Aluminum alloy plate water-soluble stamping oil

An aluminum alloy plate, water-soluble technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of easy corrosion, discoloration and dark color on the surface of the workpiece, and achieve excellent extreme pressure, lubricity, and low odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

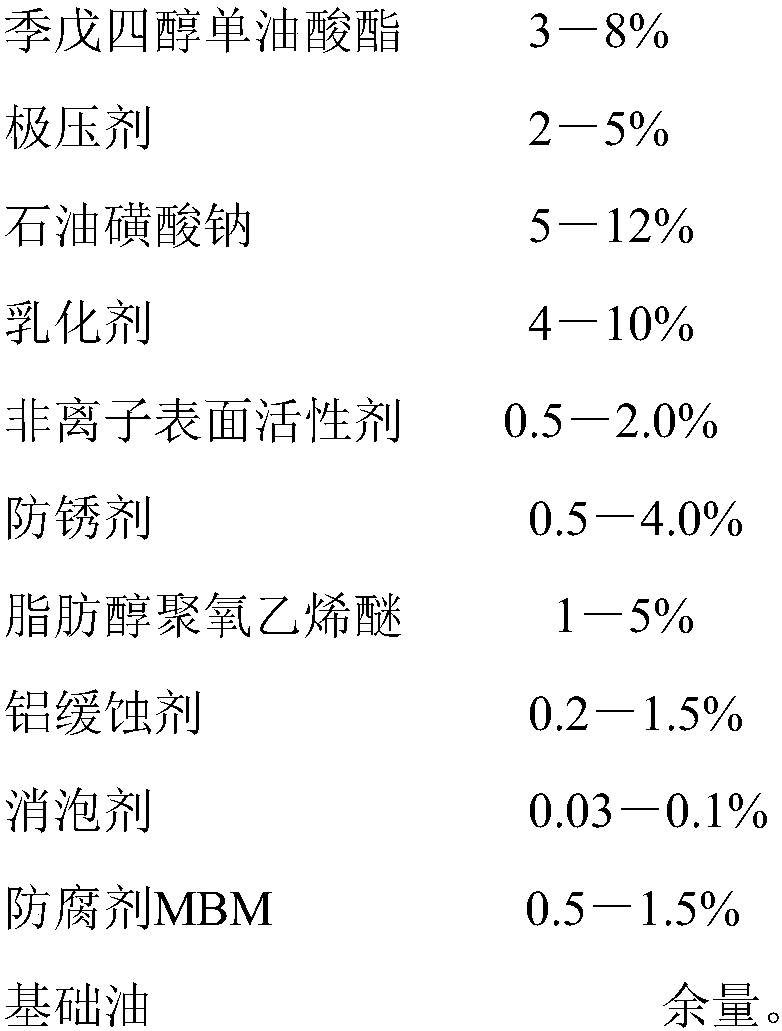

[0020] A kind of water-soluble stamping oil for aluminum alloy plate, its raw material components and weight are respectively:

[0021]

[0022] The preparation method of the above-mentioned aluminum alloy plate water-soluble stamping oil is:

[0023] Mix all raw materials according to the ratio, stir evenly, and let stand for 20 minutes to get the finished product. Example 2:

Embodiment 2

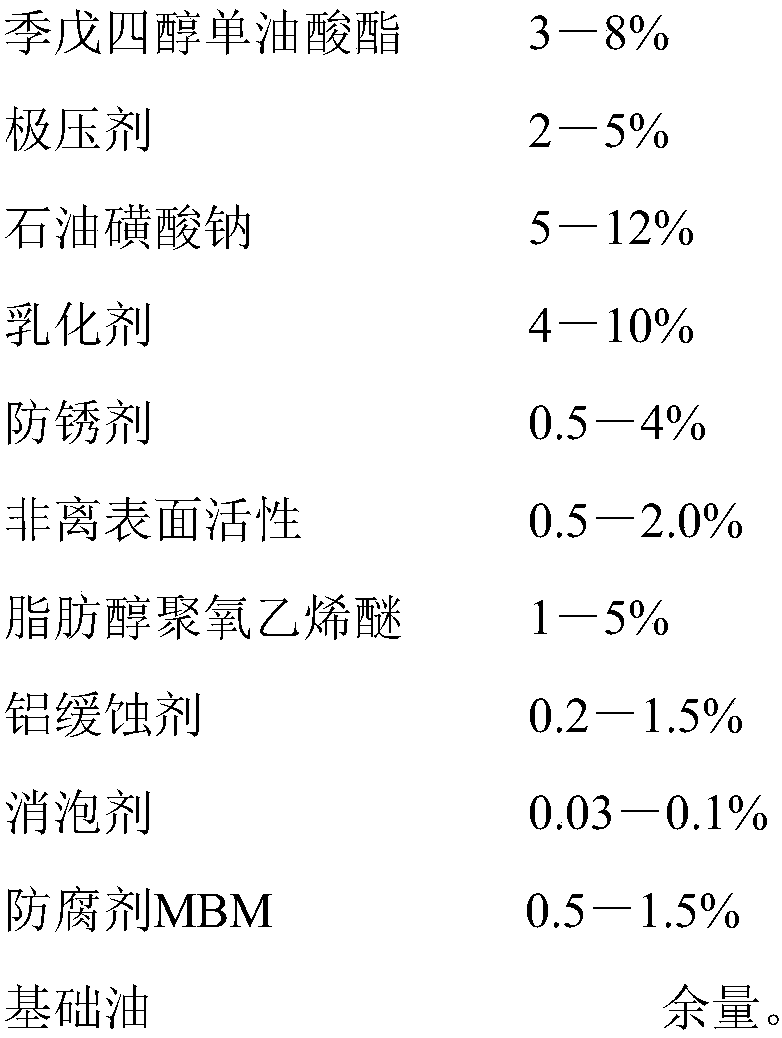

[0024] A kind of water-soluble stamping oil for aluminum alloy plate, its raw material components and weight are respectively:

[0025]

[0026] The preparation method of the above-mentioned water-soluble stamping oil for aluminum alloy sheet is the same as that in Example 1.

Embodiment 3

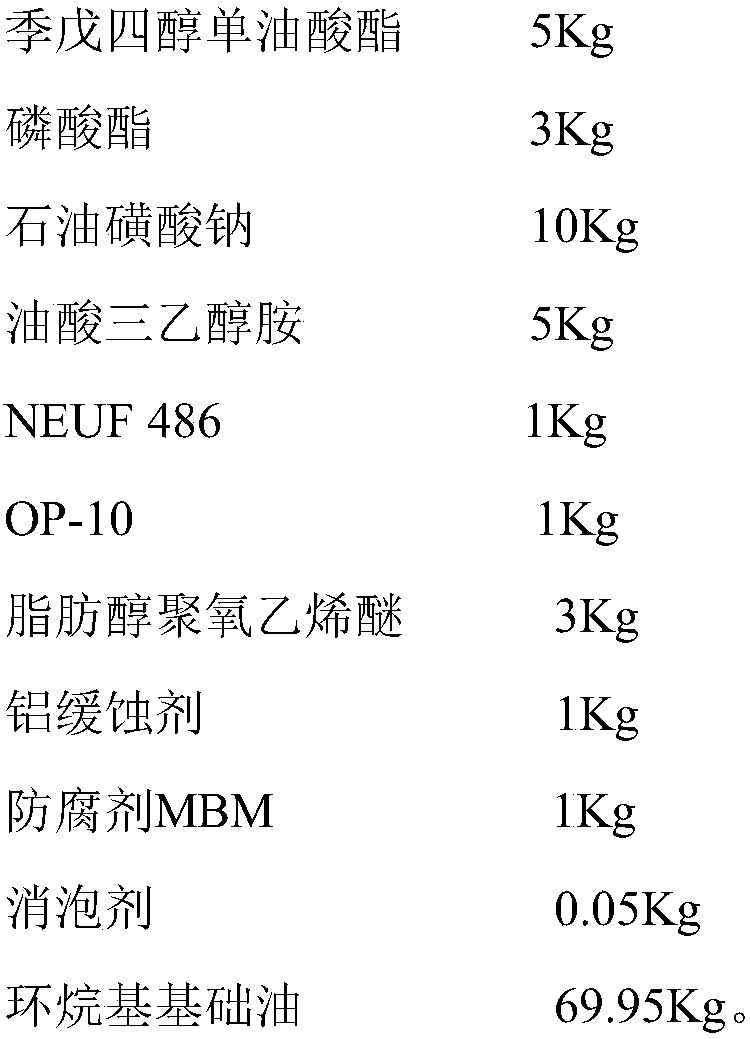

[0028] A kind of water-soluble stamping oil for aluminum alloy plate, its raw material components and weight are respectively:

[0029]

[0030] The preparation method of the above-mentioned water-soluble stamping oil for aluminum alloy sheet is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com