Water treatment method using stainless steel nanotube arrays

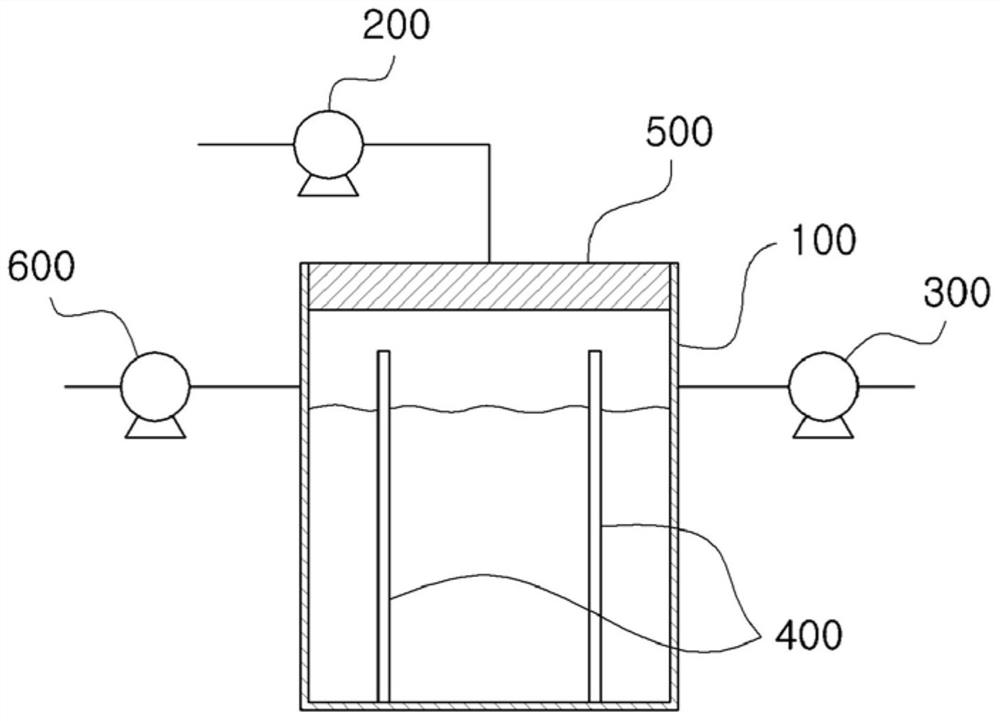

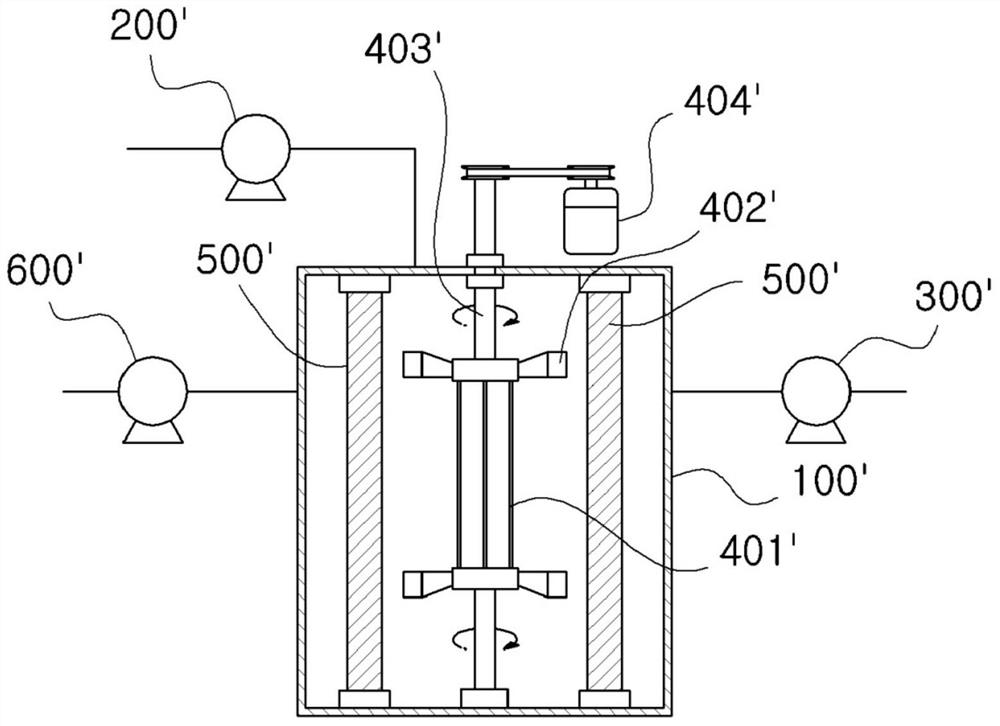

A nanotube array, stainless steel technology, applied in water/sewage treatment, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of huge economic burden of treatment cost and time, complicated treatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

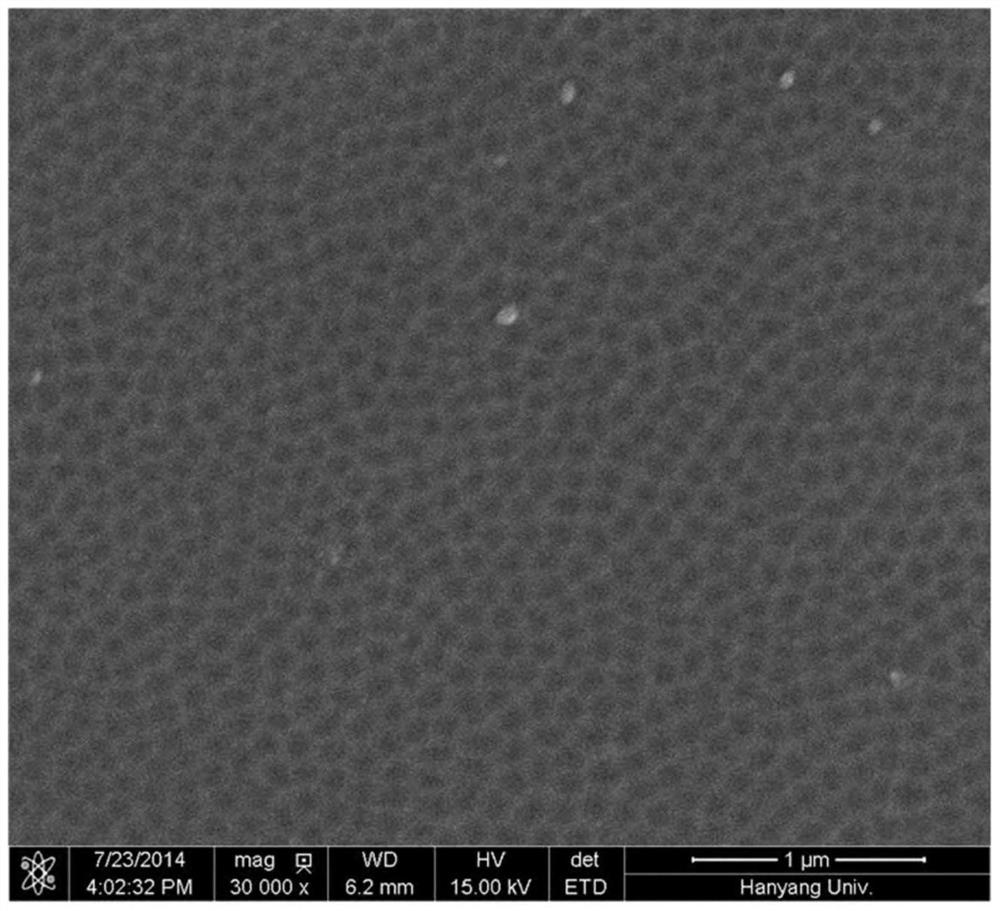

preparation example 1

[0070] The stainless steel (304L) film was cut into a size of 10 mm × 10 mm, which is favorable for anodic oxidation and electroreduction. Remove possible impurities such as organic substances from the surface of the stainless steel film by physical / chemical etching. Clean the etched stainless steel film with distilled water and ethanol. Sandpaper was used for physical etching, and a solution of hydrofluoric acid, nitric acid, and distilled water (1:4:5, v / v / v) was used for chemical etching. Chemical etching was performed within 30 seconds to prevent the formation of metal defects and the generation of toxic gases caused by hydrogen embrittlement. Formation of nanotubes on a stainless steel surface pretreated using an anodizing system. A 5% by volume solution of perchloric acid (70%) in ethanol was used as electrolyte for the anodic oxidation. Anodizing was performed using a power supply system (EP1605, PNCYS) under constant voltage conditions. A thin film of stainless ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com