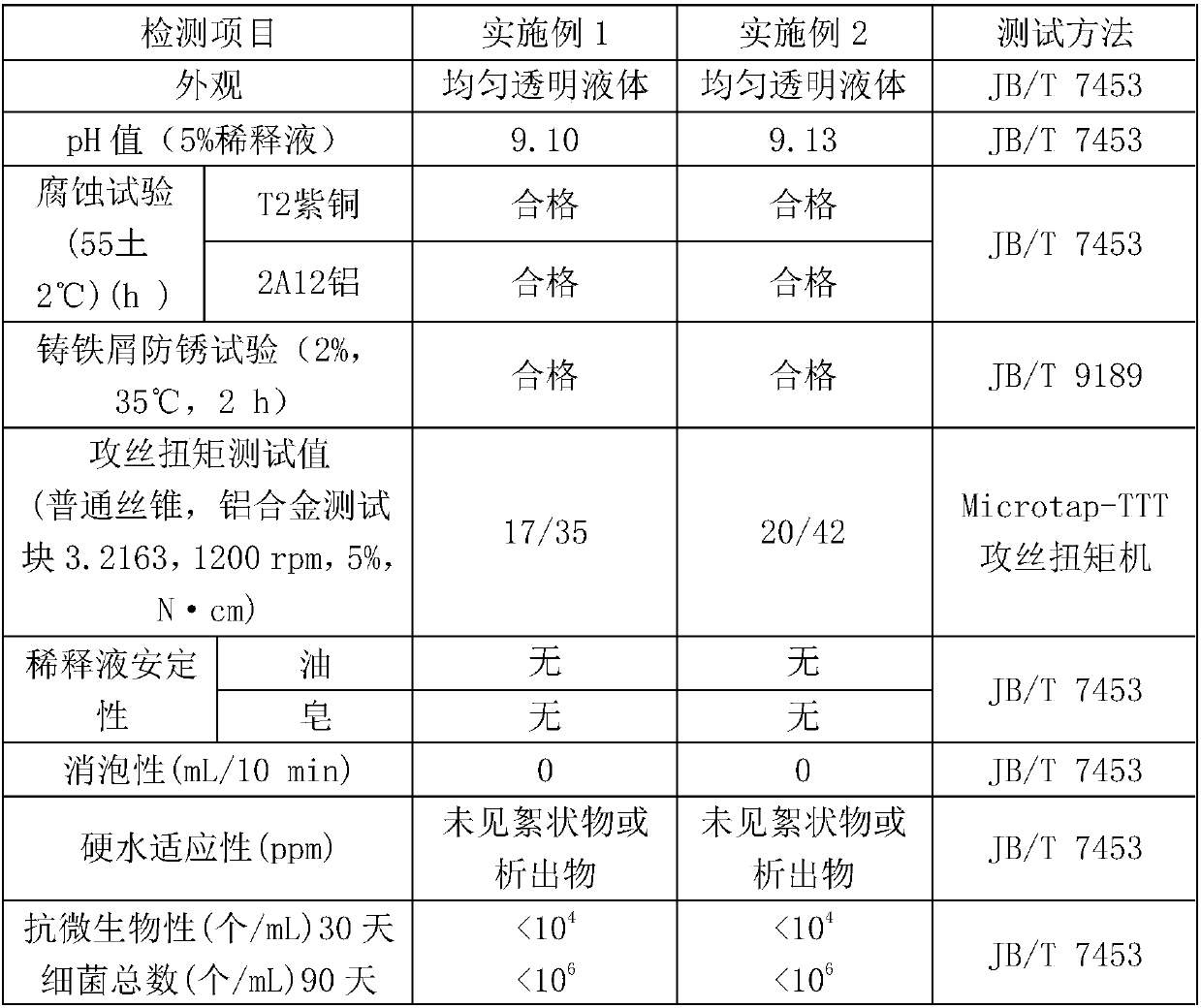

Aluminum alloy semisynthesis cutting liquid and preparation method thereof

ActiveCN102925269AResistant to corruption and odorWill not corrodeLubricant compositionActive agentSurface-active agents

The invention discloses aluminum alloy semisynthesis cutting liquid and a preparation method thereof. The aluminum alloy semisynthesis cutting liquid is composed by weight of 12%-20% of mineral oil, 9%-15% of surfactant, 8%-12% of antirust agent, 1%-2% of aluminum corrosion inhibitor, 3%-7% of lubricant, 8%-12% of extreme pressure agent, 0.5%-1% of defoamer, 0.5%-1% of fungicide and the balance, water. The preparation method includes sequentially adding the surfactant, the antirust agent, the aluminum corrosion inhibitor, the lubricant, the extreme pressure agent, the defoamer, the fungicide and the water into the mineral oil and evenly stirring and mixing the mixture to obtain the aluminum alloy semisynthesis. The aluminum alloy semisynthesis cutting liquid has excellent performance on aluminum corrosion inhibition performance, corrosion resistance, lubricant performance, anti-rust performance, defoaming performance, use period and the like.

Owner:SHANGHAI INST OF TECH

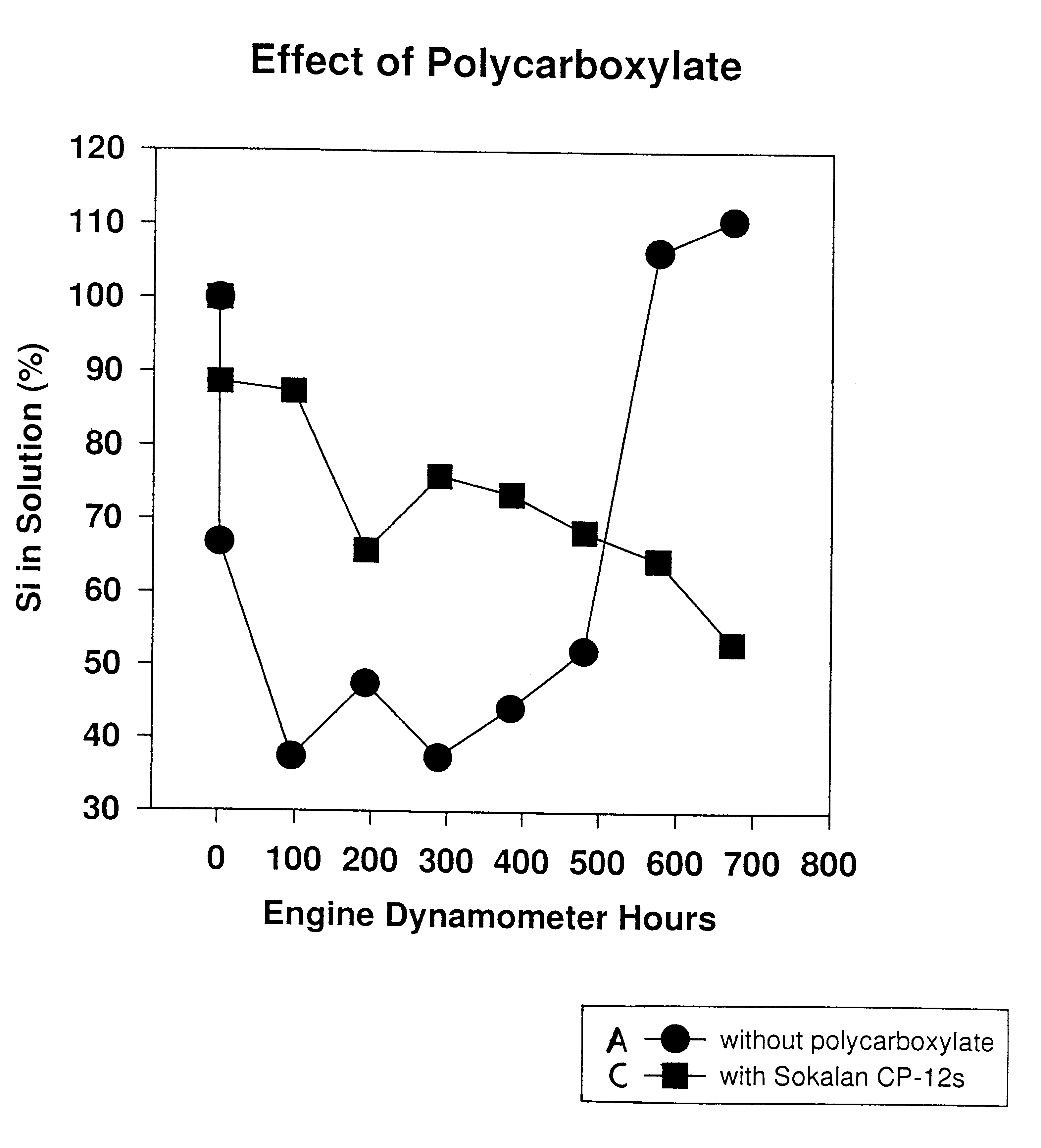

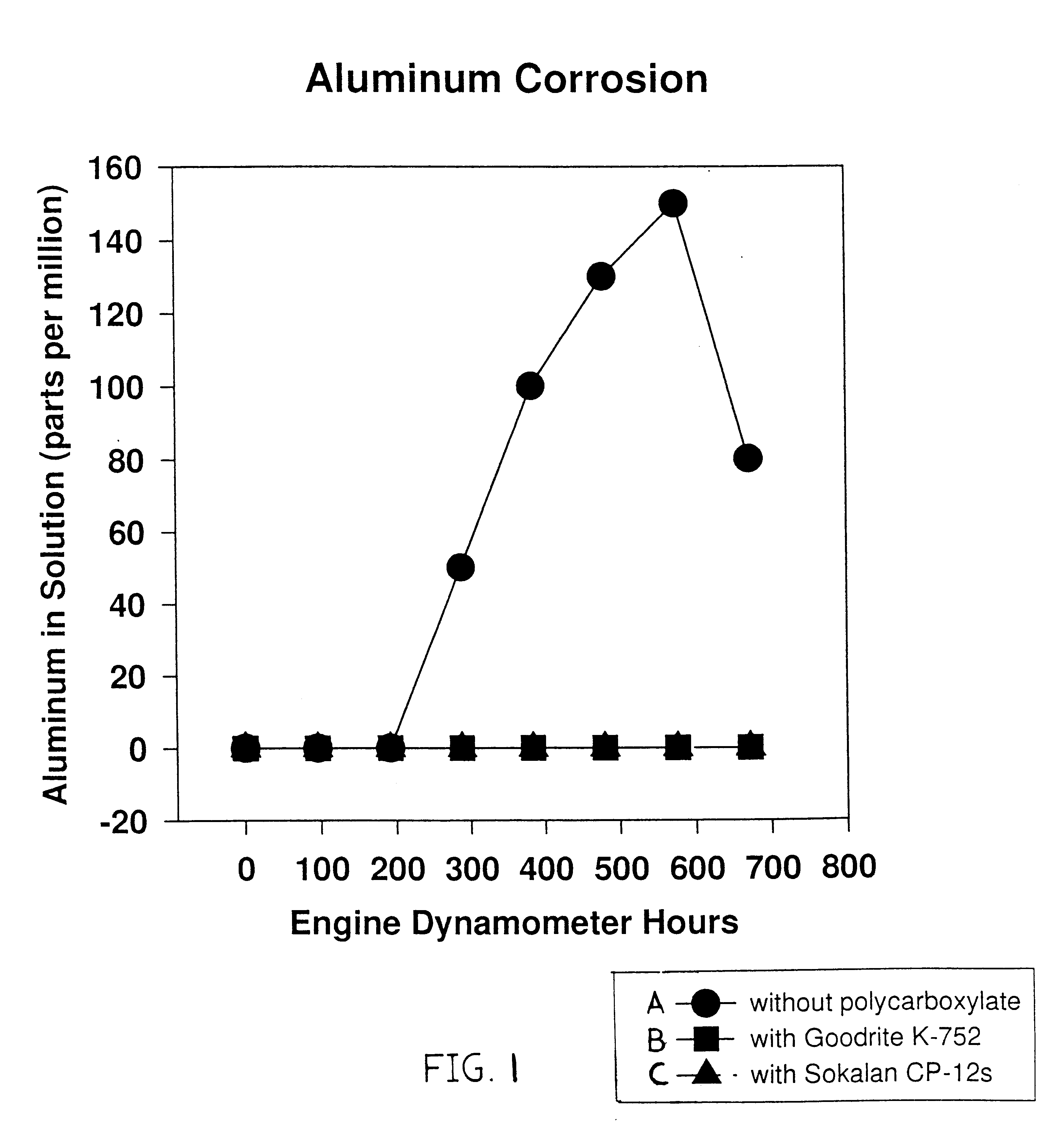

Extended engine coolant lifetime through polymeric polycarboxylate secondary silicate stabilization

InactiveUS6203719B1Inhibiting cavitation-erosion corrosionOther chemical processesHeat-exchange elementsPhosphateNitrate salts

The present invention provides corrosion inhibition formulations and compositions for inhibiting mineral scale and the corrosion of metals particularly the cavitation corrosion of aluminum in the presence of aqueous liquids. The combination of a mixture of polymeric polycarboxylates, azoles, nitrate salts, phosphates, stabilized silicates and transition metal compounds provide a synergistic protective effect against the cavitation corrosion of aluminum in aqueous liquids reducing the corrosion rate and is effective at relatively low concentrations and varying pH ranges. The addition of selected polymeric polycarboxylates not only significantly reduces glycol based coolant cavitation erosion-corrosion, heat rejecting aluminum corrosion, and hard water precipitates and scale, it has been discovered that polymeric polycarboxylates in combination with siloxane stabilized silicates enhance secondary silicate stabilization leading to improvement in aluminum corrosion protection and coolant life when utilized with selected amounts of the above-identified additives. The formulations are particularly suitable for automotive applications.

Owner:VALVOLINE LICENSING & INTPROP LLC

Calcium hexaluminate based pouring material not polluting high-purity aluminum solution

InactiveCN102211945AOvercoming the inability to meet the production process requirements of high-purity aluminumSolve pollutionPollutionAluminum corrosion

The invention discloses a calcium hexaluminate based lining pouring material not polluting components of high-purity aluminum although contacting with a high-purity solution in the refinement, fusion and insulation processes of the high-purity aluminum. Raw materials for preparing the pouring material comprise the following components: a synthesized calcium hexaluminate material, an ancillary material, micropowder, cement and an additive. By using the pouring material, a defect that the existing non-stick aluminum material has a certain aluminum corrosion resisting effect on the ordinary alloy but can not meet the high-purity requirement of the high-purity aluminum for the influence and pollution of components in an aluminum solution is overcome so as to solve the pollution problem of brasque material on the high-purity aluminum solution.

Owner:江苏瑞复达高温新材料股份有限公司

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

Method for making patterns on metal surfaces

Owner:LENOVO (BEIJING) LTD

Dishwashing composition with improved protection against aluminum corrosion

InactiveUS20140018278A1Organic/inorganic per-compounds compounding agentsDetergent bleaching agentsCounterionZinc

An automatic dishwashing composition having a preformed polymer with a zinc counterion and an amino acid based builder is useful in the reduction of corrosion in aluminum dishware.

Owner:THE PROCTER & GAMBLE COMPANY

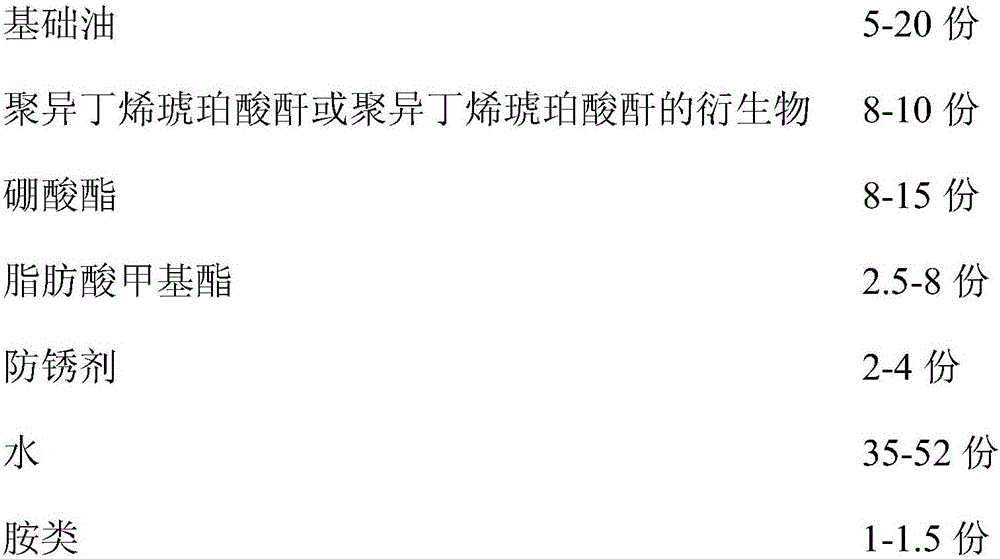

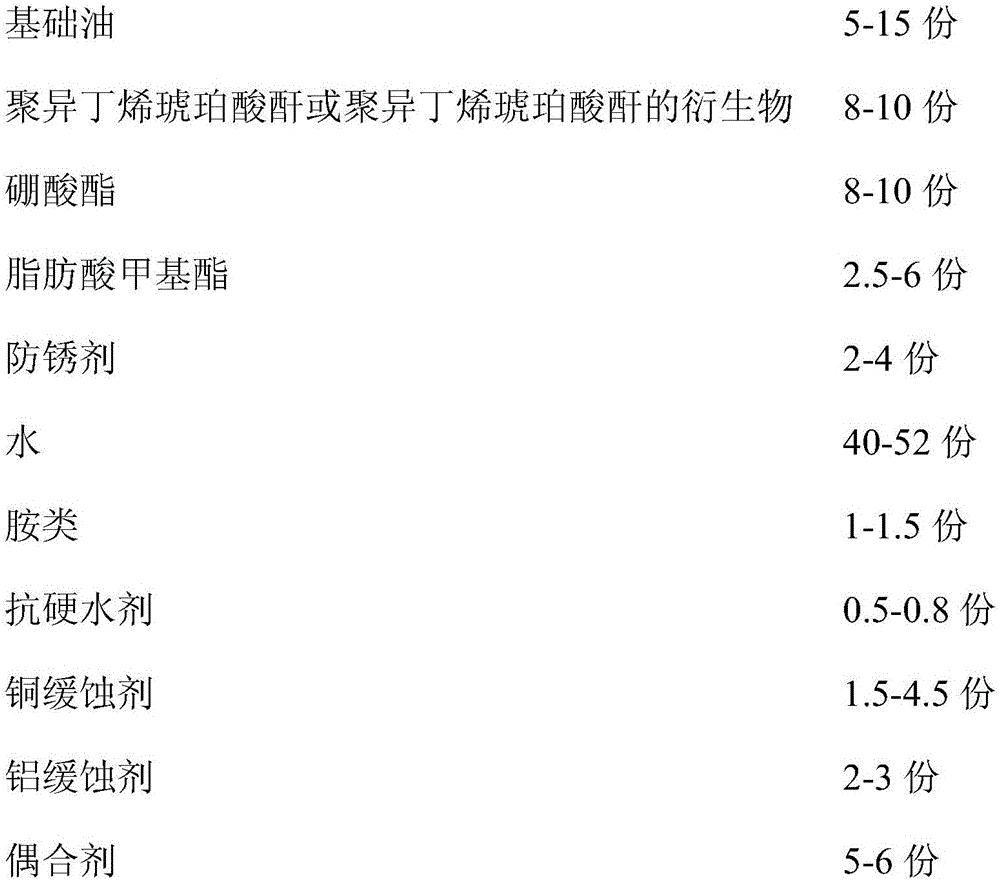

Multifunctional semi-synthetic metal processing liquid and preparation method thereof

ActiveCN106318586AImprove protectionImprove the lubrication effectLubricant compositionCooling effectFatty acid methyl ester

The invention discloses a multifunctional semi-synthetic metal processing liquid and preparation method thereof. The multifunctional semi-synthetic metal processing liquid comprises, by weight, 5-20 parts of base oil, 8-10 parts of polyisobutylene succinic anhydride or the derivative of the same, 8-15 parts of borate, 2.5-8 parts of fatty acid methyl ester, 2 to 4 parts of rust inhibitor, 35 to 52 parts of water, 1 to 1.5 parts of amine, 0.5 to 0.8 part anti-hardening agent, 0.2 to 4.5 parts of copper corrosion inhibitor, 2 to 3 parts of aluminum corrosion inhibitor, 5 to 6 parts of coupling agents, 3 to 4 parts of fungicides and 0.2 to 0.3 part of defoaming agent. The metal processing liquid provided by the invention not only has excellent cooling effects, very good lubricating effects and extreme pressure property, excellent high temperature stability and low temperature stability, but also generates little foam. The processing liquid is an environment friendly product which can be used for the cutting and grinding operation with medium and high difficulties in the high-speed cutting and large piece cutting.

Owner:广州亦盛环保科技有限公司

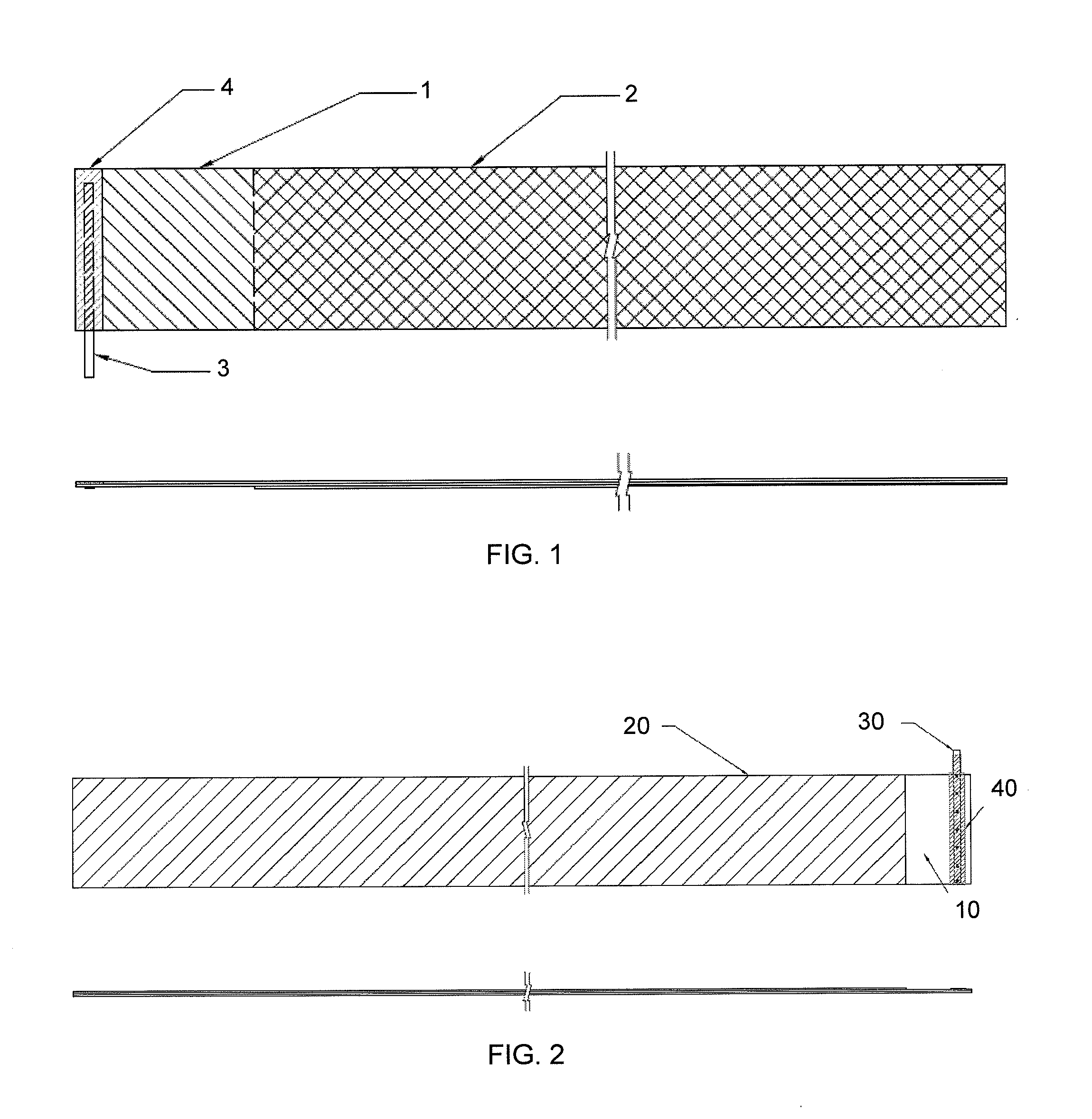

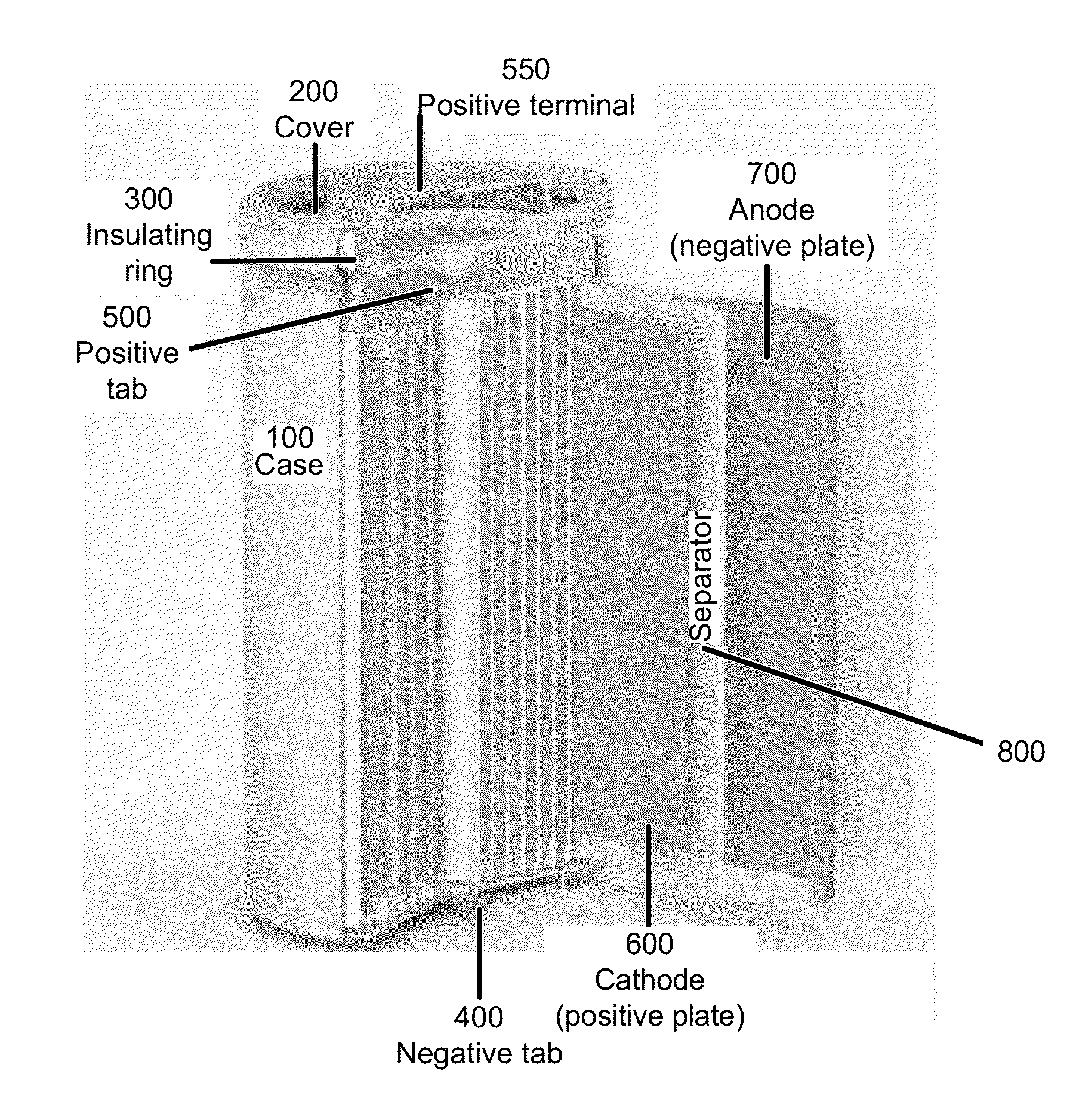

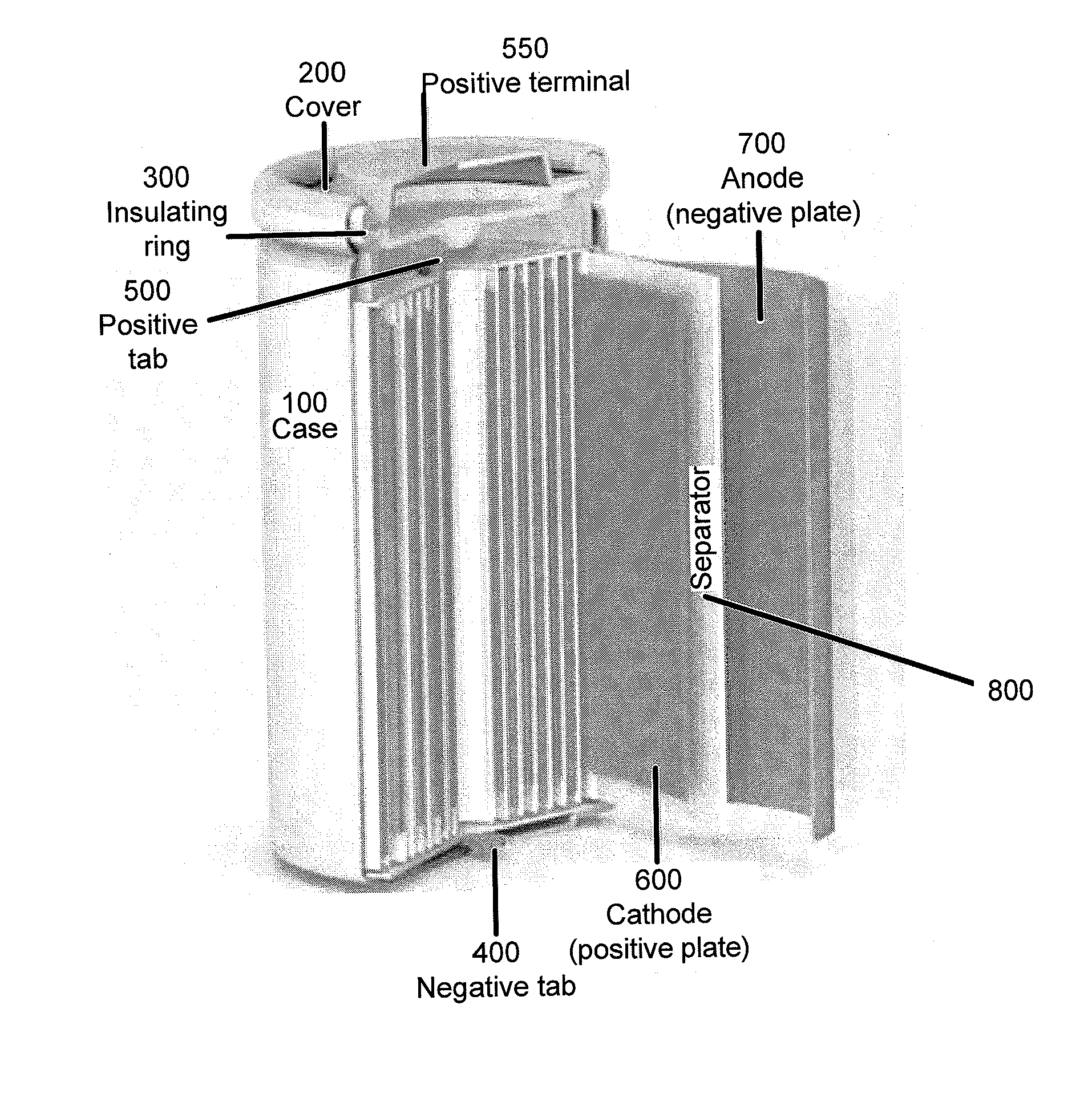

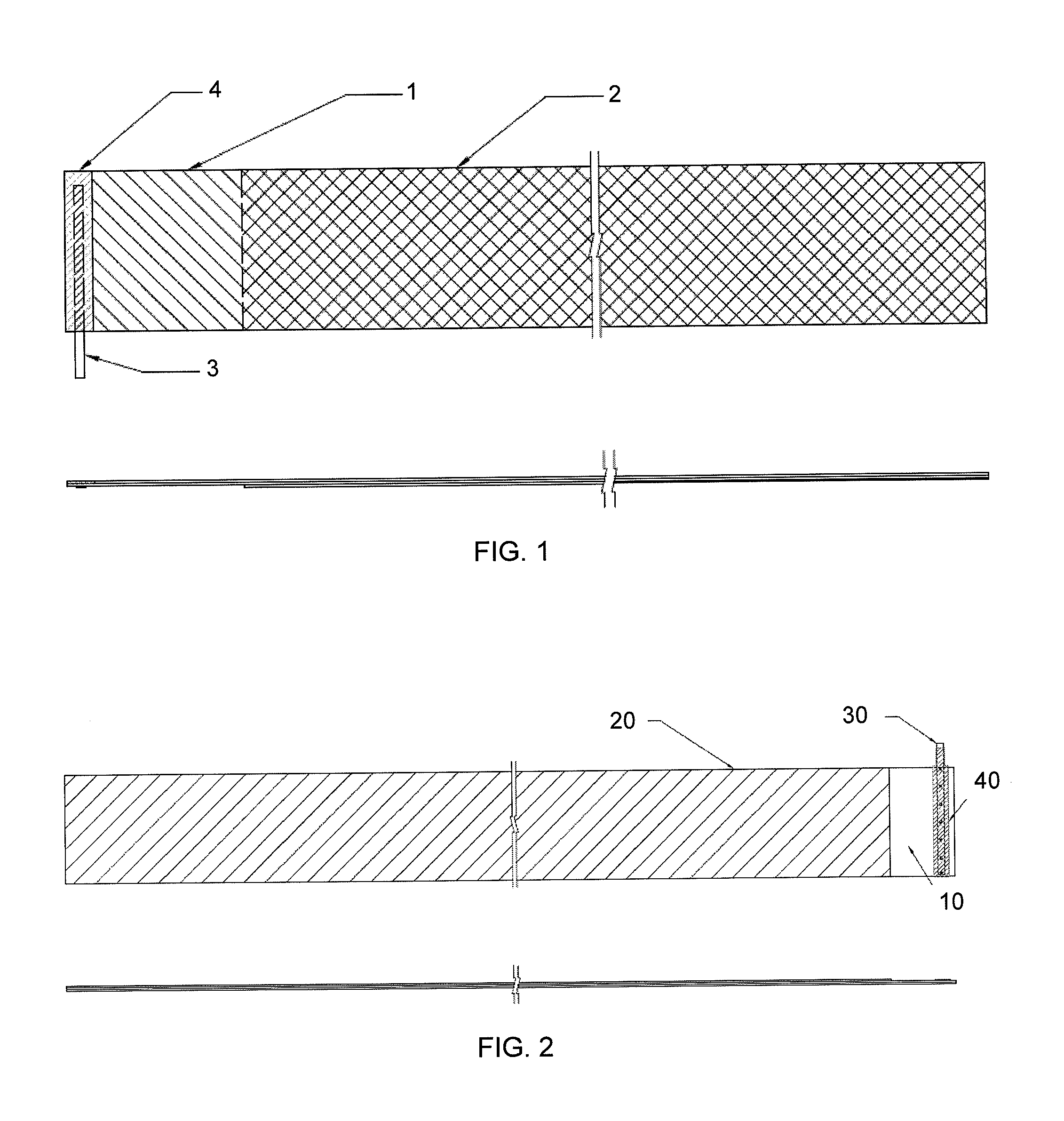

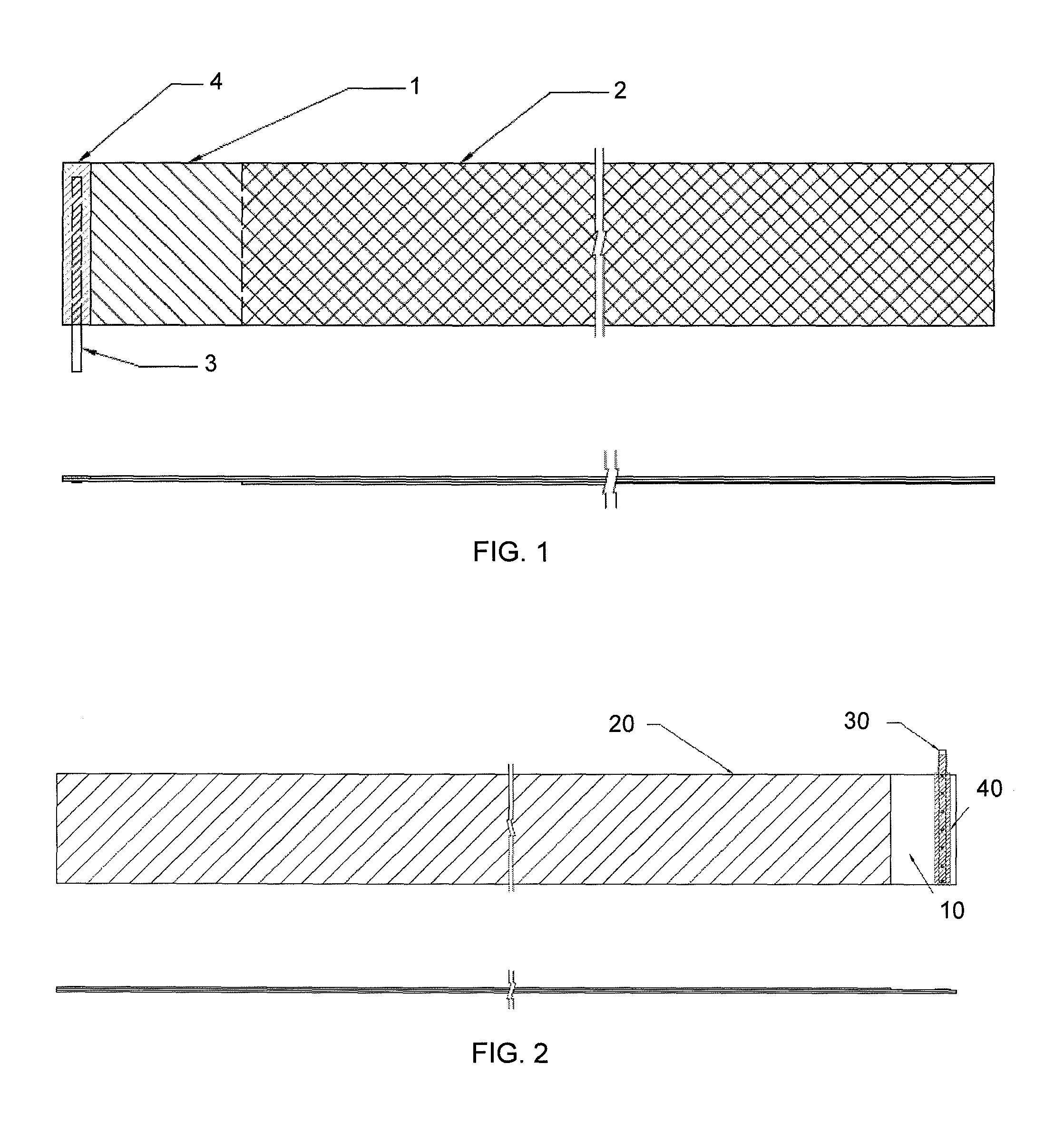

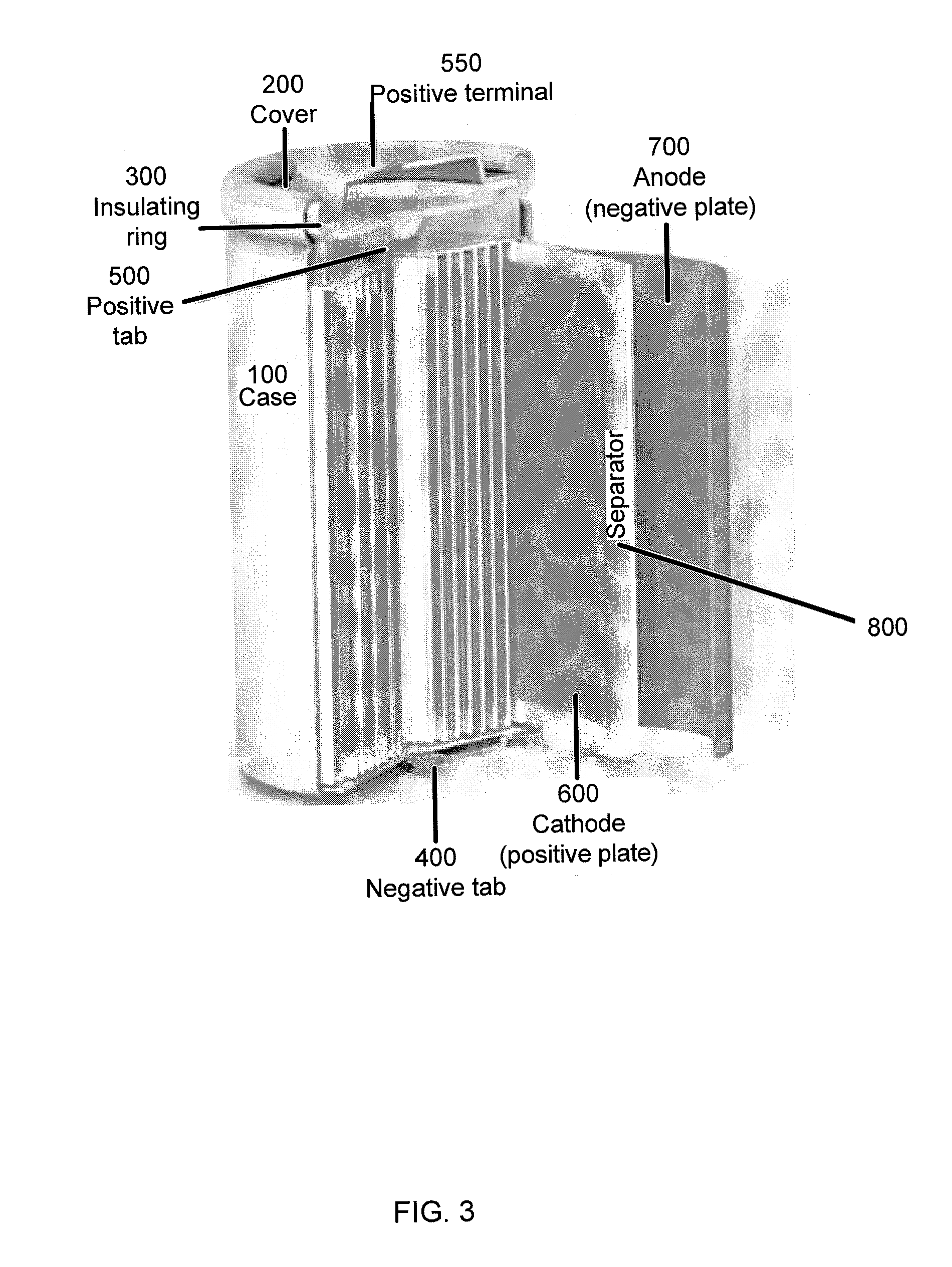

Manufacturing method of polymer lithium-ion power battery

InactiveCN101938010ALow costImprove rate charge and discharge performanceElectrode manufacturing processesFinal product manufactureInternal resistanceElectrical battery

The invention discloses a manufacturing method of a polymer lithium-ion power battery. In the battery, an aluminum corrosion foil serves as a positive current collector; a copper foil serves as a negative current collector; a layer of positive conductive carbon slurry and a layer of negative conductive carbon slurry are pre-coated on two surfaces of the positive and negative current collectors respectively; positive and negative active slurries are coated on the positive and negative current collectors respectively; and after an electrolyte is poured into the battery, in-situ polymerization is initiated through electromagnetic induction heating. The manufacturing method is used for manufacturing the polymer lithium-ion power battery serving as a power battery of an electric vehicle, can increase the utilization rate of raw materials, reduce the cost of the battery, reduce the internal resistance between active substances and the current collectors, reduce the temperature rise of the battery, prolong the service life of the battery and improve the safety of the battery. Furthermore, the way of electromagnetic induction polymerization uniformly heats at a high speed, so that the performances and consistency of the battery are greatly improved.

Owner:JIANGSU SHUANGDENG GROUP

Anti-freezing cooling liquid and preparation thereof

ActiveCN101376802AGood storage stabilityImprove stabilityHeat-exchange elementsAnti freezingSodium silicate

The invention provides an antifreezing cooling liquid which comprises glycol, water, decanedioic acid, sodium silicate and a foam killer; wherein, the cooling liquid also contains cinnamic acid and mannite. The invention also provides a preparation method of the antifreezing cooling liquid; wherein, the method includes the step of uniformly mixing the glycol, the water, the decanedioic acid, the sodium silicate and the foam killer. The storage stability of the antifreezing cooling liquid provided by the invention is better; besides, the antifreezing cooling liquid provided by the invention extensively improves the restraining effect to aluminum corrosion.

Owner:BYD CO LTD

Full synthetic aluminum drawing fluid composition

The invention relates to a full synthetic aluminum drawing fluid composition, which comprises the following components: 5 to 20 percent of mixed alkylol amine, 5 to 15 percent of mixed acid, 0.2 to 0.8 percent of copper corrosion inhibitor, 1 to 4 percent of antirusting agent, 5 to 15 percent of hexanediol, 1 to 5 percent of aluminum corrosion inhibitor, 5 to 30 percent of water-soluble polyether, and the balance of water. The full synthetic aluminum drawing fluid composition is characterized in that: the full synthetic aluminum drawing fluid composition has excellent lubricating property, cleaning and aluminum protective property; the good lubricating property can meet the machining accuracy requirement; the good cleaning ensures that a workpiece can be quickly cleaned in the next working procedure, and does not influence the operation; and the good aluminum protective property can meet the brightness requirement of the workpiece. The drawing fluid is prepared from basic solution, sothe drawing fluid does not contain a bactericide.

Owner:河北九熙新材料科技有限公司

Semi-synthesis cutting liquid for low-phosphorus chlorine-free non-formaldehyde aluminum alloy cutting processing

InactiveCN108034485AImprove stabilityAchieving Aluminum Corrosion Inhibition PropertiesLubricant compositionMetalworkingDefoaming Agents

The invention discloses semi-synthesis cutting liquid for low-phosphorus chlorine-free non-formaldehyde aluminum alloy cutting processing and belongs to the technical field of metal processing mediums. The semi-synthesis cutting liquid is prepared from the following components in percentage by weight: naphthene base crude oil, an extreme pressure lubricant, an oily lubricant, an emulsifier, organic alcohol amine combination, a silicon-containing aluminum corrosion inhibitor, an anti-rust agent, a copper corrosion inhibitor, a sterilizing agent, a coupling agent, water and a defoaming agent. Due to adoption of the combination of the extreme lubricant and the oily lubricant, the lubricating ability of the cutting liquid and the surface smoothness of a workpiece are improved; due to adoptionof the alcohol amine combination, the alkali retaining ability and the pH stability of the cutting liquid and the stability of microorganisms are improved; due to adoption of the silicon-containing aluminum corrosion inhibitor, the aluminum corrosion inhibition performance of the aluminum alloy cutting liquid is realized; due to adoption of a bacteriostatic system, introduction of phosphorus is reduced, the alcohol ether bacteriostatic component is increased and the service life of the cutting liquid is prolonged; and due to adoption of the non-formaldehyde release type sterilizing agent, theadverse influence on a human body and the environment by the cutting liquid is reduced.

Owner:NANJING KERUN NEW MATERIAL TECH

High performance lithium or lithium ion cell

InactiveUS20120121991A1Electrode carriers/collectorsOrganic electrolyte cellsConductive coatingAlloy

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

Anode aluminum corrosion method for media and high voltage aluminum electrolysis capacitor

InactiveCN101483102AHigh area expansion rateIncrease specific volumeElectrolytic capacitorsElectrolysisHigh pressure

The present invention relates to an anode aluminum foil corrosion process for middle-and high-voltage aluminum-electrolytic capacitor. The present invention solves the existence technical problems in the prior art such as the mechanical strength is reduced in the anode aluminum foil corrosion process for the high-voltage aluminum-electrolytic capacitor, the invention provides an anode aluminum foil corrosion process which can simultaneously hold the mechanical strength while achieving the prior corrosion affection. The invention has main step of: a pretreatment of soaking the aluminum foil in a mixed solution of 1.5wt%-5wt% of hydrochloric acid and 20wt%-38wt% of sulfuric acid; a first stage direct current corrosion of performing direct current electrolytic corrosion to the aluminum foil after pretreatment in the mixed solution of 1.5wt%-5wt% of hydrochloric acid and 20wt%-38wt% of sulfuric acid; a second stage direct current corrosion of performing direct current electrolytic corrosion to the aluminum foil after first stage direct current corrosion in a 0.5wt%-4wt% hydrochloric acid solution; and a post-processing of putting the aluminum foil after the second stage direct current corrosion in a 2wt%-15wt% of nitric acid solution for immersion.

Owner:横店集团东磁有限公司

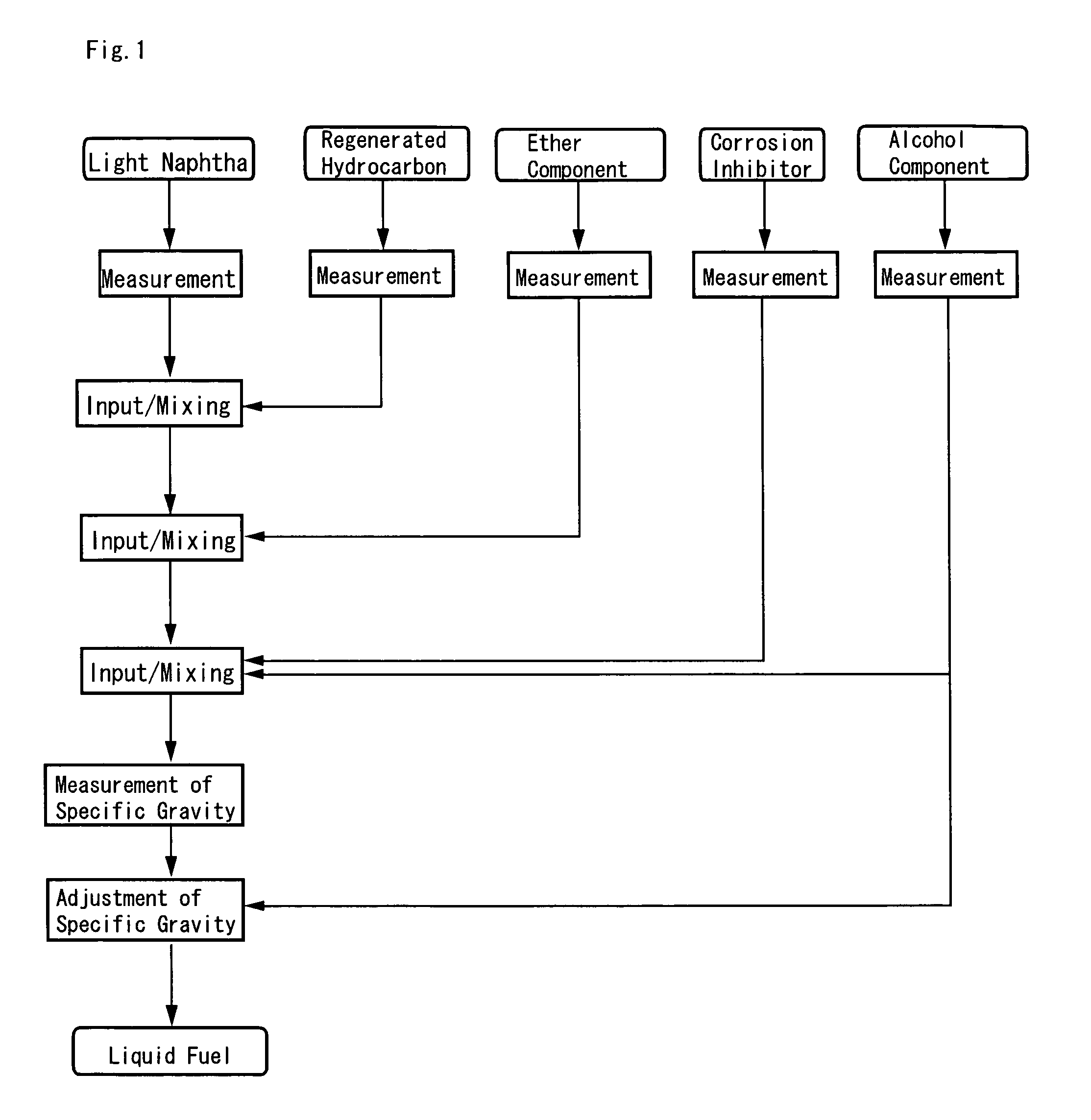

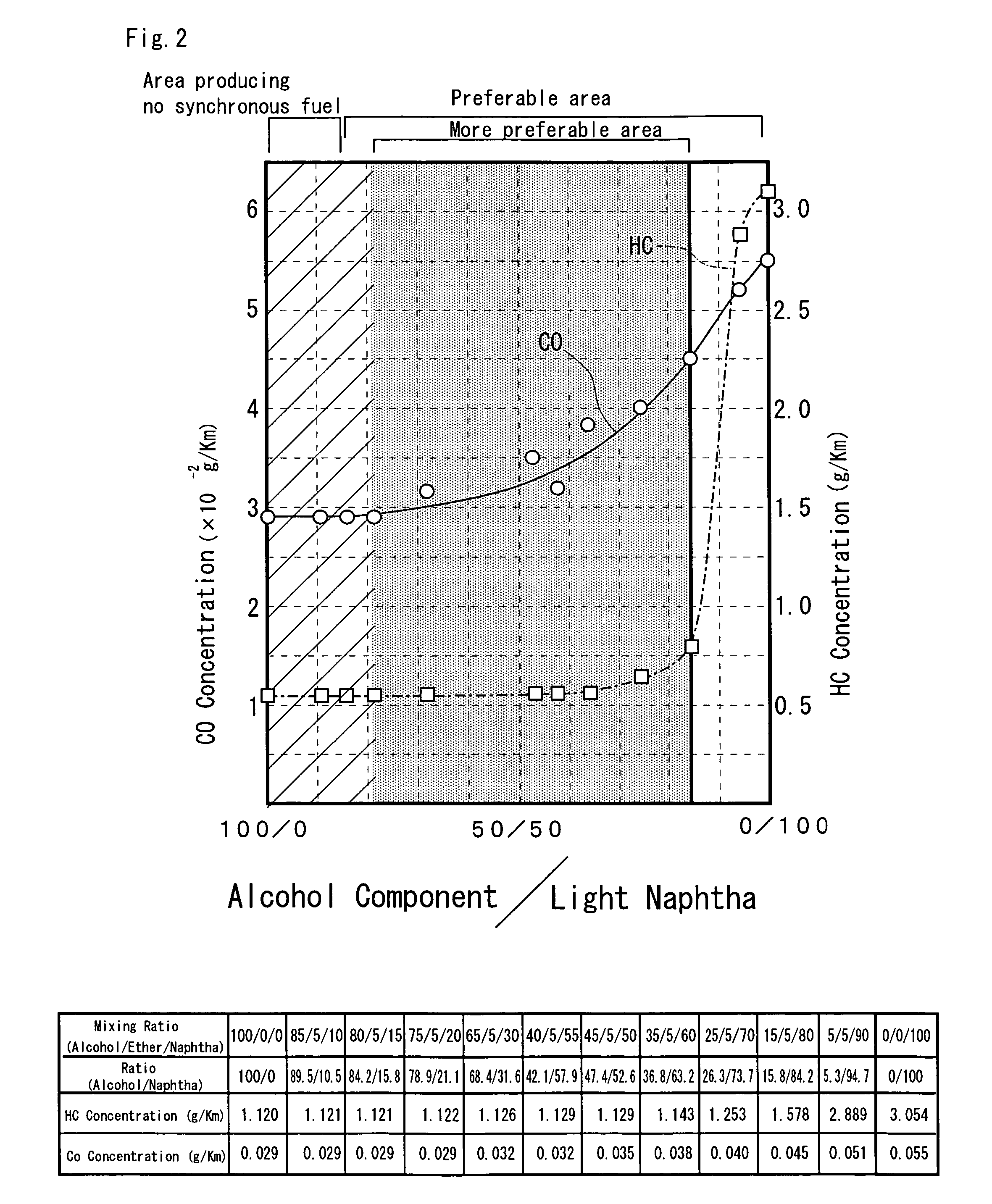

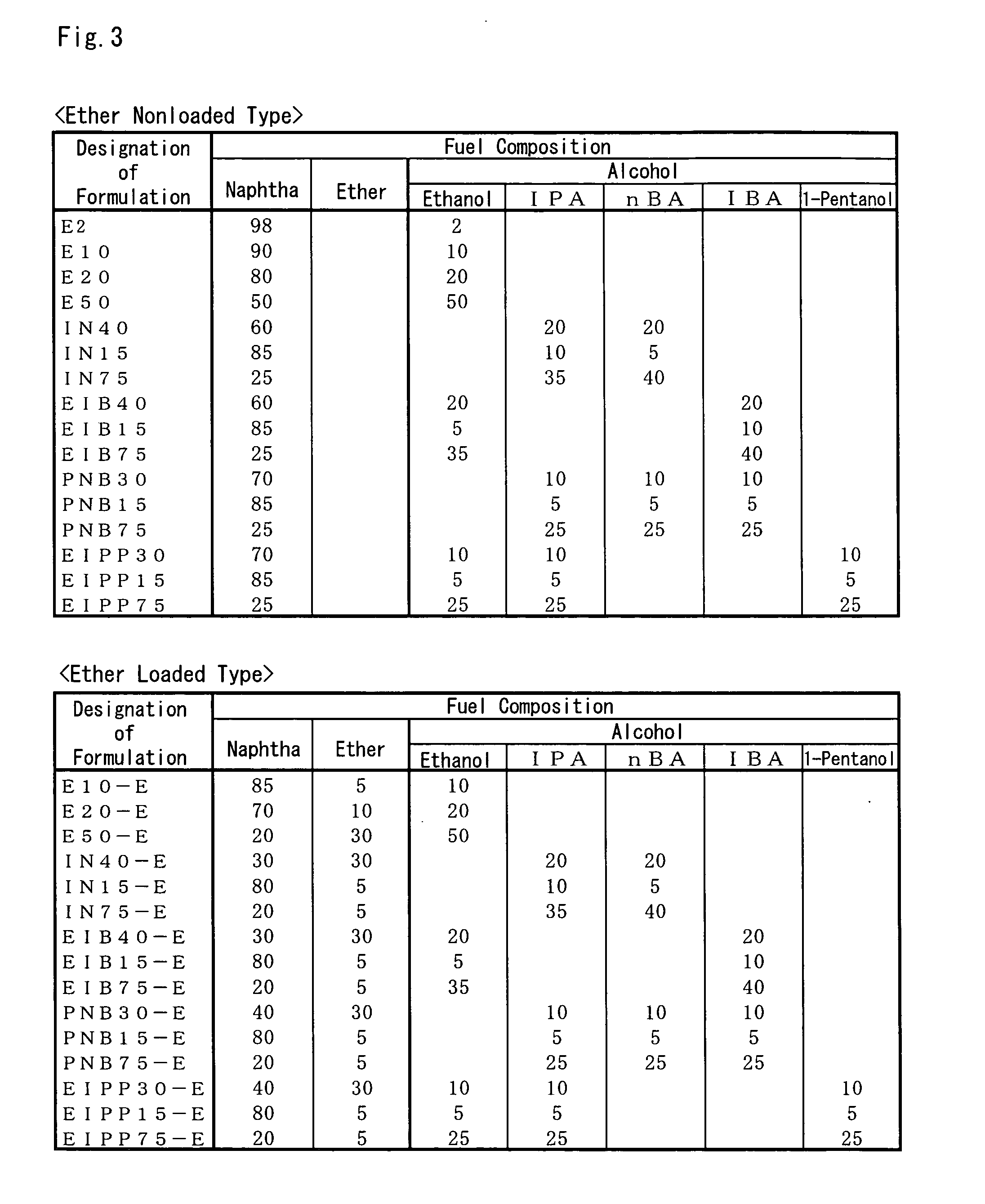

Liquid fuel for internal combustion engine

InactiveUS20060137243A1Avoid separationPracticalLiquid carbonaceous fuelsFuel additivesAlcoholKetone

A liquid fuel for internal combustion engine, comprising 2 to 85 wt % of an alcohol component of aliphatic monohydric alcohol having 2 to 6 carbon atoms per molecule per se or a mixture thereof and 15 to 98 wt. % of a hydrocarbon component. The liquid fuel for internal combustion engine contains an aluminum corrosion inhibitor in an amount capable of inhibiting the aluminum corrosion at predetermined given temperature. The aluminum corrosion inhibitor comprises at least one member selected from among methanol, glycol hydrocarbons, ketone hydrocarbons, ester hydrocarbons and aldehyde hydrocarbons.

Owner:SANGI CO LTD

Water-soluble low oil fog anti-rust cutting liquid

InactiveCN101265437AImprove the lubrication effectImprove rust resistanceAdditivesSolubilityPhosphate

The invention relates to a water-soluble low oil mist antirust cutting liquid used for the ferrous and nonferrous metal heavy-duty cutting operation, and the preparation method thereof. The preparation method comprises the following steps: firstly, the low oil mist antirust cutting liquid is prepared; secondly, the low oil mist antirust cutting liquid is added in a reaction vessel as the base oil, and is mixed, heated and warmed up to 60 to 80 DEG C; and then 5 to 15 percent of emulsifying agent, 3 to 10 percent of water solubility phosphate ester and 0.5 to 2 percent of copper / aluminum corrosion inhibitor by the base oil wight are added in sequence; after the completion of feeding, the heating to the reaction vessel is stopped, and the mixed liquor is agitated continuously untill in the uniform and transparent state. The prepared cutting liquid is used after being diluted by adding water, is particularly suitable for metal drilling, threading, gear processing and other heavy-duty cutting operations, and has good extreme pressure lubricating property and anti-rust property. The production cost of the cutting liquid is low, the oil mist is extremely low when in use, and no penetrating odor exists.

Owner:CHANGZHOU XIALEI CHEM

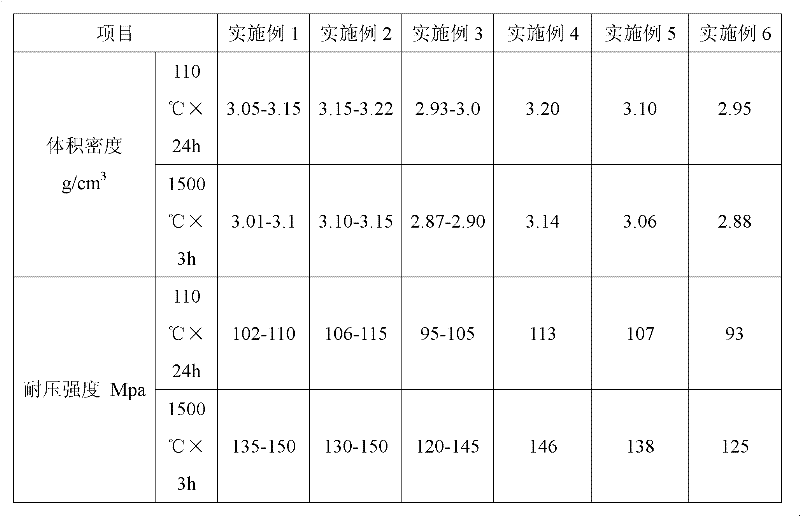

High-density cermet material resistant to molten aluminum corrosion and manufacturing method thereof

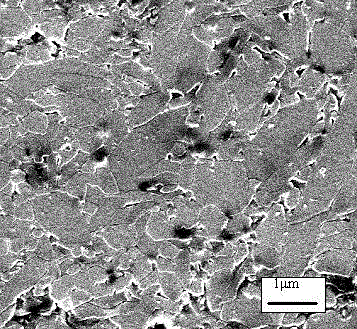

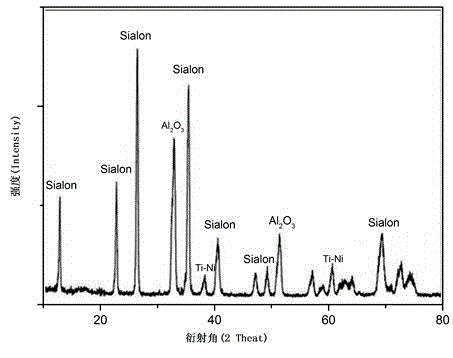

The invention discloses a high-density cermet material resistant to molten aluminum corrosion. The high-density cermet material comprises, by weight, 12-28% of Ti powder, 3-7% of Ni powder, 13-35% of AlN powder and 30-60% of Al2O3 powder, and the weight ratio of the Ti powder to Ni powder is 4:1. The manufacturing method includes the following steps of (1) batching, mixing and ball milling, (2) smashing and drying, (3) pressing and forming and (4) sintering, furnace cooling after sintering, discharging and demolding. The material is compact in structure, high in corrosion resistance and particularly high in molten aluminum corrosion resistance, and has important engineering application value due to the corrosion resistance in molten aluminum; the manufacturing method is simplified and low in production cost.

Owner:JIANGSU ZHAOLONG ELECTRIC

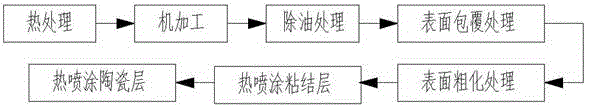

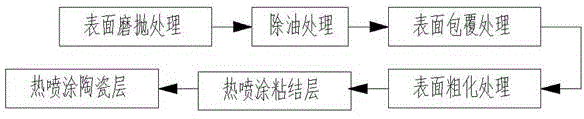

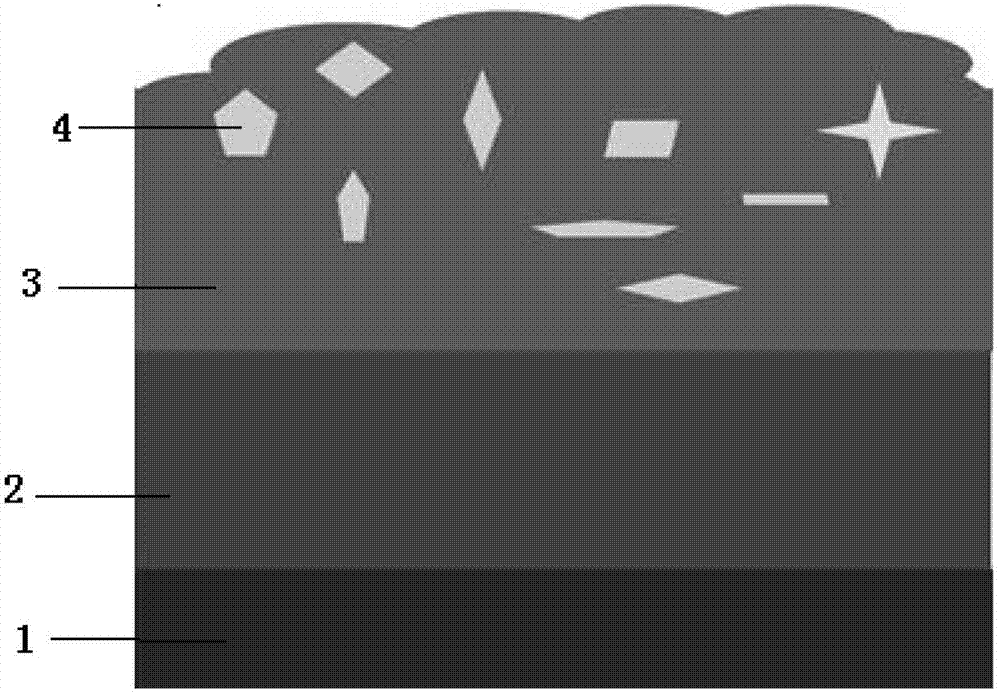

Preparation and repairing methods of molten aluminum corrosive wear resistant rotor for molten aluminum degassing

InactiveCN104593620AExtended service lifeImprove machinabilityMolten spray coatingPorosityThermal spraying

The invention relates to a preparation method of a molten aluminum corrosive wear resistant rotor for molten aluminum degassing. The preparation method comprises the following steps: thermal treating, machining, oil removal, surface coating, surface roughening, thermal-spraying of a bonding layer, and thermal-spraying of a ceramic layer. The invention further relates to a repairing method of the molten aluminum corrosive wear resistant rotor for molten aluminum degassing, the repairing method comprises the following steps: grinding and polishing the surface, removing oil, coating the surface, roughening the surface, thermal-spraying the bonding layer and thermal-spraying the ceramic layer; the rotor matrix in the invention is good in machinability, the prepared coatings are high in bonding strength with the matrix material, have high boning strength, low porosity, and non-wetting with the molten aluminum, excellent molten aluminum corrosion and abrasion resistance; therefore, the rotor is long in service life, and the rotor with coating failure can be repaired and reused, the use cost is reduced, and the rotor can be widely used for degassing purifying equipment in an aluminum smelting process.

Owner:FUZHOU UNIV

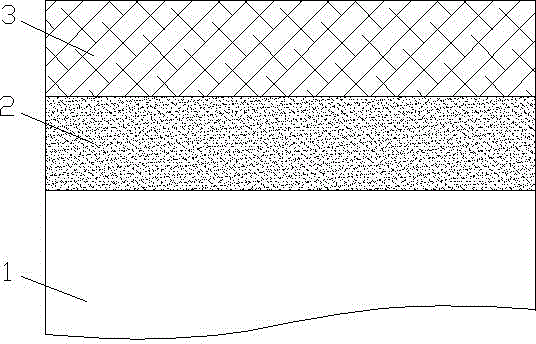

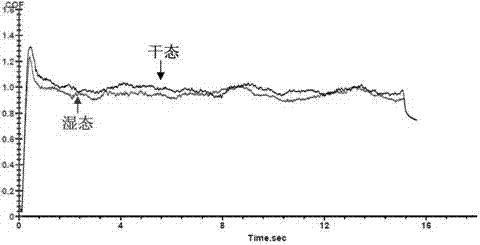

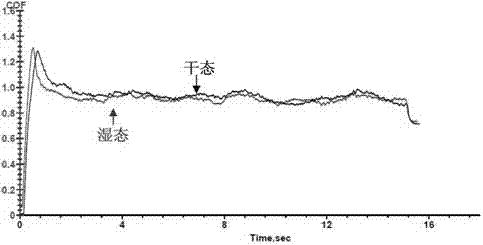

Corrosion-resistant antiskid coating with aluminum matrix composite structure and preparation process thereof

InactiveCN102732876AQuality improvementGood anti-corrosion and anti-skid performancePressure inorganic powder coatingNeopreneZinc

The invention relates to a corrosion-resistant antiskid coating with an aluminum matrix composite structure and a preparation process thereof, belonging to the technical fields of surface treatment and marine corrosion prevention, wherein the coating is capable of being rapidly repaired after damage. The corrosion-resistant antiskid coating consists of a composite structure of a zinc-aluminum corrosion-resistant bottom layer and an aluminum / ceramic antiskid top layer and is prepared through the following steps: carrying out sand-blast treating on a matrix so as to allow the surface of the matrix to be free of attached foreign materials and have roughness; spraying zinc-aluminum powder onto the matrix so as to form the zinc-aluminum corrosion-resistant bottom layer which has a bonding strength of more than 15 MPa and a thickness of 150 to 250 mu m; and spraying aluminum / ceramic powder onto the zinc-aluminum corrosion-resistant bottom layer of the matrix so as to form the corrosion-resistant antiskid coating with the aluminum matrix composite structure, wherein the coating has a bonding strength of more than 15 MPa, a thickness of more than 200 mu m and a coefficient of friction with chloroprene rubber of more than 0.85. The preparation process is simple; the quality of the coating is good; spraying is easy to carry out; and the coating has good anticorrosion and antiskid performances and a long service life and can be easily and rapidly repaired.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High performance lithium or lithium ion cell

Disclosed herein are lithium or lithium-ion batteries that employ an aluminum or aluminum alloy current collector protected by conductive coating in combination with electrolyte containing aluminum corrosion inhibitor and a fluorinated lithium imide or methide electrolyte which exhibit surprisingly long cycle life at high temperature.

Owner:A123 SYSTEMS LLC

Ultramicro kyanite refractory castable and application thereof

ActiveCN105622122AHigh resistance to aluminum corrosionImproved resistance to aluminum corrosionDecompositionRefractory

The invention belongs to the field of refractory materials and discloses an ultramicro kyanite refractory castable. The ultramicro kyanite refractory castable comprises, by weight, 47-80 parts of high alumina bauxite aggregate, 10-40% of alumina powder, 0.05-3% of admixture and 3-10% of ultramicro kyanite, content of alumina in the ultramicro kyanite is greater than or equal to 50%, kyanite phase is greater than or equal to 70%, and granularity is less than or equal to 10 um. Through premixing technology, ultramicro kyanite is mixed with alpha-Al2O3 and sub-white corundum powder, so that ultramicro kyanite can be uniformly dispersed in a matrix; ultramicro kyanite plays a role in offsetting structural contraction caused by high-temperature contraction of alumina or high-temperature decomposition of aluminum corrosion resisting agent through structural expansion of highly-uniformly-dispersed kyanite at 1250 DEG C. Ultramicro kyanite is used, and when grain diameter is reduced to 5 um, size expansion rate of ultramicro kyanite is lower than 3%; kyanite has high aluminum corrosion resistance, so that when same water adding quantity and fluidity are maintained, aluminum corrosion resistance of refractory lining materials can be improved greatly.

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

High-temperature molten aluminum corrosion resistance ultrasonic horn and production method thereof

InactiveCN102935742ALow priceImprove performanceMolten spray coatingCeramic layered productsTemperingComposite ceramic

The invention aims at providing a molten aluminum corrosion resistance ultrasonic horn which is made of No.30 carbon steel. After heat treatment tempering, an Al2O3 and TiO2 composite ceramic coating is warped on the outer surface of the horn in plasma spraying method, wherein TiO2 occupies 10-25% according to proportion, and the thickness of the coating is 2-6mm. Compared with the traditional horn, the ultrasonic horn has excellent chemical stability and corrosion resistance, and the practical problem that the Al2O3 ceramic layer is crisp and brittle is solved by adding TiO2 particles, vibration frequency stability of the ultrasonic horn is ensured, and the ultrasonic horn is offset, is improved in emission efficiency and prolonged in service life. The molten aluminum corrosion resistance ultrasonic horn is made of inexpensive carbon steel instead of expansive titanium alloy materials, effectively reduces cost and has good economic benefit.

Owner:JIANGSU UNIV

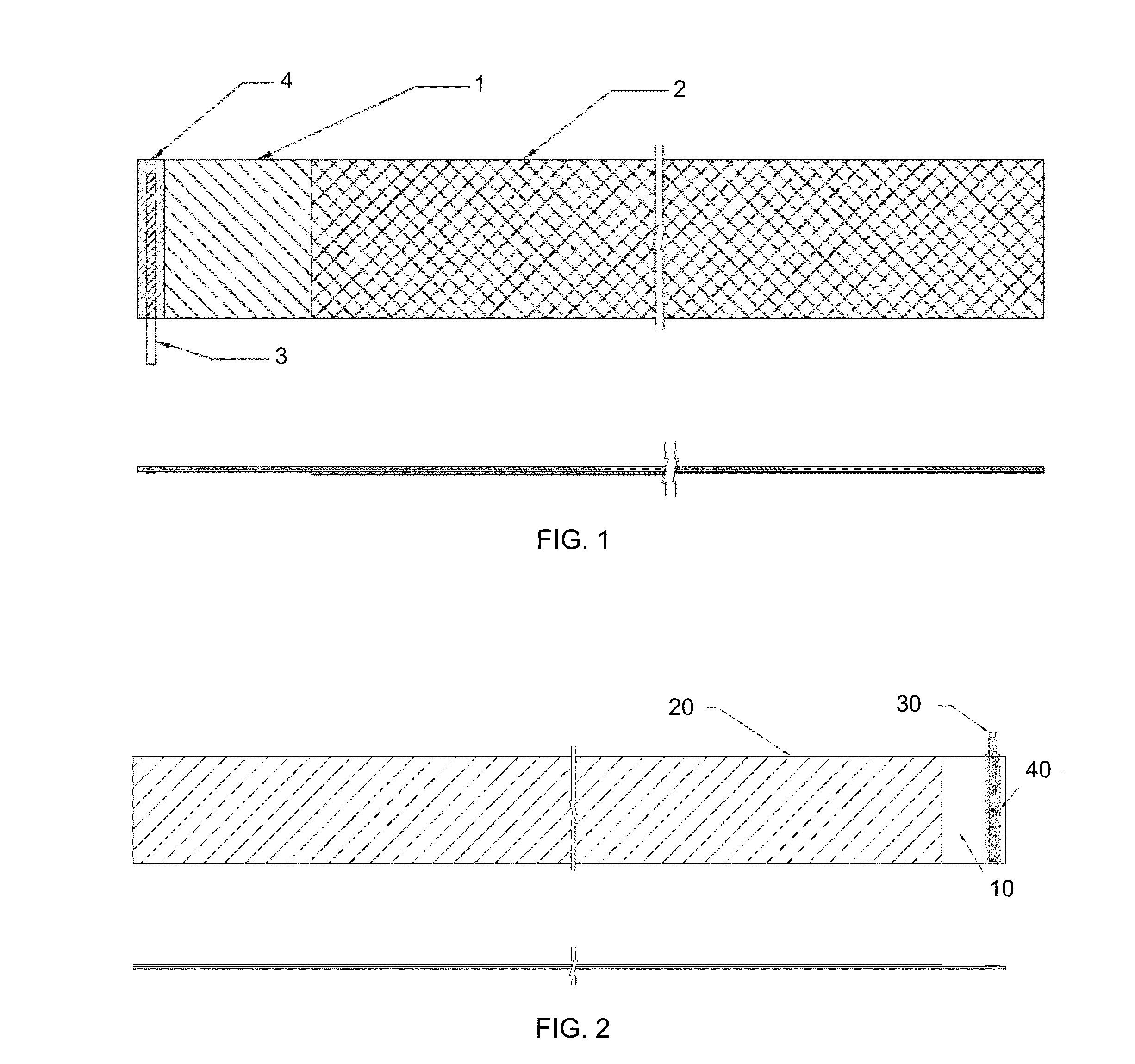

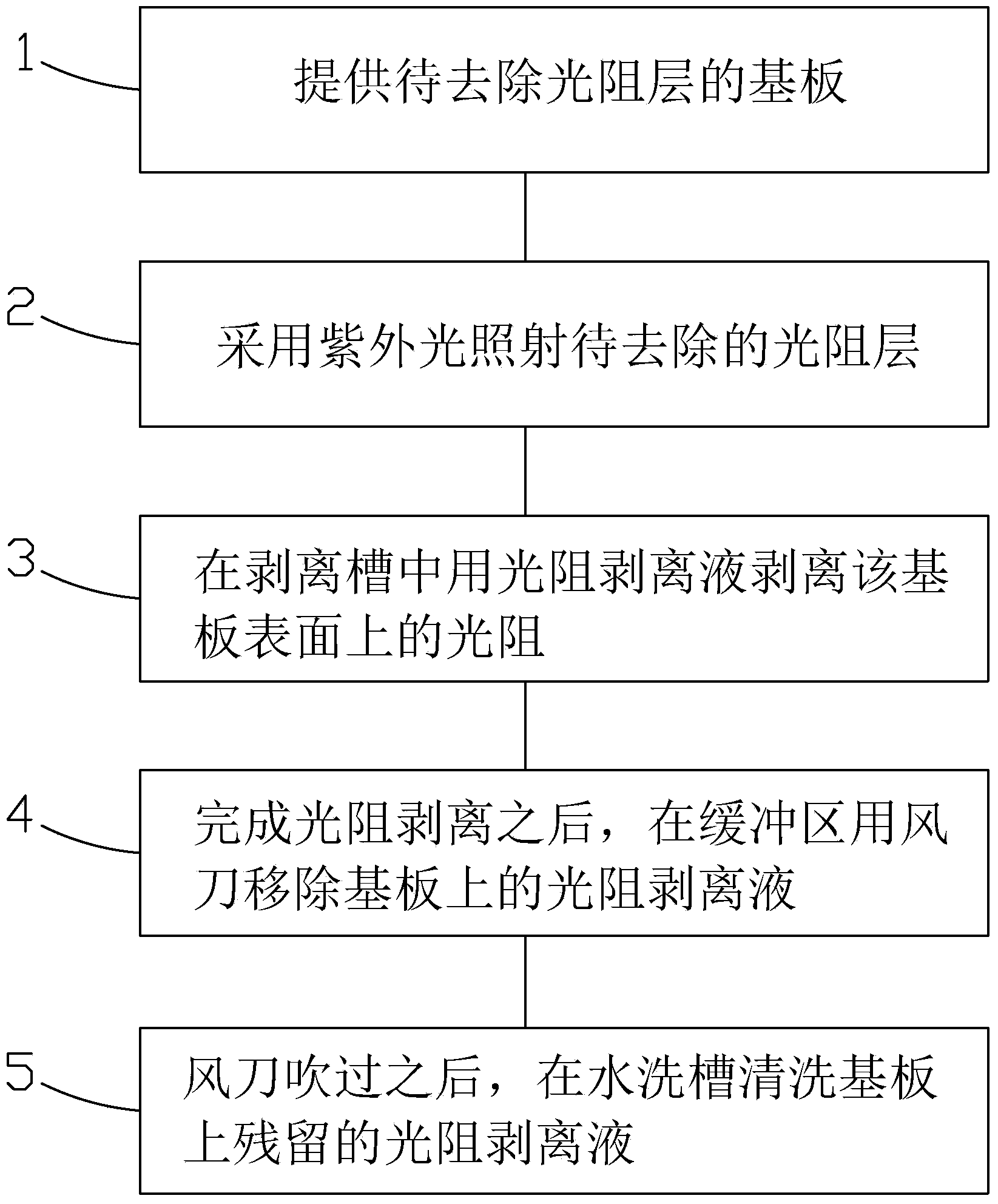

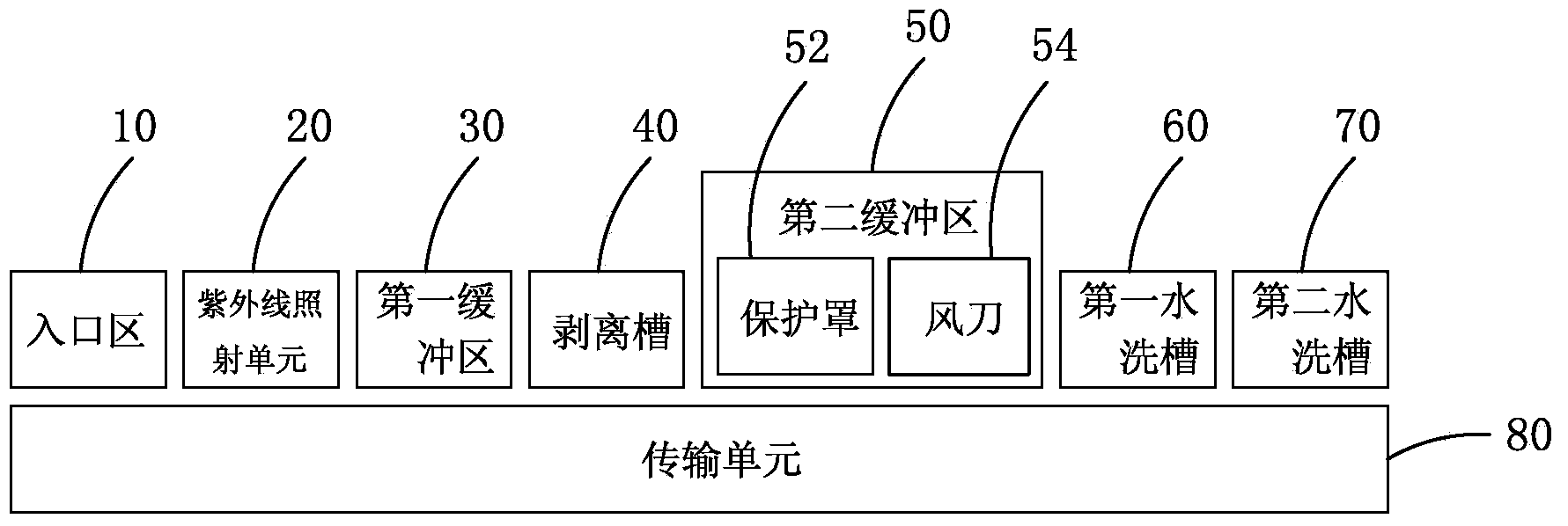

Light resistance stripping method and light resistance stripping device

ActiveCN103995441ASimple processSimple structureNon-surface-active detergent compositionsDetergent mixture composition preparationPhoto irradiationUltraviolet lights

The invention provides a light resistance stripping method and a light resistance stripping device. The light resistance stripping method comprises the steps: 1, providing a substrate of a to-be-removed light resistance layer; 2, irradiating the to-be-removed light resistance layer by adopting ultraviolet light; 3, stripping light resistance on the surface of the substrate by using a light resistance stripping solution in a stripping groove; 4, after the light resistance stripping is completed, removing the light resistance stripping solution on the substrate by using an air knife on a buffer region; and 5, after the air knife blows, cleaning the light resistance stripping solution remained on the substrate on a washing tank. According to the light resistance stripping method, the aluminum corrosion and IGZO (Indium Gallium Zinc Oxide) corrosion in the light resistance stripping process can be maximally reduced, and the quality of a flat panel display is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Metal ceramic material resistant to molten aluminum corrosion, and preparation method and application thereof

The invention provides a metal ceramic material resistant to molten aluminum corrosion, and a preparation method and an application thereof, and relates to the technical field of metal material corrosion and protection. The chemical composition of the metal ceramic material provided by the invention is Ti(C0.3,N0.7)-Al0.25FeNiCoCr, raw materials for preparing the metal ceramic material comprise Ti(C0.3,N0.7) and an Al0.25FeNiCoCr high-entropy alloy; the mass percentage of the Al0.25FeNiCoCr high-entropy alloy in the metal ceramic material is 8-30%; the microscopic Vickers hardness of the metalceramic material ranges from 779.4 HV[0.2] to 1237.1 HV[0.2]. The metal ceramic material provided by the invention has excellent molten aluminum corrosion resistance and good hardness and toughness,and can be applied to the aluminum industry. The preparation method of the metal ceramic material is simple in process and beneficial to large-scale production.

Owner:XIANGTAN UNIV

Plasma etching residual washing liquid

InactiveCN101561641ANo corrosion problemsReduce pollutionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydroxylamineHydroxylamine Hydrochloride

The invention discloses a plasma etching residual washing liquid which contains hydroxylamine and derivate thereof, solvent, water and chelating agent. The plasma etching residual washing liquid is characterized by also comprising carboxylic polymer and polymer containing paint affinity groups and is compounded by the carboxylic polymer and the polymer containing paint affinity groups, thereby radically solving the problem of metal corrosion, particularly aluminum corrosion caused by rinsing with water during the washing in a wet method washing of the traditional hydroxylamine washing liquid in a process of semiconductor manufacture and omitting the solvent rinsing for avoiding the metal corrosion after the washing by the transitional hydroxylamine washing liquid. The invention keeps stronger washing property of the prior hydroxylamine washing liquid, causes metal corrosion, particularly aluminum corrosion resulted from direct washing by water after the washing of wafer, can remove the solvent washing procedure after the removal of plasma etching residual, and is beneficial to reduce the pollution and lower the cost.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

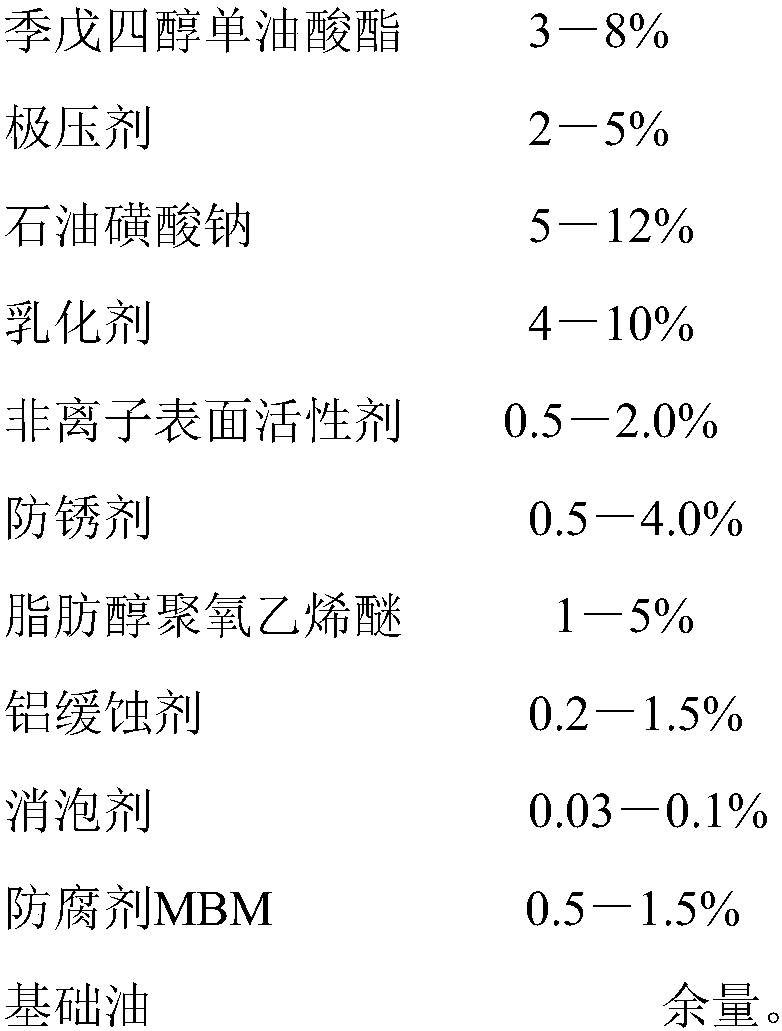

Aluminum alloy plate water-soluble stamping oil

InactiveCN107629844ASmall smellImprove extreme pressure performanceLubricant compositionPhosphateFatty alcohol

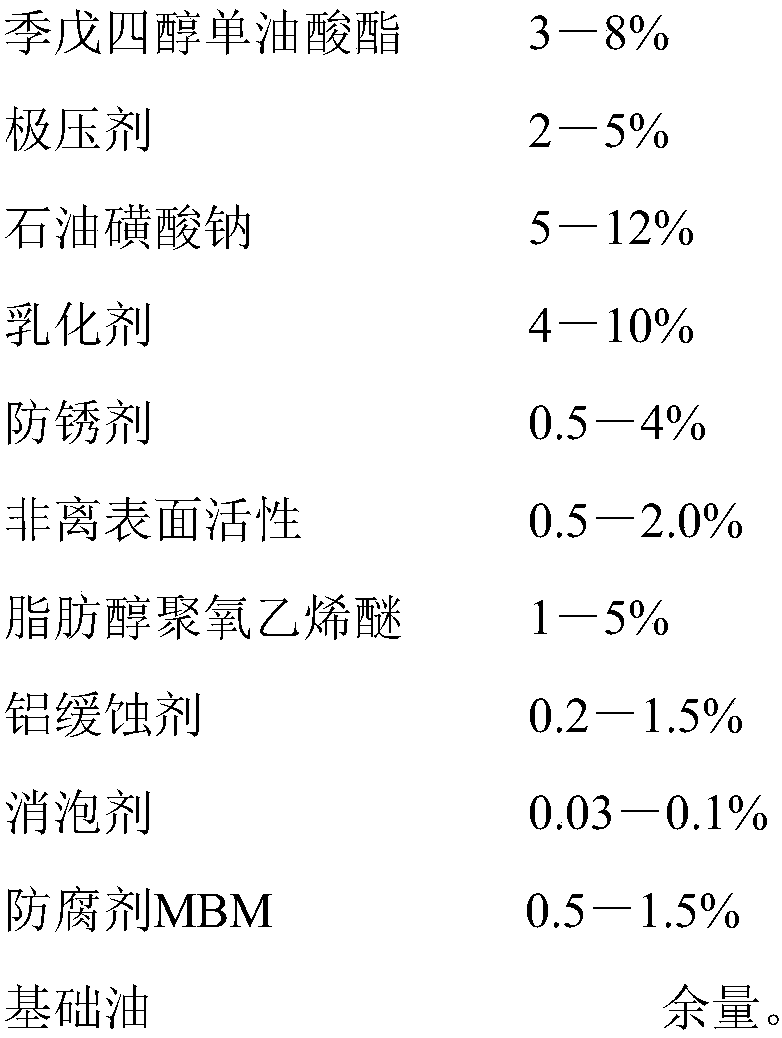

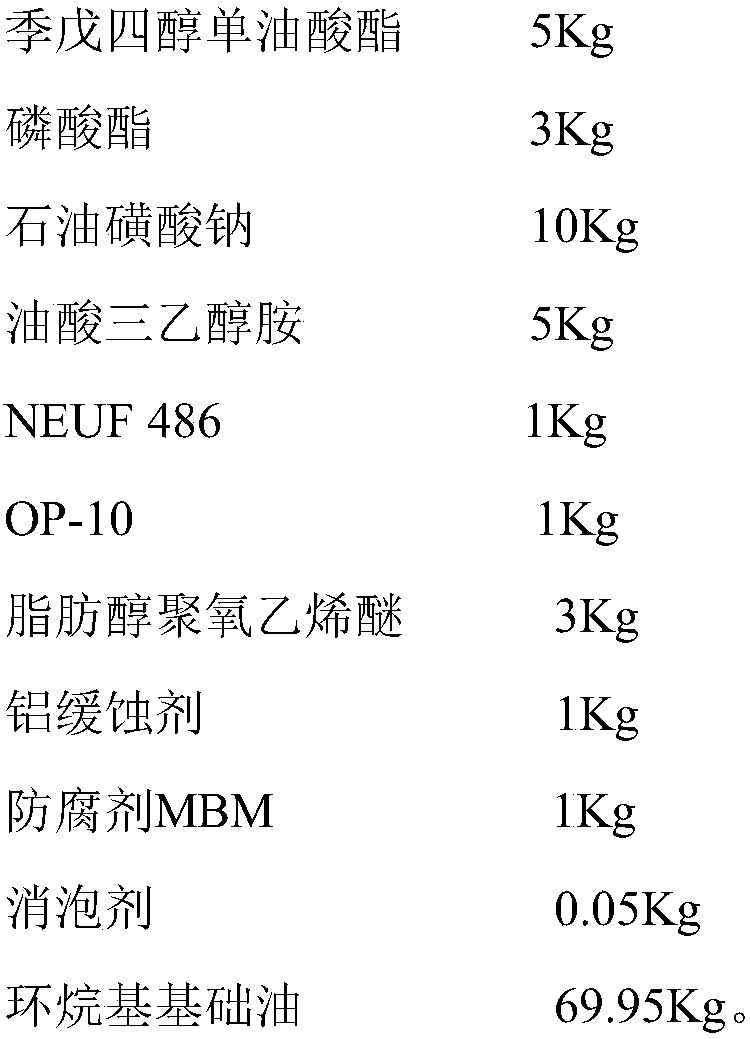

The invention relates to an aluminum alloy plate water-soluble stamping oil, which comprises the following raw material components by weight: 3-8% of pentaerythritol monooleate, 2-5% of an extreme pressure agent, 5-12% of sodium petroleum sulfonate, 4-10% of an emulsifier, 0.5-4% of an anti-rust agent, 0.5-2.0% of a non-ionic surfactant, 1-5% of fatty alcohol polyoxyethylene ether, 0.2-1.5% of anamine neutralized phosphate aluminum corrosion inhibitor, 0.03-0.1% of a defoaming agent, 0.5-1.5% of preservative MBM, and the balance of base oil. According to the present invention, the aluminum alloy plate water-soluble stamping oil is finely blended from the highly-refined paraffin base oil and the additives such as the emulsifier, the extreme pressure agent, the synthetic ester oily agent, the surfactant, the defoaming agent, the bactericide, the anti-rust agent and the like, has advantages of low odor, excellent extreme pressure property, excellent corrosion resistance and excellent lubricity, and is suitable for the stamping, the drawing, the punching and other processing processes of aluminum alloy plates.

Owner:TIANJIN AOLUPU LUBRICATION TECH CO LTD

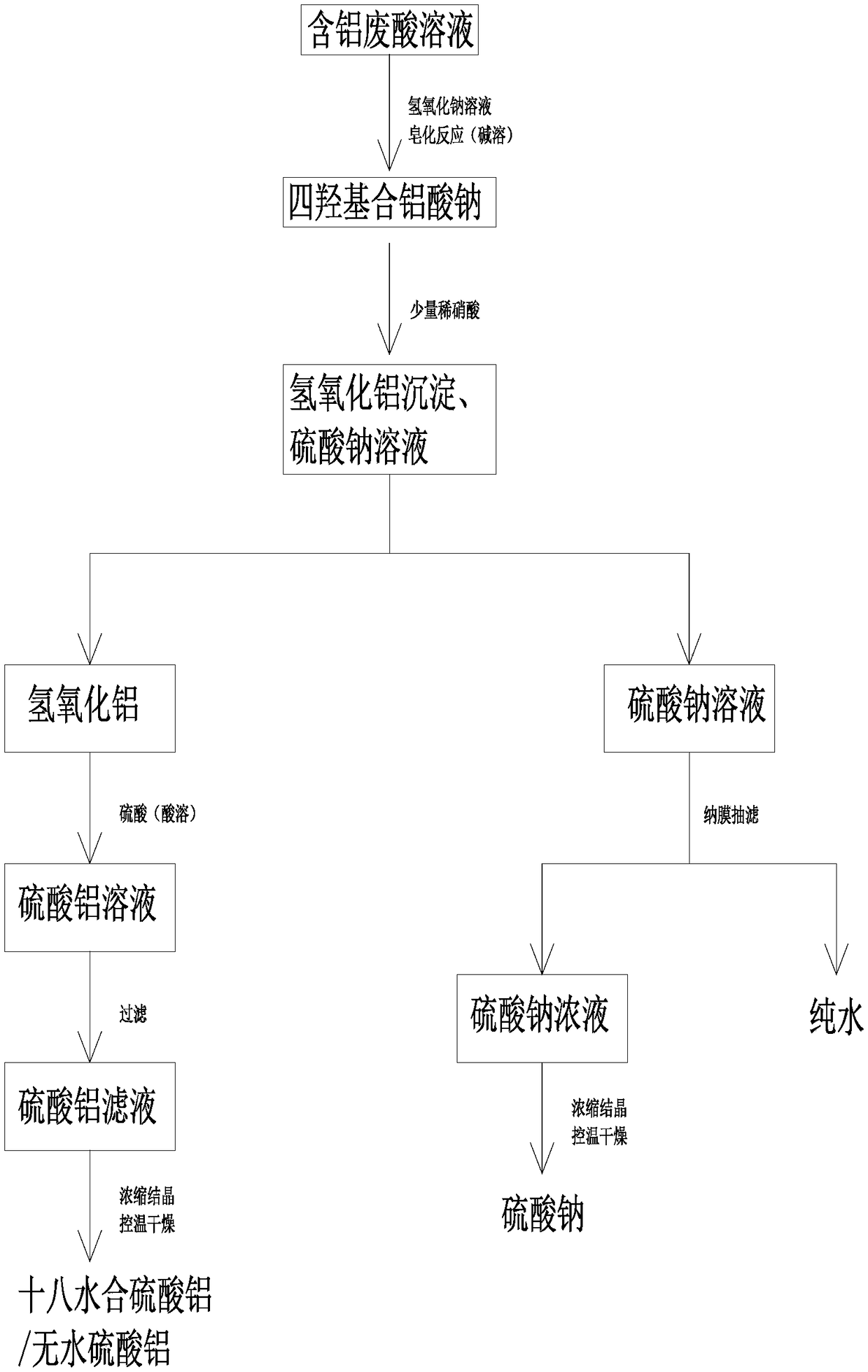

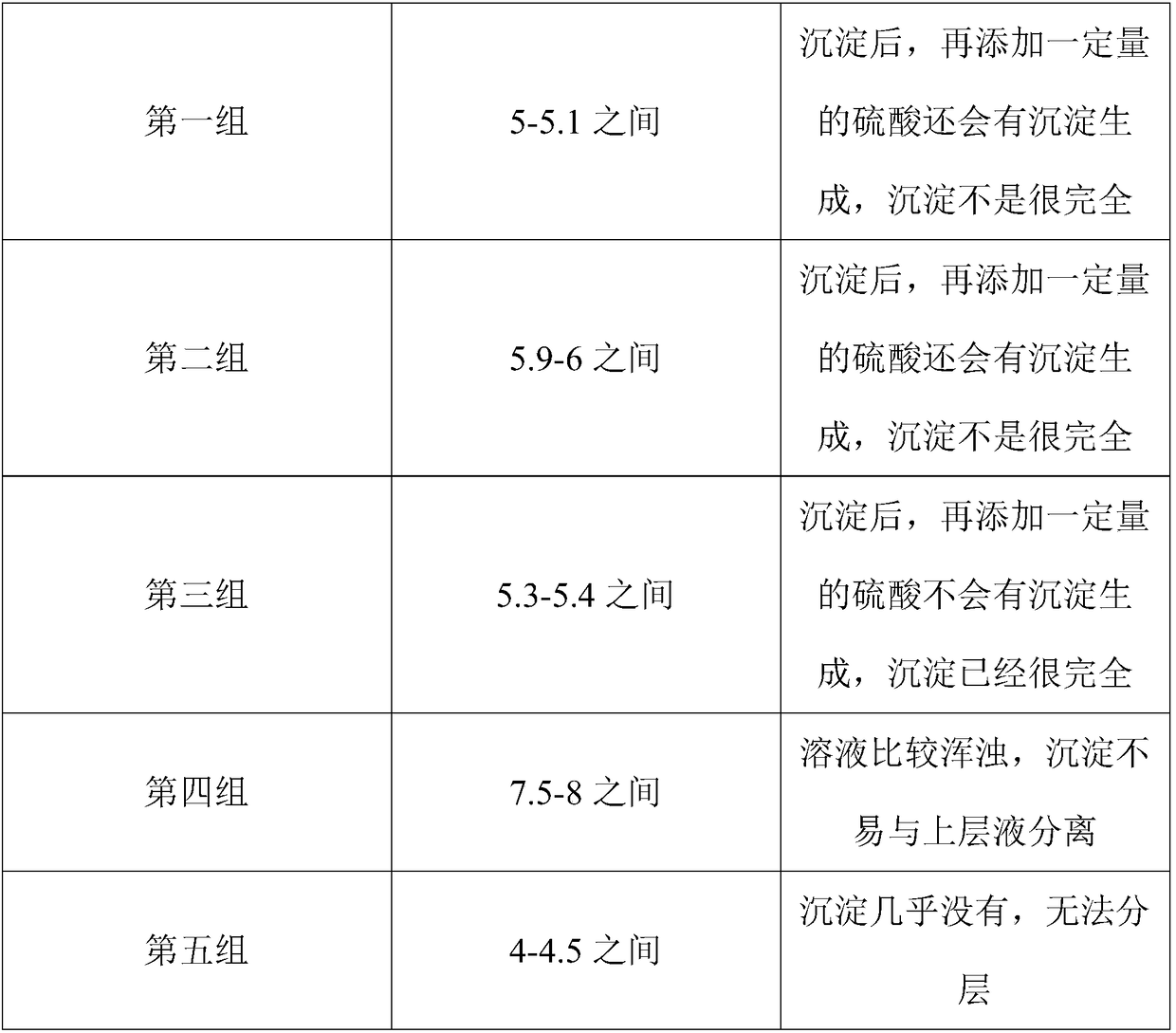

Method for recovering aluminum sulfate from waste acid solution

PendingCN109368677AFriendly treatmentEasy to handleAlkali metal sulfites/sulfatesAluminium sulfatesElectrolysisChemical products

The invention provides a method for recovering aluminum sulfate from a waste acid solution. The method comprises the following steps: 1) adding sodium hydroxide into an aluminum-containing waste acidsolution, and stirring for a period of time; 2) adding sulfuric acid, regulating the pH value to 5-6, and producing a precipitate; 3) filtering the substance obtained in the step 2) to obtain the supernatant and lower precipitate, and adding the sulfuric acid into the lower precipitate to dissolve; and 4) concentrating and crystallizing the dissolving solution in the step 3), thereby obtaining theproduct. By virtue of organic combination of inorganic chemistry and physical chemistry related knowledge, the method disclosed by the invention is specifically applied to waste acid liquor of electronic material aluminum foils for treating the wastewater and recovering valuable chemical products. Therefore, technical reference is provided for other aluminum electrolysis and aluminum corrosion industries and other metal electrolysis and metal corrosion industries.

Owner:BEIJING BCEG GOLDEN SOURCES ENVIRONMENT PROTECTIONS DEV CO LTD

Preparation method of seepage-proof castable

The invention belongs to the field of refractory materials and relates to a preparation method of a seepage-proof castable. The castable comprises the following raw materials by weight percent: 63-69wt% of alumina particles with sizes of 8-0mm, 18-21wt% of aluminium nitride fine powder with particle size less than 0.044mm, 4-7wt% of pure calcium aluminate cement with particle size less than 0.074mm and 5-6wt% of silicon dioxide micro powder with D90 equivalent to 0.1mu m. The castable is characterized in that a compound of BaSO4, TiB2, SrTiO3 and Na3AlF6 is adopted as a molten aluminum wetting resisting agent; the addition of the compound is 1-6wt%; 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate are added as dispersing agents; alumina sol serves as construction liquid. The prepared castable has enough strength, excellent thermal shock resistance and good volume stability and chemical stability, is mainly resistant to molten aluminum wetting, has good thermal stability, is resistant to molten aluminum corrosion, does not affect the components of molten aluminium and has long service life.

Owner:秦皇岛市首耐新材料有限公司

Die-casting aluminum housing spraying cleaning agent applied to ultrahigh pressure

The invention discloses a die-casting aluminum housing spraying cleaning agent applied to ultrahigh pressure. The die-casting aluminum housing spraying cleaning agent applied to ultrahigh pressure comprises the following components in percentage by weight: 1-2% of sodium citrate, 2-4% of sodium gluconate, 3-5% of 3-methoxy-3-methyl-butanol, 1.5-3% of aluminum corrosion inhibitor, 1-2% of ethyl alcohol, 3-5% of polyethylene glycol, 0.5-1% of sodium polyacrylate, 3-5% of alkyl glycoside, 5-8% of EO-PO segmented copolymer, 1-2% of fatty alcohol EO-PO segmented copolymer, 0.1-0.2% of antifoaming agent, and 65-75% of water. The cleaning agent can remain a low-bubble and even non-bubble state while removing burr at the spraying pressure of 2-15MPa under the temperature of 20 to 40 DEG C, and the residue level is low after cleaning.

Owner:NANJING KERUN LUBRICANTS

Diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance and preparation method thereof

InactiveCN105647633AExcellent extreme pressure lubricityGood resistance to hard waterLubricant compositionHard waterSurface-active agents

The invention discloses a diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The cutting fluid comprises, by weight, 30-40% of synthetic ester, 3%-5% of a surface active agent, 12%-20% of an antirust, 2%-5% of a solubilizer, 1%-5% of a corrosion inhibitor, 0.2%-0.5% of an aluminum corrosion inhibitor, 0.5%-1% of a defoaming agent, 2%-5% of a bactericidal agent and the balance of water. The invention also provides a preparation method of the semisynthetic cutting fluid. The method is as below: adding the surface active agent, antirust agent, corrosion inhibitor, solubilizer, aluminum corrosion inhibitor, defoaming agent, bactericidal agent and water in the synthetic diester in order, and mixing evenly to obtain the diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance has superior performances in lubrication, hard water resistance, aluminum corrosion inhibition, corrosion resistance, rust proof and defoaming.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com