Anti-freezing cooling liquid and preparation thereof

A technology of antifreeze coolant and coolant, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor storage stability and inhibition effect, and achieve the effects of improving stability, inhibiting precipitation, and improving inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

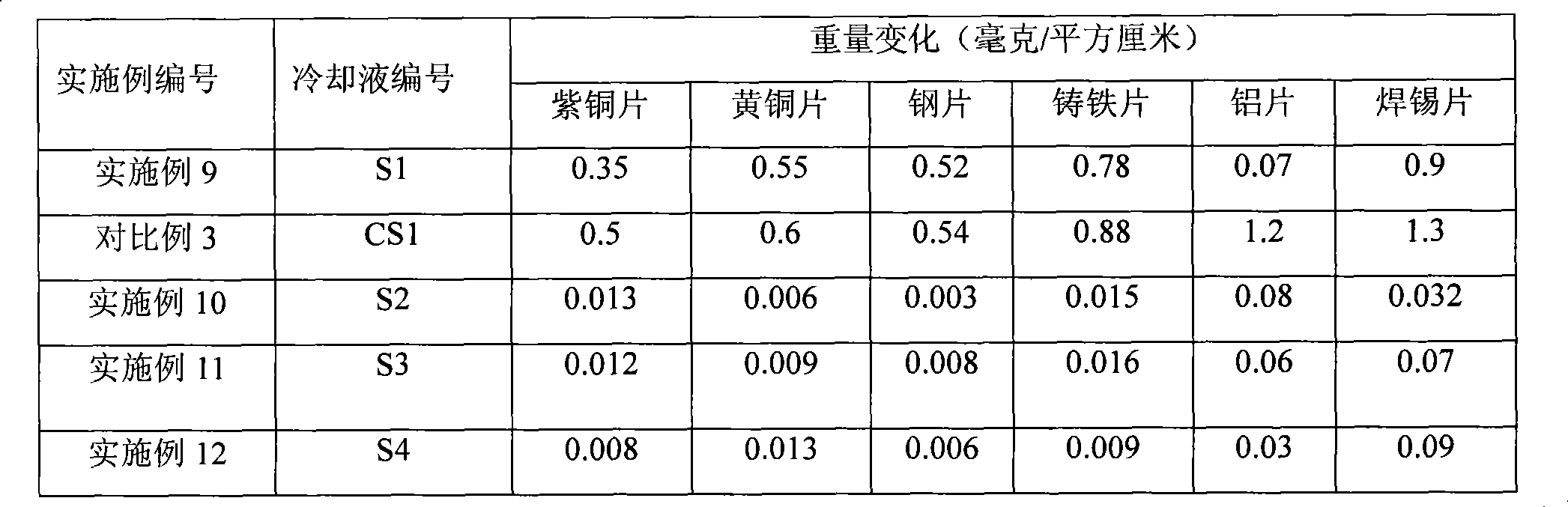

Examples

preparation example Construction

[0015] The invention also provides a method for preparing the antifreeze cooling liquid, wherein the method comprises uniformly mixing ethylene glycol, water, sebacic acid, sodium silicate, cinnamic acid, mannitol and an antifoaming agent.

[0016] Preferably, the method comprises uniformly mixing ethylene glycol and water at a mixing temperature of 40-80° C., then adding sebacic acid, sodium silicate, cinnamic acid and mannitol and mixing evenly at a mixing temperature of 40-80° C. °C, adjust the pH value to 7-11, and then add a defoamer to obtain a cooling liquid.

[0017] According to the present invention, the method for adjusting the pH value to 7-11 is well known to those skilled in the art, for example, the pH value can be adjusted by adding sodium hydroxide and / or potassium hydroxide, preferably, the pH value is adjusted to 8 -10.

[0018] According to the preparation method of the present invention, ethylene glycol, water, sebacic acid, sodium silicate and antifoamin...

Embodiment 1

[0023] This embodiment is used to illustrate the antifreeze coolant provided by the present invention.

[0024] 100 parts by weight of water and 90 parts by weight of ethylene glycol are mixed evenly, and the mixing temperature is 60 ° C, and then sequentially add 0.6 parts by weight of sodium silicate, 0.05 parts by weight of cinnamic acid, 0.5 parts by weight of mannitol and 0.8 parts by weight of 2 parts of sebacic acid were mixed evenly, and sodium hydroxide was added to adjust the pH value to 7, and then 0.04 parts by weight of defoamer OF50 (Beijing Shijingshan Hangping Organosilicon Factory) was added to obtain antifreeze coolant S1.

Embodiment 2

[0028] This embodiment is used to illustrate the antifreeze coolant provided by the present invention.

[0029] Mix 100 parts by weight of water and 100 parts by weight of ethylene glycol uniformly at 40°C, then add 0.2 parts by weight of benzotriazole, 1.2 parts by weight of borax, and 2.0 parts by weight of sodium silicate , 0.5 parts by weight of sodium benzoate, 0.05 parts by weight of cinnamic acid, 0.05 parts by weight of mannitol, 0.5 parts by weight of sodium nitrate, 1.0 parts by weight of sebacic acid and 0.15 parts by weight of disodium diethylamine tetraacetate mixed uniformly , adding potassium hydroxide to adjust the pH value to 11, and then adding 0.05 parts by weight of tributyl phosphate to obtain antifreeze coolant S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com