Cluster-type water temperature control system for floating tobacco seedling growing pond

A technology for floating seedlings and water temperature control, applied in the fields of botanical equipment and methods, soilless cultivation, cultivation, etc., can solve the problem that it is difficult to achieve the optimal temperature for seed emergence and growth, and affects the emergence time of tobacco seedlings. Problems such as low temperature of nutrient solution, to avoid cross infection of pests and diseases, good adaptability, easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings.

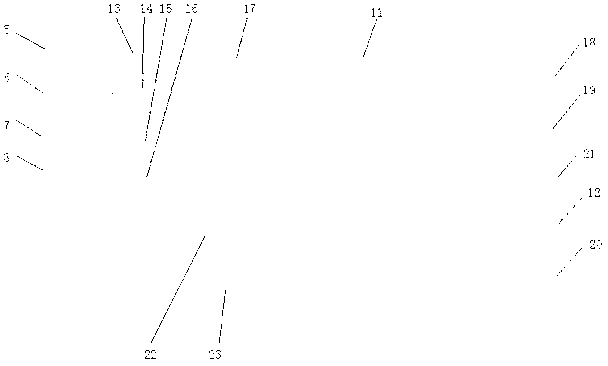

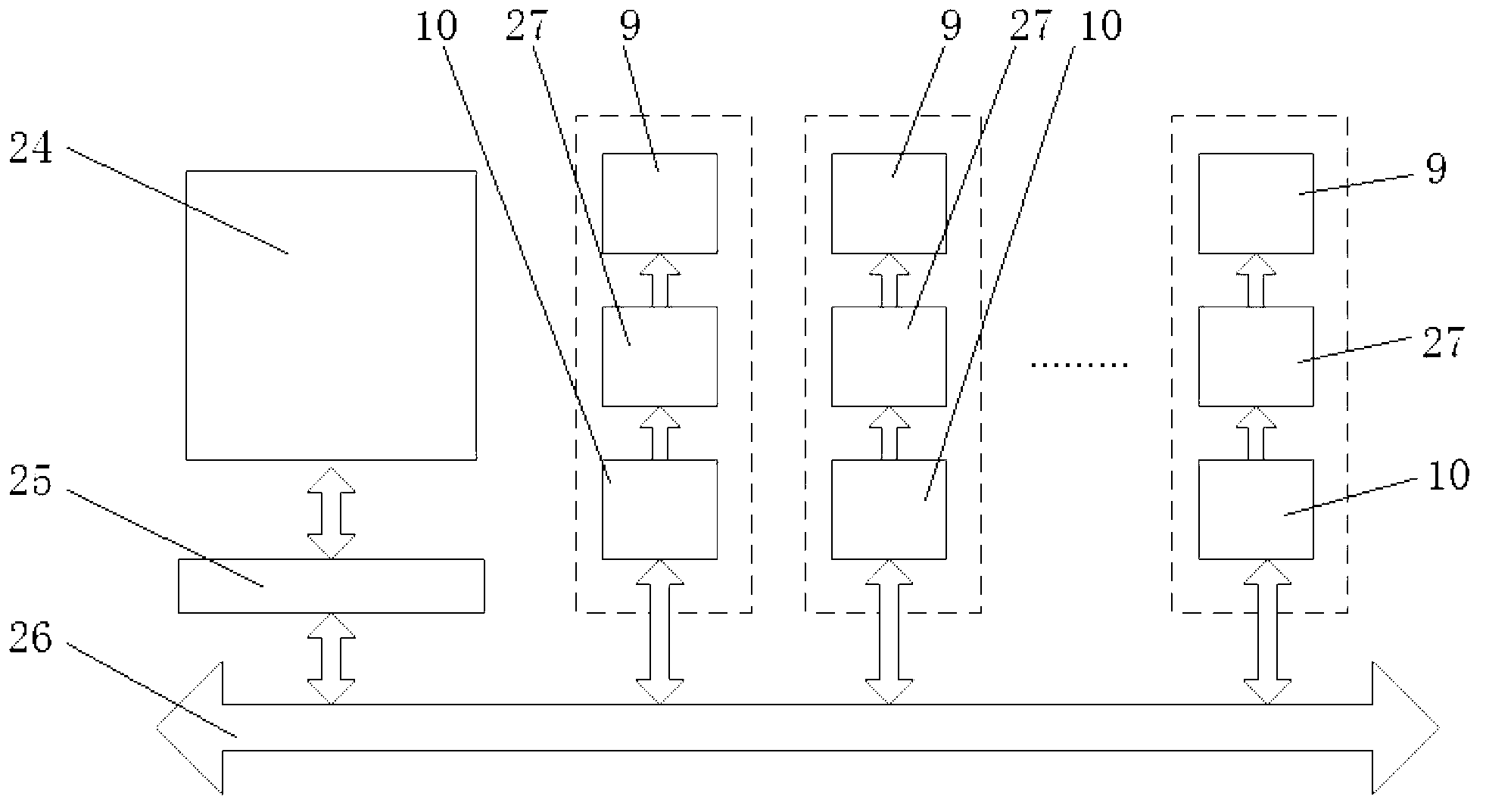

[0024] The technical scheme adopted by the present invention is: composed of an external heat exchange type pool heating device, an independent pool water temperature controller, a control bus and a central control computer

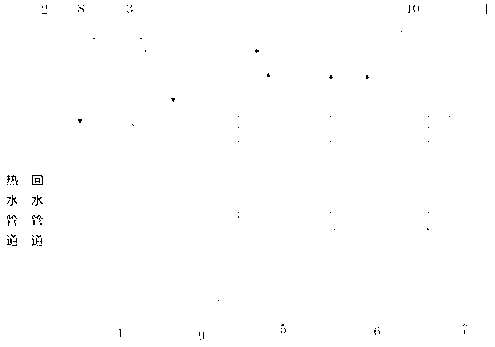

[0025] Such as figure 1 As shown, the external heat exchange pool heating device includes a heat exchanger 1, an electromagnetic valve 2, a circulating water pump 3, and a circulating pipe 4. The circulation pipe 4 is installed outside the seedling pool 9, and the circulation pipe 4 is equipped with a heat exchanger 1 and a circulating water pump 3. The nutrient solution in the seedling raising pool 9 is pumped out into the circulating pipe 4 by the circulating water pump 3, and then the nutrient solution in the circulating pipe 4 is heated by the heat exchanger 1, and then returned to the seedling raising pond 9 through the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com