Metal ceramic material resistant to molten aluminum corrosion, and preparation method and application thereof

A cermet, fusion-resistant technology, applied in the field of corrosion and protection of metal materials, can solve the problems of limited application, easy crack initiation, poor corrosion resistance of molten aluminum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the present invention, the Al 0.25 The preparation method of FeNiCoCr high entropy alloy preferably comprises the following steps:

[0034] (A) the aluminum powder, iron powder, nickel powder, cobalt powder and chromium powder that mass percent is respectively 2.9%, 24.06%, 25.35%, 25.35% and 22.34% are mixed by ball milling, obtains the ball mill of mechanical alloying;

[0035] (B) drying the ball mill material in a vacuum environment of 80-110°C and -0.1MPa for 8-24 hours to obtain the first dry powder;

[0036] (C) mixing the first dry powder with polyethylene glycol, and continuing to dry at 80-110° C. under a vacuum environment of -0.1 MPa for 8-24 hours to obtain a second dry powder;

[0037] (D) Vacuum sintering the second dry powder to obtain Al 0.25 FeNiCoCr high entropy alloy.

[0038]In the present invention, the purity of the aluminum powder, iron powder, nickel powder, cobalt powder and chromium powder in the step (A) is preferably 99.9%, and the ind...

Embodiment 1

[0055] Al 0.25 Preparation of FeNiCoCr high entropy alloy powder:

[0056] (1) Aluminum powder, iron powder, nickel powder, cobalt powder and chromium powder (all of which are 99.9% in purity and 2 to 5 μm in particle size) with mass percentages of 2.9%, 24.06%, 25.35%, 25.35%, and 22.34% respectively ) into a ball mill for ball milling, adding steel balls with a ball-to-material ratio (mass ratio) of 10:1, and pouring 50mL of absolute ethanol (wet milling medium), and ball milling at a speed of 300r / min for 50h to obtain mechanical alloying mixed powder.

[0057] (2) The mixed powder after ball milling was dried at 90° C. and a vacuum environment of -0.1 MPa for 24 hours, and the quality was added to the dried mixed powder after polyethylene glycol was 1% of the mixed powder mass, at the same temperature Continue to dry under vacuum for 12 hours.

[0058] (3) Put the mixed powder after vacuum drying into the vacuum sintering furnace for vacuum sintering: vacuumize the vacu...

Embodiment 2

[0060] Preparation of cermet materials resistant to corrosion by molten aluminum:

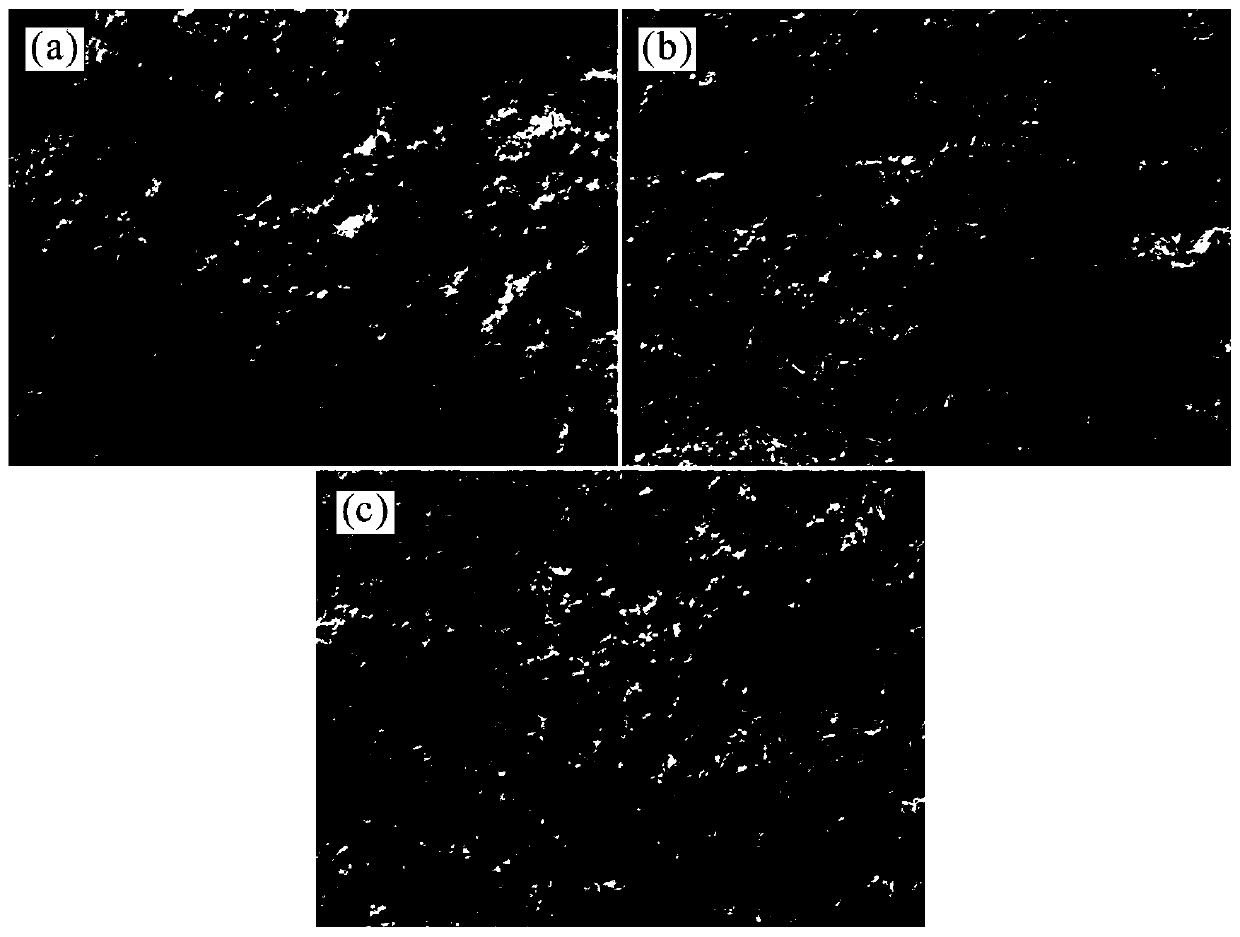

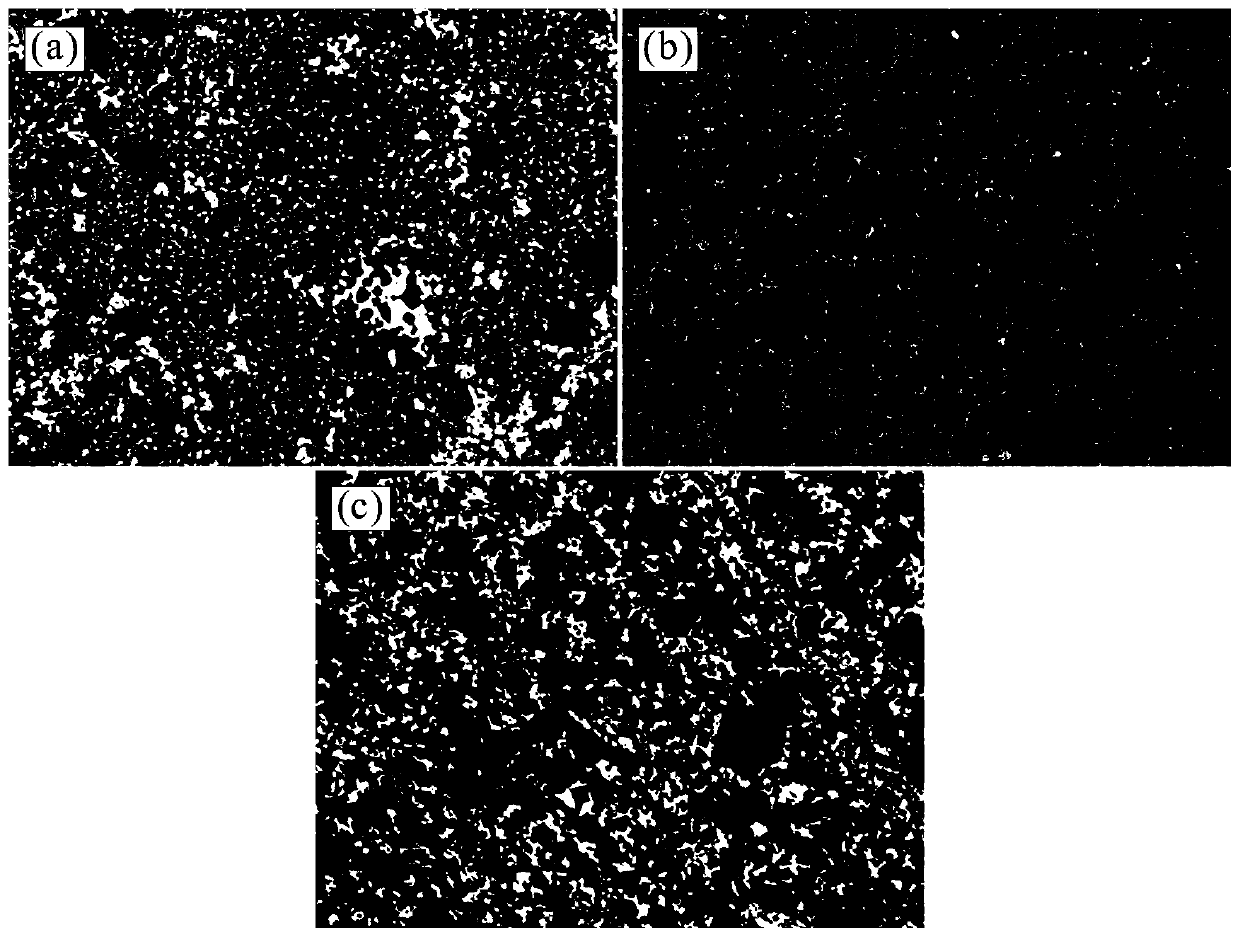

[0061] (1) the mass percent that embodiment 1 prepares is 8% Al 0.25 FeNiCoCr high-entropy alloy powder and 92% Ti(C 0.3 ,N 0.7 ) powder into a ball mill for ball milling, put into balls with a ball-to-material ratio (mass ratio) of 3:1, and pour 80mL of absolute ethanol into it, and ball mill for 3 hours at a speed of 200r / min to obtain a uniform mixed powder; ball mill The scanning electron microscope image of the mixed powder obtained later is as follows figure 1 As shown in (a), after ball milling, the phase of the mixed powder is composed of Ti(C 0.3 ,N 0.7 ) and Al 0.25 FeNiCoCr high-entropy alloy (FCC solid solution) composition, the phase has not changed;

[0062] (2) The mixed powder after ball milling was dried for 24 hours at 100° C., in a vacuum environment of -0.1 MPa, and the polyethylene glycol with a mass of 1% of the mixed powder mass was added to the dried mixed powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com