Method for recovering aluminum sulfate from waste acid solution

An acid solution, aluminum sulfate technology, applied in aluminum sulfate, chemical instruments and methods, alkali metal sulfites/sulfites, etc., to achieve the effects of improving economic benefits, environmentally friendly treatment, and effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

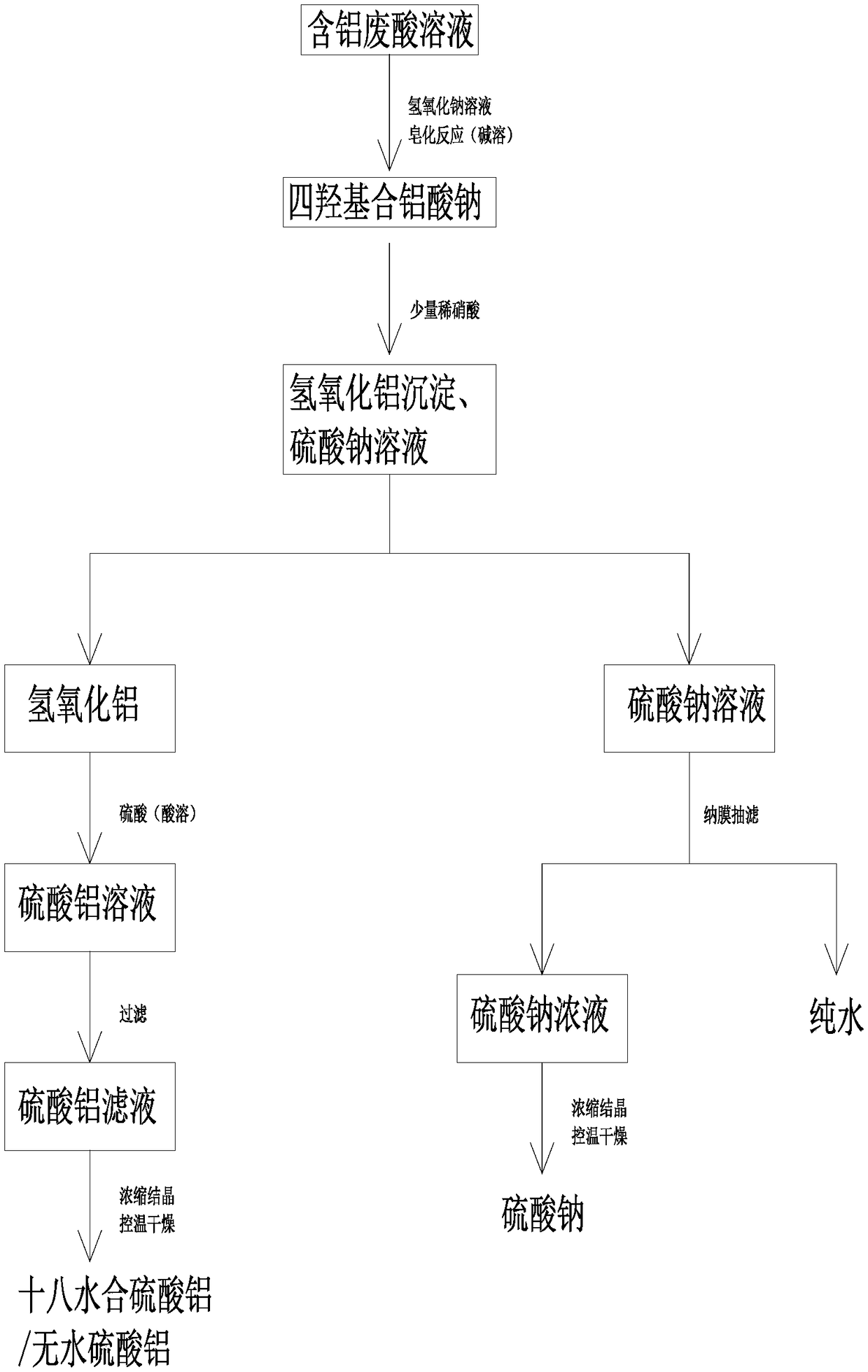

Method used

Image

Examples

Embodiment 1

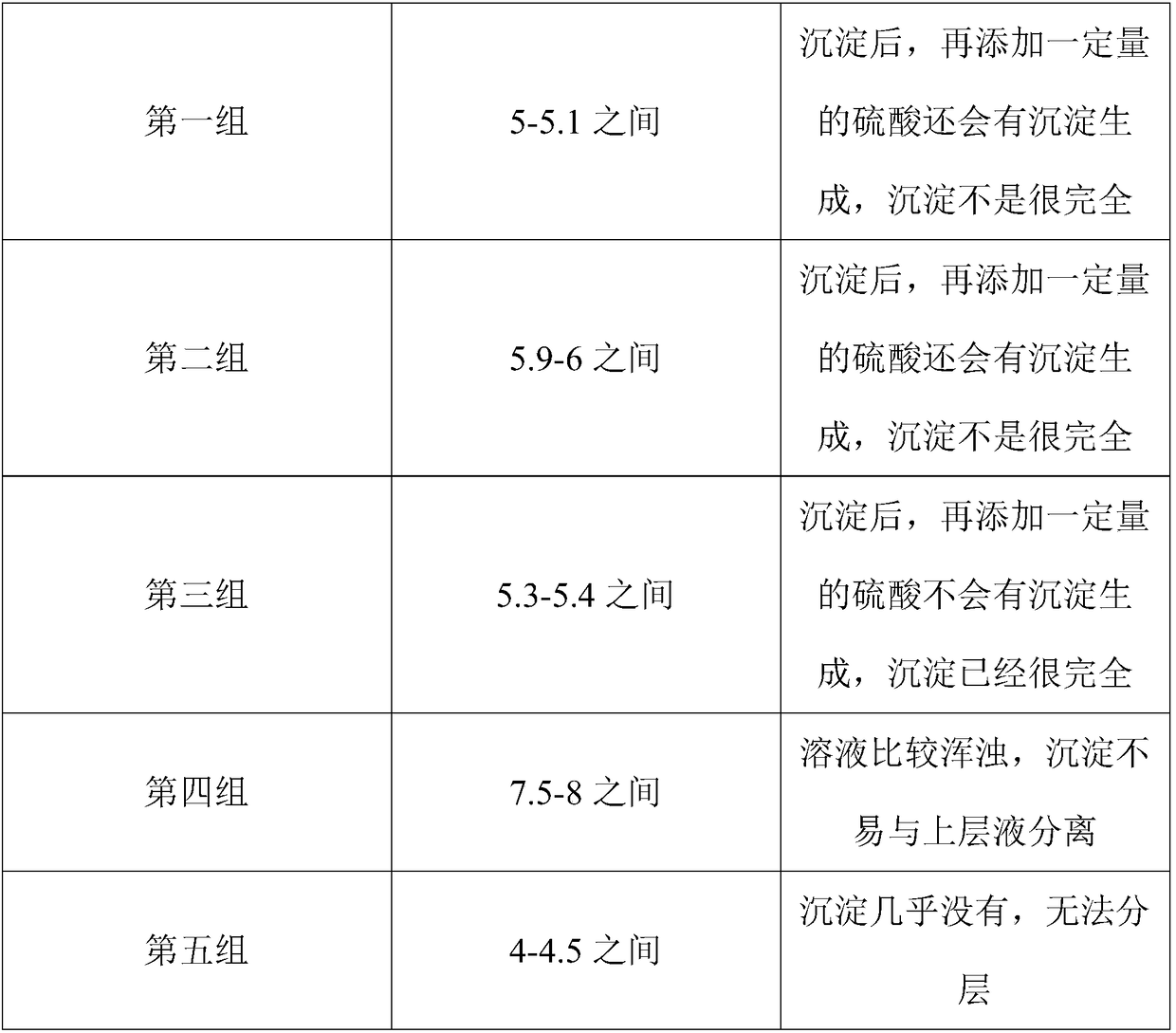

[0056] Heat a certain amount of aluminum-containing waste acid solution to 60°C, add sodium hydroxide solution in a uniform amount under stirring conditions with a rotation speed of 80rad / min, adjust the pH value of the mixed solution to 6, and make the aluminum ions in the waste acid solution Saponification reaction occurs with sodium hydroxide, the stirring time is 30min, and sodium tetrahydroxyaluminate is generated after full reaction. Continue stirring after the saponification reaction, and heat the mixed solution. When the temperature rises to 90°C, add dilute sulfuric acid with a concentration of 0.1mol / L to the solution to adjust the pH value of the mixture to 5, so that the tetrahydroxyaluminum acid The sodium is fully converted to precipitate aluminum hydroxide. After dilute sulfuric acid was added and stirring was continued for 10 min, the stirring was stopped and the mixture was allowed to stand for stratification. After standing for 20 minutes, the mixture was di...

Embodiment 2

[0058] Heat a certain amount of aluminum-containing waste acid solution to 90°C, add sodium hydroxide solution in a uniform amount under stirring conditions with a rotation speed of 120rad / min, adjust the pH value of the mixed solution to 5, and make the aluminum ions in the waste acid solution Saponification reaction occurs with sodium hydroxide, the stirring time is 60min, and sodium tetrahydroxyaluminate is generated after full reaction. Continue stirring after the saponification reaction, and heat the mixed solution. When the temperature rises to 95°C, add dilute sulfuric acid with a concentration of 0.1mol / L to the solution to fully convert sodium tetrahydroxyaluminate into aluminum hydroxide precipitation . After dilute sulfuric acid was added and stirring was continued for 15 min, the stirring was stopped and the mixture was allowed to stand for stratification. After standing for 30 minutes, the mixture was divided into the upper clarified liquid and the lower precipit...

Embodiment 3

[0060] Heat a certain amount of aluminum-containing waste acid solution to 80°C, add sodium hydroxide solution in a uniform amount under the stirring condition of 100 rad / min, adjust the pH value of the mixed solution to 5.5, and make the aluminum ions in the waste acid solution Saponification reaction occurs with sodium hydroxide, the stirring time is 40min, and sodium tetrahydroxyaluminate is generated after full reaction. Continue stirring after the saponification reaction, and heat the mixed solution. When the temperature rises to 93°C, add dilute sulfuric acid with a concentration of 0.1mol / L to the solution to fully convert sodium tetrahydroxyaluminate into aluminum hydroxide precipitation . After adding dilute sulfuric acid and continuing to stir for 20 min, stop stirring and let the mixture stand for stratification. After standing for 25 minutes, the mixture was divided into the upper clarified liquid and the lower precipitated layer, and part of the clarified liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com