Calcium hexaluminate based pouring material not polluting high-purity aluminum solution

A technology of calcium hexaaluminate and castables, which is applied in the field of refractory materials and can solve problems such as easy damage to the furnace lining and contamination of the melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

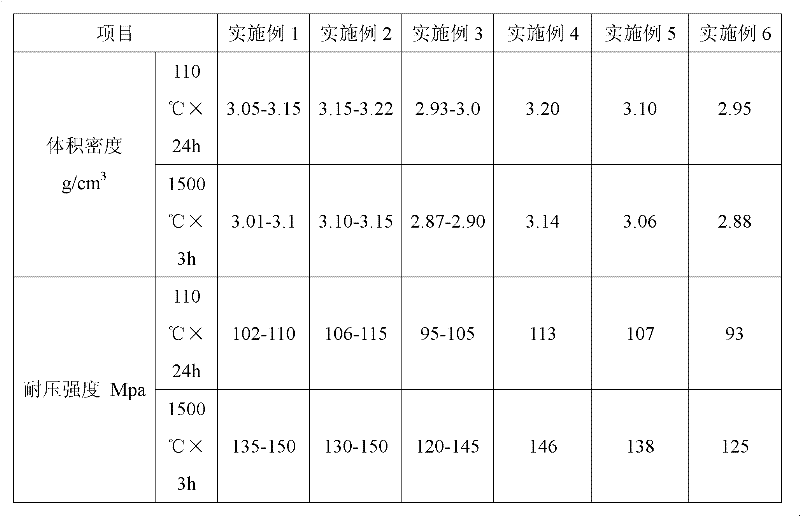

Examples

Embodiment 1

[0026] The mass percentage of each component is calcium hexaaluminate aggregate 32-38%, white corundum aggregate 28-31%, calcium hexaaluminate fine powder 8-12%, white corundum fine powder 10-13%, alumina powder 5% -8%, silica powder 1-2%, pure calcium aluminate cement 7-9%, admixture sodium tripolyphosphate, sodium hexametaphosphate, barium sulfate mixture 1-2%.

Embodiment 2

[0028] The mass percentage of each component is calcium hexaaluminate aggregate 50-60%, white corundum aggregate 5-15%, calcium hexaaluminate fine powder 10-15%, white corundum fine powder 5-10%, alumina powder 3 -5%, silica micropowder 1-2%, pure calcium aluminate cement 7-9%, admixture sodium tripolyphosphate, sodium hexametaphosphate, barium sulfate mixture 2-3%.

Embodiment 3

[0030] The mass percentage of each component is calcium hexaaluminate aggregate 5-15%, white corundum aggregate 50-60%, calcium hexaaluminate fine powder 5-10%, white corundum fine powder 10-15%, alumina powder 8 -10%, silica powder 1-2%, pure calcium aluminate cement 7-9%, admixture sodium tripolyphosphate, sodium hexametaphosphate, barium sulfate mixture 0.5-1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com