Patents

Literature

35results about How to "Does not affect ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

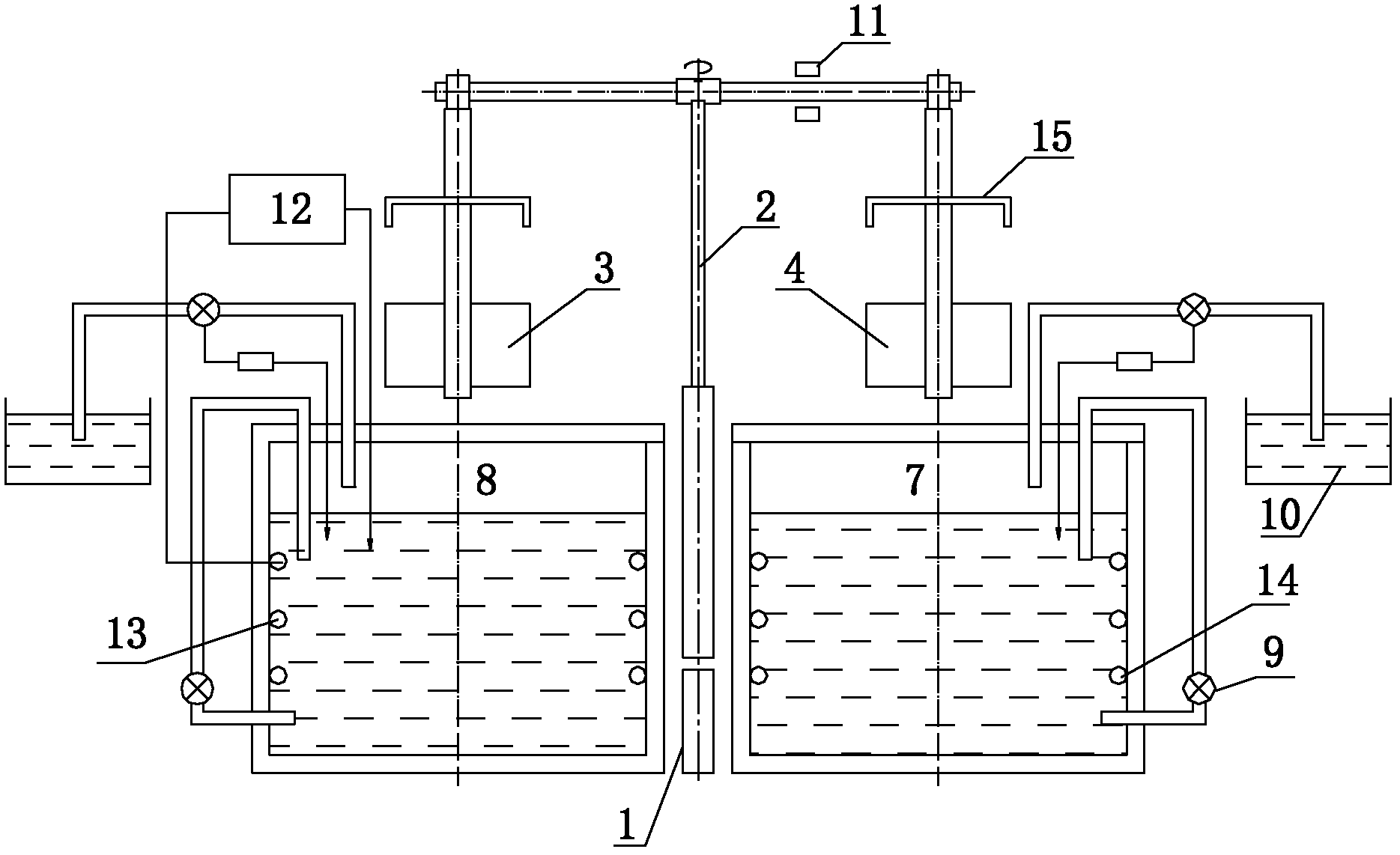

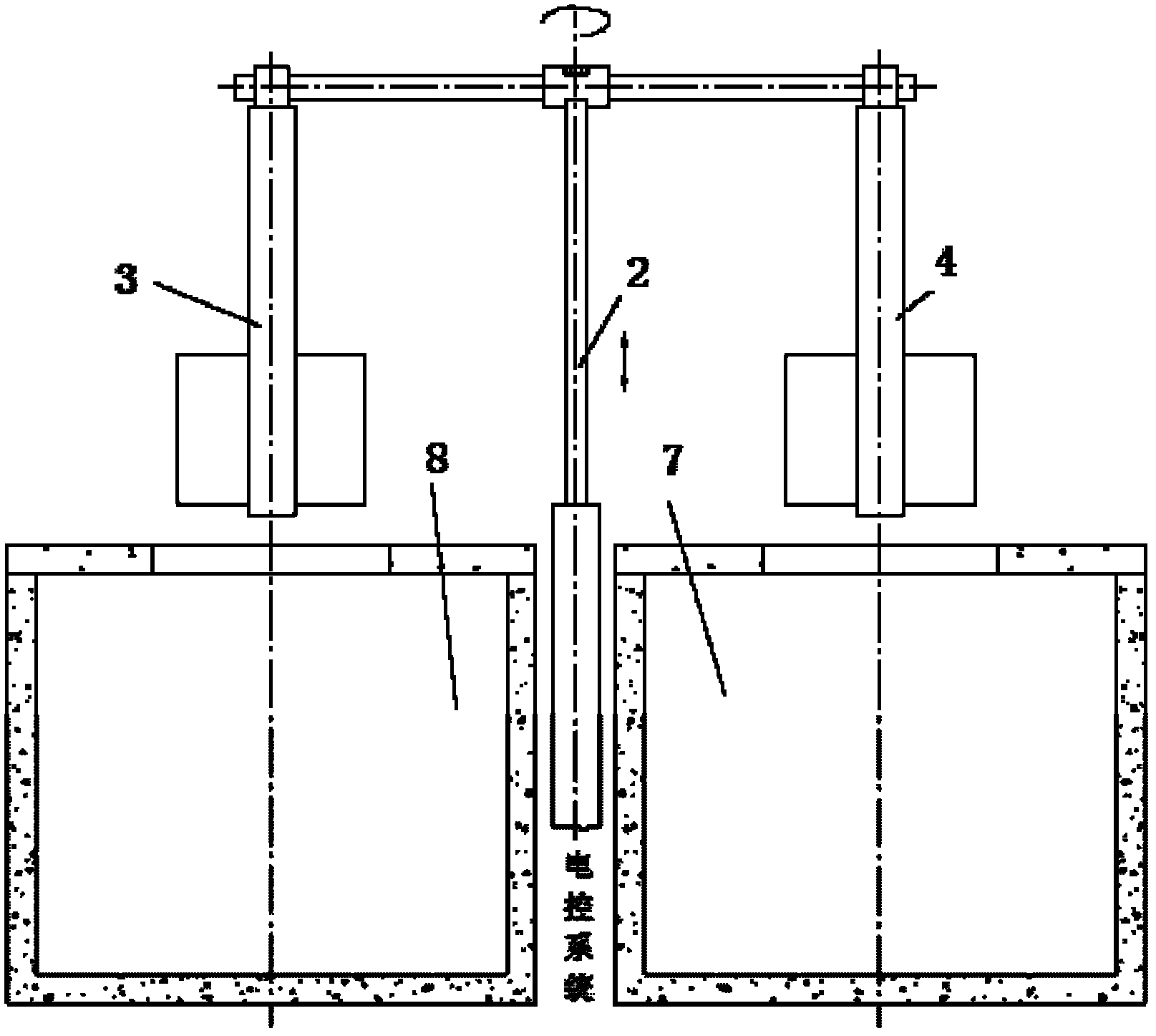

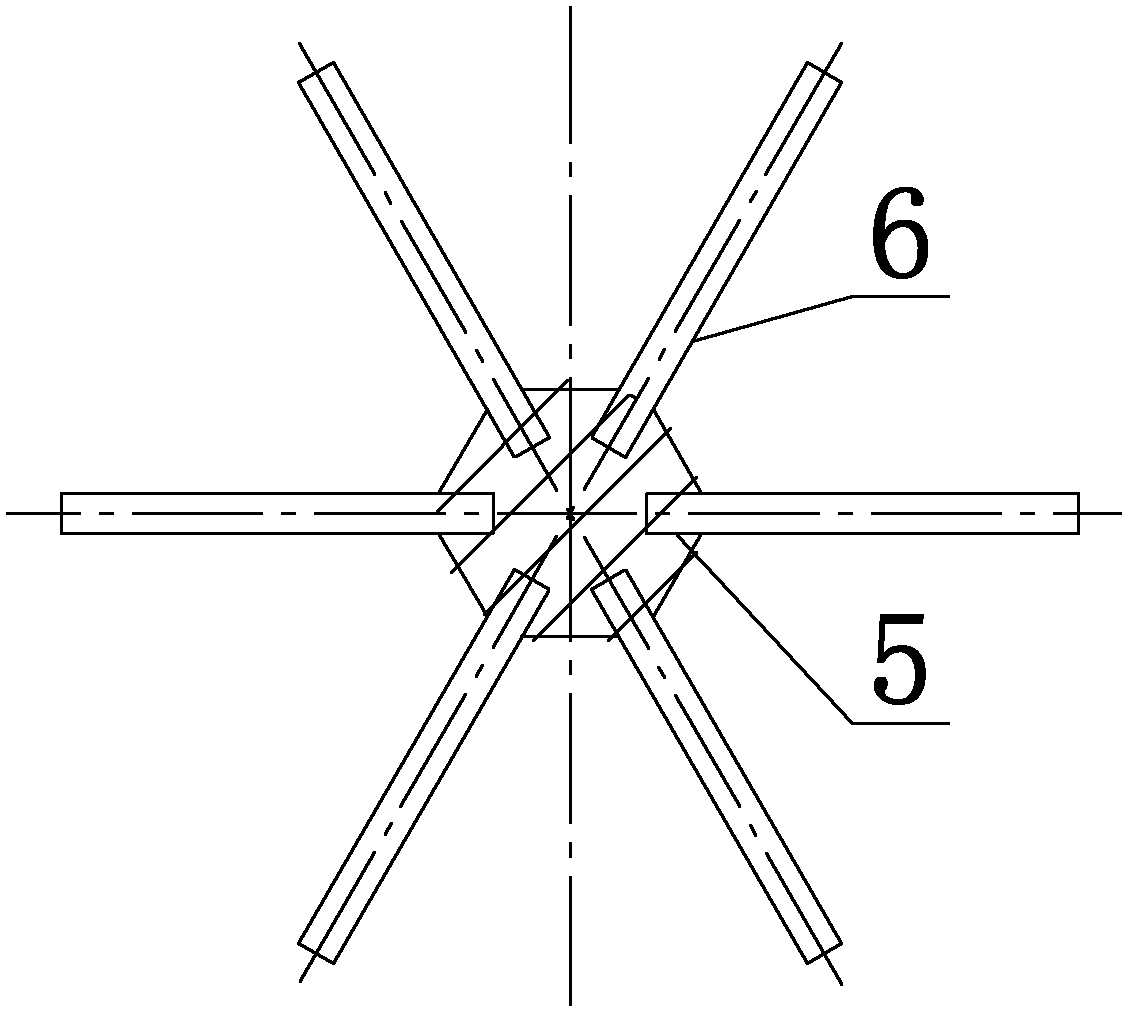

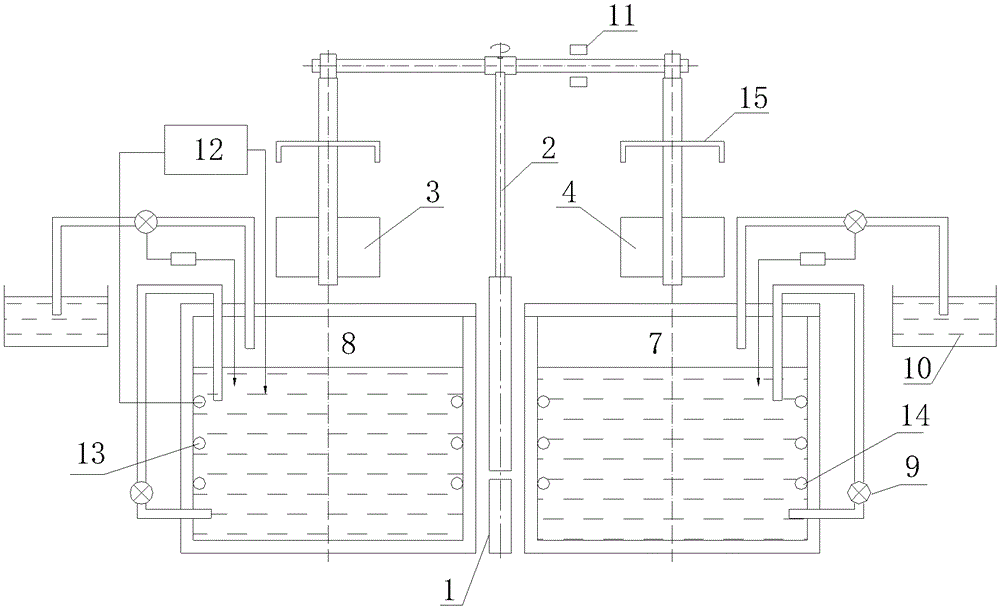

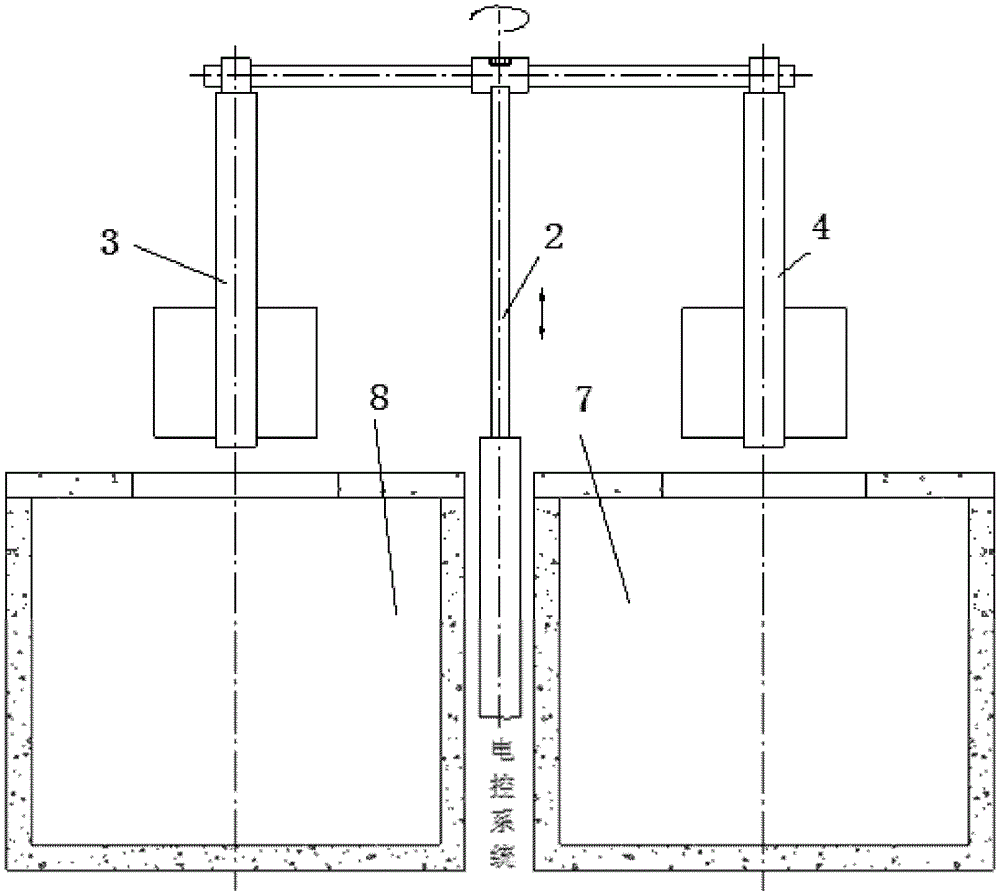

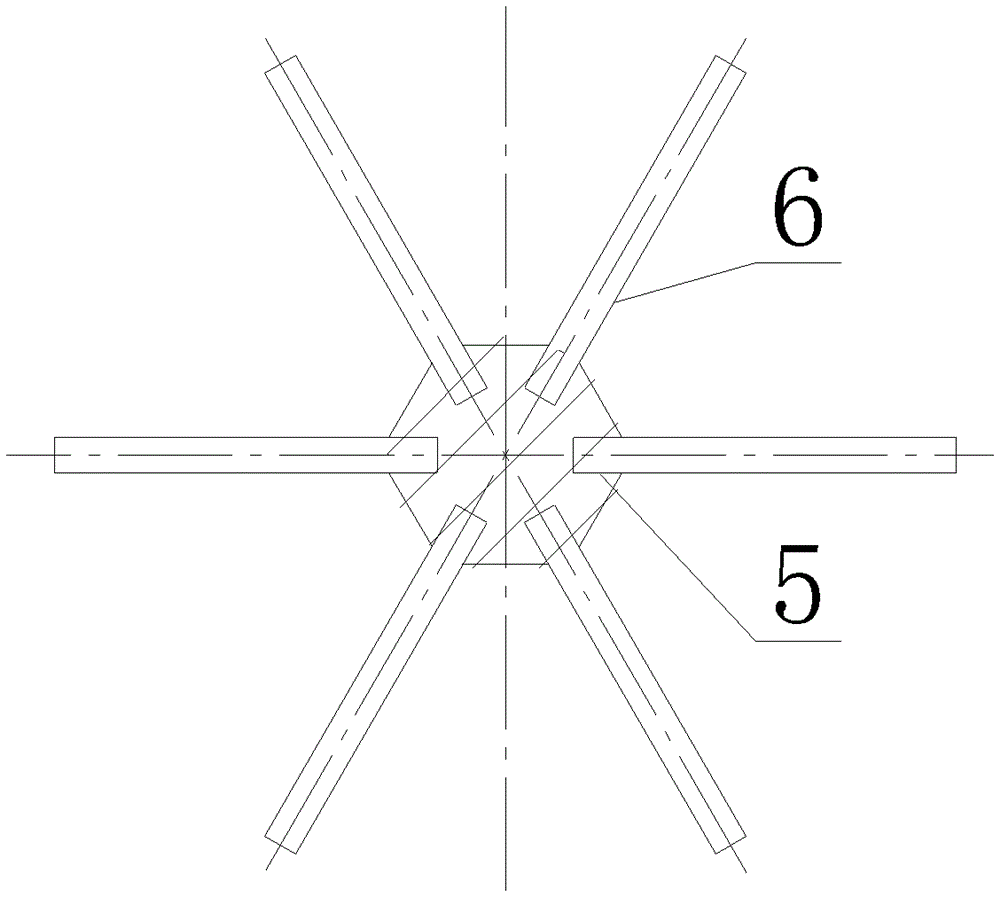

Protection material hot-cold pulse fatigue resistance test apparatus

InactiveCN103257104APerformance pros and consHigh temperature control accuracyWeather/light/corrosion resistanceUsing mechanical meansEngineeringElectric control

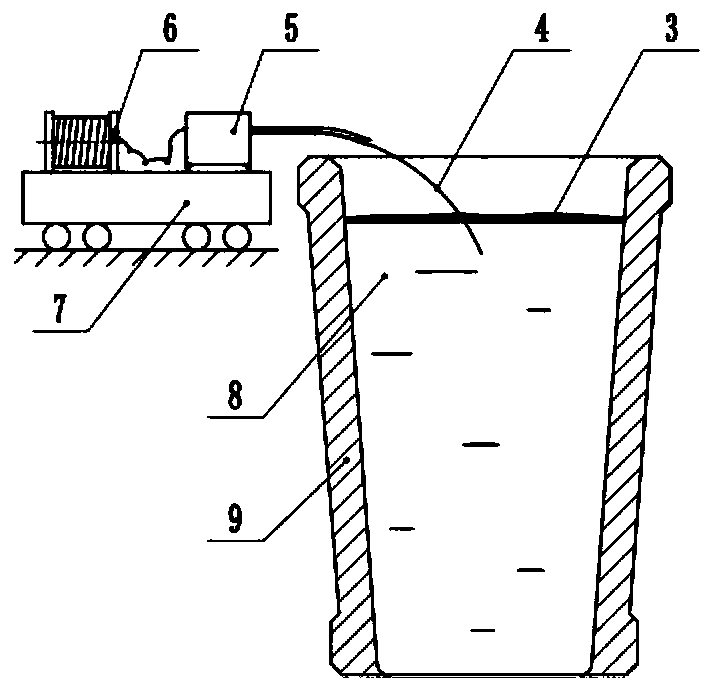

A protection material hot-cold pulse fatigue resistance test apparatus includes an electric control system (1), an elevating rotation device (2), sample supports and test tanks wherein the electric control system (1) and the elevating rotation device (2) are connected into one; the sample supports are fixedly arranged on the elevating rotation device (2) having a rotary axis arranged in the vertical direction, and sample slots (5) used for disposing a sample (6) are fixedly arranged on the sample supports; and the test tanks used for disposing the sample (6) are arranged below the rotation paths of the sample supports outside the rotary axis of the elevating rotation device (2). The apparatus has the advantages of high automation degree, good temperature stability and excellent technological effects.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Sheep feed for promoting milk production

InactiveCN105918630ARich in nutrientsPromote secretionFood processingAnimal feeding stuffSodium bicarbonateSelenium methionine

The invention discloses sheep feed for promoting milk production. The sheep feed comprises, by weight, 15-25 parts of corn powder, 10-15 parts of barley, 10-20 parts of soybean meal, 8-10 parts of red biogas residues, 0.4-0.6 parts of sodium chloride, 12-16 parts of beer residues, 0.5-1 part of yeast, 0.3-0.5 parts of selenium methionine, 20-30 parts of clover silage, 15-20 parts of soya straws, 10-15 parts of cucurbit seedlings, 10-15 parts of peanut seedlings, 1.5-2.5 parts of a premix for sheep, 0.2-0.3 parts of sodium bicarbonate and 10-20 parts of an additive. The additive comprises beet pulp, fermented apple slag, sophora bud extract, soybean powder, tomato peel silage, seeds of cowherb, corn silks, radix astragali, ligusticum wallichii and licorice root. The sheep feed can promote lactation, improve inflammatory, virus and bacterium resistance and improve sheep immunity, has comprehensive nutrition and enough energy, has no toxic and side effects and does not produce drug resistance.

Owner:丁永胜

High-purity Mg-Ca sand and preparation method thereof

The invention discloses high-purity Mg-Ca sand and a preparation method thereof. The high-purity Mg-Ca sand is prepared mainly from 17 to 62% of lightly calcined dolomite, 20 to 65% of lightly calcined dolomite Mg powder, 15 to 25% of a mixture of a binder and bittern, and 2 to 5% of electric-melting zirconia. The preparation method comprises the following steps of raw material proportioning, raw material blending, ball milling, wet method-based mixing, pressing pelleting, natural drying, sintering and discharging. The high-purity Mg-Ca sand has high green-pressing ball strength, high post-sintering compactness, excellent hydration resistance, high purity and low stable zirconia content and thus a brick prepared from the high-purity Mg-Ca sand has low impurity content and excellent thermal shock resistance. The brick prepared from the high-purity Mg-Ca sand contains a large amount of CaO and thus the brick has excellent molten steel cleaning performances and is especially suitable for production of high-cleanliness steel such as stainless steel.

Owner:PERFECT WORLD CO LTD

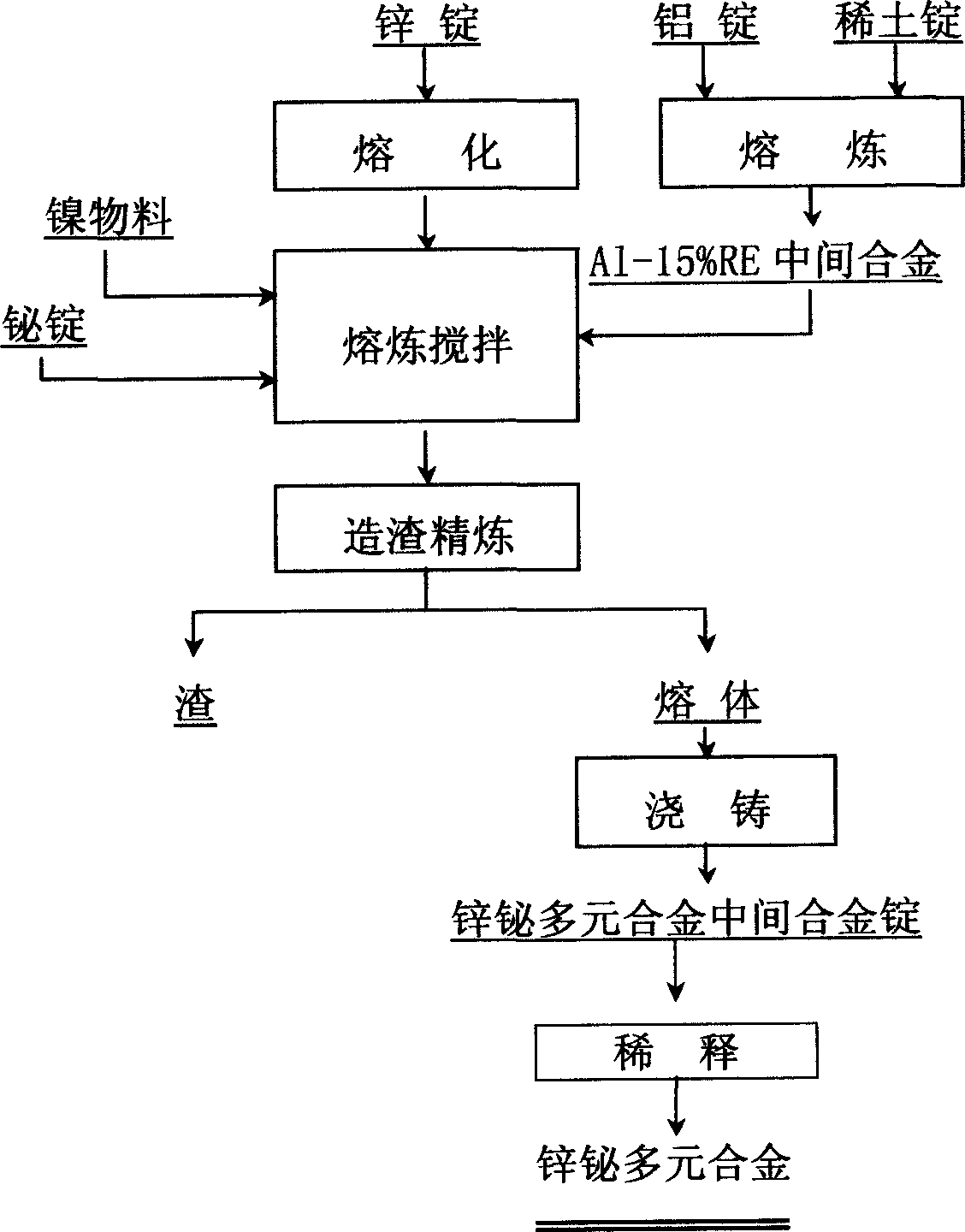

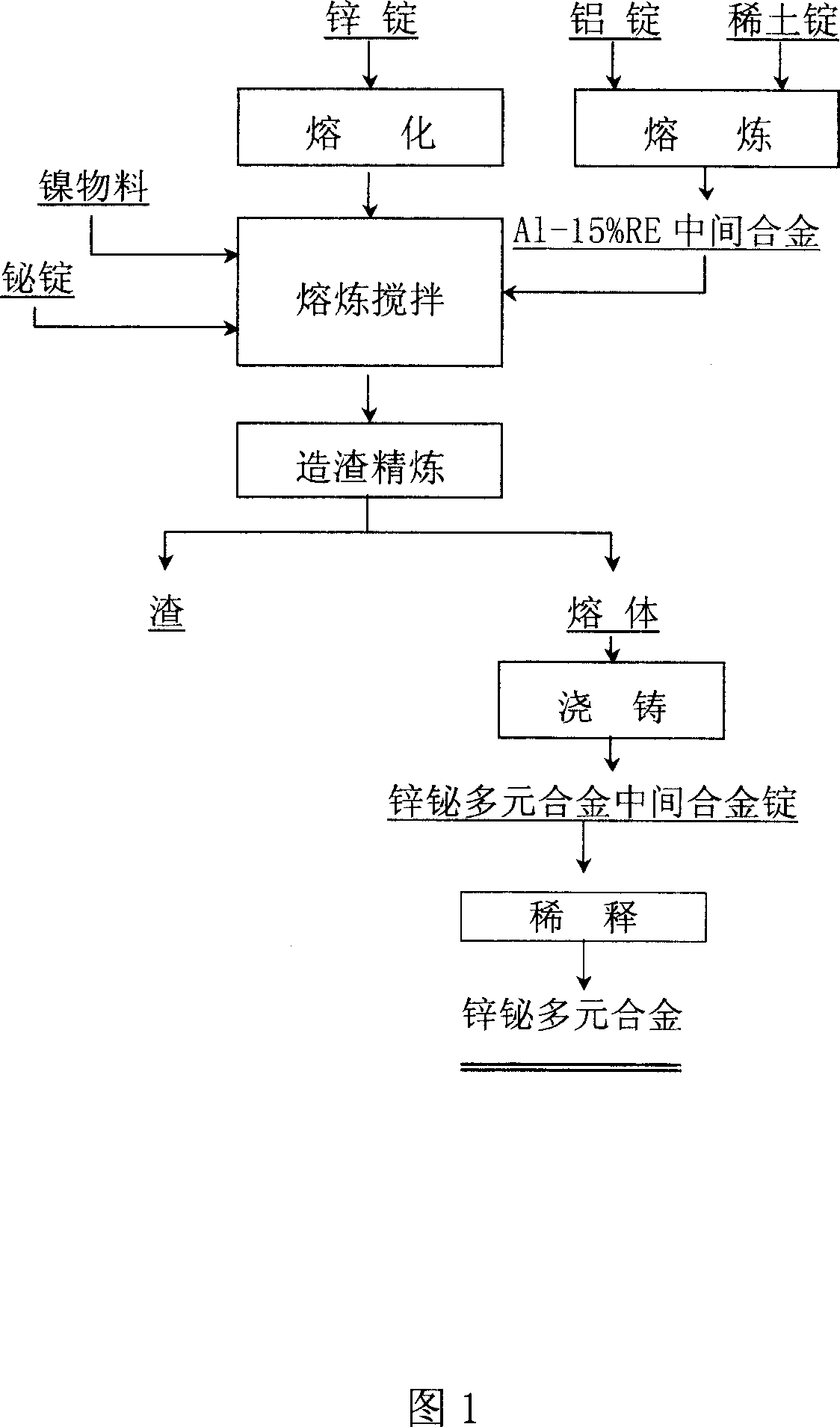

Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

The present invention relates to production of zinc alloy. The technological scheme of producing Zn-Bi alloy includes first compounding intermediate alloy with alloy ingot and RE ingot at the smelting temperature of 750-850 deg.c, subsequent smelting zinc ingot at 550-650 deg.c and adding nickel material and final adding bismuth ingot to form the polynary Zn-Bi alloy. The said process can avoid the burning loss of RE metal to avoid waste, may have certain amount of Al-RE intermediate alloy added to form different alloys, and has smelting and stirring time over 15 min to reach effect of homogeneous mixing. The present invention uses preferably inducing furnace as smelting apparatus and the product has stable and homogeneous alloy element components, high alloy element utilization and clean and environment friendly production process.

Owner:株洲冶炼集团有限责任公司

Feed capable of promoting milk secretion of sheep

InactiveCN105941877AIncrease milk productionRich in nutrientsFood processingAnimal feeding stuffBiotechnologyPeanut meal

The invention discloses a feed capable of promoting milk secretion of sheep. The feed is prepared from the following raw materials in parts by weight: 20-30 parts of corn flour, 10-15 parts of cassava residues, 8-10 parts of green bran, 10-15 parts of rapeseed meal, 0.5-0.8 part of sodium chloride, 10-15 parts of fermented distiller's grains, 0.2-0.4 part of yeast selenium, 10-15 parts of tomato powder, 20-30 parts of silage grass powder, 10-15 parts of corn straw, 10-20 parts of silage alfalfa, 15-20 parts of wheat straw, 1-2 parts of a premix for sheep, 0.3-0.4 part of calcium carbonate and 15-25 parts of an additive, wherein the additive is prepared from the following raw materials of black bean powder, fermented citrus residues, a hypericum ascyron extract, peanut meal, medulla tetrapanacis, radix bupleuri, radix angelicae sinensis and licorice roots. The feed disclosed by the invention is comprehensive in nutrients and sufficient in energy, can promote milk secretion, can strengthen the capacity of resisting inflammation, resisting bacteria and resisting viruses, can enhance the resistibility of the sheep, can promote growth, is free from toxic and side effects, and does not generate drug resistance.

Owner:丁永胜

Preparation method of seepage-proof castable

The invention belongs to the field of refractory materials and relates to a preparation method of a seepage-proof castable. The castable comprises the following raw materials by weight percent: 63-69wt% of alumina particles with sizes of 8-0mm, 18-21wt% of aluminium nitride fine powder with particle size less than 0.044mm, 4-7wt% of pure calcium aluminate cement with particle size less than 0.074mm and 5-6wt% of silicon dioxide micro powder with D90 equivalent to 0.1mu m. The castable is characterized in that a compound of BaSO4, TiB2, SrTiO3 and Na3AlF6 is adopted as a molten aluminum wetting resisting agent; the addition of the compound is 1-6wt%; 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate are added as dispersing agents; alumina sol serves as construction liquid. The prepared castable has enough strength, excellent thermal shock resistance and good volume stability and chemical stability, is mainly resistant to molten aluminum wetting, has good thermal stability, is resistant to molten aluminum corrosion, does not affect the components of molten aluminium and has long service life.

Owner:秦皇岛市首耐新材料有限公司

Method for preparing castable materials

The invention belongs to the field of fireproof materials, and relates to a method for preparing silicon carbide castable materials resistant to molten aluminum wetting. The castable materials comprise, by weight, 63% to 69% of corundum particles with the sizes ranging from 8 mm to 10 mm, 18% to 21% of aluminum nitride fine powder with the particle sizes smaller than 0.044 mm, 4% to 7% of pure calcium aluminate cement with the particle sizes smaller than 0.074 mm, 5% to 6% of silicon dioxide fine powder with the D90 equal to 0.1 micrometer, 1% to 6% of the combination of BaSO4, TiB2, SrTiO3 and Na3AlF6, 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate, wherein the combination is used as molten aluminum wetting resistant agents, the sodium tripolyphosphate and the sodium hexametaphosphate are added to serve as dispersing agents, and alumina sol serves as construction liquid. The castable materials prepared with the method have the sufficient strength, are excellent in thermal shock resistance, good in size stability and good in chemical stability, most importantly, are resistant to molten aluminum wetting, good in thermal stability, resistant to molten aluminum erosion, free of influencing molten aluminum ingredients and long in service life.

Owner:南通新兴机械制造有限公司

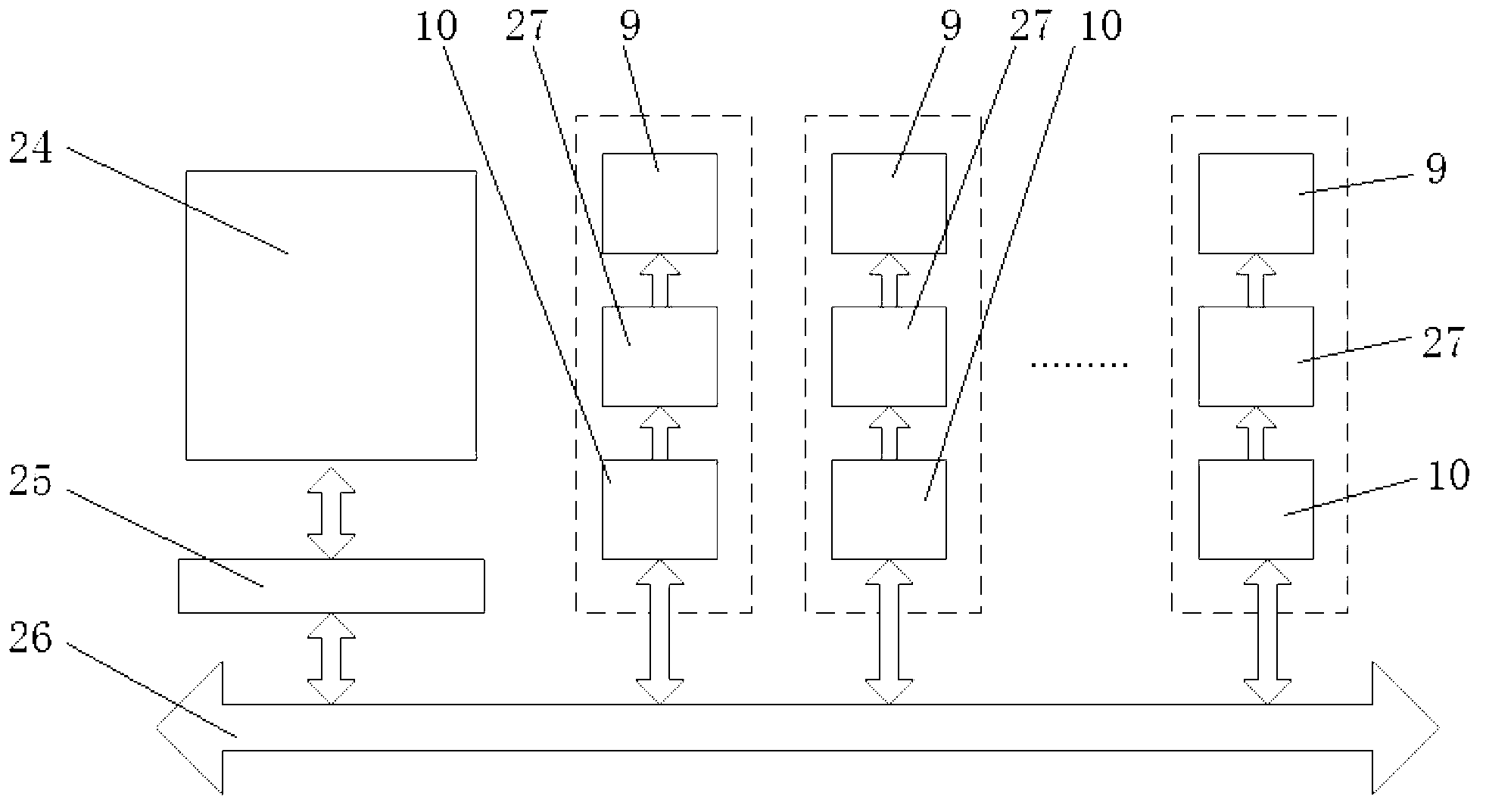

Cluster-type water temperature control system for floating tobacco seedling growing pond

InactiveCN103299892AUniform water temperatureWill not affect the totalAgriculture gas emission reductionCultivating equipmentsControl systemEngineering

A cluster-type water temperature control system for a floating tobacco seedling growing pond comprises an external heat exchange type water pond heating device, a plurality of independent water pond water temperature controllers, a control bus and a central control computer, wherein the external heat exchange type water pond heating device is used for heating a water pond; as an external heat exchange type heating mode is adopted, all parts are mounted outside the seedling growing pond, and the modifying and mounting operations are convenient on the basis of a conventional seedling growing pond; the independent water pond water temperature controllers are used for accurately controlling the water temperature of a single seedling growing pond by controlling a combined action of an electromagnetic valve and a circulating water pump; and the independent water pond water temperature controllers are connected with the central control computer through the control bus to form a cluster-type control system for achieving centralized monitoring. By using the system, the water temperature of the floating seedling growing pond can be adjusted to an optimal seedling growth temperature, so that the seedling growing time is shortened, the tobacco seedling quality is improved, and the purposes of improving productivity and efficiency are achieved; and the system has the advantages of convenience for mounting and use, preciseness for control, high automation level and the like.

Owner:HUNAN AGRICULTURAL UNIV

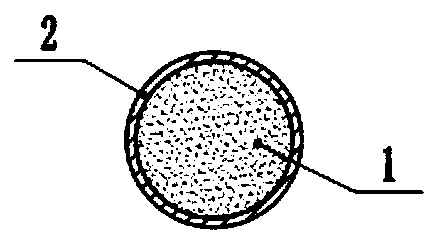

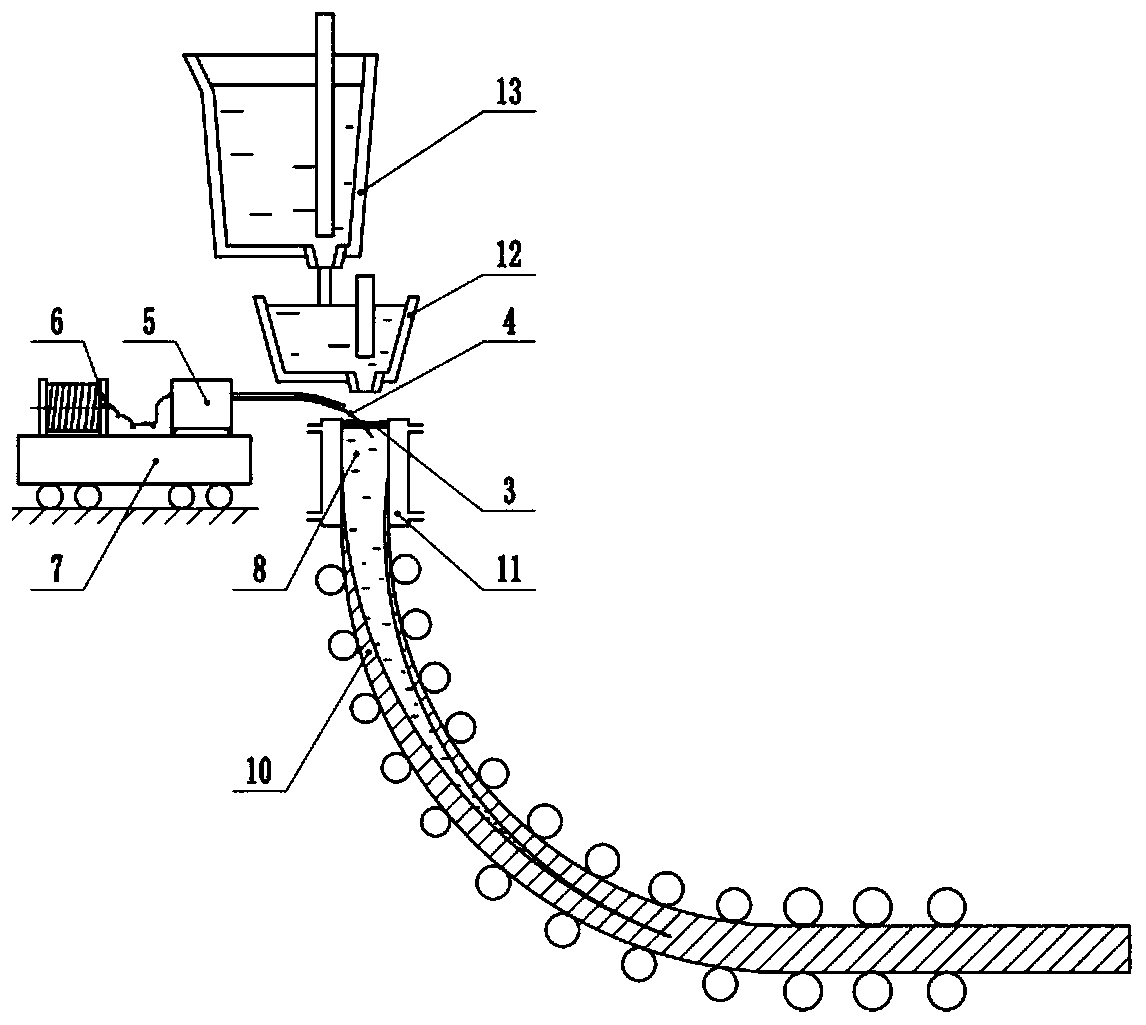

Alloy cored wire capable of lowering superheat degree of molten steel and use method thereof

The invention relates to the technical field of steel casting, in particular to an alloy cored wire capable of lowering the superheat degree of molten steel and a use method thereof. The alloy cored wire provided by the invention comprises inorganic heat-absorbing materials of a core, and an outside metal shell. The alloy cored wire is fed into a crystallizer or the molten steel in an ingot mold through a wire feeder in the casting process. The metal shell of the alloy cored wire melts gradually and enters the molten steel (components of the molten steel are not influenced), the heat-absorbingmaterials of the core absorb sensible heat to melt and float up to the surface at the same time, thus the superheat degree of the molten steel is lowered, the cooling rate of the molten steel is increased, and finally the target of improvement of quality of casting blanks is achieved.

Owner:SHANGHAI UNIV

Preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material

The invention discloses a preparation method of polyethylene glycol repaired graphene reinforced aluminum-based composite material, and relates to the preparation method of graphene reinforced aluminum-based composite material. The preparation method aims to solve a problem that grinding aid is residual in an aluminum alloy matrix, and realize self-repairing of the graphene. The preparation methodcomprises the step 1 of weighing the graphene, the polyethylene glycol and aluminum metal powder; the step 2 of putting the material obtained in the step 1 into a ball milling tank for ball milling;the step 3 of cold pressing; and the step 4 of preparing the composite material after the cold pressing. The grinding aid, polyethylene glycol is subjected to thermal decomposition to generate activeC atoms, and the C atoms can adsorb on the pits of the graphene, so that integrity of the graphene structure is greatly improved, good interface connection is formed, and overall performance of the material is greatly improved; the polyethylene glycol is beneficial to flake formation of the aluminum metal powder, so that a problem of high dispersion difficulty of the single-layer or few-layer graphene in the aluminum-based composite material is solved, and cold welding between the aluminum metal powders is reduced; polyethylene glycol is easy to remove, and the prepared few-layer graphene reinforced aluminum-based composite material is excellent in comprehensive performance. The method is suitable for preparing the graphene reinforced aluminum-based composite material.

Owner:HARBIN INST OF TECH

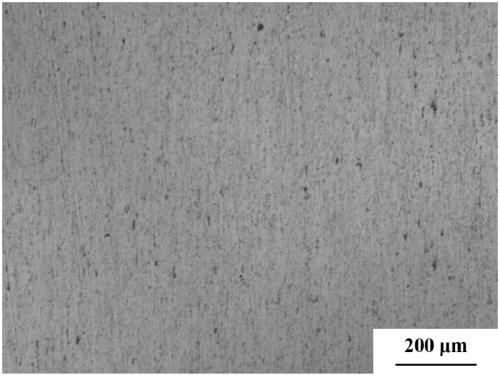

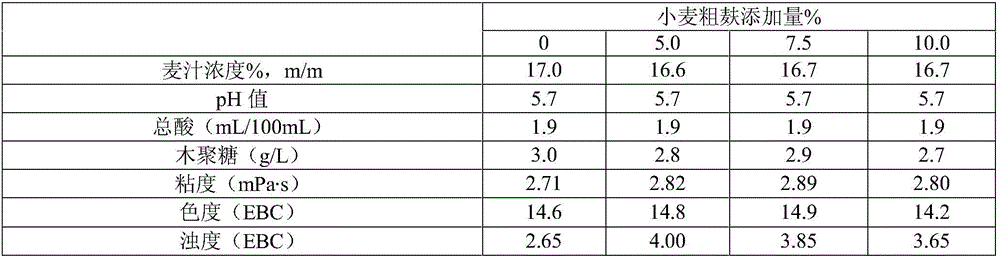

Method for preparing full wheat malt turbid beer wheat juice

ActiveCN106497714ADoes not affect ingredientsDoes not affect flavorWort preparationFilter mediaWaste treatment

The invention relates to a method for preparing full wheat malt turbid beer wheat juice. Wheat bran serves as a filter medium in the preparation process of the full wheat malt wheat juice, the wheat juice obtained through filtering has a good quality index, and the filtering time is identical with that of common wheat juice. A filtering tank is adopted for filtering out pure wheat malt wheat dregs, and development and production of a new beer product are achieved on the premise of not changing technological parameters or increasing fixed assets and avoiding three waste treatment expenses. The method is easy to operate, filtering of all mash can be completed at a time, and the wheat juice is high in quality. The method is simultaneously suitable for preparing the wheat turbid beer wheat juice large in wheat malt use amount.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

High-efficiency slag collecting agent

InactiveCN105925748ASimple structureImprove propertiesProcess efficiency improvementSlagThermal insulation

The invention discloses a high-efficiency slag collecting agent which is prepared from the following components: clay, modified perlite, coal ash, forsterite powder, mullite powder, hollow glass microsphere powder, zeolite powder and palygorskite powder. The slag collecting agent provided by the invention has good spreadability, resists high temperature, has favorable heat-resistance and thermal-insulation effects, keeps a nodulizing process stable, has a high slag removal ratio and does not affect the components of molten iron; iron slag is fragile after being cooled, so that the iron slag is convenient to recover and the loss of the molten iron is can be reduced; and the slag collecting agent can change the form of desulfurized slag to reduce the slag content of the molten iron entering a converter and the phenomenon of molten iron resulfurization, the loss of iron is reduced by an average of 44%, and on average, the desulfurized molten iron contains about 0.007% of sulfur.

Owner:HEFEI CITY TENVER PRECISION CASTING

High-performance slag collecting agent

InactiveCN105925747AImprove structure and propertiesGood slag collecting performanceProcess efficiency improvementThermal insulationSlag

The invention discloses a high-performance slag collecting agent which is prepared from the following components: clay, modified perlite, straw ash, forsterite powder, pottery clay powder, zeolite powder, sepiolite powder, mullite powder, hollow glass microsphere powder, pyrophillite powder and palygorskite powder. The slag collecting agent provided by the invention resists high temperature, has favorable heat-resistance and thermal-insulation effects, keeps a nodulizing process stable, has high slag removal efficiency and does not affect the components of molten iron; iron slag is fragile after being cooled, so that the iron slag is convenient to recover and the loss of the molten iron is can be reduced; and the slag collecting agent can change the form of desulfurized slag to reduce the slag content of the molten iron entering a converter and the phenomenon of molten iron resulfurization, the loss of iron is reduced by an average of 48%, and on average, the desulfurized molten iron contains about 0.061% of sulfur.

Owner:HEFEI CITY TENVER PRECISION CASTING

Method for preparing ceramic coating for replacing refractory coating prepared with centrifugal cast-steel pipe thermal mold method

The invention discloses a method for preparing a ceramic coating for replacing a refractory coating prepared with a centrifugal cast-steel pipe thermal mold method. The method comprises the following steps of: adding water into a ceramic coating raw material to obtain slurry; coating the slurry onto the inner surface of a pipe mold in a flowing way; heating the pipe mold at low temperature for fully evaporating free water; and after the coating is solidified fully, sintering with high-temperature molten steel till crystal waster is released fully to obtain the ceramic coting for replacing therefractory coating prepared with the centrifugal cast-steel pipe thermal mold method. The ceramic coating prepared with the method has the advantages of lowering the production cost, realizing continuous production and not influencing the pipe blank quality.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Preparation method of molten aluminum wetting resistant aluminium nitride castable

The invention belongs to the field of refractory materials and relates to a preparation method of a molten aluminum wetting resistant aluminium nitride castable. The castable comprises the following raw materials by weight percent: 63-69wt% of aluminium nitride particles with sizes of 8-0mm, 18-21wt% of aluminium nitride fine powder with particle size less than 0.044mm, 4-7wt% of pure calcium aluminate cement with particle size less than 0.074mm and 5-6wt% of silicon dioxide micro powder with D90 equivalent to 0.1mu m. The castable is characterized in that a compound of BaSO4, TiB2, SrTiO3 and Na3AlF6 is adopted as a molten aluminum wetting resisting agent; the addition of the compound is 1-6wt%; 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate are added as dispersing agents; alumina sol serves as construction liquid. The prepared castable has enough strength, excellent thermal shock resistance and good volume stability and chemical stability, is mainly resistant to molten aluminum wetting, has good thermal stability, is resistant to molten aluminum corrosion, does not affect the components of molten aluminium and has long service life.

Owner:广东鸿劲金属铝业有限公司

Method for detecting antibiotics in ultra-high temperature instantaneous processed acidic milk drink

InactiveCN101629205ASolve the problem of false negativesMeet the test requirementsMicrobiological testing/measurementLaboratory cultureChemistry

The invention relates to a method for detecting antibiotics in ultra-high temperature (UHT) instantaneous processed acidic milk drink. The method comprises the following steps: adding an alkaline reagent in the UHT acidic milk drink, regulating the pH value of the UHT acidic milk drink to 6.4-6.7 and using an antibiotic residue assay kit for detecting antibiotic residues in the UHT acidic milk drink by using the microbial culture method. The invention can further prepare a positive control milk by taking raw material milk which does not contain antibiotics or antagonists and adding the antibiotics, and the content of the antibiotics is detected with the UHT acidic milk drink with the regulated value of 6.4-6.7 under same conditions.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

A kind of preparation method of castable

The invention belongs to the field of fireproof materials, and relates to a method for preparing silicon carbide castable materials resistant to molten aluminum wetting. The castable materials comprise, by weight, 63% to 69% of corundum particles with the sizes ranging from 8 mm to 10 mm, 18% to 21% of aluminum nitride fine powder with the particle sizes smaller than 0.044 mm, 4% to 7% of pure calcium aluminate cement with the particle sizes smaller than 0.074 mm, 5% to 6% of silicon dioxide fine powder with the D90 equal to 0.1 micrometer, 1% to 6% of the combination of BaSO4, TiB2, SrTiO3 and Na3AlF6, 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate, wherein the combination is used as molten aluminum wetting resistant agents, the sodium tripolyphosphate and the sodium hexametaphosphate are added to serve as dispersing agents, and alumina sol serves as construction liquid. The castable materials prepared with the method have the sufficient strength, are excellent in thermal shock resistance, good in size stability and good in chemical stability, most importantly, are resistant to molten aluminum wetting, good in thermal stability, resistant to molten aluminum erosion, free of influencing molten aluminum ingredients and long in service life.

Owner:南通新兴机械制造有限公司

Preparation method of ceramic coating for replacing refractory coating produced by using centrifugal cast iron pipe heated mould method

ActiveCN102322550ALow costRealize continuous productionRigid pipesCalcium biphosphateSodium metasilicate

The invention discloses a preparation method of a ceramic coating for replacing a refractory coating produced by using a centrifugal cast iron pipe heated mould method. Raw materials of the ceramic coating comprise sintered tabular alundum, calcium phosphate and sodium metasilicate. The preparation method comprises the following steps of: adding water in the raw materials of the ceramic coating to form slurry; coating the slurry on the inner surface of a pipe tie in a flow manner; then heating the pipe die at low temperature to enable free water to be completely evaporated; and after the coating is completely solidified, sintering with high-temperature molten iron until crystallization water is completely released to obtain the ceramic coating for replacing the refractory coating producedby using the centrifugal cast iron pipe heated mould method. The ceramic coating disclosed by the invention has the advantages of reduced production cost, continuous production availability and no influence on the quality of pipe billets.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Heat-preservation slag collecting agent

InactiveCN106048126AImprove structure and propertiesGood slag collecting performanceProcess efficiency improvementSlagPerlite

The invention discloses a heat-preservation slag collecting agent which is prepared from clay, modified perlite, straw ash, sepiolite powder, mullite powder, hollow glass bead powder, pyrophyllite powder and palygorskite powder. The slag collecting agent is good in spreadability and resistant to high temperature, has good heat-resisting and heat-preservation effects, enables the nodulizing process to be stable, is high in deslagging rate and does not affect molten iron ingredients; iron slag is brittle after being cooled and convenient to recover, and molten iron loss can be reduced; and the slag state after removal can be changed, the amount of molten iron slag entering a converter is reduced, the molten iron resulfurization phenomenon is reduced, the average iron loss is lowered by 45%, and the average molten iron sulfur content after removal is about 0.0068%.

Owner:HEFEI CITY TENVER PRECISION CASTING

Preparation method of ceramic coating for replacing refractory coating produced by using centrifugal cast iron pipe heated mould method

ActiveCN102322550BHigh refractorinessDoes not affect ingredientsRigid pipesCalcium biphosphateSodium metasilicate

The invention discloses a preparation method of a ceramic coating for replacing a refractory coating produced by using a centrifugal cast iron pipe heated mould method. Raw materials of the ceramic coating comprise sintered tabular alundum, calcium phosphate and sodium metasilicate. The preparation method comprises the following steps of: adding water in the raw materials of the ceramic coating to form slurry; coating the slurry on the inner surface of a pipe tie in a flow manner; then heating the pipe die at low temperature to enable free water to be completely evaporated; and after the coating is completely solidified, sintering with high-temperature molten iron until crystallization water is completely released to obtain the ceramic coating for replacing the refractory coating producedby using the centrifugal cast iron pipe heated mould method. The ceramic coating disclosed by the invention has the advantages of reduced production cost, continuous production availability and no influence on the quality of pipe billets.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method for preparing aluminum-liquid wetting resisting silicon carbide castable

The invention relates to a method for preparing aluminum-liquid wetting resisting silicon carbide castable, belonging to the field of the refractory material. The silicon carbide castable comprises the following raw materials by weigh percent: 63-69 percent of silicon carbide particles of 0-8 mm, 18-21 percent of fine silicon carbide powder of less than 0.044 mm, 4-7 percent of pure calcium aluminate cement of less than 0.074 mm and 5-6 percent of micro silica powder whose D50 is equal to 0.4 Mum. BaSO4 and Na3AlF6 are compounded to be used as aluminum-liquid wetting resisting agent, and 1-6 percent by weight of the aluminum-liquid wetting resisting agent is added. Sodium tripolyphosphate whose weight is 0.12 percent of the total weight of the raw materials and sodium hexametaphosphate whose weight is 0.03 percent of the total weight of the raw materials are additionally added to be used as dispersant. The silicon carbide castable has sufficient strength, good thermal shock resistance, good volume stability, good chemical stability and long service life and particularly can resist the aluminum-liquid wetting without affecting the components of the aluminum liquid.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for preparing ceramic coating for replacing refractory coating prepared with centrifugal cast-steel pipe thermal mold method

ActiveCN102320842BHigh refractorinessDoes not affect ingredientsRigid pipesCeramic coatingRefractory

The invention discloses a method for preparing a ceramic coating for replacing a refractory coating prepared with a centrifugal cast-steel pipe thermal mold method. The method comprises the following steps of: adding water into a ceramic coating raw material to obtain slurry; coating the slurry onto the inner surface of a pipe mold in a flowing way; heating the pipe mold at low temperature for fully evaporating free water; and after the coating is solidified fully, sintering with high-temperature molten steel till crystal waster is released fully to obtain the ceramic coting for replacing therefractory coating prepared with the centrifugal cast-steel pipe thermal mold method. The ceramic coating prepared with the method has the advantages of lowering the production cost, realizing continuous production and not influencing the pipe blank quality.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

The present invention relates to production of zinc alloy. The technological scheme of producing Zn-Bi alloy includes first compounding intermediate alloy with alloy ingot and RE ingot at the smelting temperature of 750-850 deg.c, subsequent smelting zinc ingot at 550-650 deg.c and adding nickel material and final adding bismuth ingot to form the polynary Zn-Bi alloy. The said process can avoid the burning loss of RE metal to avoid waste, may have certain amount of Al-RE intermediate alloy added to form different alloys, and has smelting and stirring time over 15 min to reach effect of homogeneous mixing. The present invention uses preferably inducing furnace as smelting apparatus and the product has stable and homogeneous alloy element components, high alloy element utilization and clean and environment friendly production process.

Owner:株洲冶炼集团有限责任公司

Granular rice hull ash heat preservation agent

The invention discloses a granular rice hull ash heat preservation agent, which comprises the following components by weight percentage: 39-59% of rice hull ash, 24-48% of coal ash, 5-7% of a binder,and 6-12% of expanded vermiculite. Specifically, the binder is a mixture of lignin, sepiolite, calcium silicate and a rare earth composite thermal insulation material. The granular rice hull ash heatpreservation agent has the advantages of good heat preservation effect, long heat preservation time, good spreadability, small environmental pollution, no adhesion to ladle, no slag falling, no influence on molten steel components and the like.

Owner:湘潭微动农业发展有限公司

Preparation method of seepage-proof castable

The invention belongs to the field of refractory materials and relates to a preparation method of a seepage-proof castable. The castable comprises the following raw materials by weight percent: 63-69wt% of alumina particles with sizes of 8-0mm, 18-21wt% of aluminium nitride fine powder with particle size less than 0.044mm, 4-7wt% of pure calcium aluminate cement with particle size less than 0.074mm and 5-6wt% of silicon dioxide micro powder with D90 equivalent to 0.1mu m. The castable is characterized in that a compound of BaSO4, TiB2, SrTiO3 and Na3AlF6 is adopted as a molten aluminum wetting resisting agent; the addition of the compound is 1-6wt%; 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate are added as dispersing agents; alumina sol serves as construction liquid. The prepared castable has enough strength, excellent thermal shock resistance and good volume stability and chemical stability, is mainly resistant to molten aluminum wetting, has good thermal stability, is resistant to molten aluminum corrosion, does not affect the components of molten aluminium and has long service life.

Owner:秦皇岛市首耐新材料有限公司

Method for preparing pouring material for aluminum smelting

InactiveCN105272296ADoes not affect ingredientsExtended service lifeSilicon dioxideChemical stability

Owner:汤炼芳

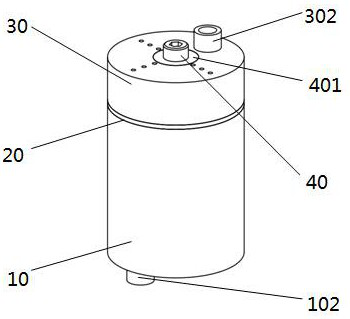

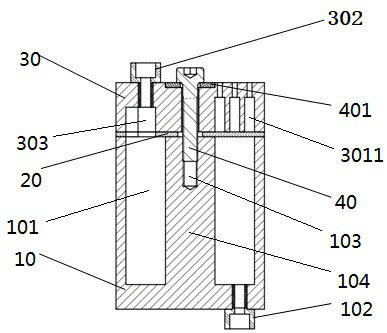

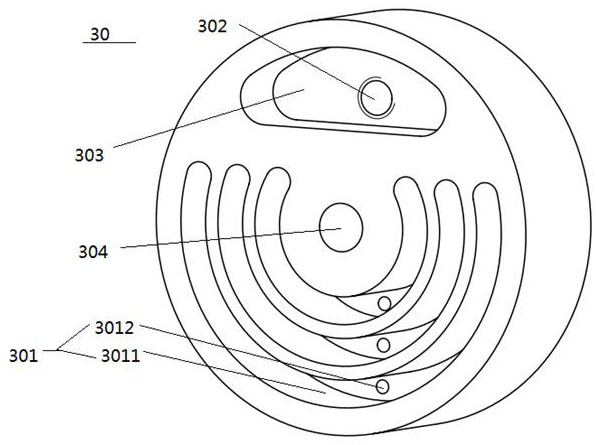

a defoamer

ActiveCN109305711BDoes not affect ingredientsAchieve separationWater/sewage treatment by degassingEngineeringMechanics

The invention provides a defoamer, which comprises a cylinder body, a hydrophobic membrane and an end cap, wherein a liquid storage chamber with an open upper end is arranged in the cylinder body, the end cap is located at the upper end of the cylinder body, and the end cap covers Set at the upper opening of the liquid storage chamber; the lower side of the cylinder is provided with a water outlet port communicating with the liquid storage chamber; the end cover is provided with a water inlet port communicated with the liquid storage chamber ; The end cover is provided with a defoaming gap with an open upper end, and the defoaming gap is isolated from the liquid storage chamber by the hydrophobic membrane. The bubble remover provided by the invention has small volume and simple structure, does not need to consume extra electric energy and does not affect the composition of the sample liquid.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of aluminum nitride castable anti-aluminum liquid wetting

The invention belongs to the field of refractory materials and relates to a preparation method of a molten aluminum wetting resistant aluminium nitride castable. The castable comprises the following raw materials by weight percent: 63-69wt% of aluminium nitride particles with sizes of 8-0mm, 18-21wt% of aluminium nitride fine powder with particle size less than 0.044mm, 4-7wt% of pure calcium aluminate cement with particle size less than 0.074mm and 5-6wt% of silicon dioxide micro powder with D90 equivalent to 0.1mu m. The castable is characterized in that a compound of BaSO4, TiB2, SrTiO3 and Na3AlF6 is adopted as a molten aluminum wetting resisting agent; the addition of the compound is 1-6wt%; 0.12% of sodium tripolyphosphate and 0.03% of sodium hexametaphosphate are added as dispersing agents; alumina sol serves as construction liquid. The prepared castable has enough strength, excellent thermal shock resistance and good volume stability and chemical stability, is mainly resistant to molten aluminum wetting, has good thermal stability, is resistant to molten aluminum corrosion, does not affect the components of molten aluminium and has long service life.

Owner:广东鸿劲金属铝业有限公司

A protective material resistance to cold and heat pulse fatigue test device

InactiveCN103257104BHigh temperature control accuracyHigh precisionWeather/light/corrosion resistanceUsing mechanical meansThermal fatigueEngineering

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

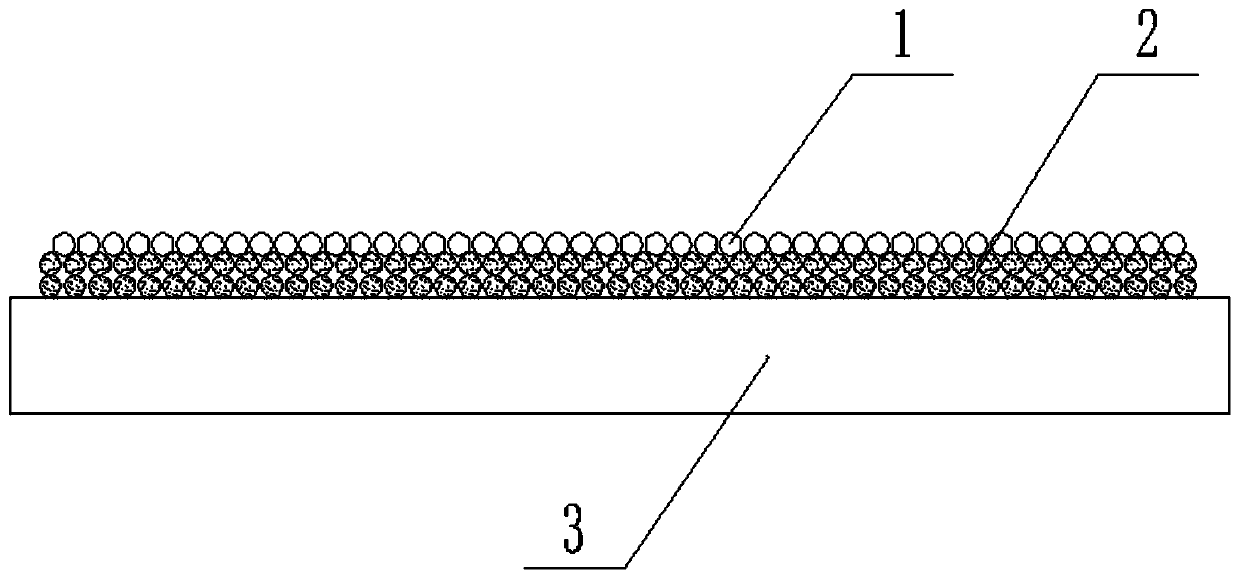

Laser cladding powder presetting method

InactiveCN111058028ADoes not affect ingredientsUniform thicknessMetallic material coating processesAdhesive glueMetal powder

The invention discloses a laser cladding powder presetting method, and belongs to the technical field of laser cladding. The method comprises the following steps of (1) pretreating the surface of a cladding substrate material to be clad, cleaning dust, oil stain or rust on the surface, and drying after pretreatment; (2) evenly laying cladding powder on the surface of the substrate material; (3) spraying chemical glue on the surface of the preset cladding powder, and fixing the preset cladding powder; and (4) airing the chemical glue until the chemical glue is dry, thus completing the laser cladding powder presetting. According to the method, metal powder is fixed through a method of spraying a layer of the chemical glue, so that the thickness of the metal powder can be kept uniform in thelaser cladding process. Due to the fact that the chemical glue can volatilize under the high-temperature condition, components of the cladding layer are not affected, the good cladding effect can be achieved, and the surface after cladding is flat and smooth.

Owner:GUANGDONG OCEAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com