Lubricant

A technology of lubricants and conditioners, applied in the direction of lubricating compositions, petroleum industry, etc., can solve the problems of health hazards for operators, environmental pollution, etc., and achieve the effects of good wear resistance, simple production process, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

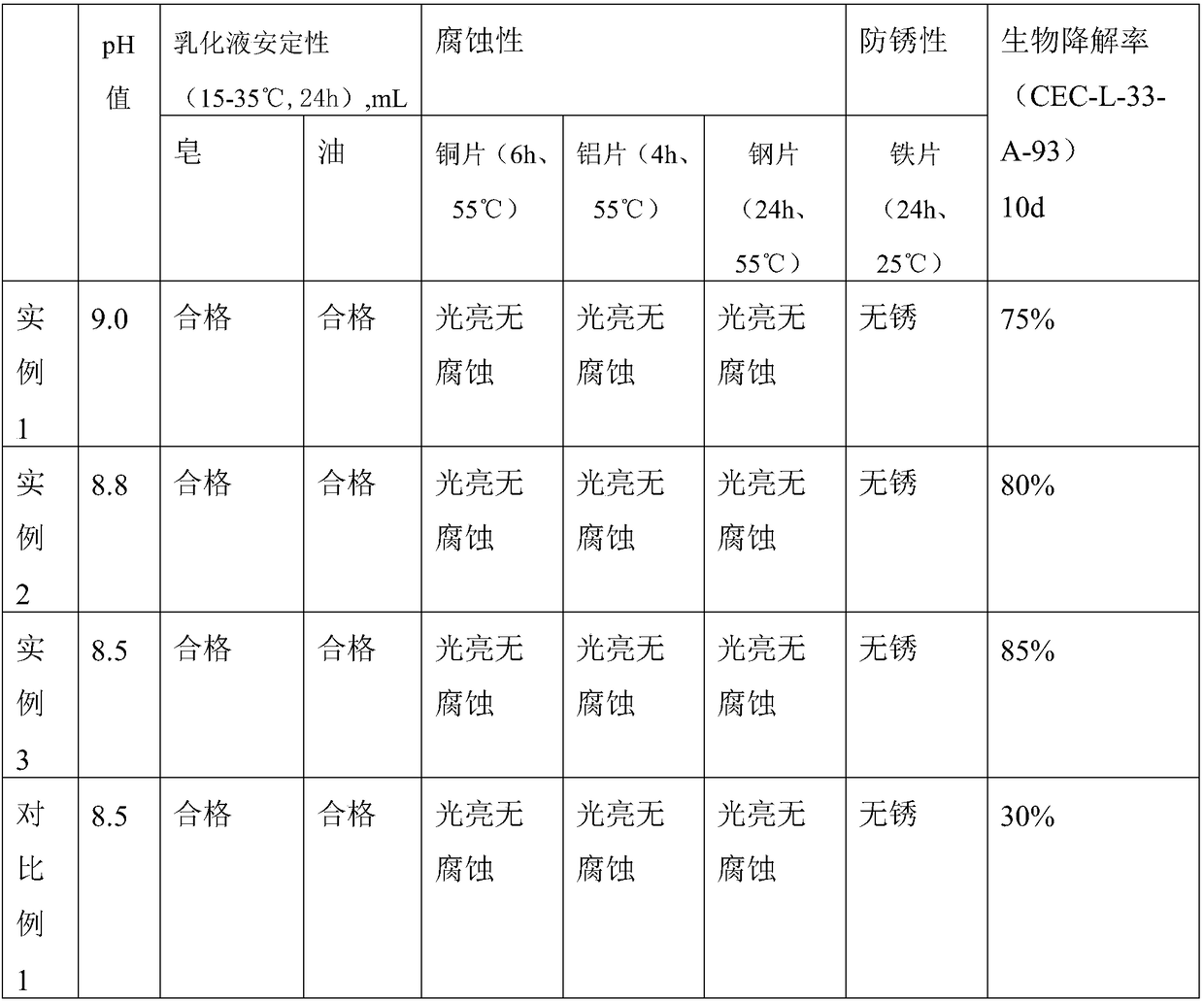

Examples

Embodiment 1

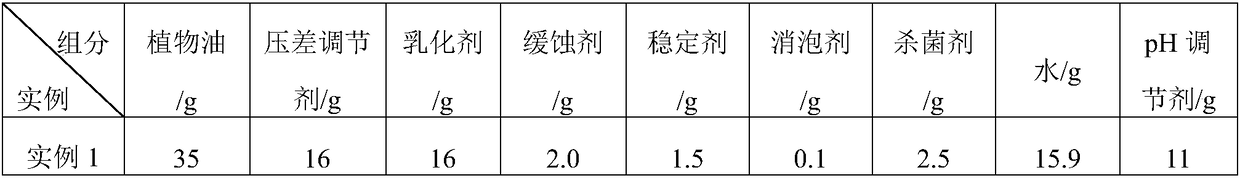

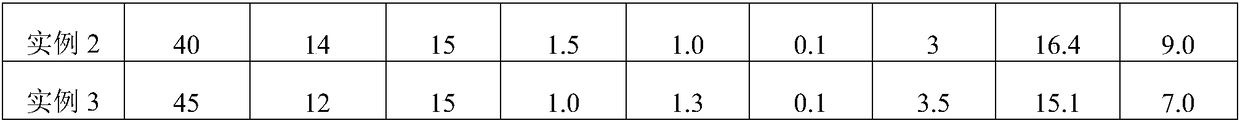

[0021] A kind of lubricant, its composition and the amount of each composition of this vegetable oil-based microemulsion cutting fluid can be:

[0022] ① 30g of vegetable oil, 4g of pH regulator, 8g of differential pressure regulator, 12g of emulsifier, 3.5g of corrosion inhibitor, 0.1g of stabilizer, 0.3g of defoamer, 1g of fungicide and 23g of water .

[0023] ② 50g of vegetable oil, 4g of pH regulator, 18g of differential pressure regulator, 22g of emulsifier, 0.1g of corrosion inhibitor, 3g of stabilizer, 0.01g of defoamer, 5g of fungicide and 13g of water.

[0024] ③ 36g of vegetable oil, 11g of pH regulator, 12g of differential pressure regulator, 19g of emulsifier, 1g of corrosion inhibitor, 1.2g of stabilizer, 0.1g of defoamer, 3g of bactericide and 16g of water.

[0025] ④ 44g of vegetable oil, 7g of pH regulator, 15g of differential pressure regulator, 15g of emulsifier, 2g of corrosion inhibitor, 0.8g of stabilizer, 0.2g of defoamer, 2g of fungicide and 20g of wate...

Embodiment 2

[0029] According to an embodiment of the present invention, the specific type of vegetable oil is not particularly limited. According to a specific embodiment of the present invention, the vegetable oil can have a density of 0.85 to 0.93 g / cm 3 , the kinematic viscosity at a temperature of 40 degrees Celsius is 30.0-44.0mm 2 / s vegetable oil,

[0030] According to a specific example of the present invention, the specific type of vegetable oil is not particularly limited, and the vegetable oil in ①~⑥ in embodiment 1 can be at least one of soybean oil, castor oil, peanut oil, palm oil and rapeseed oil, This type of vegetable oil can be used as the basic component for forming water-soluble cutting fluid microemulsion, and the formed system has good lubricity and heat transfer. For example, the vegetable oil may be: ① soybean oil; ② castor oil; ③ peanut oil; ④ palm oil; ⑤ rapeseed oil; ⑥ soybean oil and peanut oil; ⑦ palm oil and rapeseed oil; ; ⑨ soybean oil, castor oil and pea...

Embodiment 3

[0032] According to all embodiments of the present invention, the pH value of the lubricant is not particularly limited, and the pH value of the cutting fluid for the cutting fluid in ①~⑥ in Example 1 can be 7.5~9.3, preferably, the pH value It can be 8.0-9.0. The cutting oil in this pH range can not only inhibit the reproduction of bacteria, but also not cause skin contact and discomfort to the operator due to an excessively high pH value.

[0033] According to an embodiment of the present invention, the cutting fluid pH regulator is not particularly limited, and the pH regulator of the cutting fluid in ①~⑥ in Example 1 can be triethanolamine, monoethanolamine, diglycolamine, A mixture of one or more of isopropanolamine and 2-amino-2-methyl-1-propanol, the reasonable use of this pH regulator meets the performance requirements and environmental protection requirements of water-soluble cutting oil, and has Good pH value stability, which is conducive to maintaining its long-term...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com