Multifunctional semi-synthetic metal processing liquid and preparation method thereof

A metalworking fluid and semi-synthetic technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as difficult to clean, carcinogenic, and affect the balance of the system, and achieve a good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

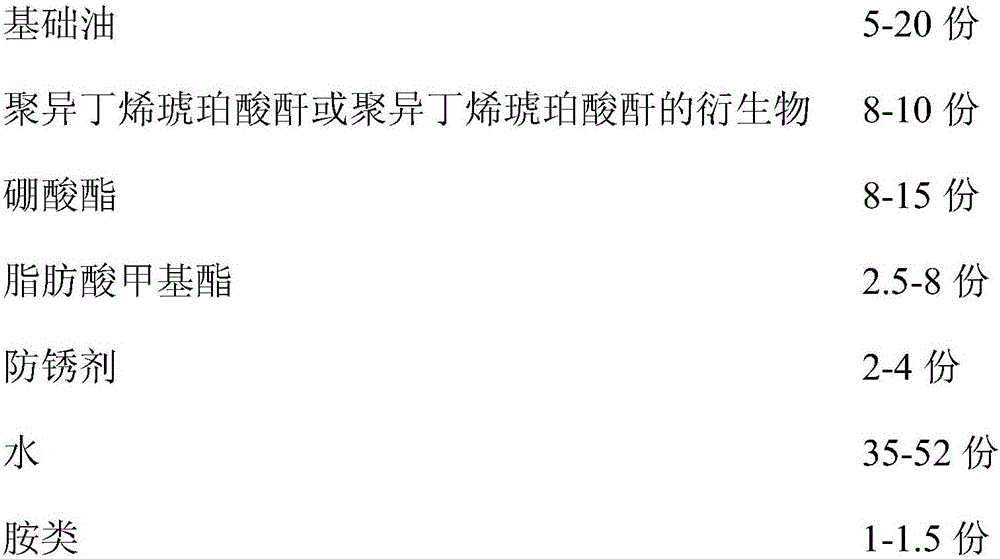

[0062] A multi-purpose semi-synthetic metalworking fluid, said multi-purpose semi-synthetic metalworking fluid contains the following raw material components by weight:

[0063]

[0064] The preparation method of multi-purpose semi-synthetic metalworking fluid:

[0065] Dissolve the above-mentioned 0.2kg silicone defoamer and inorganic silicon defoamer mixture with 4kg of water to obtain phase A; mix the remaining 48kg of water, boric acid, AMP-95 and monoethanolamine, benzotriazole, Add acidic phosphate ester and diethylene glycol into the oil adjustment tank, stir evenly as phase B; mix base oil, polyisobutylene succinic anhydride, fatty acid methyl ester, EDTA, monoethanolamine borate and the mixture of MBM, BIT20 and IPBC evenly As phase C, then phase A, phase B and phase C are mixed and stirred until the obtained product is uniform and transparent to obtain a multi-purpose semi-synthetic metalworking fluid.

[0066] The performance testing results of the multi-purpose...

Embodiment 2

[0068] A multi-purpose semi-synthetic metalworking fluid, said multi-purpose semi-synthetic metalworking fluid contains the following raw material components by weight:

[0069]

[0070] The preparation method of multi-purpose semi-synthetic metalworking fluid:

[0071] Dissolve the above-mentioned 0.3kg of organic silicon defoamer and inorganic silicon defoamer with 6kg of water to obtain phase A; the remaining 29kg of water, sebacic acid, a mixture of DGA and monoethanolamine, benzotriazole, Acidic phosphate ester and the mixture of n-butanol and ethylene glycol monobutyl ether are added to the oil adjustment tank, and stirred evenly as phase B; base oil, polyisobutylene succinic anhydride, fatty acid methyl ester, EDTA, triethanolamine borate and MBM The mixture of , BIT20 and IPBC is uniformly mixed as phase C, then phase A, phase B and phase C are mixed and stirred until the obtained product is uniform and transparent to obtain a multi-purpose semi-synthetic metalworki...

Embodiment 3

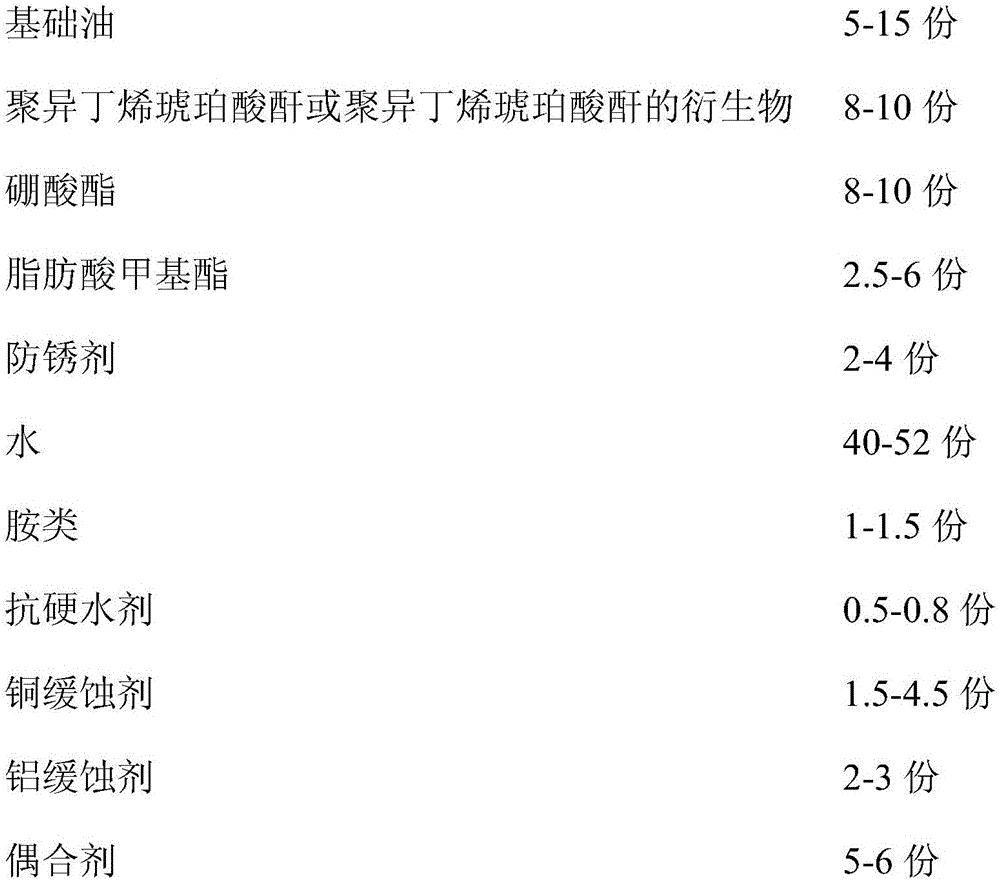

[0074] A multi-purpose semi-synthetic metalworking fluid, said multi-purpose semi-synthetic metalworking fluid contains the following raw material components by weight:

[0075]

[0076] The preparation method of multi-purpose semi-synthetic metalworking fluid:

[0077] Dissolve the above-mentioned 0.2kg of organic silicon defoamer and inorganic silicon defoamer with 4kg of water to obtain phase A; mix the remaining 36kg of water, the mixture of boric acid and dimer acid, the mixture of AMP-95, DGA and triethanolamine Add the mixture, benzotriazole, acidic phosphate and isohexanediol into the oil adjustment kettle, stir evenly as phase B; add base oil, polyisobutylene succinic anhydride, fatty acid methyl ester, EDTA, monoethanolamine borate and three The mixture of ethanolamine borate and the mixture of MBM, BIT20 and IPBC are uniformly mixed as phase C, and then phase A, phase B and phase C are mixed and stirred until the obtained product is uniform and transparent to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com