Micro-emulsion cutting fluid and preparation method thereof

A cutting fluid and microemulsion technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems that the actual production demand cannot be met, and the variety of microemulsion cutting fluid is small, and achieves the effects of easy control, simple preparation method and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

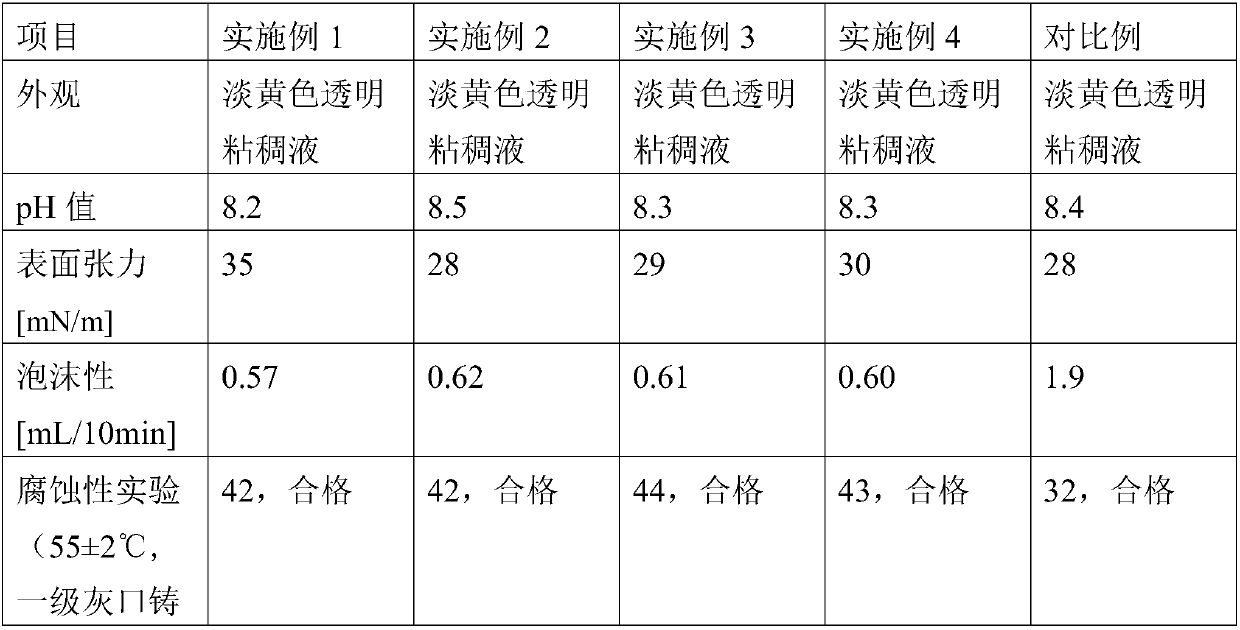

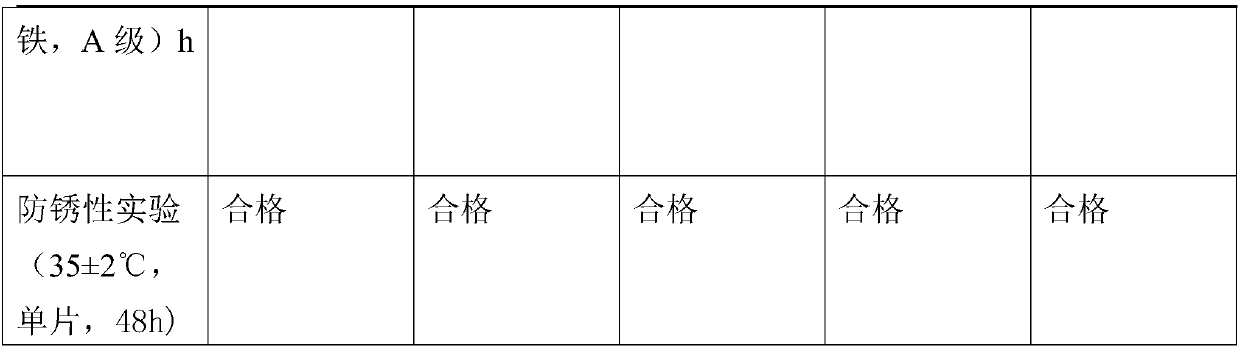

Examples

Embodiment 1

[0037] A kind of microemulsion cutting fluid, calculated according to mass percentage, triethanolamine borate accounts for 14%, triethanolamine oleic acid soap 14%, lanolin 8%, polyethylene glycol 400 10%, fatty alcohol polyoxyethylene ether AEO- 9 12%, refined lubricating oil 20%, sorbitan fatty acid ester 3%, deionized water 19%.

[0038] The preparation method of the above-mentioned microemulsion cutting fluid is specifically to add deionized water to the agitator first, and then slowly add polyethylene glycol 400, fatty alcohol polyoxyethylene ether AEO-9, and Sorbitan fatty acid ester, stirred at 25°C until uniform and transparent, then added triethanolamine borate, triethanolamine oleic acid soap, lanolin and refined lubricating oil, and stirred for 20 minutes to obtain the product.

Embodiment 2

[0040]A microemulsified cutting fluid, calculated by mass percentage, triethanolamine borate 16%, triethanolamine oleic acid soap 16%, lanolin 10%, polyethylene glycol 400 10%, fatty alcohol polyoxyethylene ether AEO- 9 15%, refined lubricating oil 20%, sorbitan fatty acid ester 3%, deionized water 20%.

[0041] The preparation method of the above-mentioned microemulsion cutting fluid is specifically to add deionized water to the agitator first, and then slowly add polyethylene glycol 400, fatty alcohol polyoxyethylene ether AEO-9, and Sorbitan fatty acid ester, stirred at 25°C until uniform and transparent, then added triethanolamine borate, triethanolamine oleic acid soap, lanolin and refined lubricating oil, and stirred for 20 minutes to obtain the product.

Embodiment 3

[0043] A kind of microemulsion cutting fluid, calculated according to mass percentage, triethanolamine borate accounts for 15%, triethanolamine oleic acid soap 15%, lanolin 10%, polyethylene glycol 400 10%, fatty alcohol polyoxyethylene ether AEO- 9 15%, refined lubricating oil 20%, sorbitan fatty acid ester 3%, deionized water 22%.

[0044] The preparation method of the above-mentioned microemulsion cutting fluid, specifically, firstly add deionized water to the agitator, and slowly add polyethylene glycol 400, fatty alcohol polyoxyethylene ether AEO-9 in sequence at a low speed of 200 rpm 1. Sorbitan fatty acid ester, stir at 25°C until uniform and transparent, then add triethanolamine borate, triethanolamine oleic acid soap, lanolin and refined lubricating oil, stir for 15 minutes, and you are done.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com