Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

A technology for multi-component alloys and steel components is applied in the production field of zinc-bismuth multi-component alloys used for hot-dip galvanizing of steel components, which can solve the problems of affecting alloy composition, large fluctuation of alloy composition, inability to set stirring devices, etc. The effects of stable composition, high utilization rate of alloying elements, and clean and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

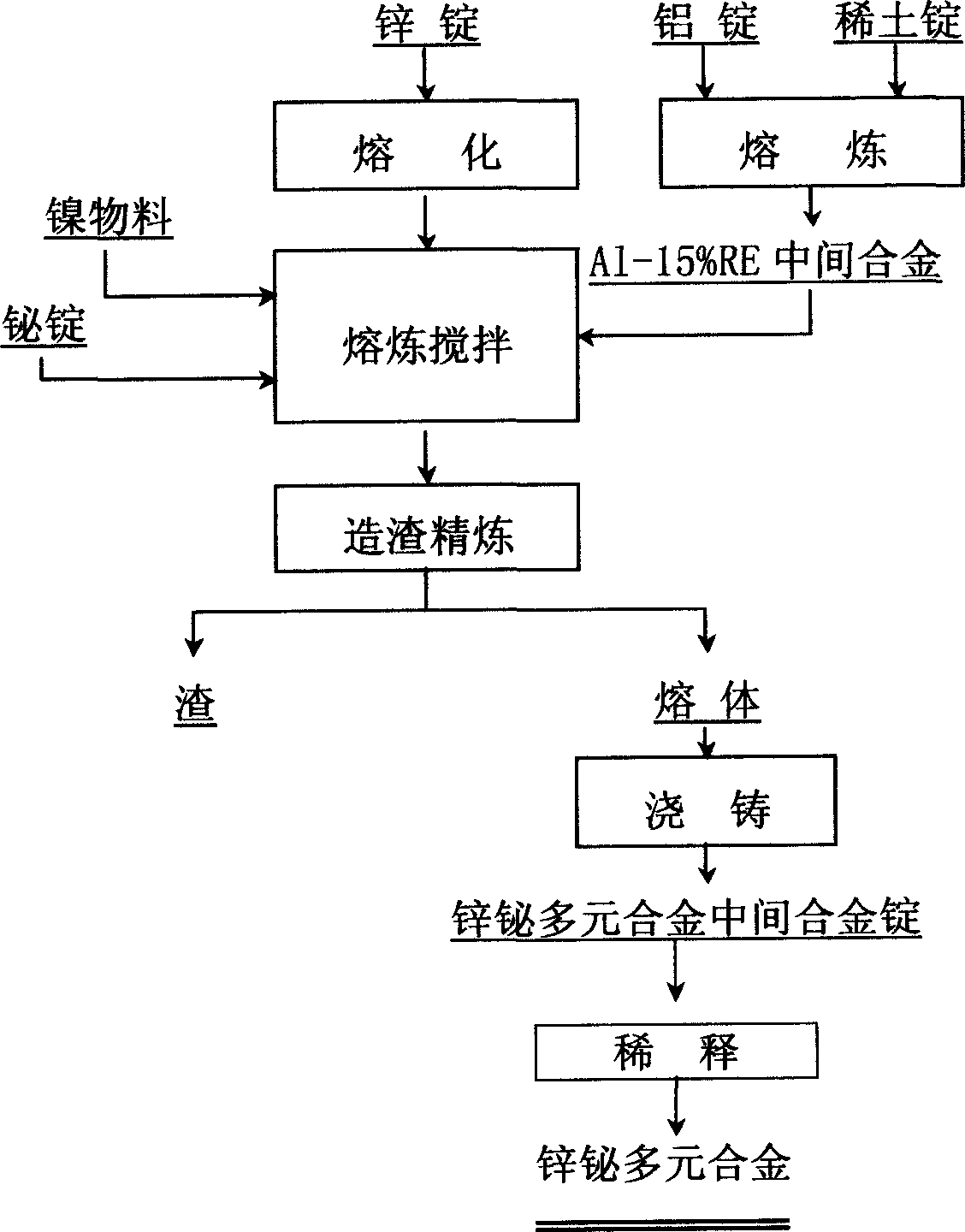

[0019] A kind of production method of zinc-bismuth multi-element alloy, its production steps are:

[0020] Step 1: Add 85% (wt) solid aluminum and 15% (wt) solid rare earth metal RE into an induction furnace directly heated by an electric field and use a zinc block as a core, heat up to a melting temperature of 750°C, and keep warm for 30 Minutes, while stirring for 8 minutes, the preparation of Al-15% rare earth metal RE master alloy;

[0021] Step 2: When 90% (wt) of the zinc ingot is melted to a temperature of 650°C in the smelting equipment, 3% (wt) of the Al-15% rare earth metal RE master alloy obtained in step 1 is added for neutralization, and then added 2.0% (wt) pure nickel material and 5% (wt) bismuth ingot, smelting for 12 minutes;

[0022] Step 3: adding refining agent to the material obtained in step 2 at 600° C. according to a conventional method, making slag and refining, removing the slag and casting it into a zinc-bismuth multi-element alloy master alloy ingo...

Embodiment 2

[0025] A kind of production method of zinc-bismuth multi-element alloy, the produced zinc-bismuth multi-element alloy is composed of its production steps as follows:

[0026] Step 1: Add 85% (wt) solid aluminum and 15% (wt) solid rare earth metal RE into a coreless induction furnace with alternating electric and magnetic fields, heat up to a melting temperature of 850°C, and keep it warm for 30 minutes. Stir for 20 minutes to prepare Al-15% rare earth metal RE master alloy;

[0027] Step 2: When 96% (wt) of the zinc ingot is melted to a temperature of 550°C in the smelting equipment, 2% (wt) of the Al-15% rare earth metal RE master alloy obtained in step 1 is added for neutralization, and then added 2% (wt) bismuth ingot, smelting for 20 minutes;

[0028] Step 3: adding refining agent to the material obtained in step 2 at 700° C. according to a conventional method, making slag and refining, removing the slag and casting it into a zinc-bismuth multi-element alloy master alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com