High-density cermet material resistant to molten aluminum corrosion and manufacturing method thereof

A cermet, high-density technology, applied in the field of cermet materials and their preparation, can solve the problems of high brittleness, easy cracking limitation, etc., and achieve the effects of improving compactness, reducing production costs, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

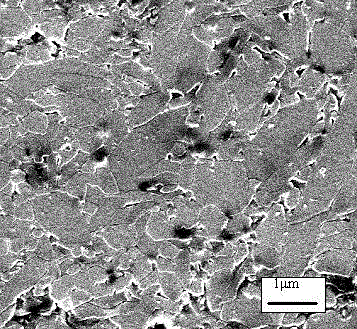

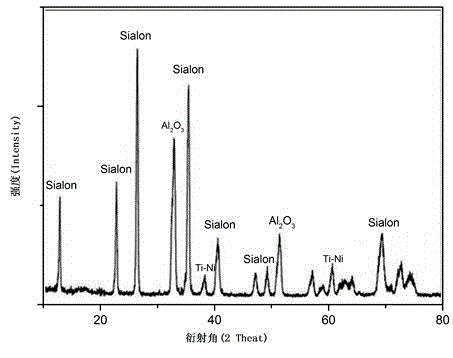

[0027] Embodiment one: see figure 1 and figure 2 , a high-density cermet material resistant to molten aluminum corrosion, including Ti powder, Ni powder, AlN powder, TiN powder, Y2O3 powder and Al2O3 powder, and the weight percentage is 16% Ti powder, 4% Ni powder, 17% AlN powder, 8% TiN powder, 5% Y2O3 powder and 50% Al2O3 powder, the Ti powder, Ni powder, AlN powder, TiN powder, Y2O3 powder and Al2O3 powder are sintered through mixed ball milling, pressing, electric field activated hot pressing auxiliary combustion furnace Its preparation method comprises the following steps: (1) batching mixed ball milling: with Ti powder, Ni powder, AlN powder, TiN powder, Y2O3 powder and Al2O3 powder as raw materials, the purity of AlN and Al2O3 powder > 99.8%, particle size 1 micron, TiN Powder, Y2O3 powder, Ti and Ni powder with a purity of >99.8% and a particle size of 0.5 microns are loaded into a ball mill according to the weight percentage, the ball milling medium is ethanol, and ...

Embodiment 2

[0032] Embodiment 2: A high-density cermet material resistant to molten aluminum corrosion, including Ti powder, Ni powder, AlN powder, TiN powder, Y2O3 powder and Al2O3 powder, and the weight percentage is 12% Ti powder, 3% Ni powder, 13% AlN powder, 7% TiN powder, 5% Y2O3 powder and 60% Al2O3 powder, the purity of the Ti powder, Ni powder, AlN, TiN, Y2O3 powder and Al2O3 powder is >99.8%, and the AlN, TiN, Y2O3 and Al2O3 The particle size of powder is 5 microns, the particle size of described Ti powder and Ni powder is 2 microns, and described Ti powder, Ni powder, AlN powder, TiN powder, Y2O3 powder and Al2O3 powder are through mixed ball milling, pressing, electric field It is sintered by activating a hot-press auxiliary combustion furnace; its preparation method is the same as in Example 1.

[0033] The density of the sample of the aluminum liquid corrosion resistant high-density cermet material of the present invention is 99.7% when tested by the drainage method.

[003...

Embodiment 3

[0037] Embodiment 3: A high-density cermet material resistant to molten aluminum corrosion, including Ti powder, Ni powder, AlN powder, TiN powder and Al2O3 powder, the weight percentage is 16% Ti powder, 4% Ni powder, 20% AlN powder, 10% TiN powder and 50% Al2O3 powder, the purity of the Ti powder, Ni powder, AlN, TiN and Al2O3 powder is >99.8%, the particle size of the AlN, TiN and Al2O3 powder is 5 microns, and the Ti The particle size of Ti powder and Ni powder is 2 microns, and described Ti powder, Ni powder, AlN powder, TiN powder and Al2O3 powder are formed through mixed ball milling, pressing, electric field activation hot-press auxiliary combustion furnace sintering; Its preparation method is the same as embodiment one.

[0038] The density of the aluminum liquid corrosion resistant high-density cermet material sample of the present invention is 99.5% when tested by the drainage method.

[0039] The average corrosion rate of two different materials after corrosion in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com