Patents

Literature

30results about How to "Excellent extreme pressure lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-nano blocking lubricant for drilling fluid and preparation method thereof

ActiveCN108239522AHigh fat contentImprove temperature resistanceDrilling compositionMicro nanoSolid particle

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

Totally-synthesized water-based stainless steel cutting liquid, and preparation method and using method thereof

ActiveCN103865622AGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

Cooling liquid used when monocrystalline silicon/polycrystalline silicon rods are cut by diamond wires

ActiveCN106590904AExcellent extreme pressure lubricityReduce wearHeat-exchange elementsLubricant compositionBalance waterMaterials science

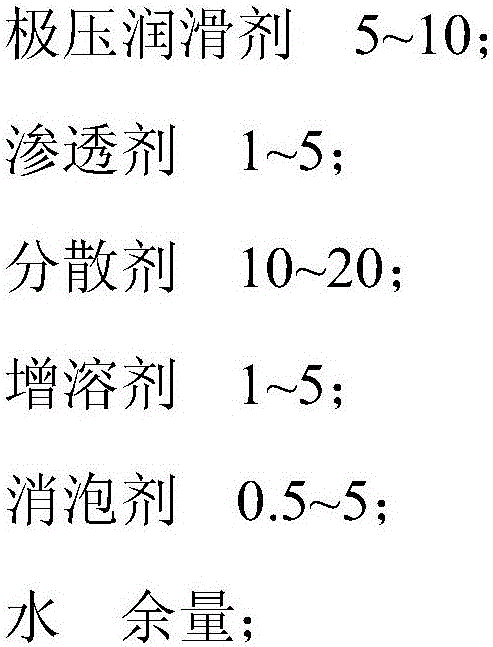

The invention relates to cooling liquid used when monocrystalline silicon / polycrystalline silicon rods are cut by diamond wires. The cooling liquid used when the monocrystalline silicon / polycrystalline silicon rods are cut by the diamond wires is prepared from, by weight, 5-10 parts of extreme pressure lubricant, 1-5 parts of penetrant, 10-20 parts of dispersing agent, 1-5 parts of solubilizer, 0.5-5 parts of defoamer and the balance water, wherein the total weight part is 100. The cooling liquid has the following advantages that the added extreme pressure lubricant has excellent extreme pressure lubricating performance, the matter can be adsorbed on the surfaces of the diamond wires to form lubricating films, abrasion between the diamond wires and the silicone rods is reduced, and adsorption of silicone powder generated by cutting on the surfaces of the wires can be avoided.

Owner:武汉宜田科技发展有限公司

Extreme pressure lubricating metal cutting fluid

InactiveCN106244295AImprove the lubrication effectExcellent extreme pressure lubricityAdditivesFatty alcoholOleic Acid Triglyceride

The invention discloses an extreme pressure lubricating metal cutting fluid, which comprises the following raw materials by weight: 20-50 parts of cycloalkyl silicone oil, 5-15 parts of a modified anionic surfactant, 2-6 parts of borax, 3-6 parts of diethanolamine, 1-5 parts of boric acid, 2-6 parts of heptanoic acid, 3-6 parts of oleic acid, 1-4 parts of polyoxyethylene stearyl phosphate, 2-5 parts of polyoxyethylene phenyl phosphate, 1-3 parts of maleic anhydride, 2-6 parts of dodecyl ammonium benzene sulfonate, 3-5 parts of sodium alkylsulfonate, 1-4 parts of fatty alcohol polyoxyethylene ether, 2-6 parts of sodium benzoate, 3-5 parts of an antifoaming agent, 1-5 parts of methyl benzotriazole, 2-6 parts of an antirust additive, 1-4 parts of an anticorrosive bactericide, and 3-9 parts of water. The metal cutting fluid of the present invention has advantages of excellent extreme pressure lubricating performance, excellent lubricating performance, excellent cooling performance, excellent corrosion resistance, and excellent rust resistance.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Water-soluble rust prevention cutting fluid and preparation method thereof

InactiveCN103351938AExtended service lifeImprove rust resistanceLubricant compositionBenzoic acidBenzene

The invention relates to a water-soluble rust prevention cutting fluid which contains the following components in parts by weight: 4.5-15.5 parts of p-tertiary butylbenzoic acid, 1.2-8.1 parts of benzoic acid, 1.5-11 parts of decanedioic acid, 0.5-5.1 parts of monoethanolamine, 2.3-10.8 parts of triethanolamine, 0.091-1.1 parts of benzotriazole, 4.5-11 parts of diethylene glycol, 2.3-10.5 parts of monoisopropanolamine, 4.5-15.5 parts of polyethylene glycol and 19-31 parts of water. the invention also relates to a preparation method of the water-soluble rust prevention cutting fluid provided by the invention, which comprises the following steps: mixing the p-tertiary butylbenzoic acid, the benzoic acid, the decanedioic acid, the monoethanolamine, the triethanolamine and part of the water, and reacting to obtain a mixture A; mixing the benzotriazole, the monoisopropanolamine and the rest of the water, and reacting to obtain a mixture B; and mixing the diethylene glycol, the polyethylene glycol, the mixture A and the mixture B, and reacting to obtain the finished product.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Preparation and application for green, environmentally-friendly and highly-efficient water-based drilling fluid lubricant

ActiveCN111117577AImprove the lubrication effectExcellent extreme pressure lubricityDrilling compositionProcess engineeringOil and grease

The invention relates to the technical field of drilling fluids in petroleum and natural gas industries, specifically to preparation and application of a green, environmentally-friendly and highly-efficient water-based drilling fluid lubricant. The water-based drilling fluid lubricant is composed of vegetable oil, vegetable fat, lubricating colloidal particles, superfine organic molybdenum, an extreme pressure lubricant, a friction modifier, a dispersing agent and an emulsifying agent. The preparation method for the water-based drilling fluid lubricant comprises the following steps: respectively adding the superfine organic molybdenum, the extreme pressure lubricant and the friction modifier into the vegetable oil so as to obtain a first mixture; adding the emulsifying agent into the vegetable fat, and respectively adding the lubricating colloidal particles and the dispersing agent into the vegetable fat so as to obtain a second mixture; and adding the second mixture into the first mixture so as to obtain the water-based drilling fluid lubricant. The water-based drilling fluid lubricant disclosed by the invention is good in lubricating property and wear resistance, can be used forcarrying out directional lubricating and friction-reducing treatment on special parts, is easy to be biodegraded, belongs to a green and environmentally-friendly lubricant, and has good application prospect.

Owner:郑州洁灵科技有限公司

Diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance and preparation method thereof

InactiveCN105647633AExcellent extreme pressure lubricityGood resistance to hard waterLubricant compositionHard waterSurface-active agents

The invention discloses a diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The cutting fluid comprises, by weight, 30-40% of synthetic ester, 3%-5% of a surface active agent, 12%-20% of an antirust, 2%-5% of a solubilizer, 1%-5% of a corrosion inhibitor, 0.2%-0.5% of an aluminum corrosion inhibitor, 0.5%-1% of a defoaming agent, 2%-5% of a bactericidal agent and the balance of water. The invention also provides a preparation method of the semisynthetic cutting fluid. The method is as below: adding the surface active agent, antirust agent, corrosion inhibitor, solubilizer, aluminum corrosion inhibitor, defoaming agent, bactericidal agent and water in the synthetic diester in order, and mixing evenly to obtain the diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance. The diester-type semisynthetic cutting fluid with high lubrication and high hard water resistance has superior performances in lubrication, hard water resistance, aluminum corrosion inhibition, corrosion resistance, rust proof and defoaming.

Owner:SHANGHAI INST OF TECH

Water base emulsified cutting fluid and preparation method thereof

InactiveCN103351926AExtended service lifeStrong rust resistanceLubricant compositionWater basedMonoisopropanolamine

The invention relates to a water base emulsified cutting fluid which comprises the following components in parts by weight: 30-55.5 parts of mineral oil, 9.5-21 parts of pentaerythritol fatty acid compound ester, 0.4-2.1 parts of benzotriazole, 4-11 parts of diglycol, 2.5-11 parts of isopropanolamine, 4.5-16 parts of boric acid, 9.5-21 parts of polyethylene glycol, 0.091-1.1 parts of a polysiloxane defoamer, and 19-41 parts of water. The invention further discloses a preparation method of the water base emulsified cutting fluid. The method comprises the following steps of: weighing the mineral oil and polyethylene glycol in parts by weight, starting stirring and heating to 120 DEG C, performing a reaction for 1-2 hours at constant temperature and cooling to 70-80 DEG C; and then sequentially adding the balance of components, and stirring for reaction for 30-60 minutes to obtain a finished product. The water base emulsified cutting fluid provided by the invention not only has high lubricity, high anti-rust property, high emulsibility and high stability and long service life, but also is free from environmental pollution and damage to human body, so that the fluid can satisfy the cutting demands of various metals.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

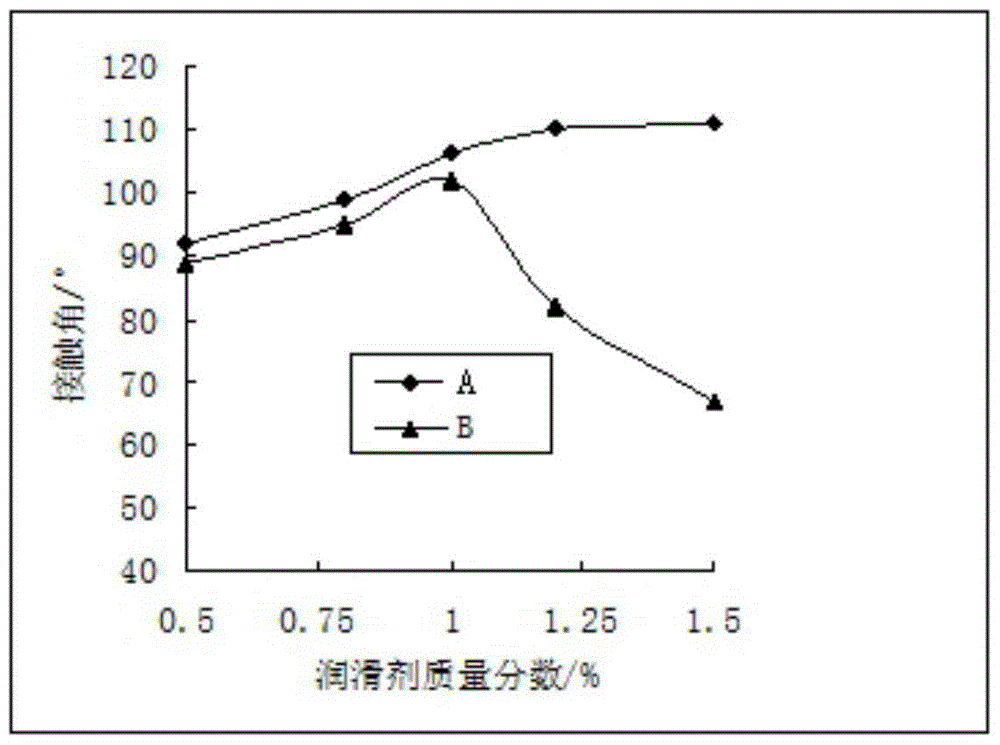

Plugging extreme-pressure lubricant as well as preparation method and application of plugging extreme-pressure lubricant

ActiveCN108251078AExcellent extreme pressure lubricityGood compatibilityDrilling compositionWell drillingDirectional well

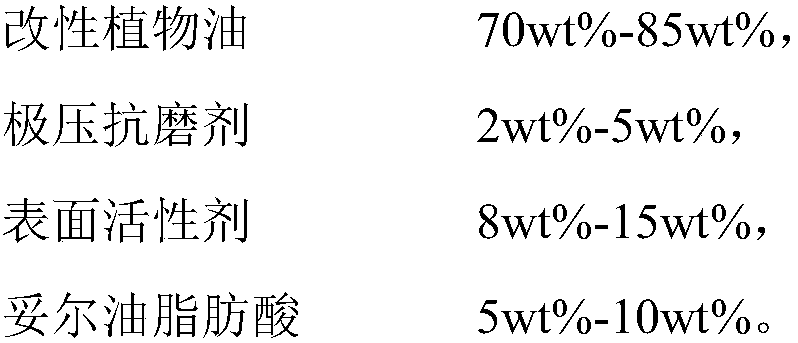

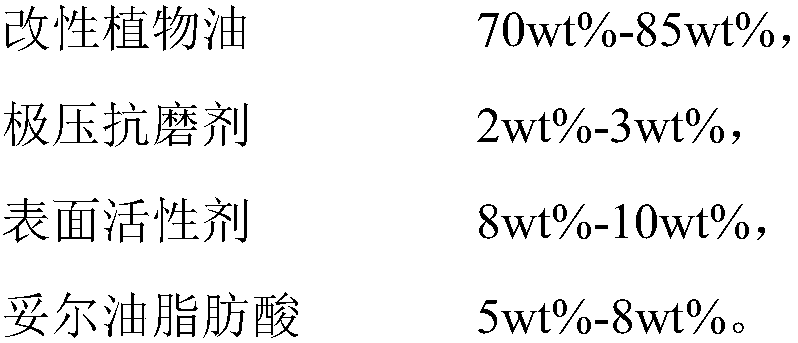

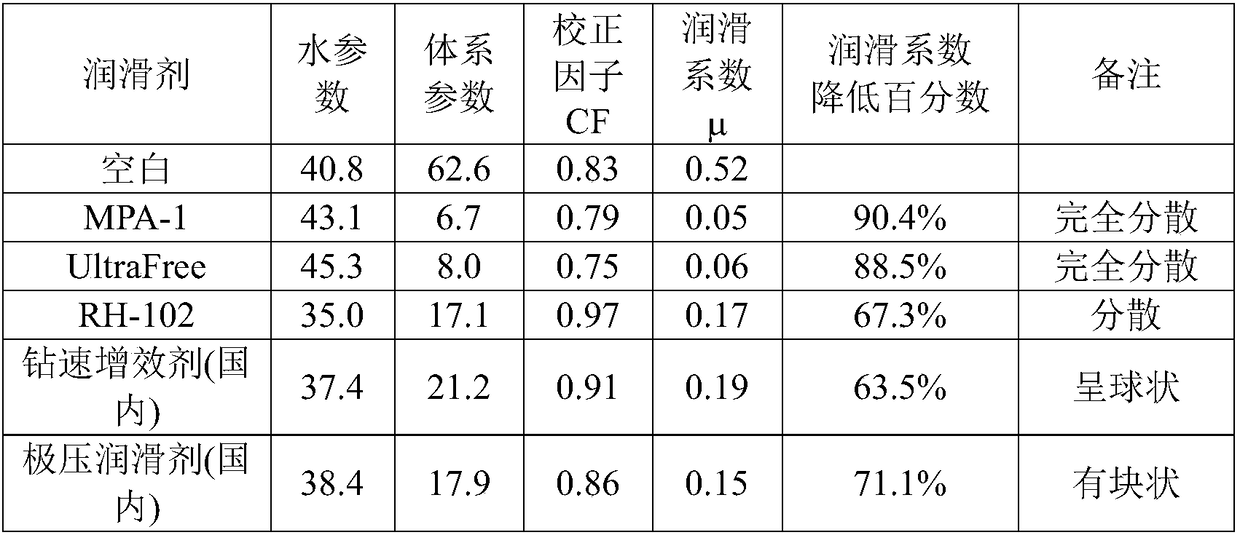

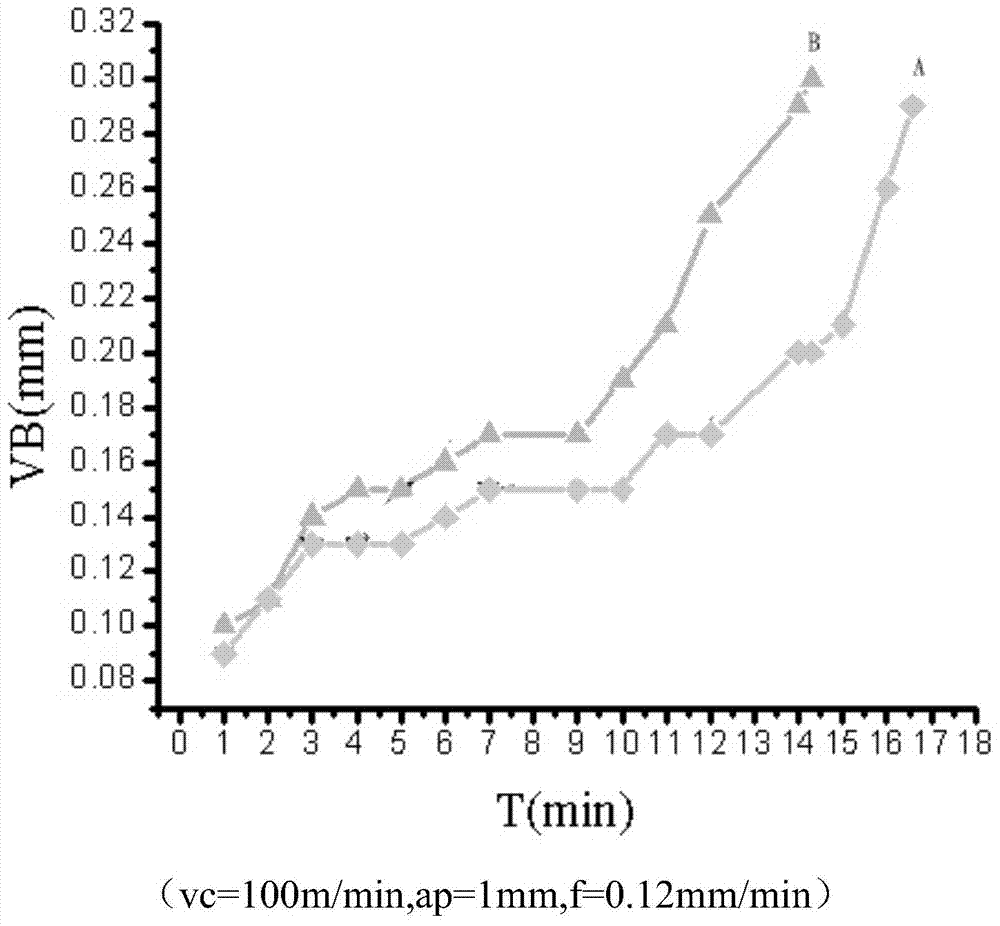

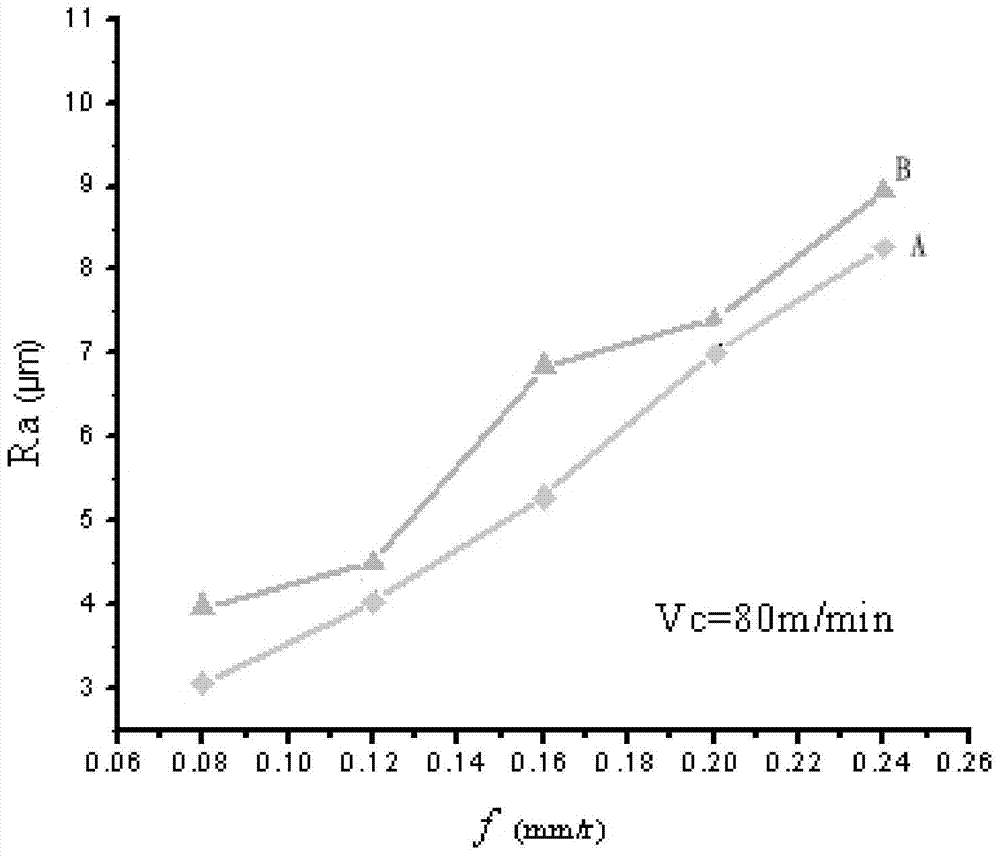

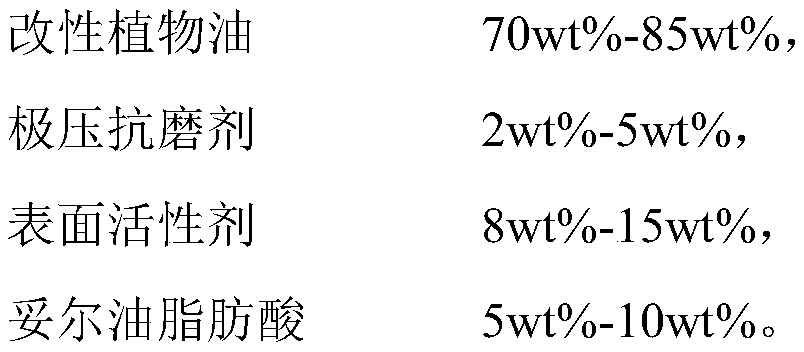

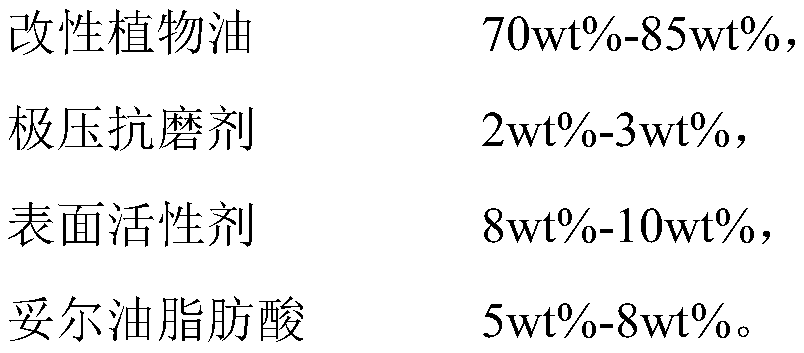

The invention provides a plugging extreme-pressure lubricant as well as a preparation method and application of the plugging extreme-pressure lubricant. The plugging extreme-pressure lubricant comprises 70wt%-85wt% of modified vegetable oil, 2wt%-5wt% of extreme-pressure anti-wear agent and 8wt%-15wt% of surfactant. According to the plugging extreme-pressure lubricant provided by the invention, the modified vegetable oil which is easily biodegraded is adopted, and a sulfur-type additive with good extreme-pressure and anti-wear properties is added, so that the lubricant is environment-friendly,good in extreme-pressure lubricating property and compatibility, capable of obviously improving the quality of a mud cake in a drilling fluid and good in plugging effect and can be favorably appliedto a well drilling site and can be applied to wear and resistance reduction during well drilling operation of a large-displacement horizontal well, a directional well, a long open hole deep well, a complex structural well and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Semi-synthetic cutting fluid containing modified nano-molybdenum disulfide and preparation method of semi-synthetic cutting fluid

InactiveCN106635352AExcellent extreme pressure lubricityImprove wear resistanceLubricant compositionChemistryDodecylsulfonic acid

The invention discloses semi-synthetic cutting fluid containing modified nano-molybdenum disulfide and a preparation method of the semi-synthetic cutting fluid. The semi-synthetic cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 15 to 25 parts of organic alkylol amine, 5 to 10 parts of boric acid, 4 to 7 parts of oleic acid, 2 to 3 parts of sodium alginate, 2 to 4 parts of nano-molybdenum disulfide, 5 to 12 parts of sodium dodecyl sulfate, 30 to 40 parts of palm oil, 5 to 9 parts of lauric acid, 2 to 3 parts of Span 80, 2 to 3 parts of Tween 80, 5 to 10 parts of paraffine-based oil, 1 to 2 parts of polydimethylsiloxane and 50 to 100 parts of distilled water. According to the semi-synthetic cutting fluid disclosed by the invention, the nano-molybdenum disulfide is dispersed by using the sodium alginate, and the surface of the nano-molybdenum disulfide is enabled to be rich in abundant functional groups; the sodium alginate is added into an additive to realize good compatibility, so that wear resistance, extreme pressure property and stability of the cutting fluid can be improved.

Owner:芜湖仓实农业装备制造有限公司

Nano-silver-containing antibacterial semi-synthetic cutting fluid and preparation method thereof

InactiveCN106590898AExcellent extreme pressure lubricityPromote degradationLubricant compositionAntibacterial activityOleic Acid Triglyceride

The invention discloses nano-silver-containing antibacterial semi-synthetic cutting fluid and a preparation method thereof. The nano-silver-containing antibacterial semi-synthetic cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of nano-silver, 15-25 parts of organic alkylol amine, 5-10 parts of boric acid, 8-15 parts of a chitosan cation glue solution, 4-7 parts of oleic acid, 2-3 parts of sodium alginate, 2-4 parts of nano molybdenum disulfide, 3-5 parts of glutaraldehyde, 5-12 parts of Sodium laurylsulfonate, 3-5 parts of an Arabic gum water solution, 30-40 parts of palm oil, 5-9 parts of lauric acid, a proper amount of a sodium hydroxide solution, 2-3 parts of Span 80, 2-3 parts of Tween 80, 5-10 parts of paraffin base oil, 1-2 parts of polydimethylsiloxane and 50-100 parts of distilled water. As the nano molybdenum disulfide is dispersed by using the sodium alginate, the surface of the nano molybdenum disulfide has rich functional groups, very good compatibility can be achieved when the mixture of the nano molybdenum disulfide and the sodium alginate is added into an additive, and thus the wearing resistance, the extreme pressure property and the stability of the cutting fluid can be improved; due to addition of the nano-sliver, the cutting fluid has antibacterial activity.

Owner:芜湖仓实农业装备制造有限公司

Semi-synthetic cutting fluid containing nano-molybdenum disulfide and having high cooling performance and preparation method of semi-synthetic cutting fluid

InactiveCN106635350AExcellent extreme pressure lubricityImprove extreme pressure performanceLubricant compositionChemistryDodecylsulfonic acid

The invention discloses semi-synthetic cutting fluid containing nano-molybdenum disulfide and having high cooling performance, and a preparation method of the semi-synthetic cutting fluid. The semi-synthetic cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 2 to 3 parts of nanometer aluminum oxide, 15 to 25 parts of organic alcohol amine, 3 to 5 parts of a silane coupling agent KH, 5 to 10 parts of boric acid, 4 to 7 parts of oleic acid, 2 to 3 parts of sodium alginate, 2 to 4 parts of nano-molybdenum disulfide, 10 to 20 parts of xylene, 5 to 12 parts of sodium dodecyl sulfate, 30 to 40 parts of palm oil, 5 to 9 parts of lauric acid, 2 to 3 parts of span 80, 2 to 3 parts of tween 80, 5 to 10 parts of paraffinic based oil, 1 to 2 parts of dimethyl silicone polymer and 50 to 100 parts of distilled water. According to the method, the nano-molybdenum disulfide is dispersed by the sodium alginate, so that the surface of the nano-molybdenum disulfide is enriched with functional groups; when added into the additive, the nano-molybdenum disulfide is extremely high in compatibility, so that the abrasive resistance, the extreme pressure property and the stability of the cutting fluid can be improved; the cooperatively added nanometer aluminum oxide improves the cooling performance of the cutting fluid.

Owner:芜湖仓实农业装备制造有限公司

Lubricant

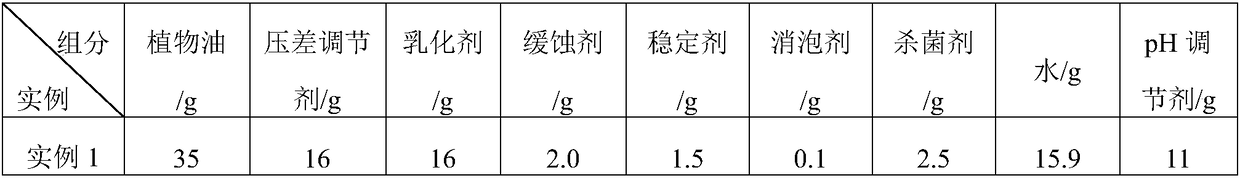

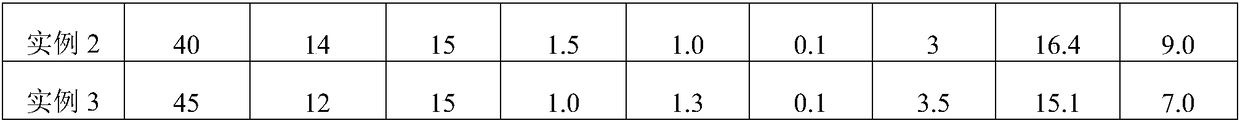

InactiveCN108559601AImprove wear resistanceExcellent extreme pressure lubricityLubricant compositionEmulsionVegetable oil

The invention relates to a lubricant. The vegetable oil based micro-emulsion cutting fluid is prepared from the following components in parts by weight: 30-50 parts of vegetable oil, 4-14 parts of pHregulator, 8-18 parts of differential pressure regulator, 12-22 parts of emulsifier, 0.1-3.5 parts of corrosion inhibitor, 0.1-3 parts of stabilizer, 0.01-0.3 part of defoamer, 1-5 parts of bactericide and 13-23 parts of water. The lubricant has good wear resistance, extreme pressure lubrication performance, rust resistance and biodegradability.

Owner:江苏马庄文化旅游发展有限公司

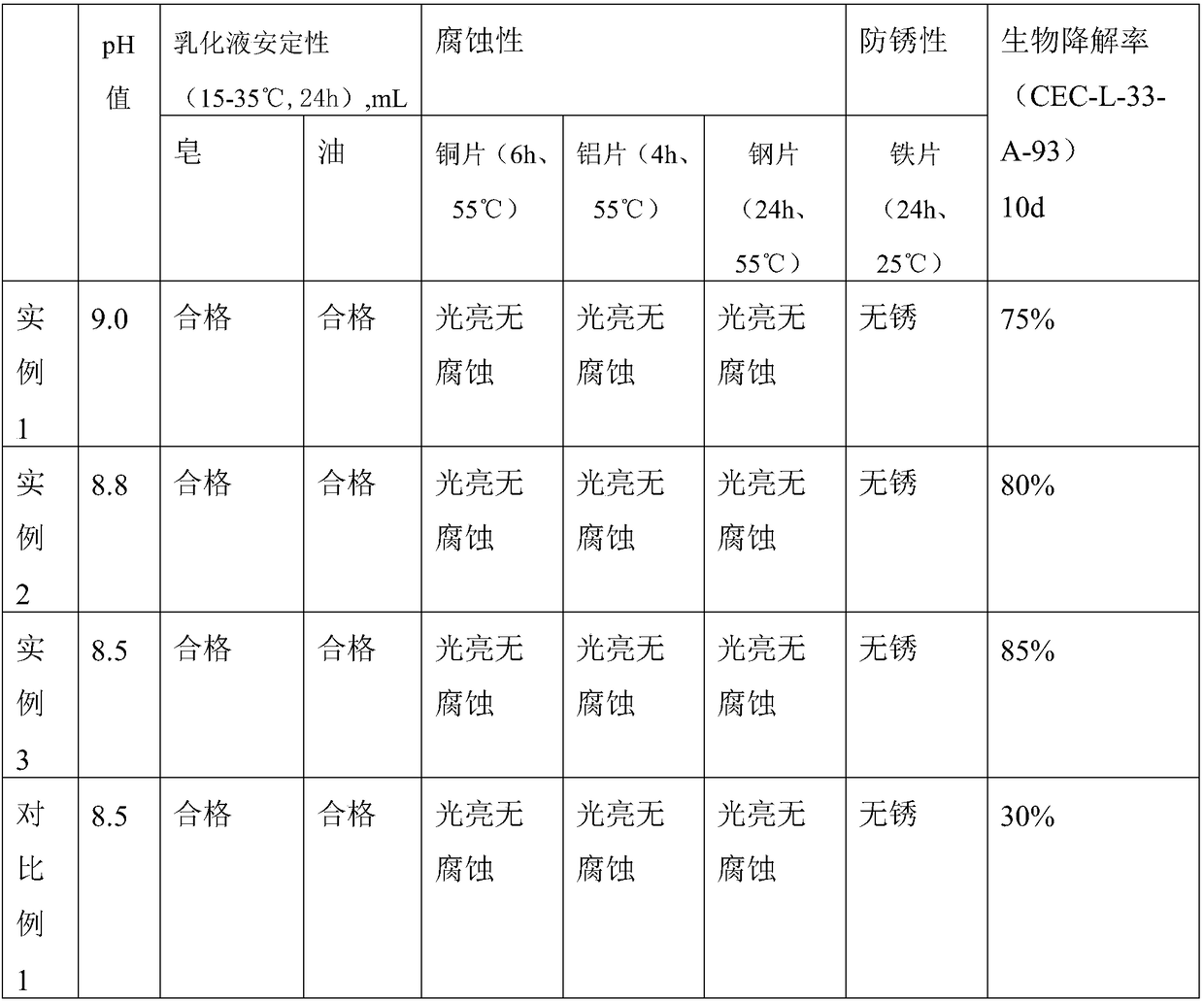

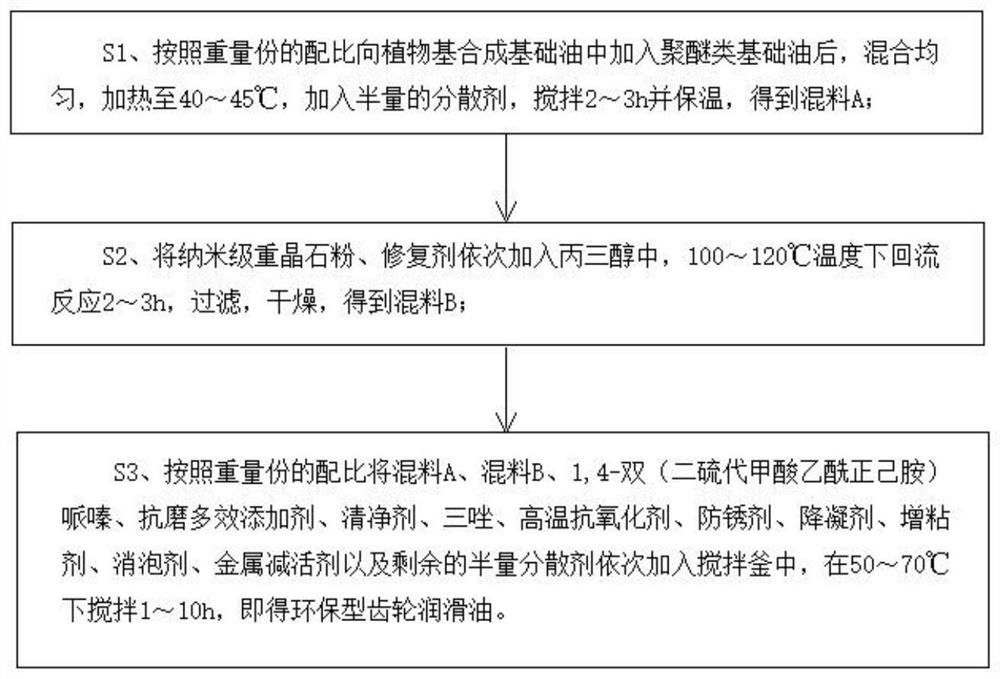

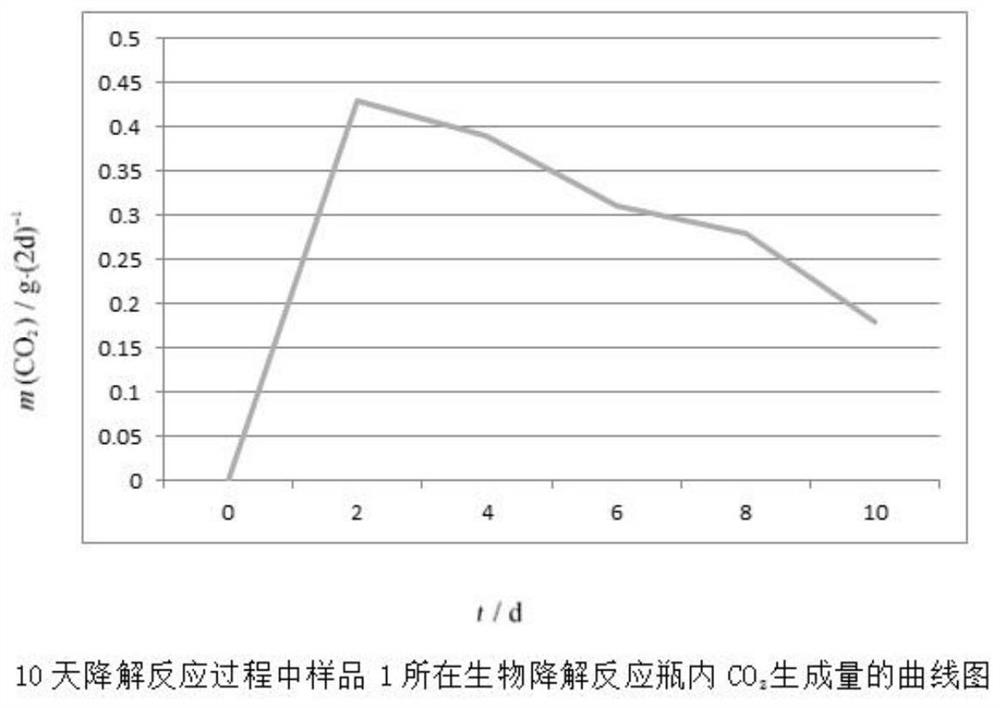

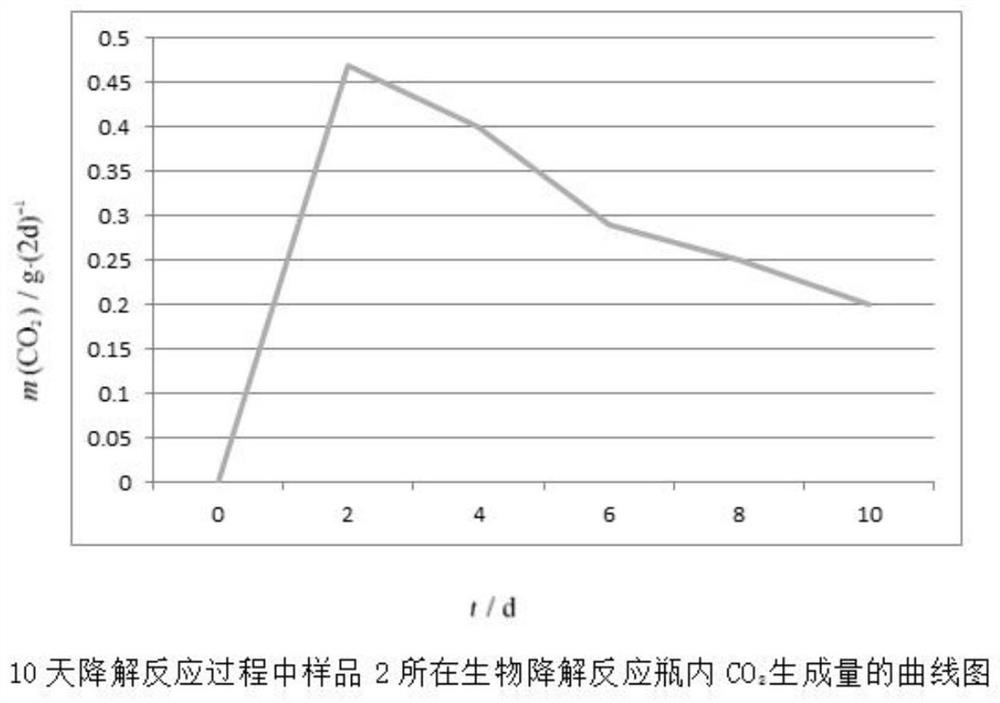

Environment-friendly gear lubricating oil and preparation method thereof

InactiveCN112300853AReduce manufacturing costPromote degradationLubricant compositionTackifierAnti oxidant

The invention discloses environment-friendly gear lubricating oil and a preparation method thereof. The environment-friendly gear lubricating oil comprises the following components in parts by weight:50-85 parts of plant-based synthetic base oil, 5-12 parts of polyether base oil, 0.5-1.2 parts of 1, 4-bis (dithioformic acid acetyl n-hexylamine) piperazine, 0.8-4.5 parts of an anti-wear multi-effect additive, 2-5 parts of nanoscale barite powder, 10-62 parts of a repairing agent, 2-4 parts of a clearing agent, 1.2-2 parts of a high-temperature antioxidant, 0.2-0.7 parts of an anti-rust agent,0.2-1.6 parts of a pour point depressant, 4-6 parts of a tackifier, 1-3 parts of a dispersing agent, 0.5-1 part of a defoaming agent and 0.5-6.5 parts of a metal deactivator. The environment-friendlygear lubricating oil provided by the invention has excellent biodegradability, rust resistance, corrosion resistance, extreme pressure lubricating performance and performance of inhibiting increase ofviscosity and acid value, does not cause pollution and harm to the environment, and has a wide application range. The preparation method of the environment-friendly gear lubricating oil is simple, low in cost, safe and environment-friendly.

Owner:上海易到润滑油有限公司

A kind of antiwear drag reducing agent for drilling fluid and preparation method thereof

ActiveCN103571441BAdjustable fluorescenceGood extreme pressure and anti-wear propertiesDrilling compositionVegetable oilWear resistant

The invention relates to a wear-resistant drag reducer for drilling fluid and a preparation method thereof. The wear-resistant drag reducer is characterized in that a formula of the wear-resistant drag reducer is prepared from the following main raw materials: vegetable oil acid, cotton seed oil, sulfur powder, diethanol amine and kerosene; the auxiliary raw materials comprise tributyl phosphate, organic soil and T323 anti-wear reagent at extreme pressure. The wear-resistant drag reducer for drilling fluid comprises the following components in percentage by weight based on the total amount of the drag reducer: 7-13 percent of vegetable oil acid, 26-31 percent of cotton seed oil, 6-11 percent of sulfur powder, 3-5 percent of diethanol amine, 27-29 percent of kerosene and 12-17 percent of auxiliary materials and other materials. The method for preparing the wear-resistant drag reducer for drilling fluid comprises a sulfonation reaction, an amidation reaction and a mixed reaction. When the wear-resistant drag reducer is used for drilling, the drag reducer can be adsorbed to the surface of a drilling tool preferentially, a dense high-strength protective film is generated, the lubricating property of the drilling fluid is reduced, the friction and wear of the metal surface are reduced, an extreme pressure lubrication coefficient and a mud cake adhesion coefficient of the drilling fluid are effectively reduced, blockage and other accidents in the drilling process are reduced.

Owner:四川康克石油科技有限公司

Micro-emulsion cutting fluid and preparation method thereof

The invention discloses micro-emulsion cutting fluid and a preparation method thereof. The micro-emulsion cutting fluid is prepared from the following raw material components in percentage by mass: 20to 50 percent of a compound anti-rust agent, 6 to 20 percent of lanolin, 5 to 15 percent of polyethylene glycol 400, 10 to 26 percent of fatty alcohol-polyoxyethylene ether AEO-9, 8 to 35 percent oflubricating oil, 2 to 10 percent of sorbitan fatty acid ester and the balance of water. The preparation method of the micro-emulsion cutting fluid comprises the following steps: firstly, adding deionized water into an agitator, and sequentially and slowly adding polyethylene glycol 400, fatty alcohol-polyoxyethylene ether AEO-9 and sorbitan fatty acid ester in a low rotating speed state; stirringat normal temperature until a system is uniform and transparent; secondly, adding triethanolamine borate, triethanolamine oleic soap, the lanolin and refined lubricating oil into the system obtained in the first step and stirring to obtain the micro-emulsion cutting fluid. The cutting fluid disclosed by the invention has the advantages of good biodegradability, extreme pressure lubricity, rust resistance, cooling and cleaning properties, and has no harm to a human body.

Owner:苏州市神顺新晨生物科技有限公司

A kind of water-soluble antirust cutting fluid and preparation method thereof

InactiveCN103351938BWide range of processing materialsSuitable for processing lubrication needsLubricant compositionBenzoic acidBenzene

The invention relates to a water-soluble rust prevention cutting fluid which contains the following components in parts by weight: 4.5-15.5 parts of p-tertiary butylbenzoic acid, 1.2-8.1 parts of benzoic acid, 1.5-11 parts of decanedioic acid, 0.5-5.1 parts of monoethanolamine, 2.3-10.8 parts of triethanolamine, 0.091-1.1 parts of benzotriazole, 4.5-11 parts of diethylene glycol, 2.3-10.5 parts of monoisopropanolamine, 4.5-15.5 parts of polyethylene glycol and 19-31 parts of water. the invention also relates to a preparation method of the water-soluble rust prevention cutting fluid provided by the invention, which comprises the following steps: mixing the p-tertiary butylbenzoic acid, the benzoic acid, the decanedioic acid, the monoethanolamine, the triethanolamine and part of the water, and reacting to obtain a mixture A; mixing the benzotriazole, the monoisopropanolamine and the rest of the water, and reacting to obtain a mixture B; and mixing the diethylene glycol, the polyethylene glycol, the mixture A and the mixture B, and reacting to obtain the finished product.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Corundum powder reinforced wear-resistant semisynthetic cutting fluid and preparation method thereof

InactiveCN106590900AExcellent extreme pressure lubricityImprove extreme pressure performanceLubricant compositionWear resistantDodecylsulfonic acid

The invention discloses a corundum powder reinforced wear-resistant semisynthetic cutting fluid and a preparation method thereof. The corundum powder reinforced wear-resistant semisynthetic cutting fluid is characterized by being prepared from raw materials in parts by weight as follows: 1-2 parts of corundum powder, 15-25 parts of organic alkylol amine, 5-10 parts of boric acid, 1-2 parts of talc powder, 4-7 parts of oleic acid, 2-3 parts of sodium alginate, 2-4 parts of nanometer molybdenum disulfide, 2-3 parts of polytetrafluoroethylene powder, 5-12 parts of sodium dodecyl sulfate, 30-40 parts of palm oil, 5-9 parts of lauric acid, 2-3 parts of Span 80, 2-3 parts of Tween 80, 5-10 parts of paraffin-based crude oil, 1-2 parts of polydimethylsiloxane and 50-100 parts of distilled water. Sodium alginate is used for dispersing nanometer molybdenum disulfide, so that the nanometer molybdenum disulfide contains rich functional groups on the surface and has good compatibility after added to additives, and the wear resistance, the extreme pressure property and the stability of the cutting fluid can be improved; the strength and the wear resistance of the cutting fluid are improved through interaction of the corundum powder, the talc powder and the polytetrafluoroethylene powder.

Owner:芜湖仓实农业装备制造有限公司

High-wear-resistance modified-nano-molybdenum-disulfide-containing semisynthetic cutting fluid and preparation method thereof

InactiveCN106753729AExcellent extreme pressure lubricityImprove the lubrication effectLubricant compositionDodecylsulfonic acidOleic Acid Triglyceride

The invention discloses a high-wear-resistance modified-nano-molybdenum-disulfide-containing semisynthetic cutting fluid and a preparation method thereof. The invention is characterized in that the cutting fluid is prepared from the following raw materials in parts by weight: 3-8 parts of sulfur powder, 15-25 parts of organic hydramine, 5-10 parts of boric acid, 4-7 parts of oleic acid, 2-3 parts of sodium alginate, 2-4 parts of nano molybdenum disulfide, 5-12 parts of sodium dodecylsulfate, 2-3 parts of tungsten powder, 30-40 parts of palm oil, 5-9 parts of lauric acid, 2-3 parts of Span 80, 2-3 parts of Tween 80, 5-10 parts of paraffin base oil, 1-2 parts of polydimethylsiloxane and 50-100 parts of distilled water. The sodium alginate is utilized to disperse the nano molybdenum disulfide, so that the surface contains abundant functional groups; and the nano molybdenum disulfide has favorable compatibility after being added into the additives, thereby enhancing the wear resistance, extreme pressure performance and stability of the cutting fluid. The synthetic tungsten disulfide enables the lubricating oil to have higher wear resistance.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

Water-based lubricating fluid with bionic structure

InactiveCN109536241AExcellent extreme pressure lubricityExtended service lifeAdditivesWater basedTriethanolamine oleate

The invention provides a water-based lubricating fluid with a bionic structure, and belongs to the technical field of lubricating fluids. The water-based lubricating fluid comprises the following components in parts by weight: 60-80 parts of a polyurethane prepolymer, 20-30 parts of 3-aminopropyltriethoxysilane, 8-10 parts of triethanolamine borate, 8-10 parts of triethanolamine oleate, 5-8 partsof ethylene glycol, 1-2 parts of polydimethylsiloxane, 1-2 parts of dimethyl silicone oil and 150-200 parts of water. The water-based lubricating fluid provided by the invention has excellent extreme-pressure lubricating performance, and the service life is prolonged.

Owner:CHANGCHUN A&Z SCI CO LTD

A kind of cooling liquid for diamond wire cutting single/polycrystalline silicon rod

ActiveCN106590904BExcellent extreme pressure lubricityReduce wearHeat-exchange elementsLubricant compositionWire cuttingCooling fluid

The invention relates to cooling liquid used when monocrystalline silicon / polycrystalline silicon rods are cut by diamond wires. The cooling liquid used when the monocrystalline silicon / polycrystalline silicon rods are cut by the diamond wires is prepared from, by weight, 5-10 parts of extreme pressure lubricant, 1-5 parts of penetrant, 10-20 parts of dispersing agent, 1-5 parts of solubilizer, 0.5-5 parts of defoamer and the balance water, wherein the total weight part is 100. The cooling liquid has the following advantages that the added extreme pressure lubricant has excellent extreme pressure lubricating performance, the matter can be adsorbed on the surfaces of the diamond wires to form lubricating films, abrasion between the diamond wires and the silicone rods is reduced, and adsorption of silicone powder generated by cutting on the surfaces of the wires can be avoided.

Owner:武汉宜田科技发展有限公司

Long-acting anti-wear and friction-reducing agent composition, lubricating grease and processing oil

PendingCN113293044AGood anti-wear performanceStrong anti-friction performanceAdditivesPhosphite esterThiocarbamate

The invention discloses a long-acting anti-wear and friction-reducing agent composition, lubricating grease and processing oil, wherein the long-acting anti-wear and friction-reducing agent composition comprises the following components in parts by mass: 40 to 60 parts of an organic molybdenum compound, 10 to 20 parts of a thiocarbamate compound, 1 to 5 parts of a thiadiazole compound, 1 to 5 parts of a mercaptobenzothiazole compound, 10 to 15 parts of a phosphite ester compound and 10 to 20 parts of sulfide. The long-acting anti-wear and friction-reducing agent composition is good in anti-wear performance, high in friction-reducing performance and low in corrosivity, can remarkably improve the anti-wear and friction-reducing performance of lubricating grease and processing oil as an additive of the lubricating grease and the processing oil, and improves the long-acting performance.

Owner:长沙望城石油化工有限公司

Fully synthetic water-based stainless steel cutting fluid, preparation method and use method thereof

ActiveCN103865622BGood instant solubilityEasy to cleanLubricant compositionWater basedPolyethylene glycol

The invention discloses a totally-synthesized water-based stainless steel cutting liquid. The cutting liquid contains the following components: a stainless steel water-based extreme-pressure agent, caprylic-capric acid, boric acid triethanolamine ester, polyethylene glycol, a cation quaternary ammonium salt metal filings settling agent, a dicarboxylic compound antirusting agent, a monobutyl ether coupling agent, a hard-water-resisting agent, a defoamer and distilled water. By virtue of an environmental-friendly total-synthesis formula, the cleaning and settling properties of the cutting liquid are enhanced; an environmental-friendly special water-based extreme-pressure lubricant is used to substitute for the traditional synthetic ester, thereby ensuring the long-time stability of the cleaning and settling properties of the cutting liquid. The cutting liquid plays a very good role in protecting non-ferrous metal and ferrous metal; by virtue of the cation quaternary ammonium salt settling agent, the problem of iron filings settling during the processing of stainless steel is eliminated, and the transparency and stability of the cutting liquid in long-time use are guaranteed.

Owner:苏州安美润滑科技有限公司

Anti-extreme pressure engine oil

InactiveCN105567394AGood high temperature oxidation stabilityExcellent extreme pressure lubricityLubricant compositionPhosphateMechanical wear

The present invention discloses extreme pressure engine oil comprising the following raw materials in parts by weight: 95-98 parts of base oil with less than 3% of sulfur and more than 94% of saturated hydrocarbons, 0.05-0.8 part of a semi-hindered phenol type antioxidant, 0.1-0.7 part of an anti-wear agent, 0.05-0.3 part of a metal deactivating agent, 0.2-0.9 part of screen phenol, 0.4-1.5 parts of sulfur phosphate, 0.05 - 0.7 part of ZDDP (T202), 0.3-1.2 parts of benzotriazole amine salt, 0.06-0.5 part of a benzotriazole derivative, 2-5 parts of dimethylsilicone fluid and 0.1-0.5 part of an anti-foaming agent. The extreme pressure engine oil is lubricant oil having good oil sludge control and dispersion capability, excellent high temperature oxidation stability, extreme pressure lubrication, rust and corrosion resistance, anti-foaming property and water separation characteristic, can withstand heavy loads and impact loads, and can reduce mechanical wear.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Universal fully-synthetic nonferrous metal cutting fluid and preparation method thereof

PendingCN112226270ASolve the problem of poor extreme pressure lubrication performanceImprove machining accuracyLubricant compositionPolyesterCarboxylic acid

The invention discloses a universal fully-synthetic nonferrous metal cutting fluid and a preparation method thereof. The cutting fluid comprises the following components in percentage by weight: 3-6%of polyalkylene glycol, 7-15% of polyester, 5-10% of polyether ester, 3-8% of non-ferrous metal corrosion inhibitor, 7-15% of boric acid ester, 2-5% of isopropanolamine, 8-12% of triethanolamine, 1-3%of special amine, 0.5-2% of organic molybdenum, 3-5% of alcohol ether carboxylic acid, 1-2% of preservative and the balance of water. The production process is simple, heating and pressurizing are not needed, and the influence on the environment is small; the product provided by the invention is good in extreme pressure lubricating property; the product is wide in applicable material range and does not go bad easily; the service life is long, and the discharge of waste liquid is reduced.

Owner:安徽鑫诺斯润滑科技有限公司

A plugging type extreme pressure lubricant and its preparation method and application

ActiveCN108251078BExcellent extreme pressure lubricityGood compatibilityDrilling compositionVegetable oilDirectional well

The invention provides a plugging extreme-pressure lubricant as well as a preparation method and application of the plugging extreme-pressure lubricant. The plugging extreme-pressure lubricant comprises 70wt%-85wt% of modified vegetable oil, 2wt%-5wt% of extreme-pressure anti-wear agent and 8wt%-15wt% of surfactant. According to the plugging extreme-pressure lubricant provided by the invention, the modified vegetable oil which is easily biodegraded is adopted, and a sulfur-type additive with good extreme-pressure and anti-wear properties is added, so that the lubricant is environment-friendly,good in extreme-pressure lubricating property and compatibility, capable of obviously improving the quality of a mud cake in a drilling fluid and good in plugging effect and can be favorably appliedto a well drilling site and can be applied to wear and resistance reduction during well drilling operation of a large-displacement horizontal well, a directional well, a long open hole deep well, a complex structural well and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water-soluble cutting fluid and preparation method thereof

ActiveCN101948711BExtended service lifeExcellent extreme pressure lubricityLubricant compositionPolyethylene glycolMonoisopropanolamine

Owner:GUANGZHOU LANDNOK CHEM TECH

Wet leveling liquid composition and use thereof

ActiveCN102002714BImprove rust resistanceImprove detergencyLubricant compositionLiquid compositionChemistry

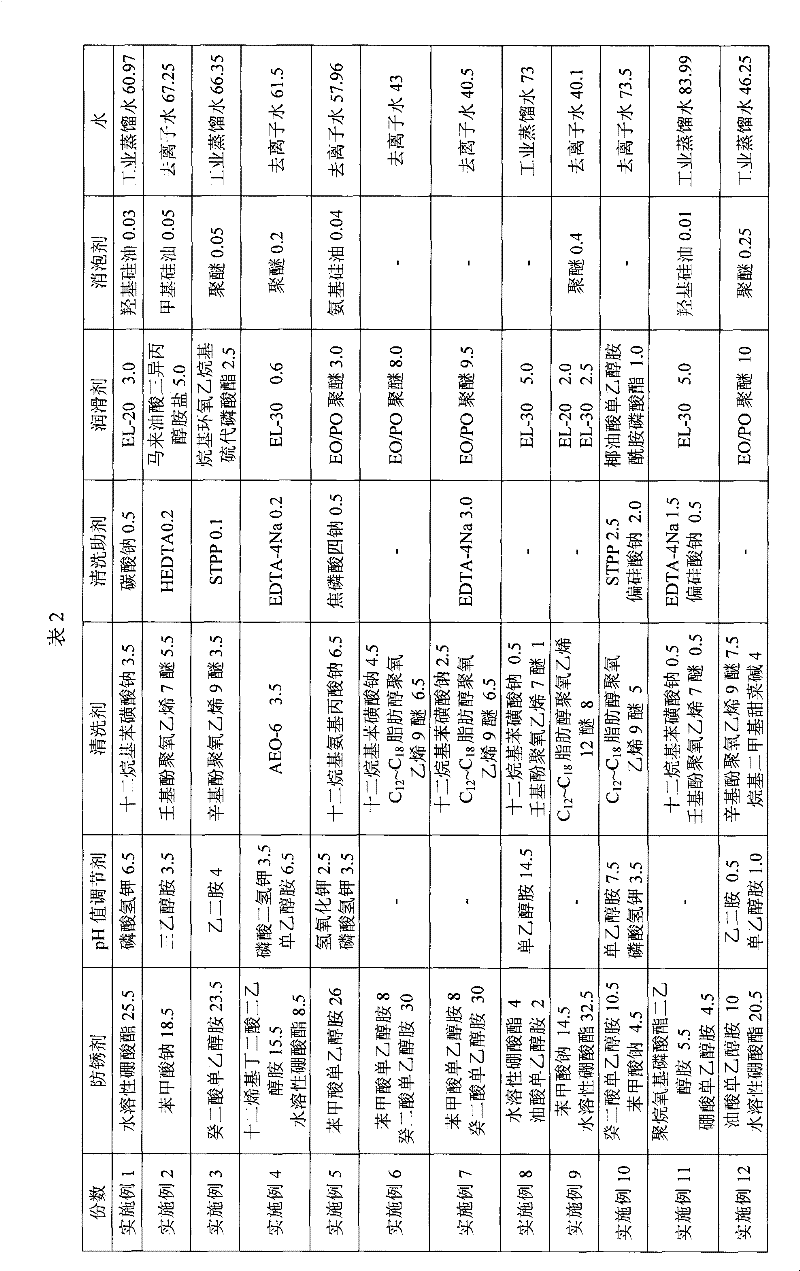

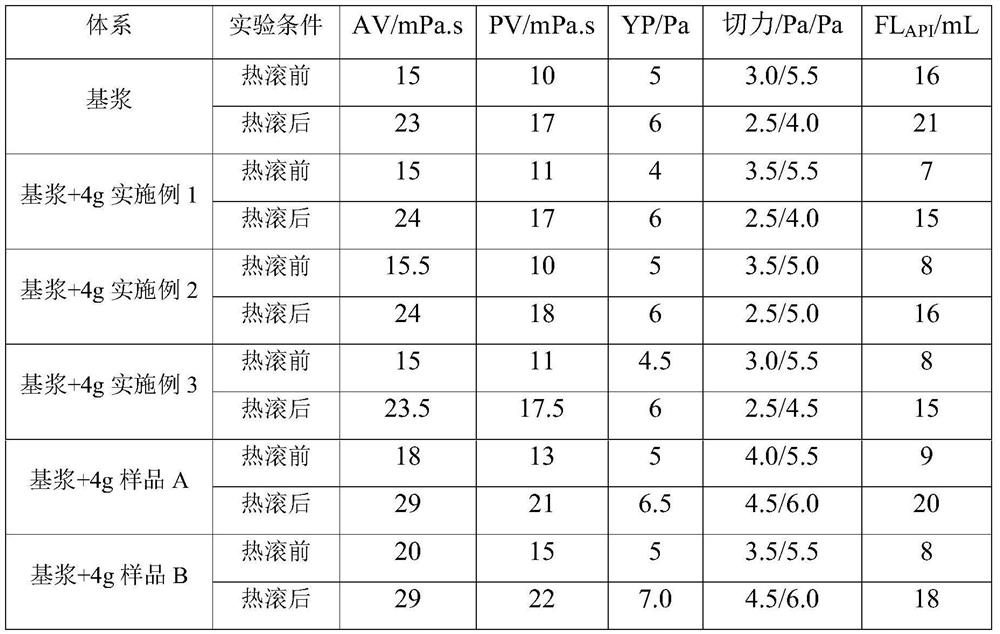

The invention relates to a wet leveling liquid composition and use thereof, and mainly solves the problem that wet leveling liquid cannot meet the requirement that a down rate is greater than 3.0 percent in the leveling process in the prior art. By adopting a technical scheme that: the wet leveling liquid composition comprises the following components in part by weight: a) 5 to 50 parts of antirust additive; b) 1 to 12 parts of cleaning agent; c) 0.5 to 10 parts of lubricating agent; and d) 28 to 93.5 parts of water, the invention better solves the problem and can be used in the leveling process of cold-rolled steel sheets.

Owner:CHINA PETROLEUM & CHEM CORP

Micro-nano plugging lubricant for drilling fluid and preparation method thereof

ActiveCN108239522BAvoid duplicate additionsAvoid mutual interferenceDrilling compositionMicro nanoParaffin wax

The invention relates to a micro-nano blocking lubricant for a drilling fluid and a preparation method thereof and belongs to the field of oil and gas field drilling and oilfield chemical auxiliary agents. The micro-nano blocking lubricant for the drilling fluid is prepared from the following components in parts by weight: 100-200 parts of a nano emulsion and 100 parts of composite graphite micropowder. The micro-nano blocking lubricant for the drilling fluid also contains a dispersant. The nanoemulsion is prepared from components including paraffin, white oil, a composite emulsifier, a co-emulsifier and water by a phase inversion emulsification method. The micro-nano blocking lubricant for the drilling fluid can resistant the temperature of 150 DEG C, does not have adverse effects to viscosity of the drilling fluid, can reduce the filter loss of the drilling fluid remarkably, improve the quality of mud cakes remarkably, reduce the frictional resistance of a drilling tool and improve the mechanical drilling speed, and can bridge and block micro-cracks of shale quickly by means of a small size effect to prevent solid particles and a filtrate from invading the stratum to achieve a good blocking effect, so that the micro-nano blocking lubricant for the drilling fluid is particularly suitable for blocking fine throats which are 0.05-50[mu]m.

Owner:CHINA PETROLEUM & CHEM CORP +1

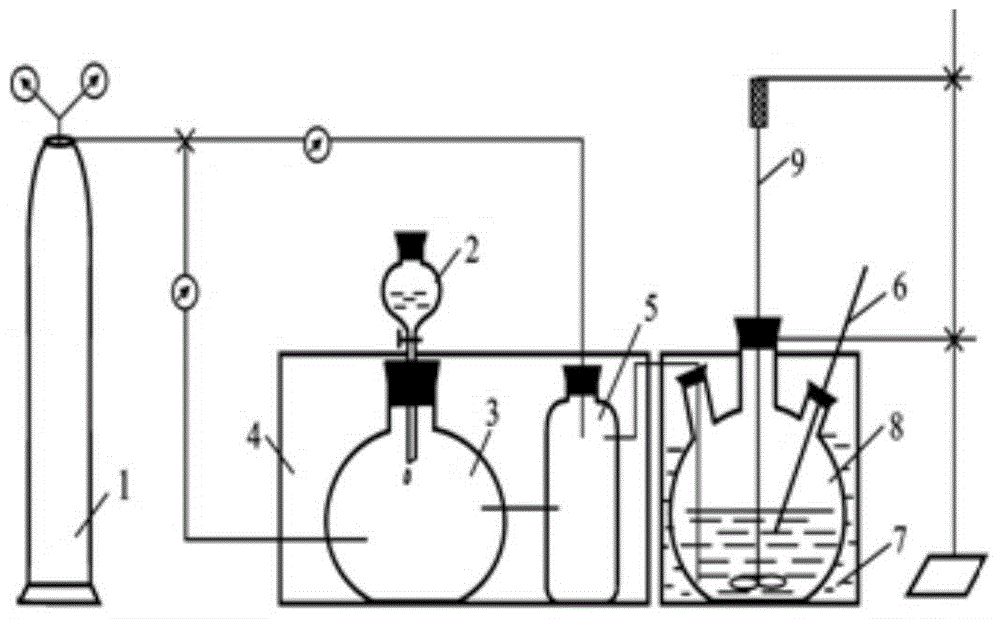

A method of using waste engine oil to prepare multifunctional lubricant for drilling fluid

InactiveCN103614121BSimple preparation processAdd lessDrilling compositionWater bathsReaction temperature

The invention discloses a method for preparing a drilling fluid multi-functional lubricant by using waste oil. The method is as follows: (1) firstly weigh the waste oil and put it into a reactor, and then put the reactor into an electric heating constant temperature water bath; (2) ) then weigh the liquid SO3 and put it into the dropping funnel, in order to make the liquid SO3 dripped from the dropping funnel become gas SO3, the gas generator connected to the dropping funnel keeps 50-70°C through the thermal circulation effect of the jacketed water bath. ℃; (3) gas SO3 is mixed with N2 before entering the reactor; (4) control the reaction temperature to 50 ℃, after the gas SO3 reacts with waste oil for 2-4h, add organic alkali to the reactor, adjust the pH to 8-9, Then add the composite surfactant into the reactor, and after stirring for 3-10min, the lubricant is obtained. Compared with similar lubricants, the lubricant prepared by the invention has simple production process and low cost, not only has good high temperature extreme pressure lubricity, but also has good fluid loss reduction and anti-slump performance, and is suitable for horizontal wells and complex formation drilling. .

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com