Environment-friendly gear lubricating oil and preparation method thereof

A gear lubricating oil and environment-friendly technology, applied in the field of environment-friendly gear lubricating oil and its preparation, can solve the problems of affecting oil performance, large evaporation loss, small viscosity index, etc., and achieve reduced preparation cost, low cost, extreme pressure Lubricating performance suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

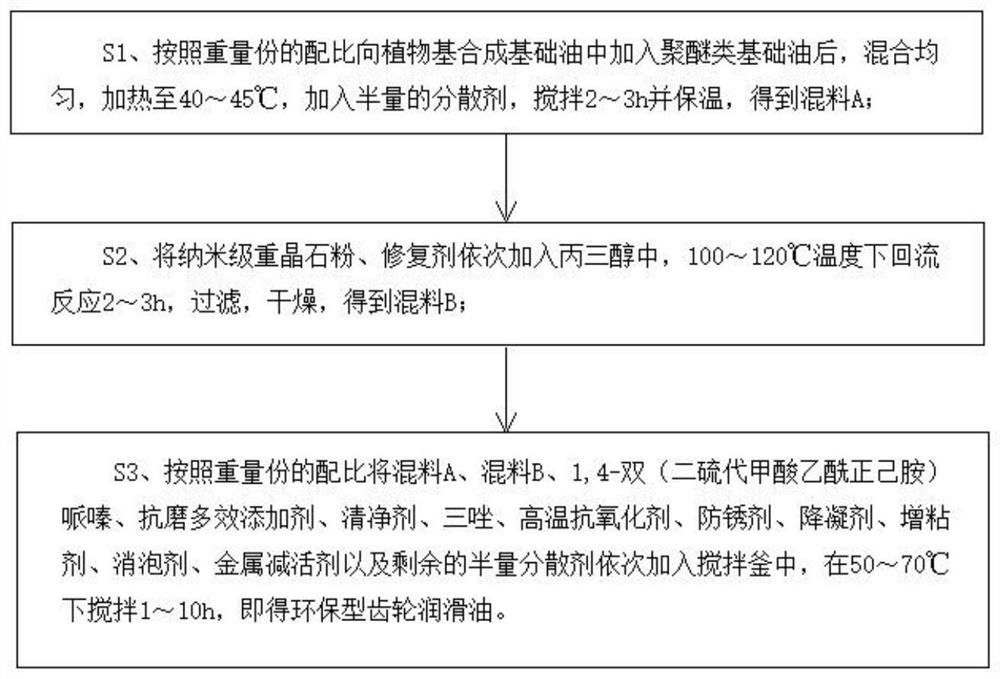

Method used

Image

Examples

Embodiment 1

[0040] An environment-friendly gear lubricating oil, comprising the following components by weight: 50-85 g of plant-based synthetic base oil, 5 g of polyether base oil, 0.5 g of 1,4-bis(acetyl-n-hexylamine dithioformate) piperazine, Anti-wear multi-effect additive 0.8g, nano barite powder 2g, repair agent 10g, detergent 2g, high temperature antioxidant 1.2g, rust inhibitor 0.2g, pour point depressant 0.2g, tackifier 4g, dispersant 1g, Defoamer 0.5g, metal deactivator 0.5g.

[0041] Wherein, the plant-based synthetic base oil is made of the following components by weight: 20 g of castor oil, 15 g of cottonseed oil, 10 g of rapeseed oil, 5 g of boric acid, and 2 g of triethanolamine oleate.

[0042] Wherein, the anti-wear multi-effect additive in an environment-friendly gear lubricating oil in this embodiment is dibutyl xanthate.

[0043] Wherein, the repairing agent in an environment-friendly gear lubricating oil in this embodiment is a mixture of nano-alumina, nano-copper po...

Embodiment 2

[0052] An environment-friendly gear lubricating oil, comprising the following components by weight: 50-85 g of plant-based synthetic base oil, 12 g of polyether base oil, 1.2 g of 1,4-bis(acetyl-n-hexylamine dithioformate) piperazine, Anti-wear multi-effect additive 4.5g, nano barite powder 5g, repair agent 62g, detergent 4g, high temperature antioxidant 2g, rust inhibitor 0.7g, pour point depressant 1.6g, tackifier 6g, dispersant 3g, disinfectant Foam agent 1g, metal deactivator 6.5g.

[0053] Wherein, the plant-based synthetic base oil is made of the following components by weight: 45 g of castor oil, 30 g of cottonseed oil, 36 g of rapeseed oil, 12 g of boric acid, and 5 g of triethanolamine oleate.

[0054] Wherein, the anti-wear multi-effect additive in an environment-friendly gear lubricating oil in this embodiment is dibutyl xanthate.

[0055] Wherein, the repairing agent in an environment-friendly gear lubricating oil in this embodiment is a mixture of nano-alumina, n...

Embodiment 3

[0064] An environment-friendly gear lubricating oil, comprising the following components by weight: 50-85 g of plant-based synthetic base oil, 7 g of polyether base oil, 0.6 g of 1,4-bis(acetyl-n-hexylamine dithioformate) piperazine, Anti-wear multi-effect additive 2.2g, nano barite powder 35g, repair agent 25g, detergent 2g, high temperature antioxidant 1.5g, rust inhibitor 0.5g, pour point depressant 1g, tackifier 5g, dispersant 2.1g, Defoamer 0.7g, metal deactivator 3.2g.

[0065] Wherein, the plant-based synthetic base oil is made of the following components by weight: 30 g of castor oil, 30 g of cottonseed oil, 126 g of rapeseed oil, 8 g of boric acid, and 4 g of triethanolamine oleate.

[0066] Wherein, the anti-wear multi-effect additive in an environment-friendly gear lubricating oil in this embodiment is dibutyl xanthate.

[0067] Wherein, the repairing agent in an environment-friendly gear lubricating oil in this embodiment is a mixture of nano-alumina, nano-copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com