Semi-synthesis cutting liquid for low-phosphorus chlorine-free non-formaldehyde aluminum alloy cutting processing

A cutting and aluminum alloy technology, which is used in the field of semi-synthetic cutting fluid, low-phosphorus, chlorine-free, non-formaldehyde aluminum alloy cutting and semi-synthetic cutting fluid, which can solve the problem of poor corrosion resistance, workpiece corrosion, and easy occurrence of built-up edge, etc. problems, to achieve the effect of improving alkali retention capacity, prolonging service life and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

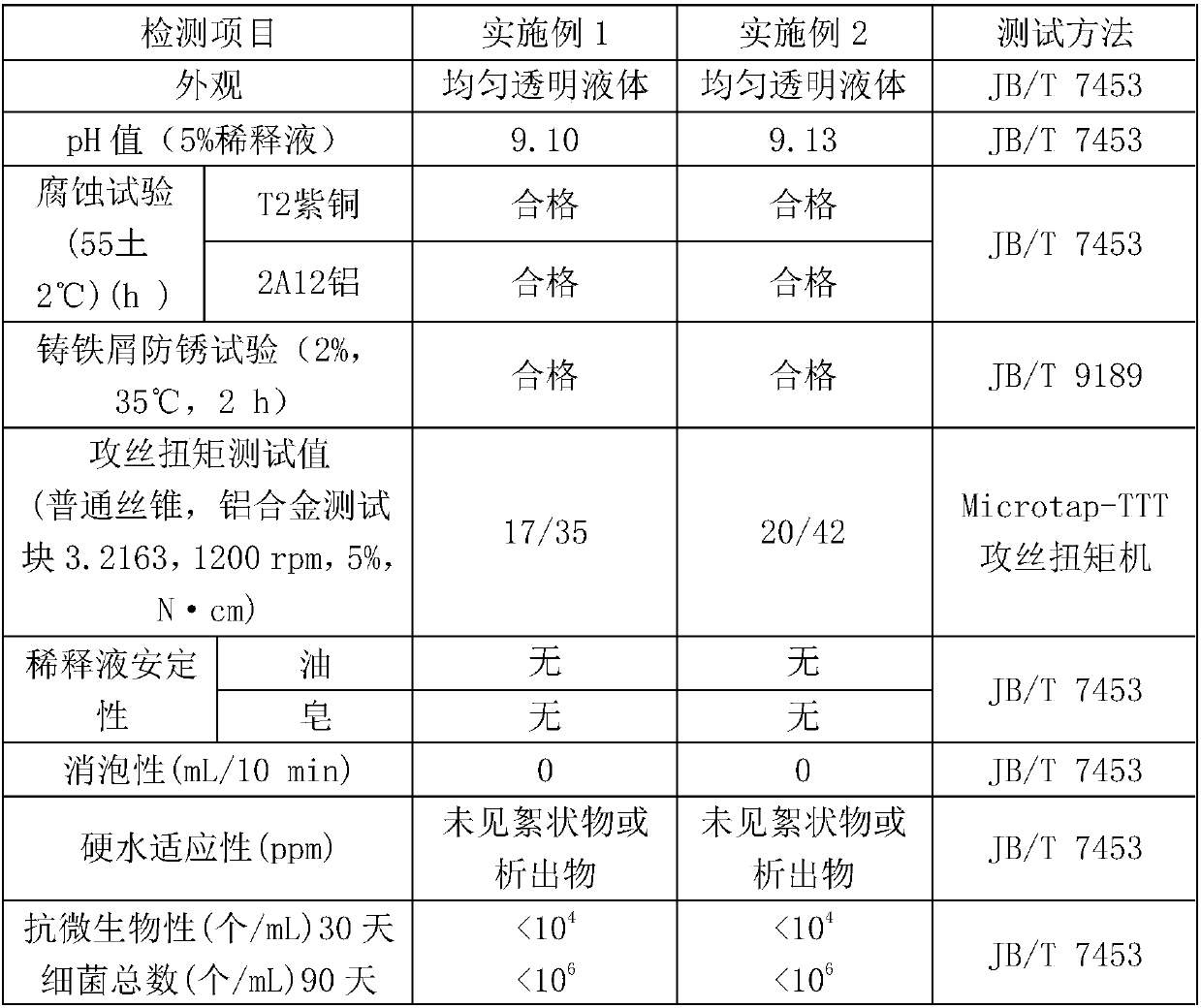

Examples

Embodiment 1

[0022] A low-phosphorus, chlorine-free, non-formaldehyde semi-synthetic cutting fluid for cutting aluminum alloys provided in Example 1, comprising: 1.5% of 2-amino-2-methyl-1-propanol and 8% of triisopropanolamine , boric acid 5%, organic dibasic acid 1%, fatty alcohol ether phosphate 0.5%, tap water 20%, naphthenic oil 25%, silicon-aluminum corrosion inhibitor 2%, polyvinyl alcohol diester 5%, castor oil Polyester 2%, saturated fatty acid trimethylolpropane ester 5%, tall oil fatty acid 5%, fatty alcohol polyoxyethylene ether (5EO / 2EO) 3%, sodium petroleum sulfonate 3%, polyisobutylene succinic acid amide 4%, castor oil polyoxyethylene ether 3%, benzotriazole 0.2%, iodopropynyl butyl carbamate 0.5%, benzisothiazolinone 2%, dipropylene glycol monobutyl ether 4% and modified Non-toxic silicone defoamer 0.3%.

[0023] The preparation of a low-phosphorus, chlorine-free, non-formaldehyde aluminum alloy cutting semi-synthetic cutting fluid provided in Example 1 includes: adding 1...

Embodiment 2

[0025] Embodiment 2: composition:

[0026] A low-phosphorus, chlorine-free, non-formaldehyde semi-synthetic cutting fluid for cutting aluminum alloys provided in Example 2, comprising: 1% of 2-amino-2-methyl-1-propanol, 1% of monoisopropanolamine, Triisopropanolamine 8%, boric acid 2%, boric acid monoethanolamine ester 5%, organic dibasic acid 1%, fatty alcohol ether phosphate 1%, tap water 25.2%, naphthenic oil 20%, silicon-aluminum buffer Etching agent 1.5%, polyvinyl alcohol diester 12%, tall oil fatty acid 4%, fatty alcohol polyoxyethylene ether (5EO / 2EO) 3%, sodium petroleum sulfonate 3%, fatty acid amide 3%, castor oil polyoxygen Vinyl ether 2%, benzotriazole 0.2%, iodopropynyl butyl carbamate 0.3%, benzisothiazolinone 2%, triclocarban 0.5%, dipropylene glycol monobutyl ether 2%, benzene Oxypropanol 2% and modified silicone defoamer 0.3%.

[0027] The preparation of a low-phosphorus, chlorine-free, non-formaldehyde aluminum alloy cutting semi-synthetic cutting fluid pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com