Plugging extreme-pressure lubricant as well as preparation method and application of plugging extreme-pressure lubricant

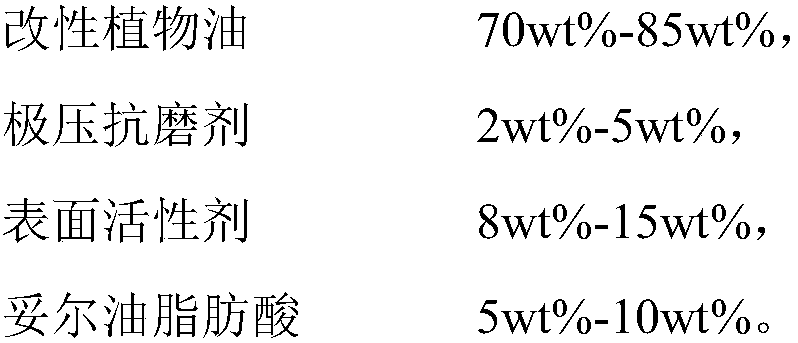

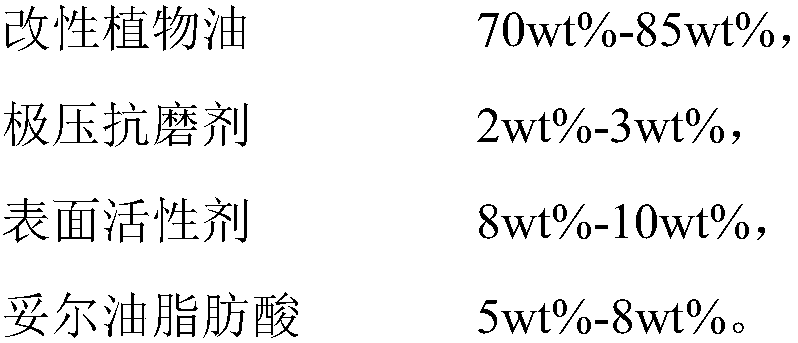

A technology of extreme pressure lubricant and extreme pressure antiwear agent, which is applied in the field of plugging extreme pressure lubricant for drilling fluid and its preparation, can solve the problems of poor lubrication durability, poor extreme pressure and antiwear, and high fluorescence level. Achieve good extreme pressure lubricity, improve mud cake quality, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This implementation provides a plugging type extreme pressure lubricant, the plugging type extreme pressure lubricant includes 85wt% modified cottonseed oil, 6wt% Span 80, 6wt% OP- 10 and 3 wt% T405.

[0034] The modified vegetable oil of this embodiment reacts cottonseed oil with methanol solution of 0.5 mol / L sodium hydroxide at 70°C to 90°C, and the esterified cottonseed oil obtained by extraction is the modified cottonseed oil of this embodiment.

[0035] This embodiment also provides the preparation method of the above-mentioned plugging type extreme pressure lubricant, which is to add Span 80, OP-10 and T405 to the modified cottonseed oil in sequence, and fully stir and mix evenly to obtain the plugging type extreme pressure lubricant of this embodiment. Press lubricant, named it MPA-1.

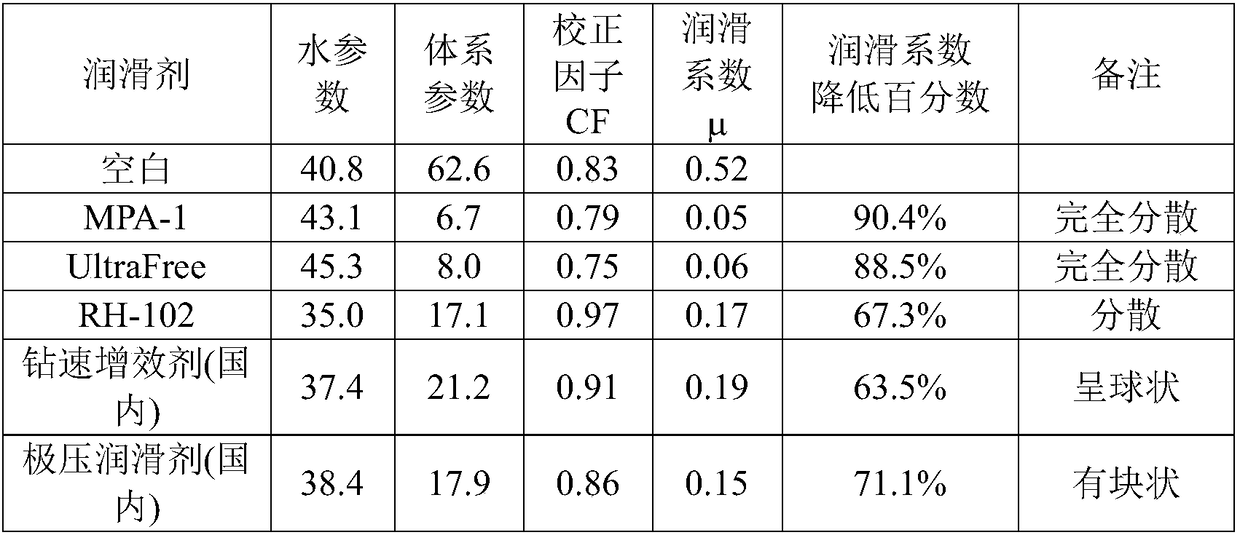

[0036] The plugging type extreme pressure lubricant MPA-1 provided in this example and several domestic and foreign lubricants were used to test the extreme pressure lubrication...

Embodiment 2

[0047] This implementation provides a plugging type extreme pressure lubricant, the plugging type extreme pressure lubricant includes 75wt% modified cottonseed oil, 5wt% Span 80, 6wt% OP- 10. 5 wt% T405 and 10 wt% tall oil fatty acid.

[0048] The modified vegetable oil of this embodiment reacts cottonseed oil with methanol solution of 0.5 mol / L sodium hydroxide at 70°C to 90°C, and the esterified cottonseed oil obtained by extraction is the modified cottonseed oil of this embodiment.

[0049]This embodiment also provides the preparation method of the above-mentioned plugging type extreme pressure lubricant, which is to add Span 80, OP-10, T405 and tall oil fatty acid into the modified cottonseed oil in sequence, and fully stir and mix evenly to obtain the present embodiment The blocking type extreme pressure lubricant is named MPA-2.

[0050] The drilling fluid performance of the following drilling fluid systems before and after adding the plugging type extreme pressure lubr...

Embodiment 3

[0057] This implementation provides a plugging type extreme pressure lubricant, the plugging type extreme pressure lubricant includes 80wt% of modified cottonseed oil, 5wt% of Span 80, 4wt% of OP- 10. 3 wt% T405 and 8 wt% tall oil fatty acid.

[0058] The modified vegetable oil of this embodiment reacts cottonseed oil with methanol solution of sodium hydroxide at 70° C. to 90° C., and the esterified cottonseed oil obtained by extraction is the modified cottonseed oil of this embodiment.

[0059] This embodiment also provides the preparation method of the above plugging type extreme pressure lubricant, which is to add Span 80, OP-10, sulfur type extreme pressure antiwear agent and tall oil fatty acid into the modified cottonseed oil in sequence, and stir thoroughly Mix evenly to obtain the plugged extreme pressure lubricant of this embodiment, which is named MPA-3.

[0060] The drilling fluid performance of the following drilling fluid systems before and after adding the plugg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com