Liquid fuel for internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

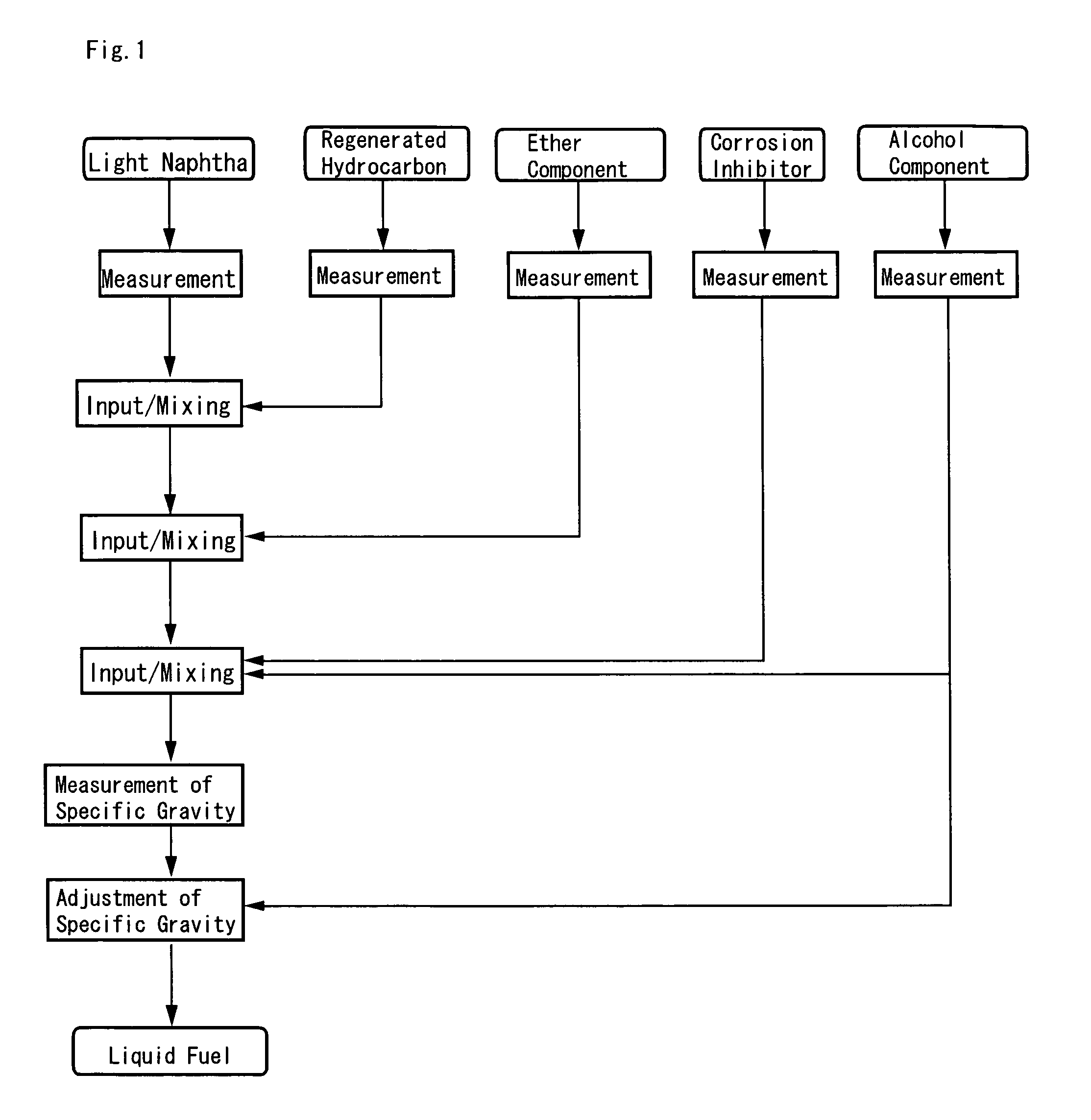

[0074]FIG. 1 is a flowchart showing the process of producing a liquid fuel for internal combustion engine in working examples of the present invention. The liquid fuel for internal combustion engine of the present invention is mainly composed of at least one kind of aliphatic monohydric (primary) alcohols, saturated or unsaturated hydrocarbons, an ether component of ether having not more than 12 carbon atoms per molecule and having an ether bond in the molecule per se or a mixture thereof, and an aluminum corrosion inhibitor (including water). After each of these raw materials is measured to a predetermined weight percentage, the ether with polarity smaller than the aliphatic primary alcohol is inputted and mixed to light naphtha as the hydrocarbon with a relatively large weight ratio and the smallest polarity.

[0075] The measured alcohol and aluminum corrosion inhibitor are inputted and mixed to the mixture of light naphtha and ether.

[0076] After inputting the alcohol and the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com