Alloy cored wire capable of lowering superheat degree of molten steel and use method thereof

A technology of cored wire and superheat, applied in the field of casting, can solve the problems of low strength of inorganic heat-absorbing materials, easy moisture absorption of inorganic heat-absorbing materials, narrow crystallizer inner cavity, etc., to improve solidification structure, macro segregation, Improvement of billet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention does not have any special limitations on the preparation method of the cored wire, and the preparation process of the cored wire well known to those skilled in the art may be used.

[0033] The present invention also provides a method for reducing the superheat of molten steel by using the cored wire described in the above technical solution, which includes the following steps:

[0034] The cored wire is fed into the molten steel through the wire feeding machine.

[0035] In the present invention, the condition for completion of the wire feeding is preferably to reduce the superheat of the molten steel by 3 to 10°C. The degree of superheat of the molten steel is preferably detected by a thermocouple.

[0036] In the present invention, the wire feeding rate and the wire feeding amount of the cored wire are preferably determined according to the amount of molten steel and the specific casting process.

[0037] When the casting process is die casting, it is pr...

Embodiment 1

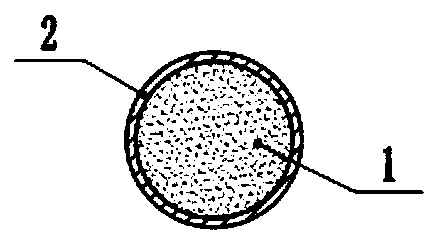

[0046] The experimental steel is GCr15SiMn. The weight of the steel ingot is 5t. The outer diameter of the cored wire is 9mm, the metal shell material is 20 steel, the thickness is 0.20mm, and the core material is CaO-CaF 2 , The corresponding mass ratio is 1:4;

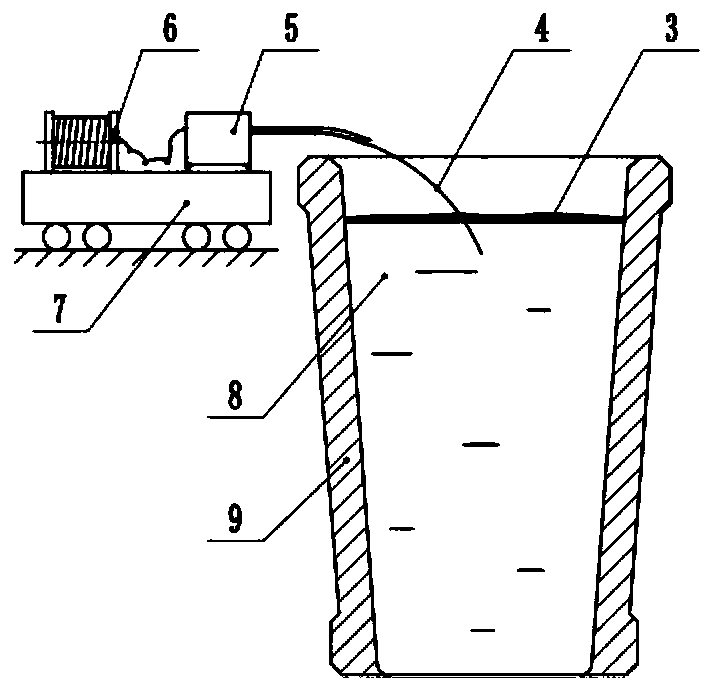

[0047] Install the cored wire in the winding reel 6 and fix it on the wire feeding machine 7;

[0048] In the steel casting mold 9, the bottom casting method is used to inject molten steel, and the pouring temperature is 1490℃. When the height of the molten steel reaches 8300mm or 35~45s after pouring starts, the wire feeder 7 is started, and the wire feeding rate is controlled by the main transmission device 5. , The wire feeding rate is 4.80~4.90cm / s, the cored wire 4 is fed into the molten steel 8. After the cored wire 4 enters the molten steel 8, the cored wire 4 gradually melts, and the metal shell 2 melts into the molten steel. The core material 1 absorbs the sensible heat in the molten steel 8 and floats to the s...

Embodiment 2

[0050] The experimental steel grade is GCr15, the pouring superheat is 20℃, the continuous casting billet size is 280×320mm, and the drawing speed is 0.6-0.8m / min.

[0051] The outer diameter of the cored wire is 9mm, the metal shell material is 20 steel, the thickness is 0.20mm, and the core material is CaO-CaF 2 , The corresponding mass ratio is 1:4.

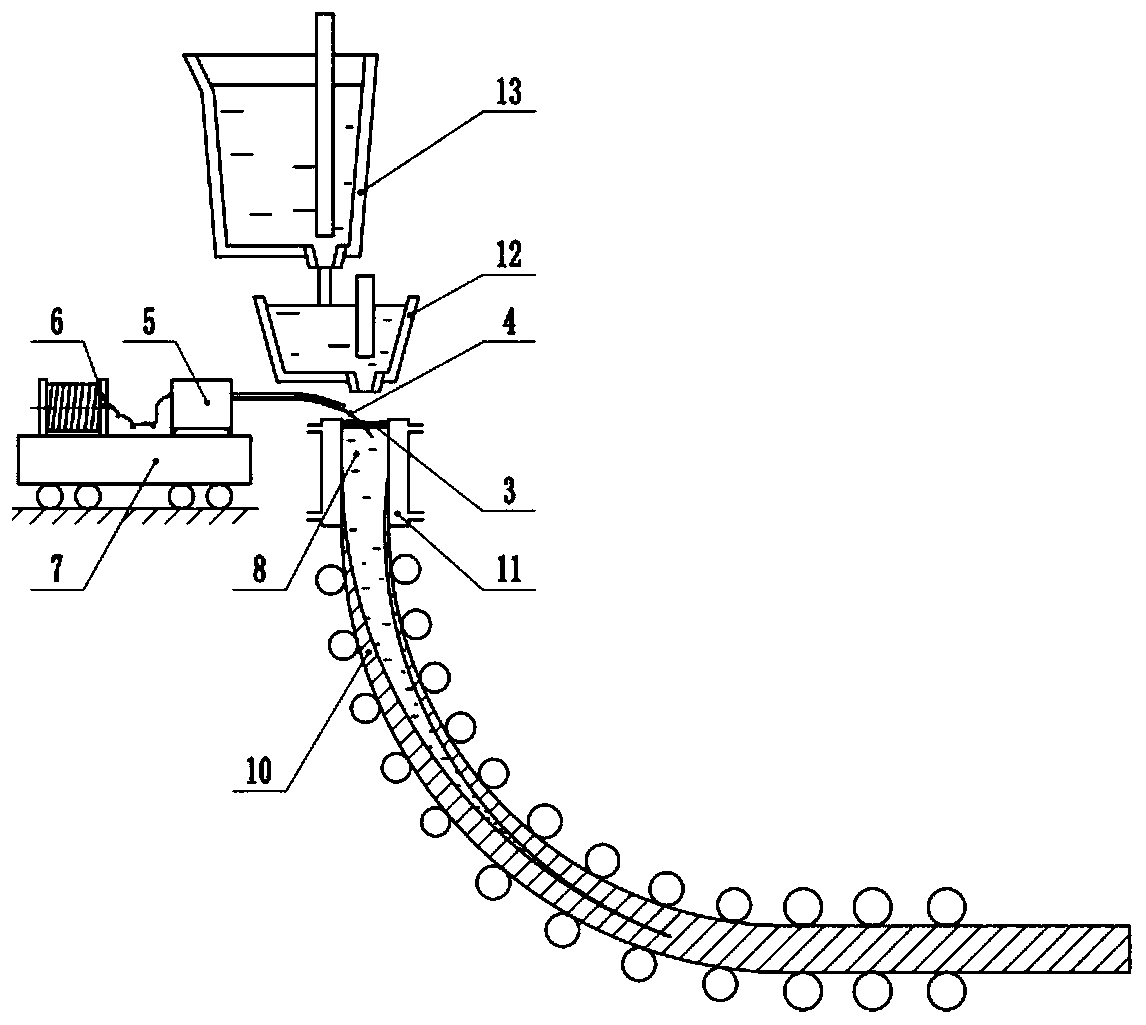

[0052] The cored wire is installed in the winding reel 6 and fixed on the wire feeding machine 7.

[0053] The molten steel in the ladle 13 enters the mold 11 through the tundish 12. After the molten steel fills the mold 11 and forms the continuous casting billet shell 10, the continuous casting starts, the wire feeding machine 7 is started, and the feeding is controlled by the main transmission device 5. The wire speed, the wire feeding rate is 6.5~8.5cm / s, the cored wire 4 is fed into the molten steel 8. After the cored wire 4 enters the molten steel 8, the cored wire 4 gradually melts, and the metal shell 2 melts into the steel T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com