Patents

Literature

58results about How to "Improve contact uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

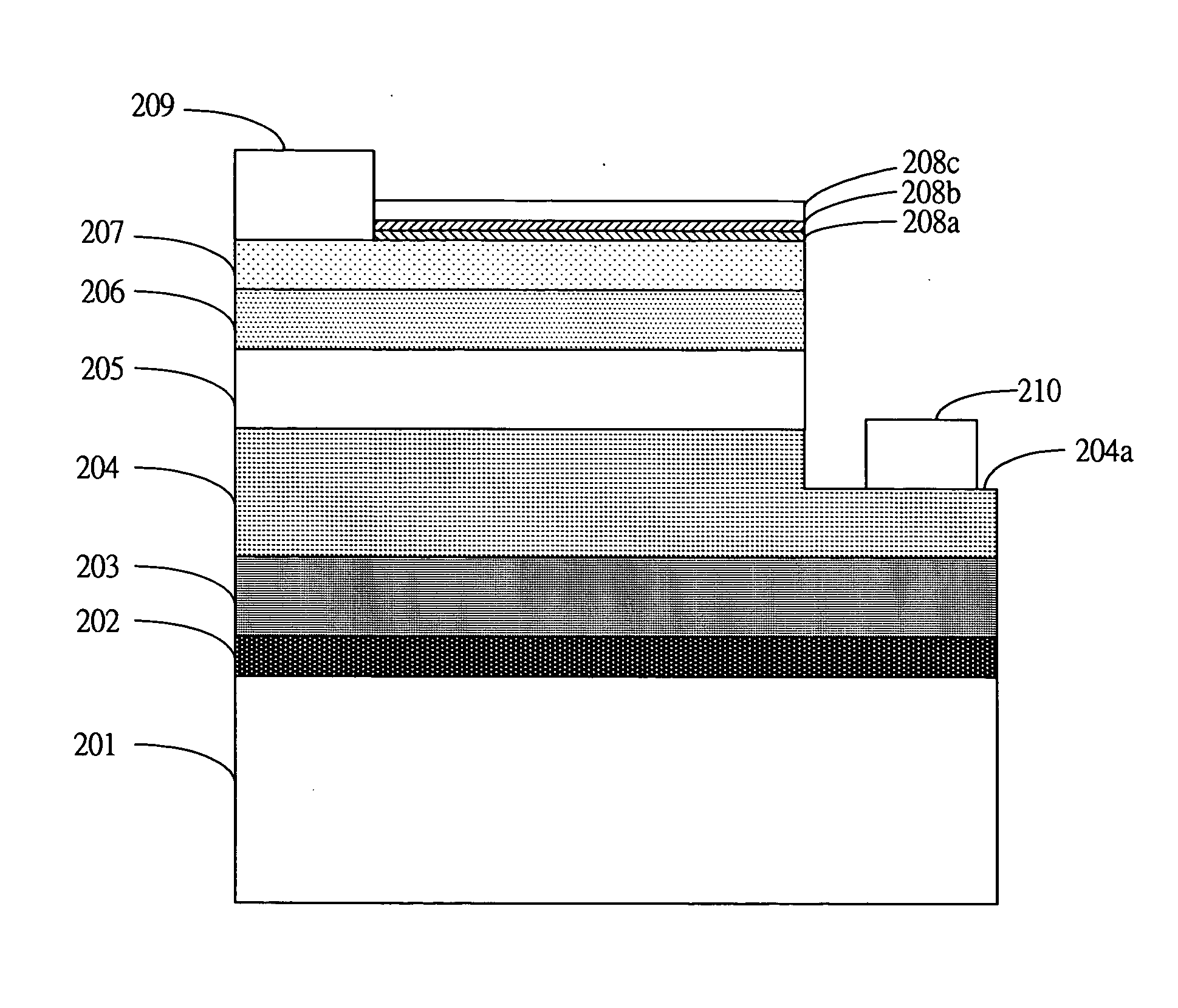

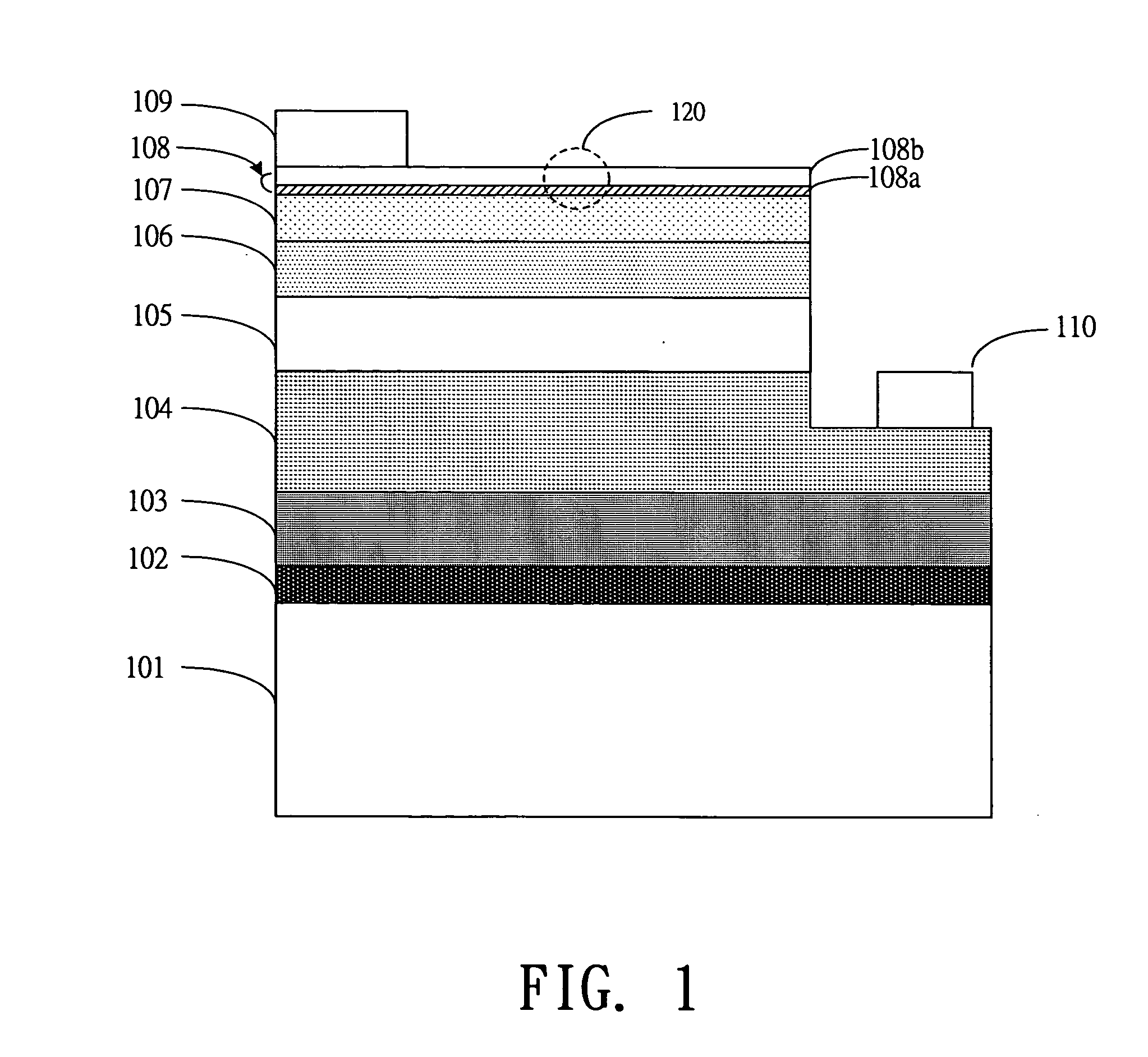

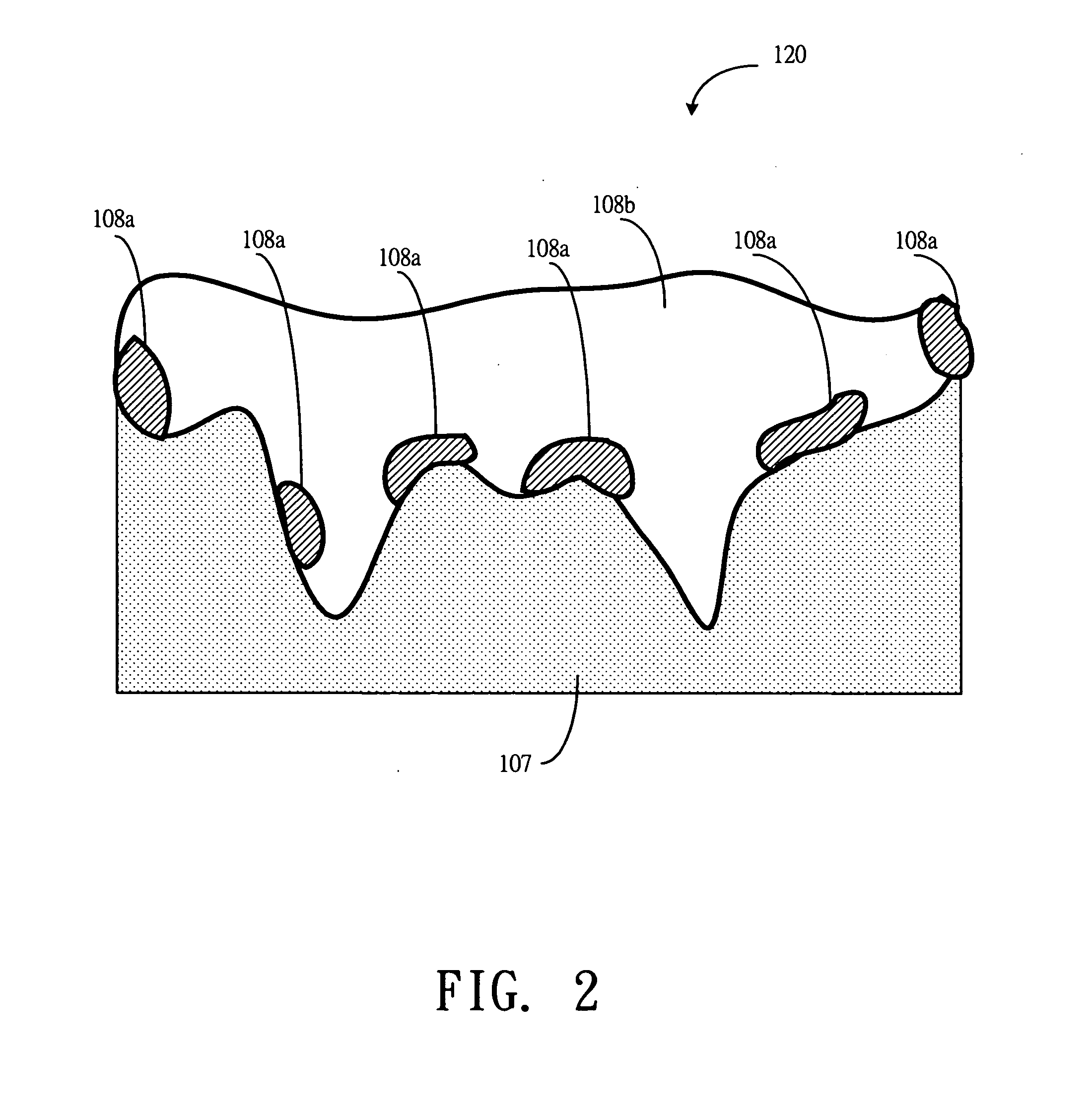

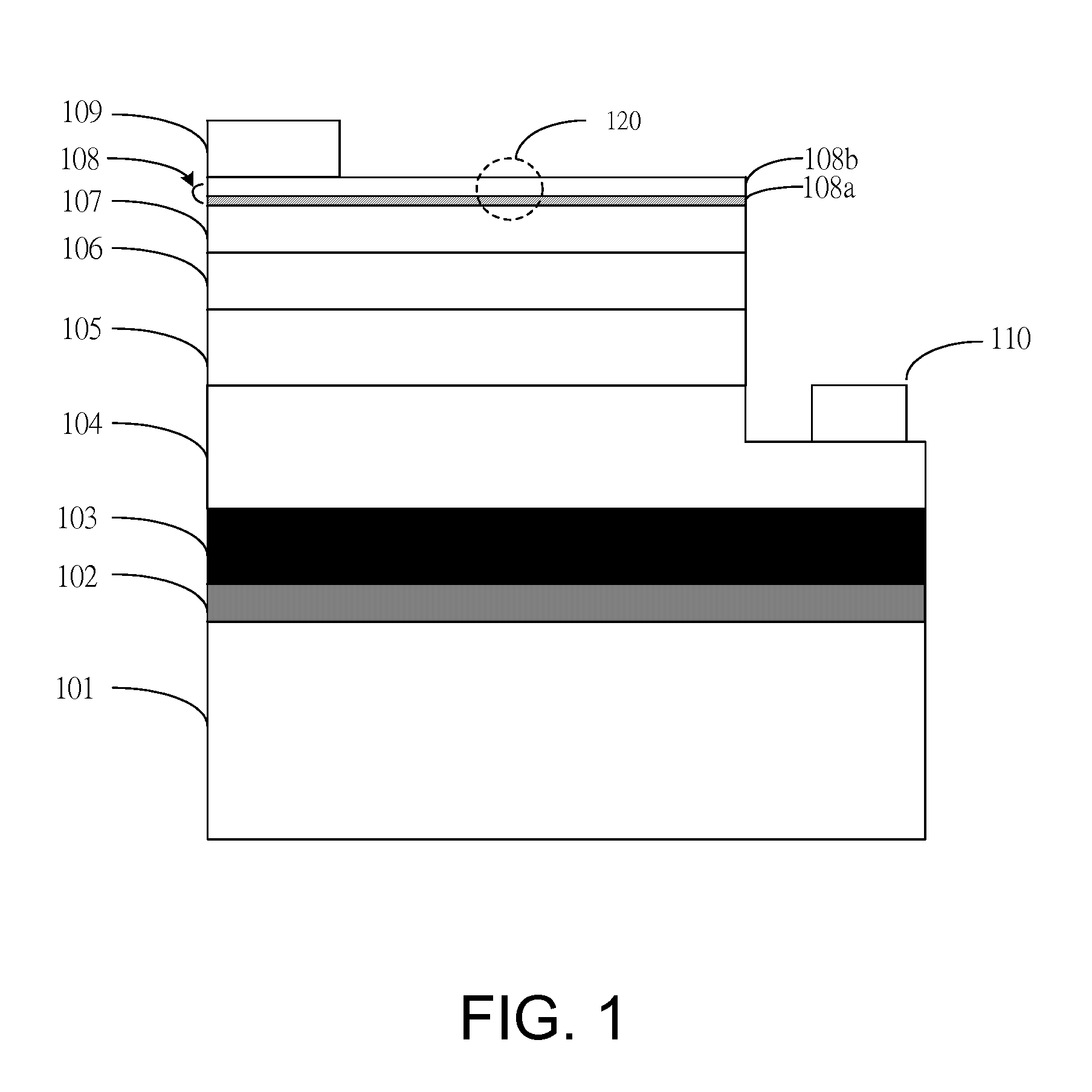

Gallium-nitride based light emitting diode structure and fabrication thereof

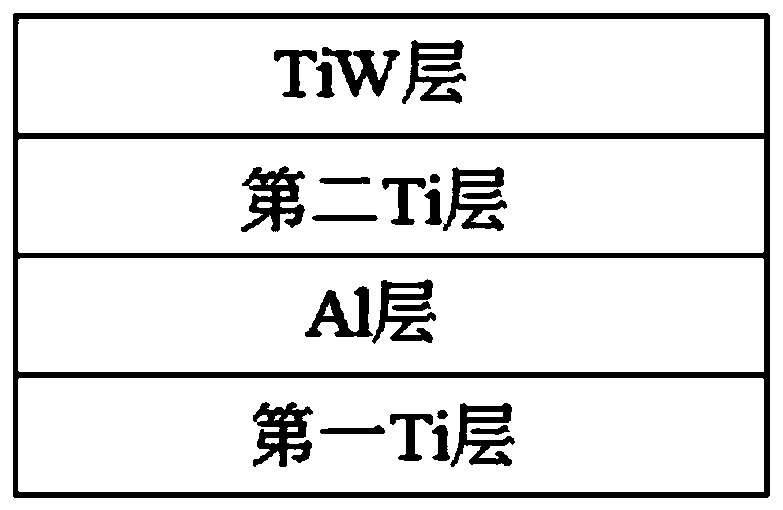

ActiveUS20050139840A1Improve conductivityImprove contact uniformitySolid-state devicesSemiconductor devicesQuantum efficiencyMetallic electrode

A method for fabricating GaN-based LED is provided. The method first forms a first contact spreading metallic layer on top of the texturing surface of the p-type ohmic contact layer. The method then forms a second and a third contact spreading metallic layers on top of the first contact spreading layer. The p-type transparent metallic conductive layer composed of the three contact spreading metallic layers, after undergoing an alloying process within an oxygenic or nitrogenous environment under a high temperature, would have a superior conductivity. The p-type transparent metallic conductive layer could enhance the lateral contact uniformity between the p-type metallic electrode and the p-type ohmic contact layer, so as to avoid the localized light emission resulted from the uneven distribution of the second contact spreading metallic layer within the third contact spreading metallic layer. The GaN-based LED's working voltage and external quantum efficiency are also significantly improved.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

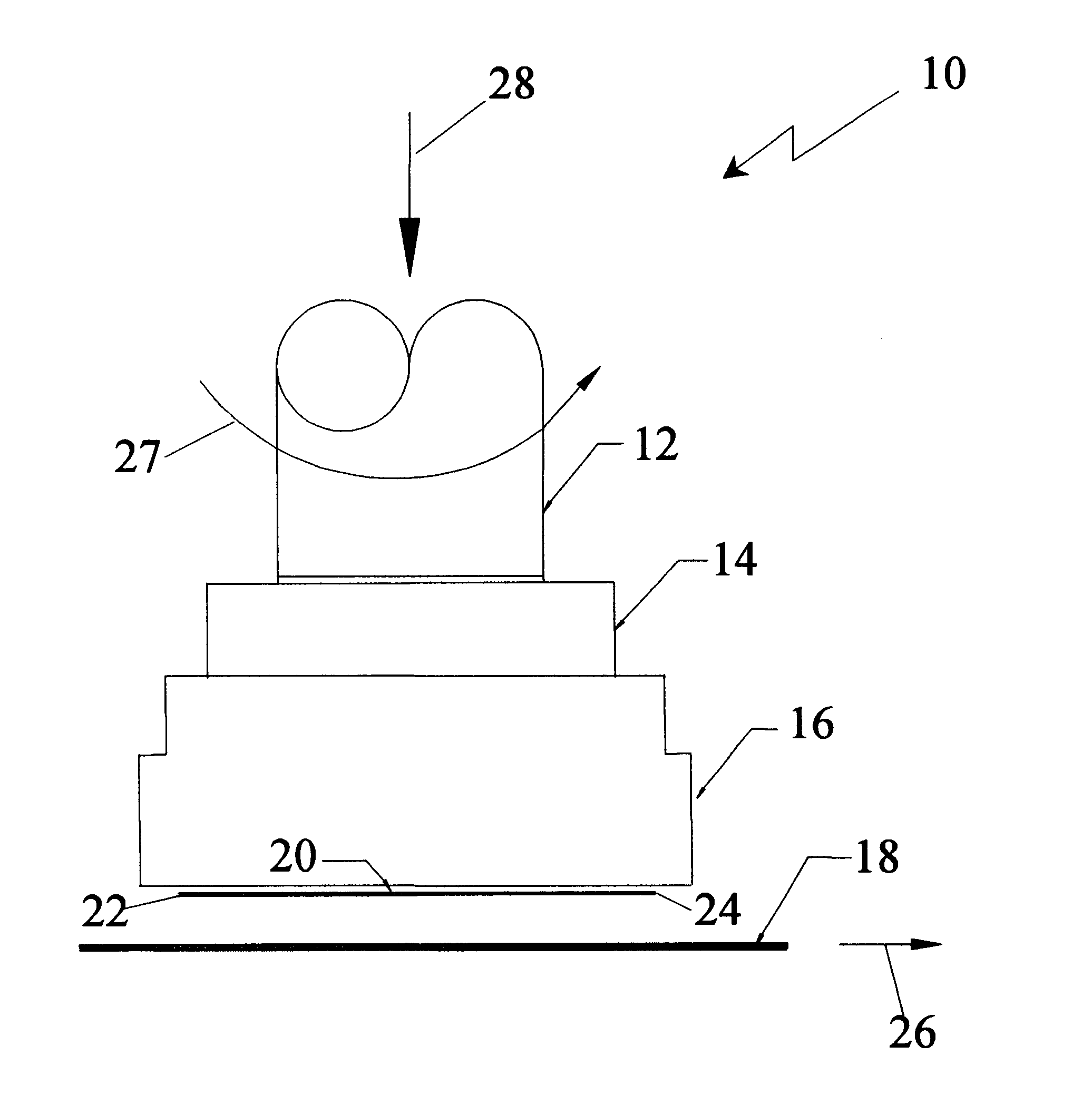

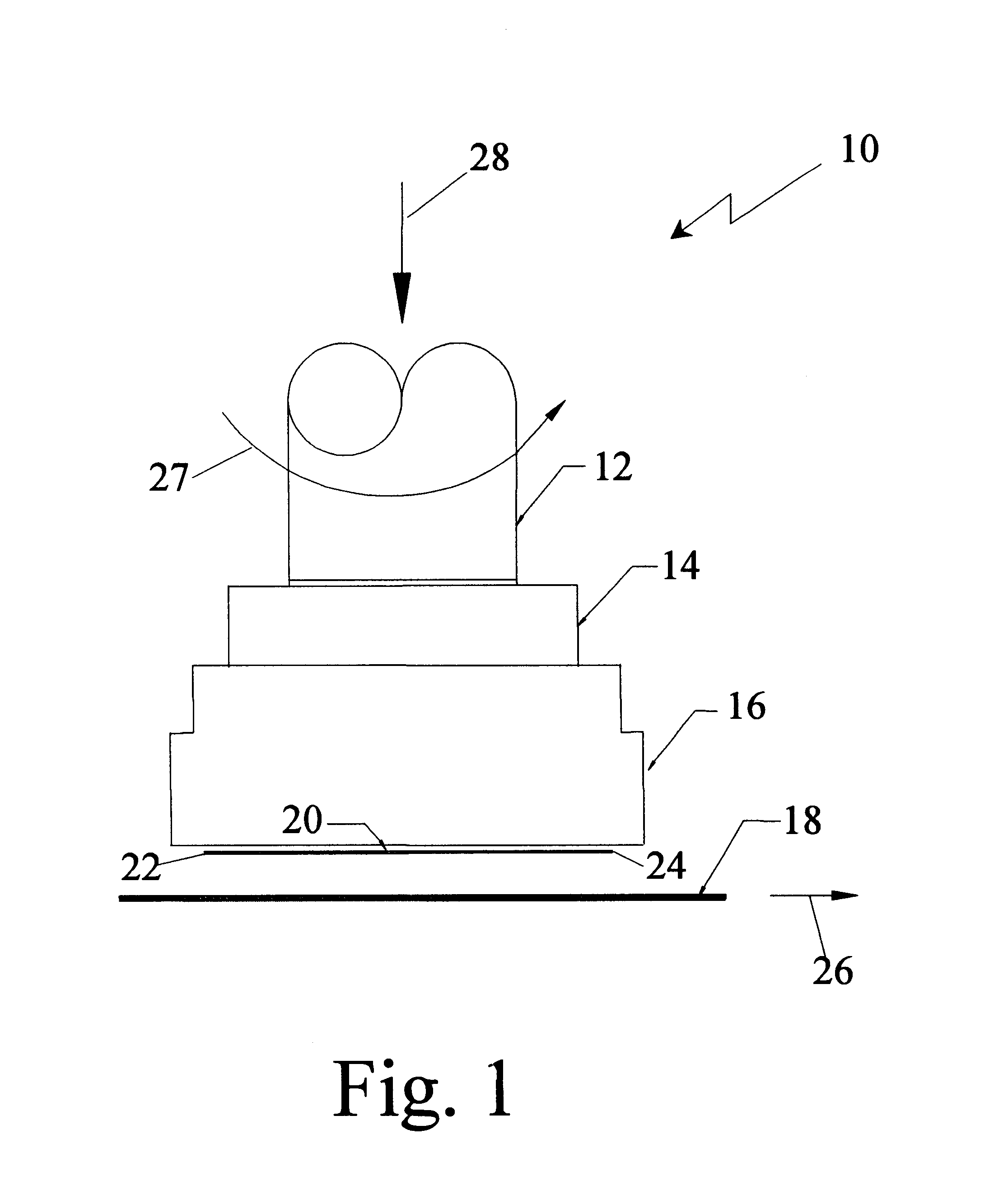

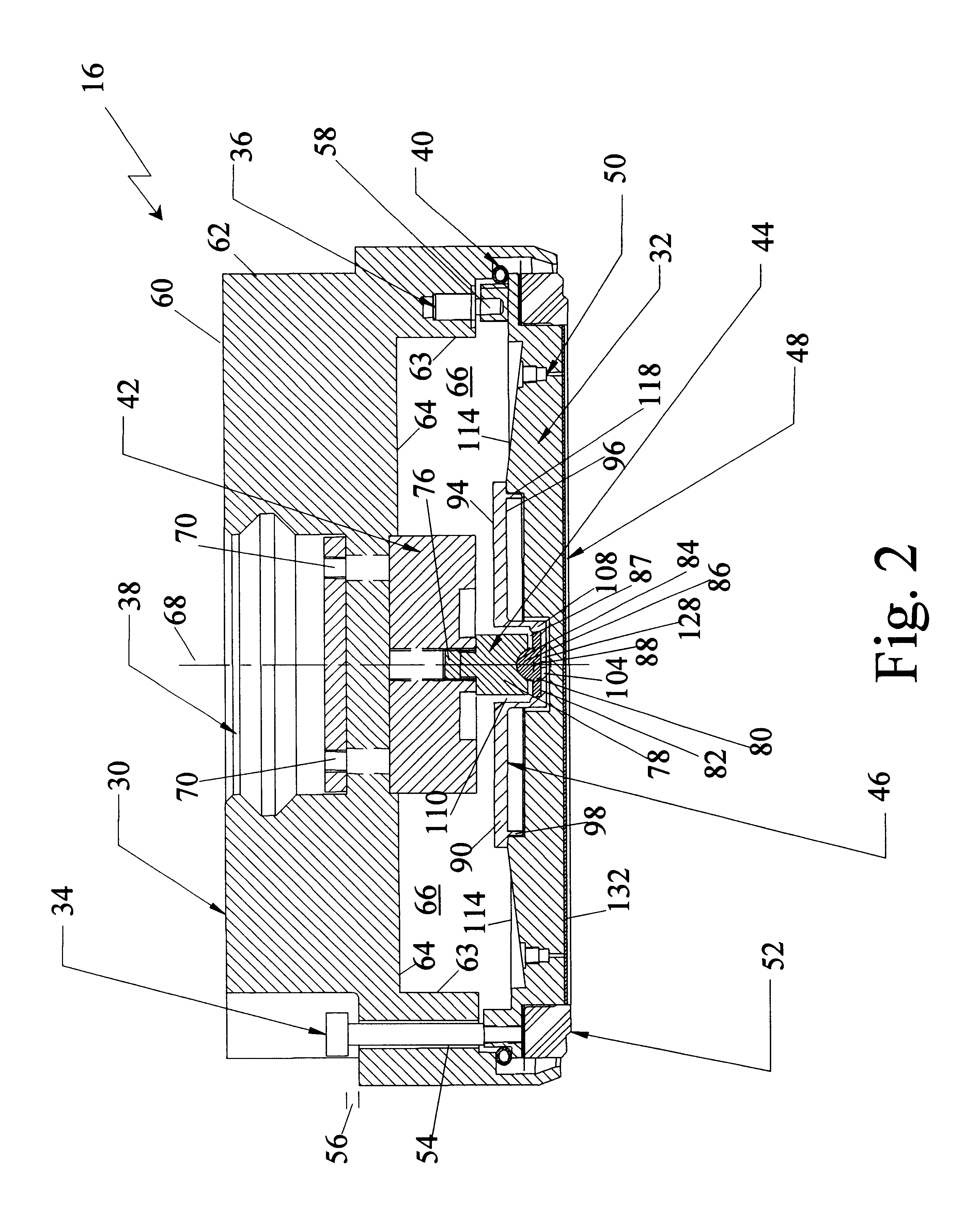

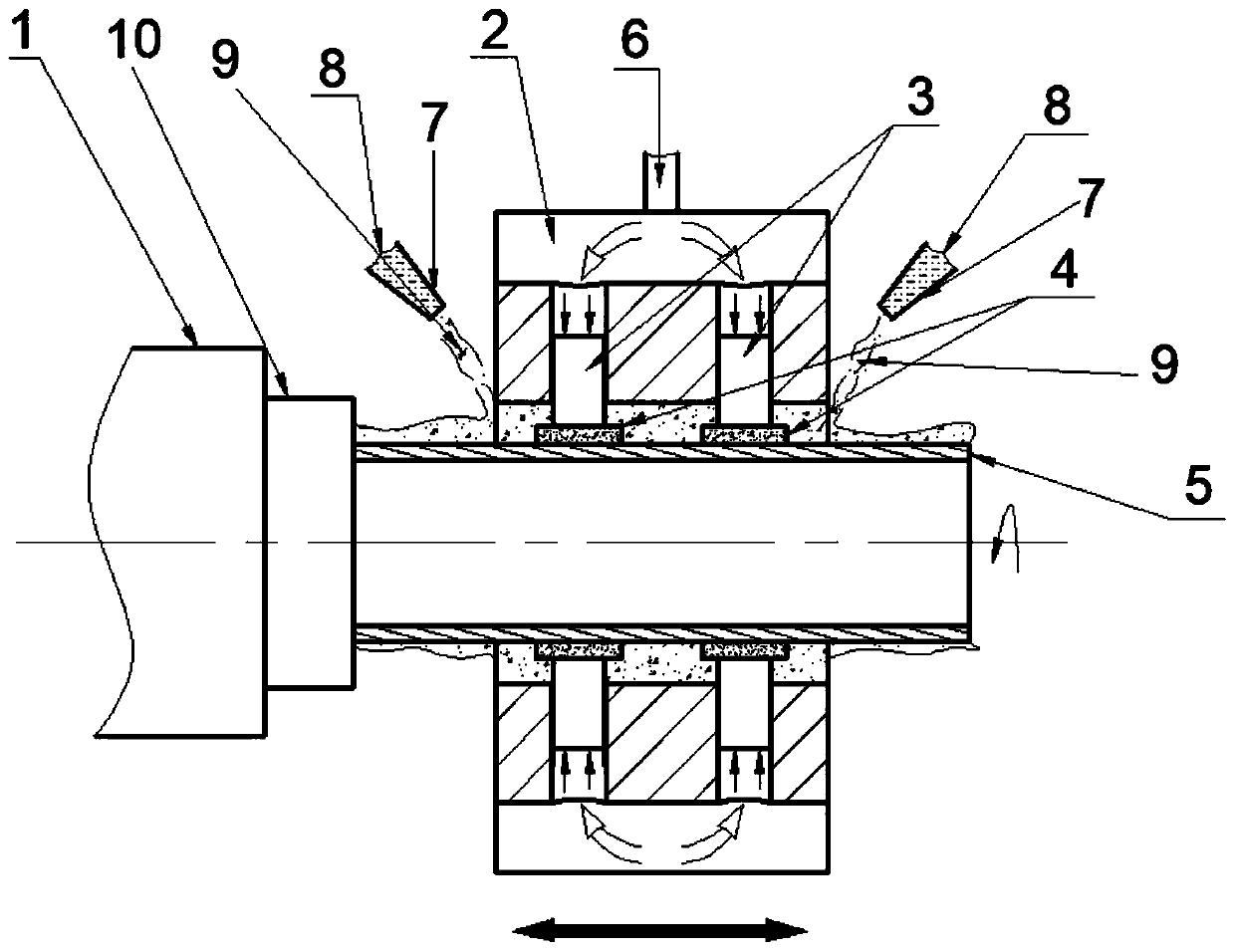

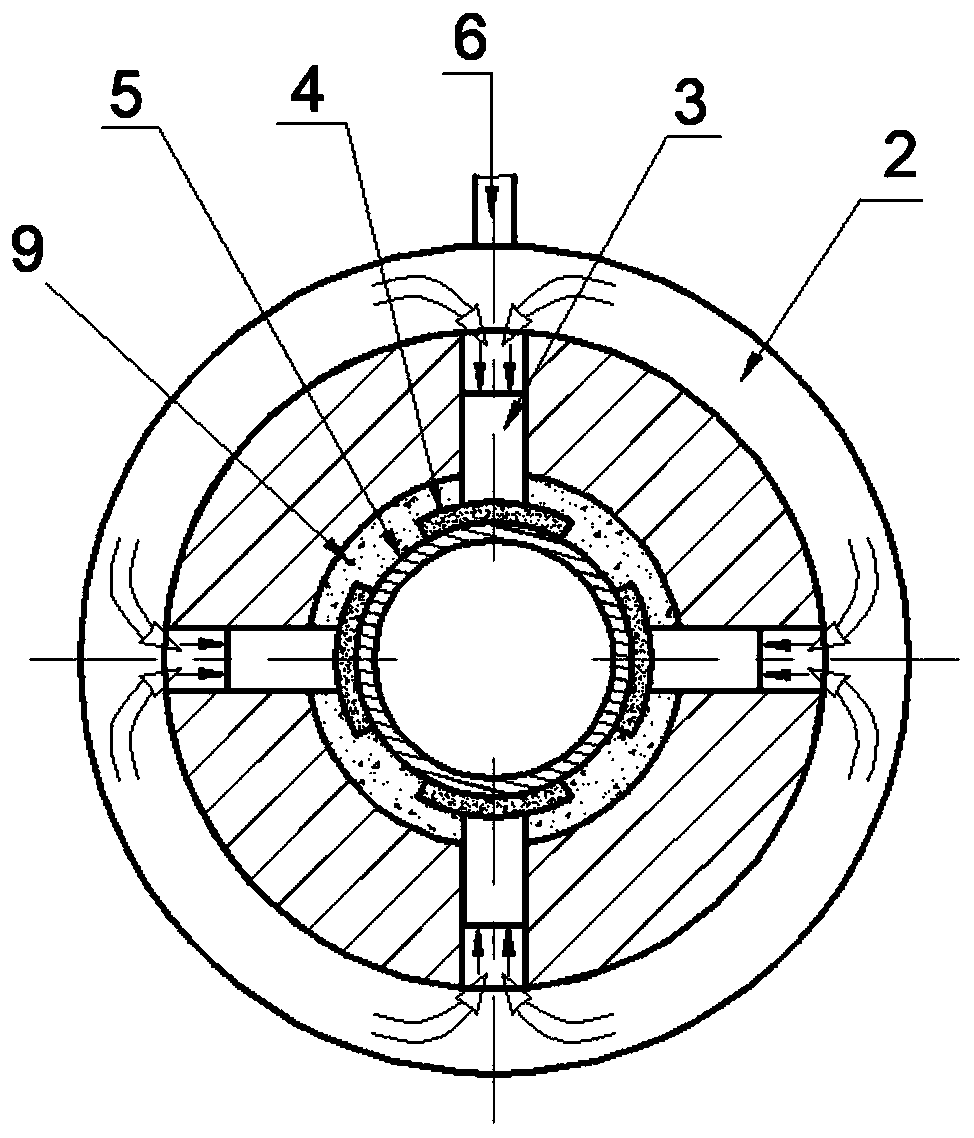

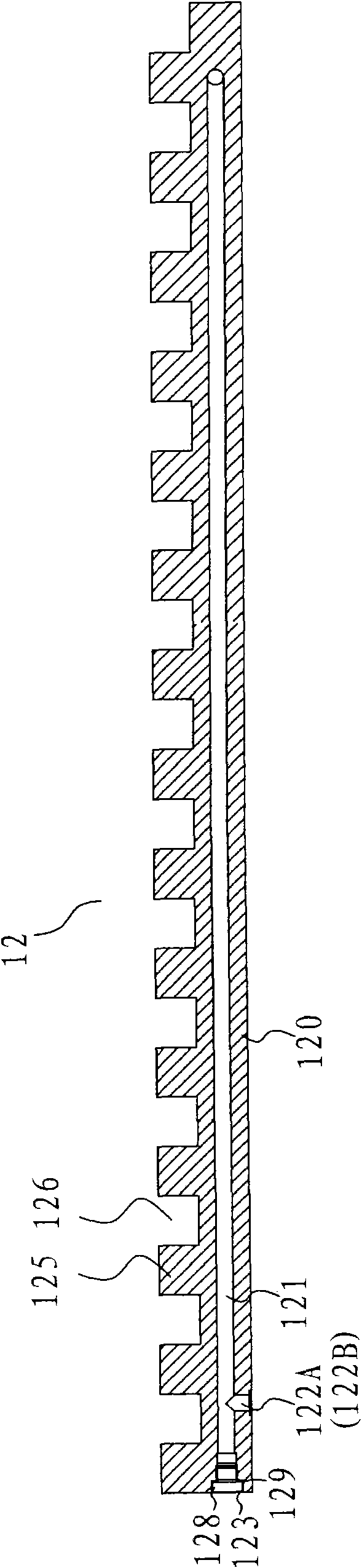

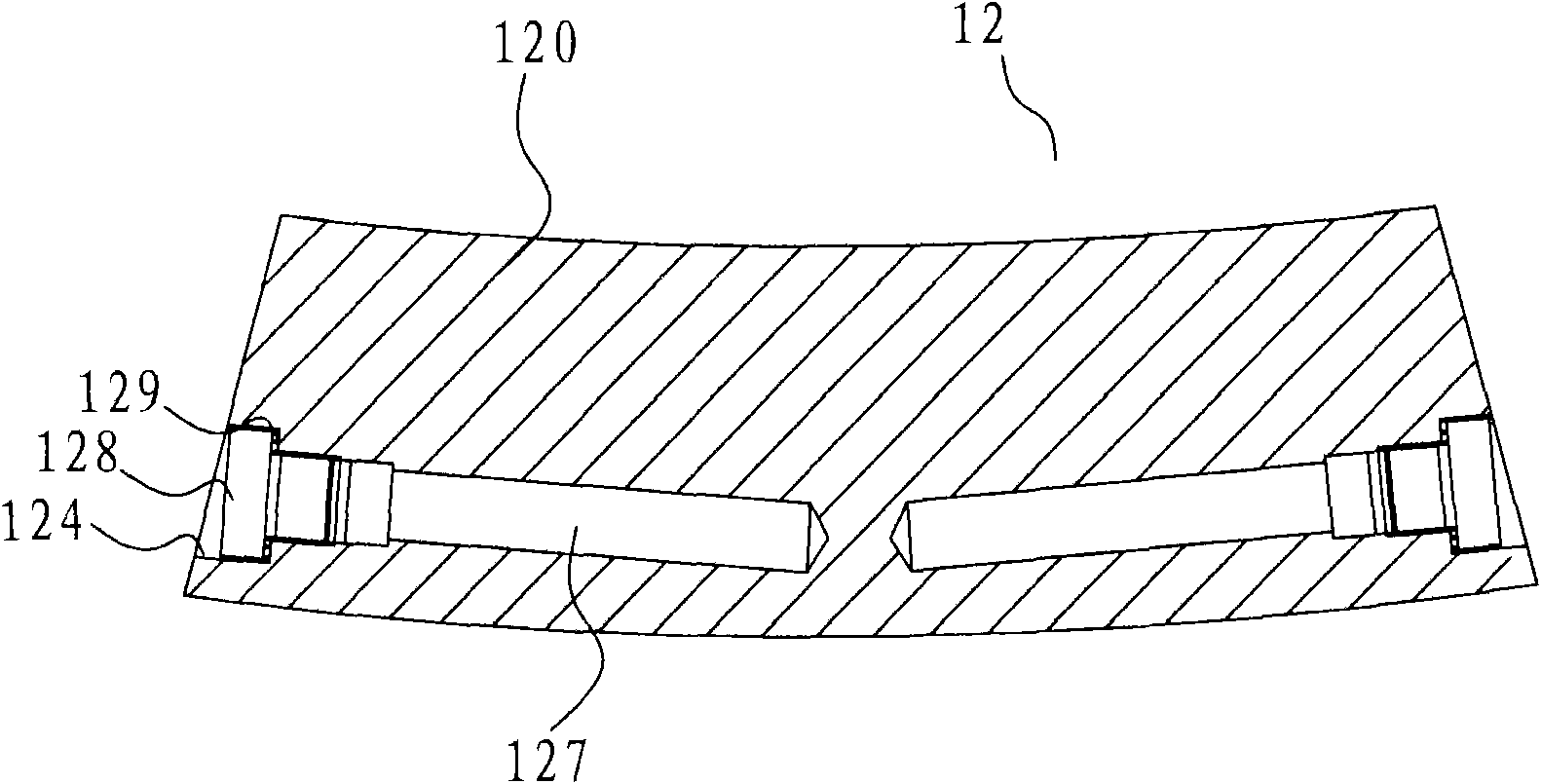

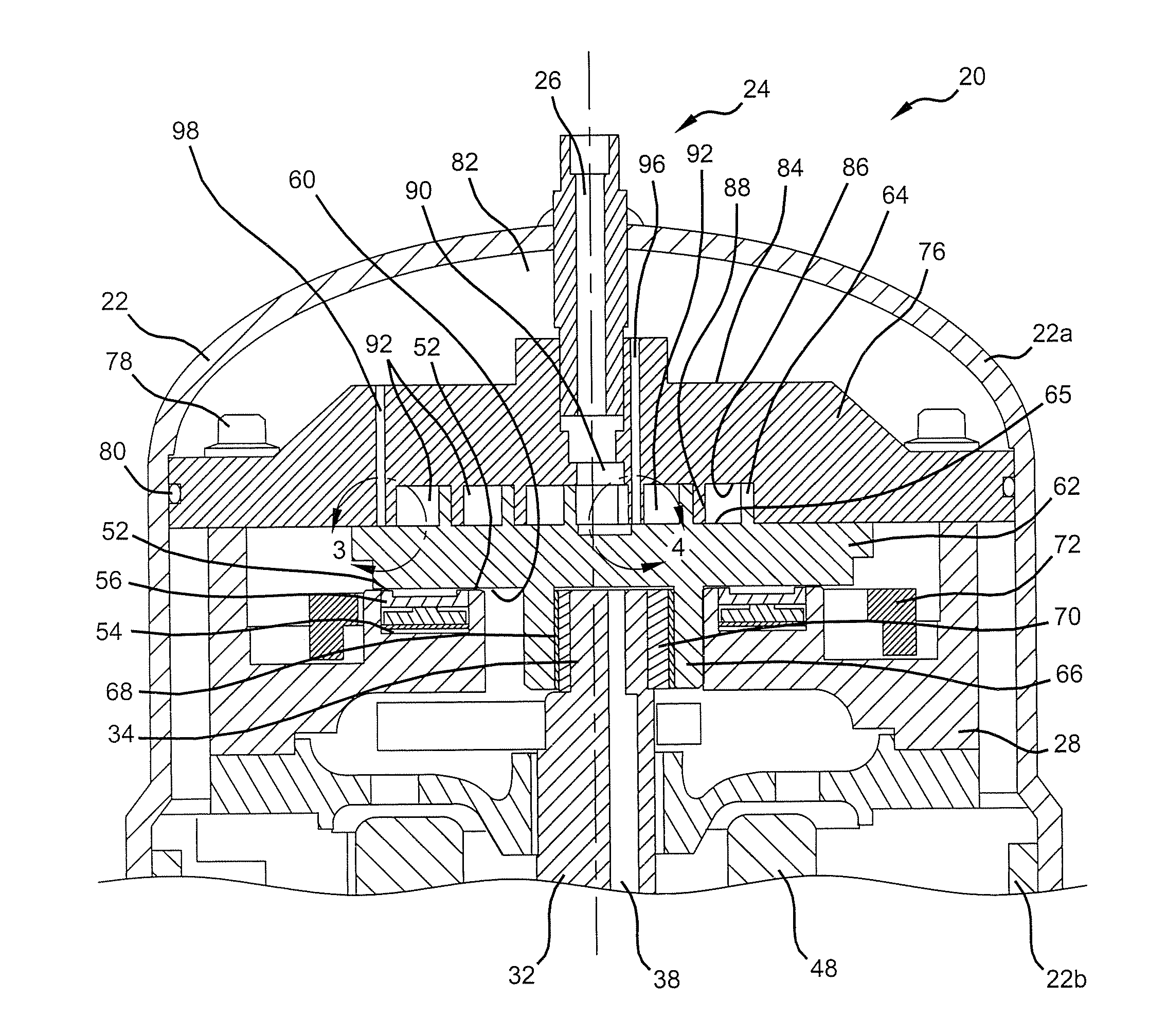

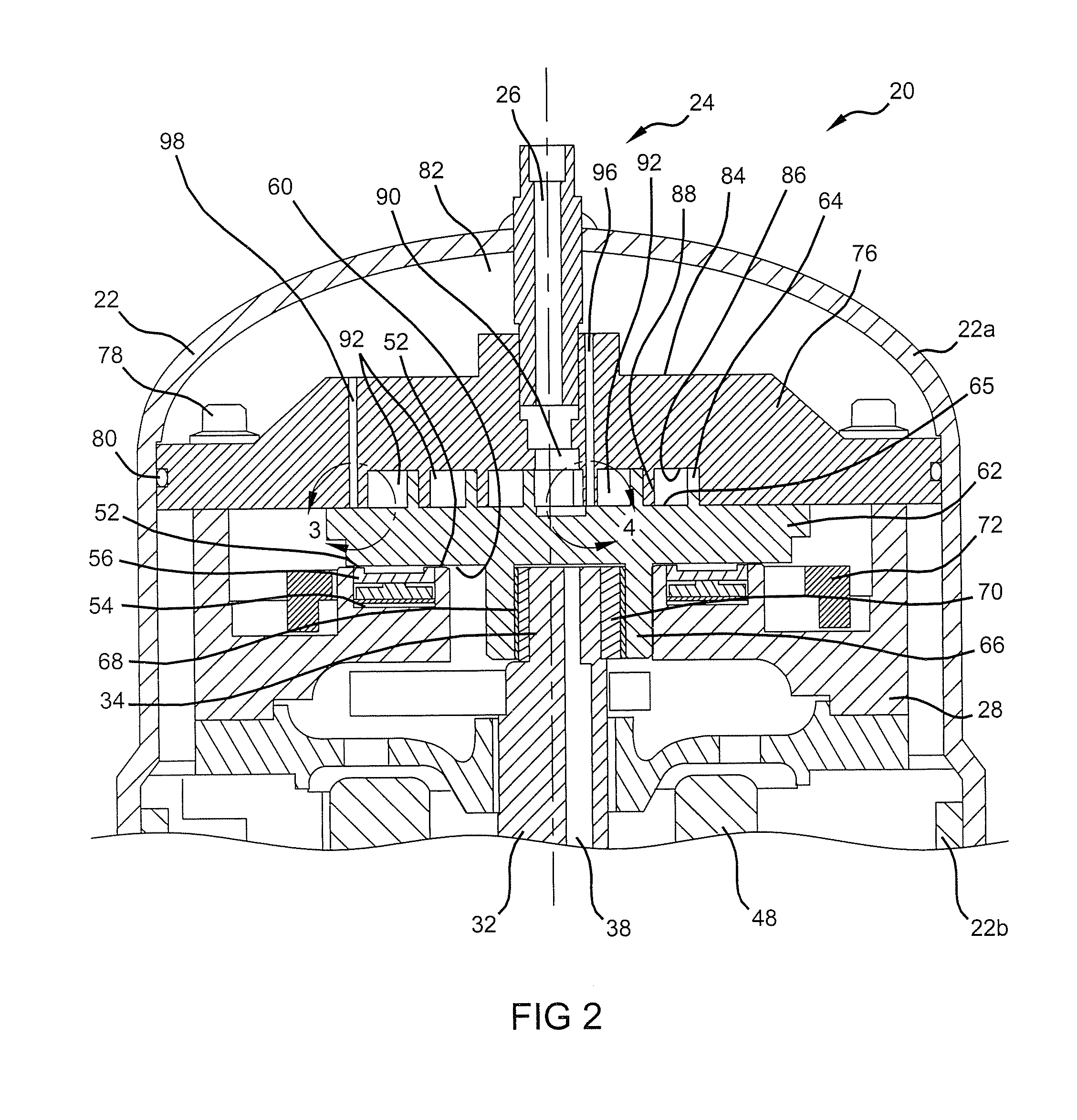

Polishing head assembly

InactiveUS6755723B1Optimize tilt and deformationEasy to tiltPolishing machinesRevolution surface grinding machinesEngineering

A polishing head assembly for retaining an object that is subject to polishing with a polishing pad is disclosed. The polishing head assembly comprises a head retainer assembly movably coupled to a wafer carrier head. The head retainer assembly includes a gimbal post and a load suspension plate. The gimbal post and the load suspension plate are operable to transfer a loading force to the wafer carrier head during polishing. The gimbal post also provides gimballing to optimize the position of the object in parallel with the polishing pad. In addition, the load suspension plate provides distribution of the loading force to optimize the flatness of the object during polishing.

Owner:APPLIED MATERIALS INC

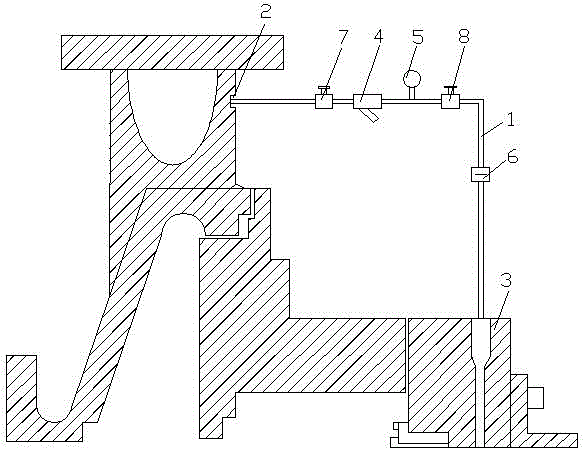

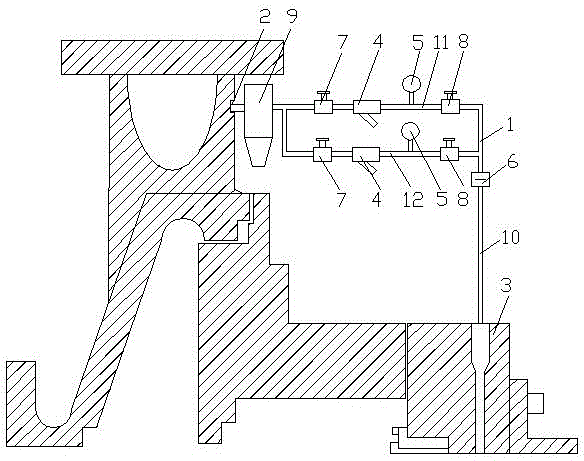

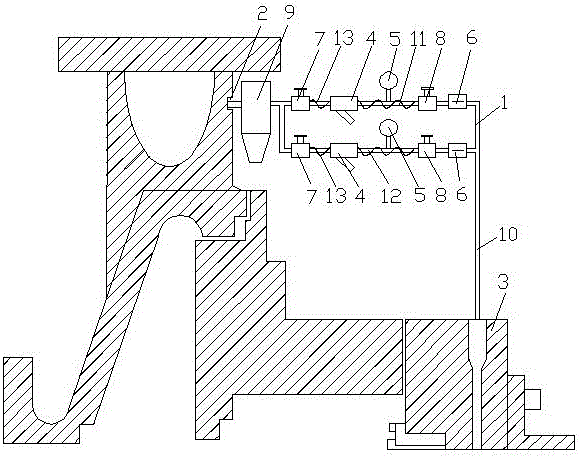

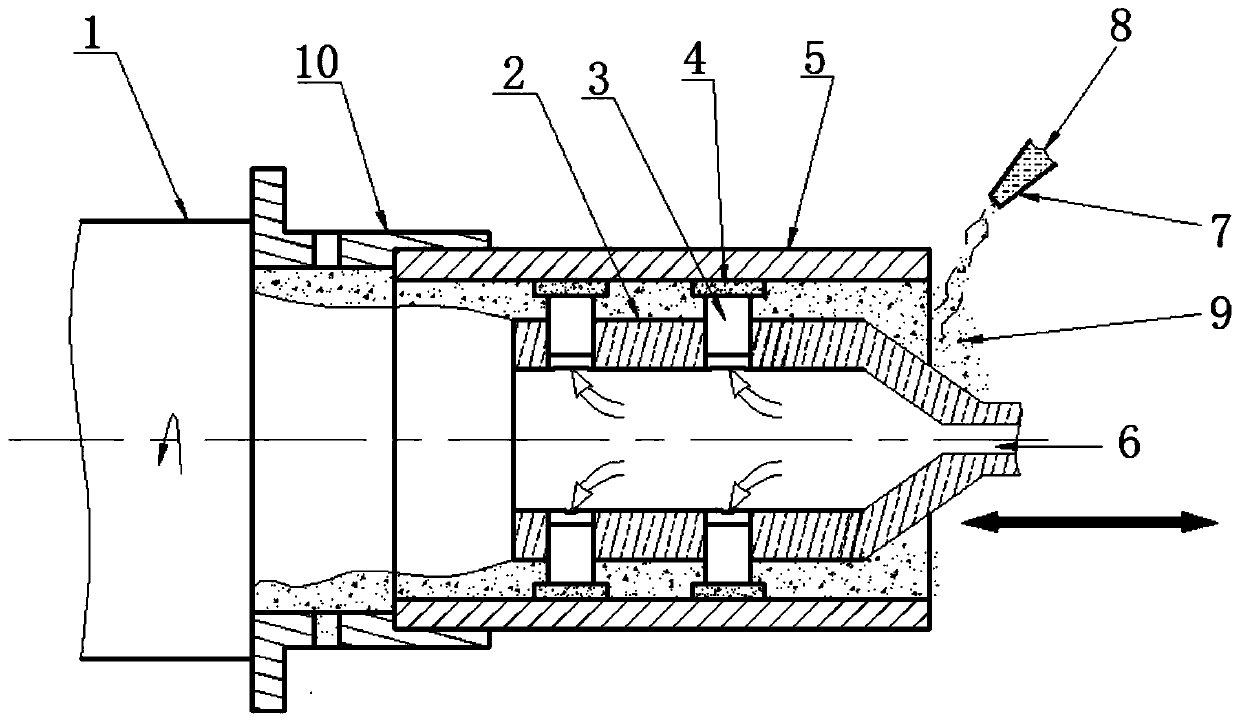

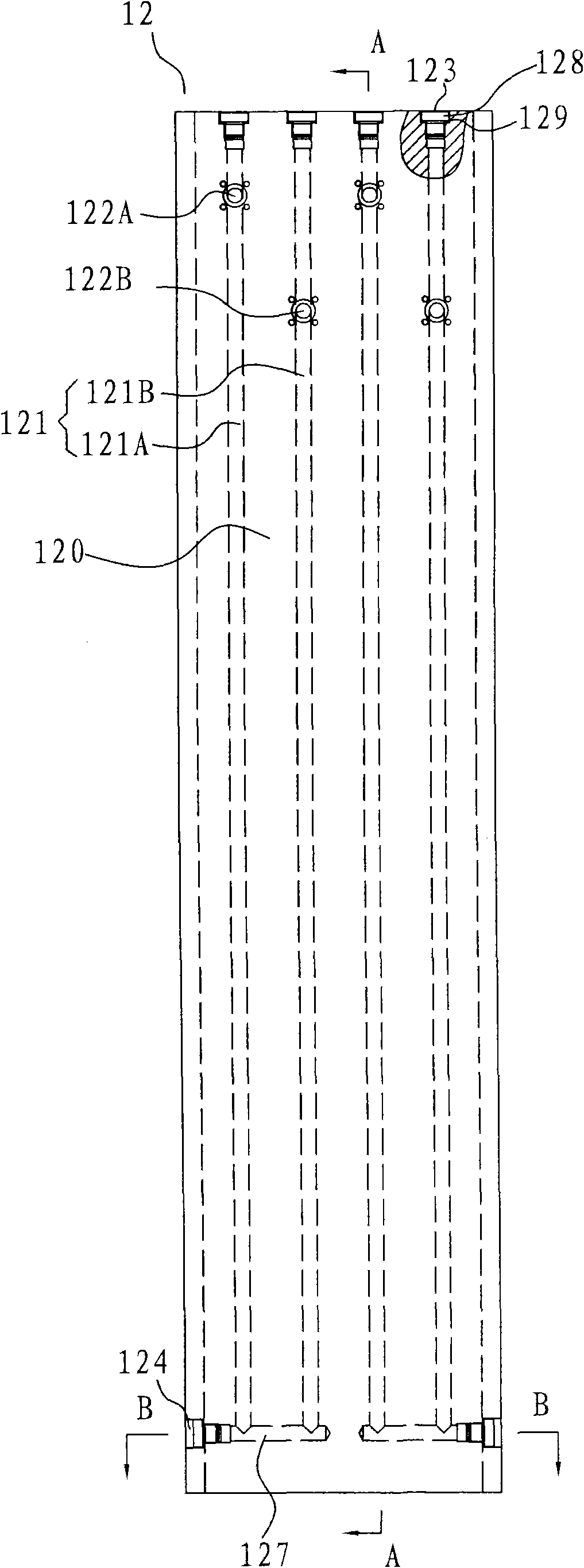

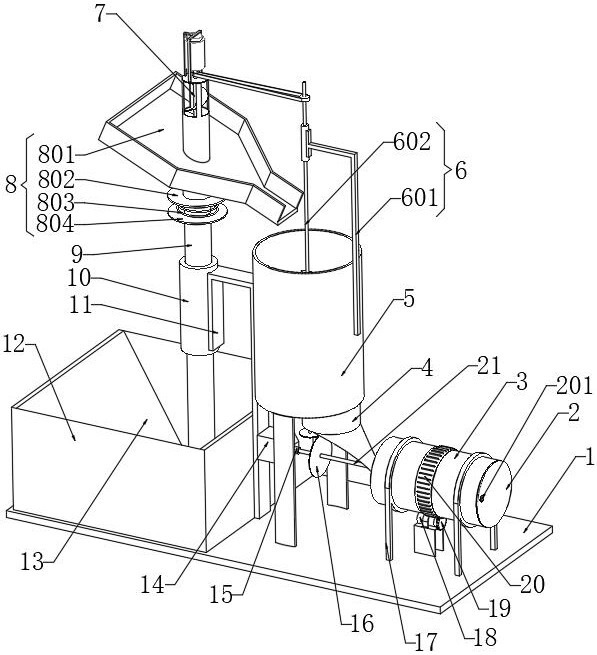

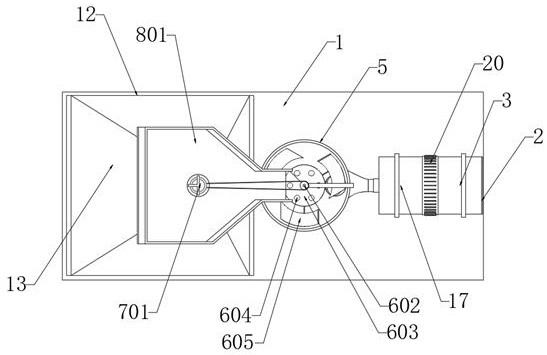

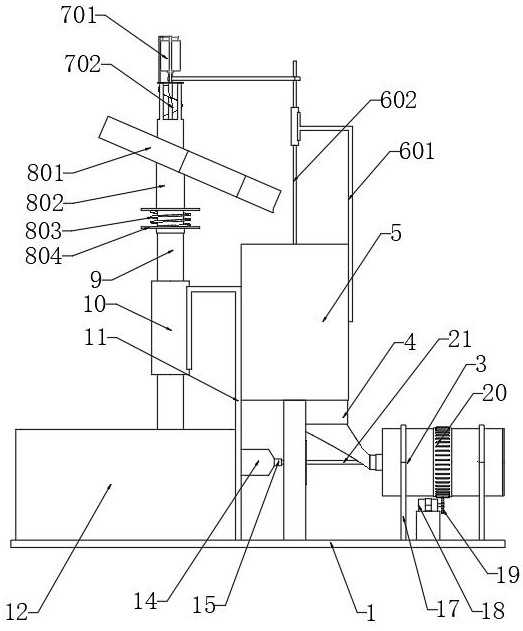

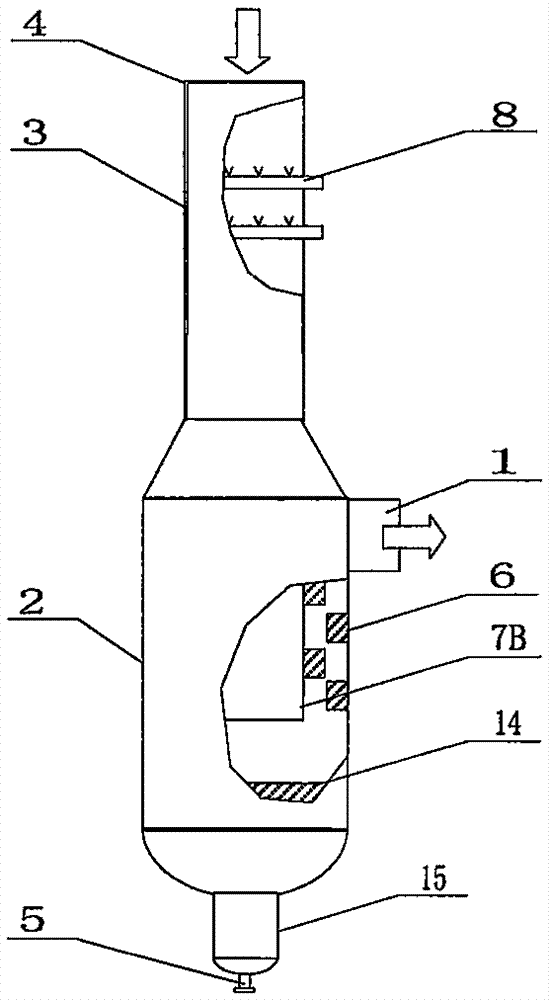

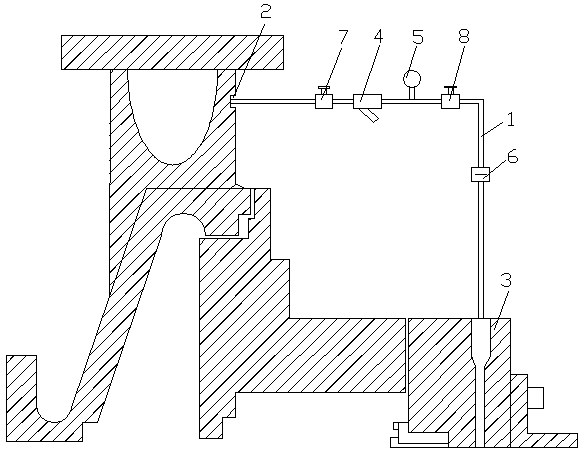

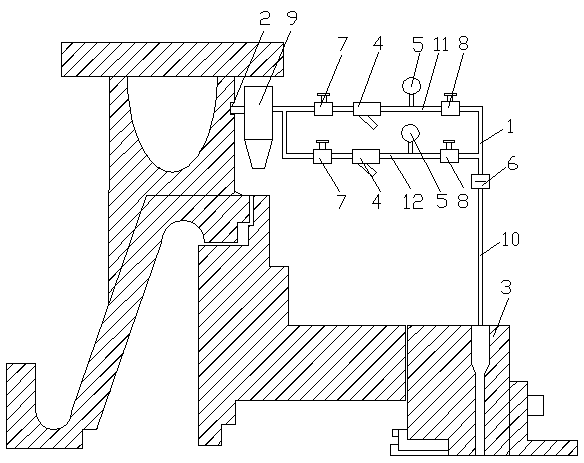

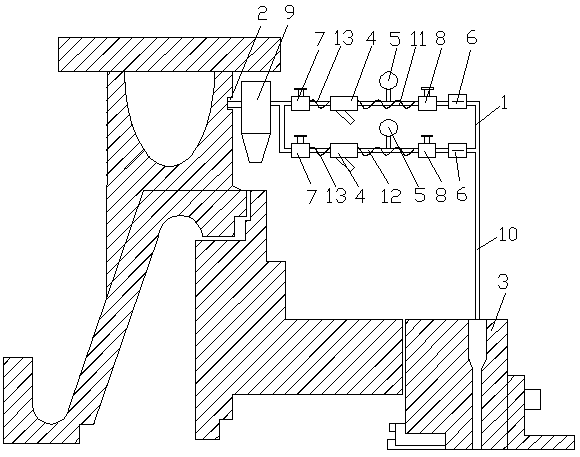

Flushing device for mechanical seal of centrifugal pump

ActiveCN106122108AFlow is stable and cleanPrevents deposition of particulate impuritiesPump componentsPumpsCentrifugal pumpOrifice plate

The invention discloses a flushing device for a mechanical seal of a centrifugal pump, and belongs to the technical field of centrifugal pumps. The flushing device comprises a flushing pipe connected to the centrifugal pump; the liquid feeding end of the flushing pipe is connected with the outlet end of the centrifugal pump; the liquid discharging end of the flushing pipe is connected with the mechanical seal of the centrifugal pump; the flushing device is characterized in that the flushing pipe is connected with a tubular filter, a pressure gauge and a throttling orifice plate; the tubular filter is close to the outlet end of the centrifugal pump; the throttling orifice plate is close to the mechanical seal of the centrifugal pump; a first stop valve and a second stop valve are arranged on the flushing pipe; the first stop valve is positioned between the outlet end of the centrifugal pump and the tubular filter; and the second stop valve is positioned between the pressure gauge and the throttling orifice plate. The flushing device can both achieve a good cooling effect on the mechanical seal and prevent particle impurities from being deposited on the sealing surfaces of movable and fixed rings, thus effectively protecting the sealing surfaces of the movable and fixed rings, relieving wear and enhancing the sealing effect; and therefore, normal and stable operation of the centrifugal pump is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

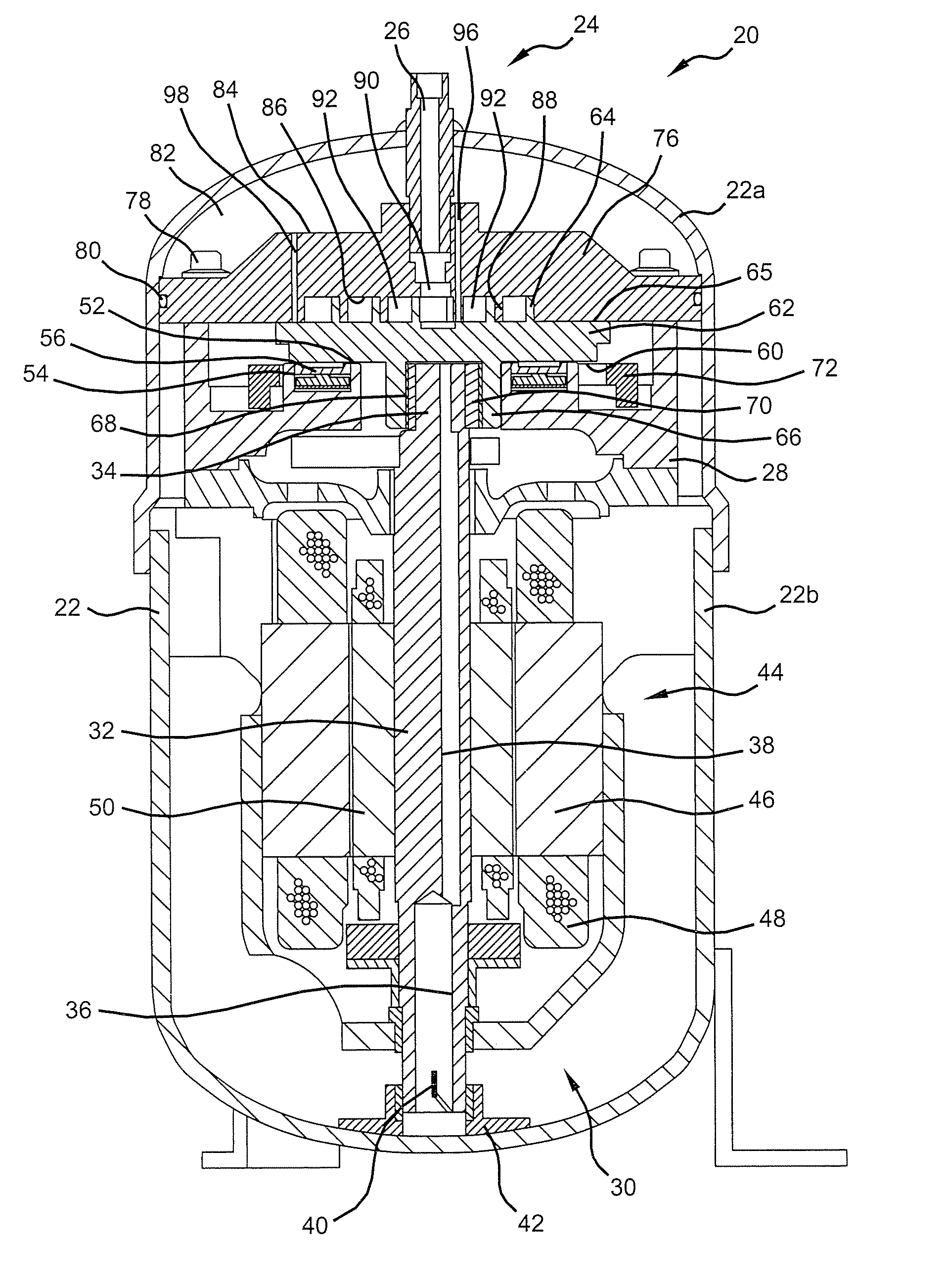

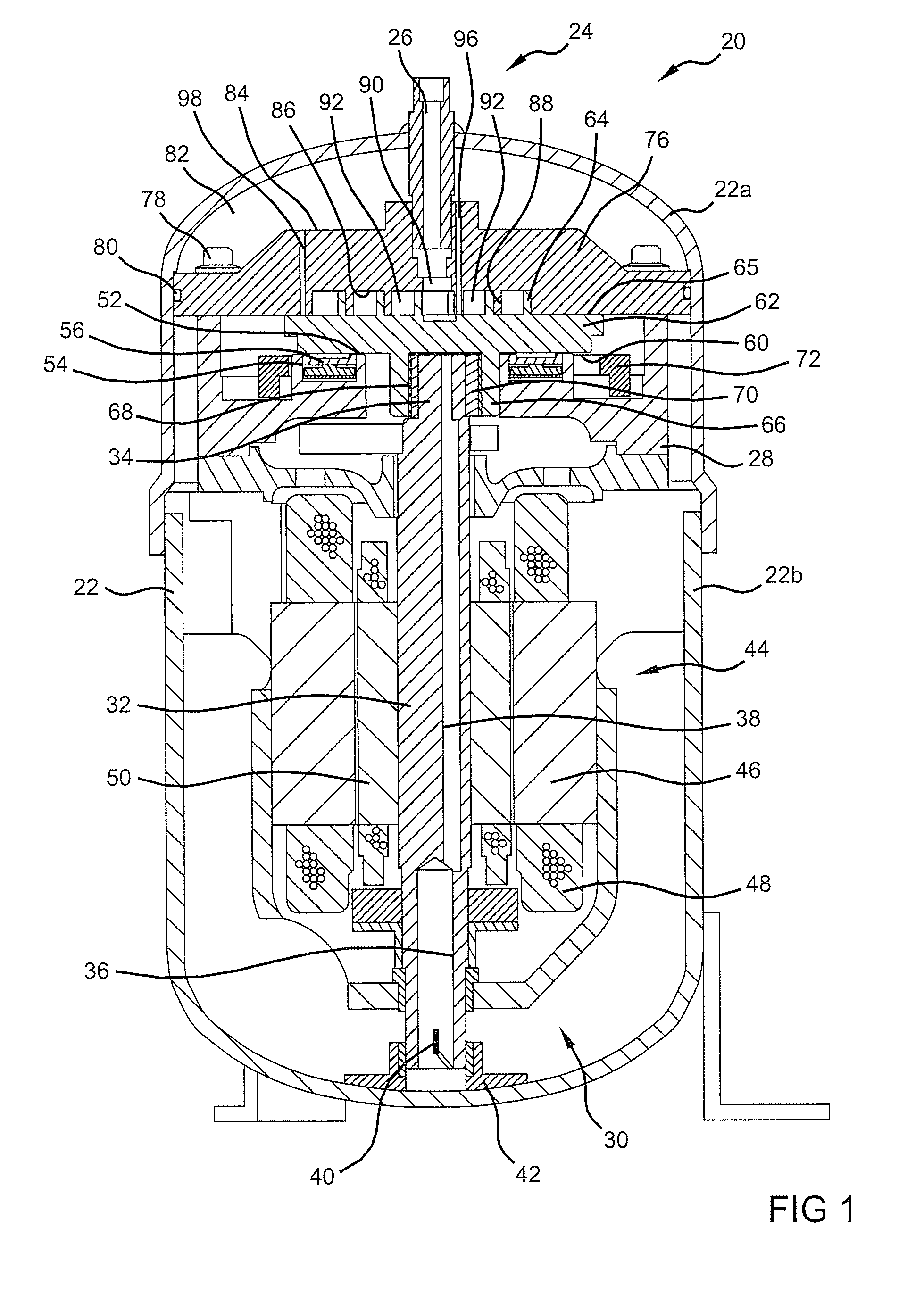

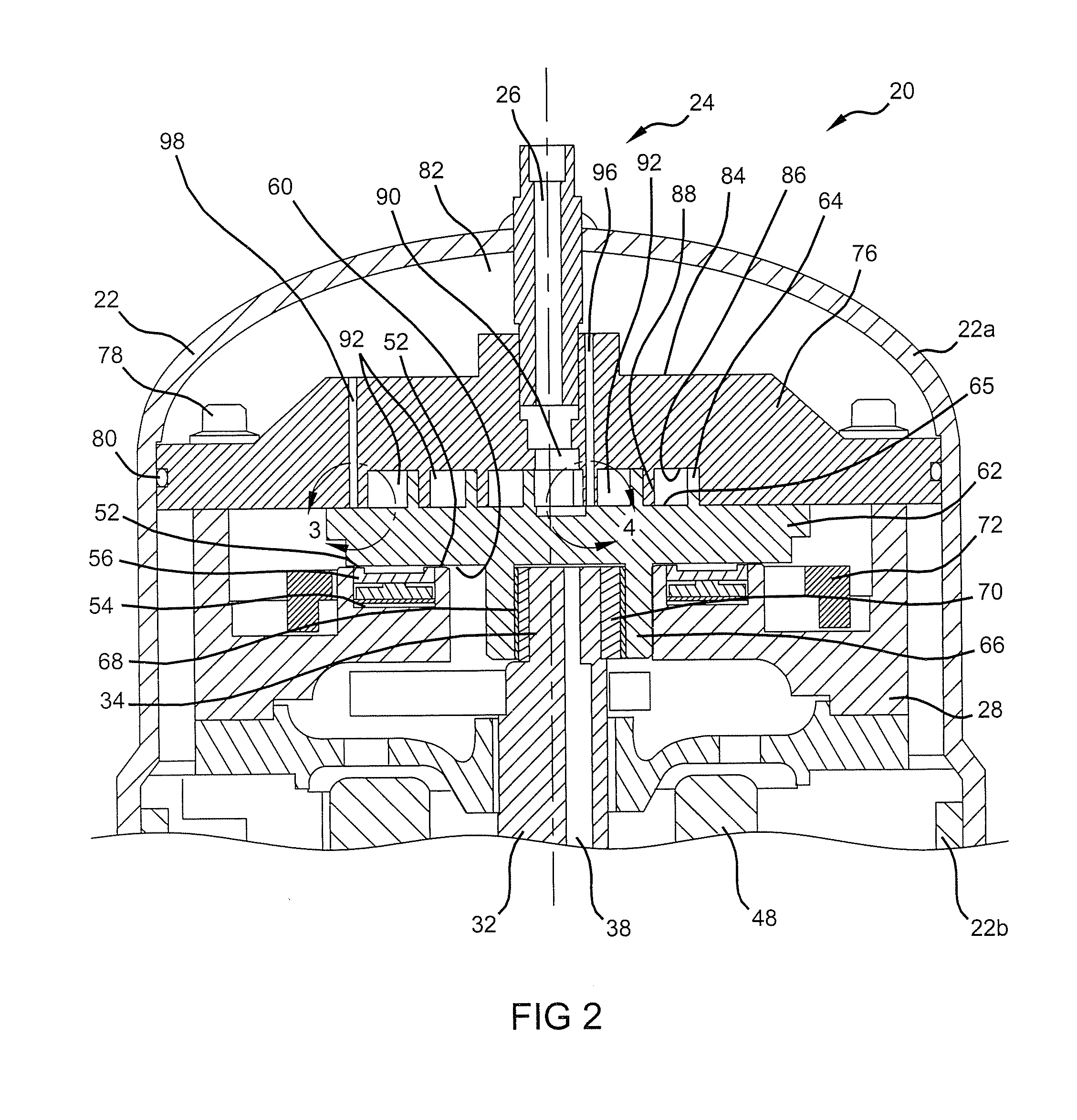

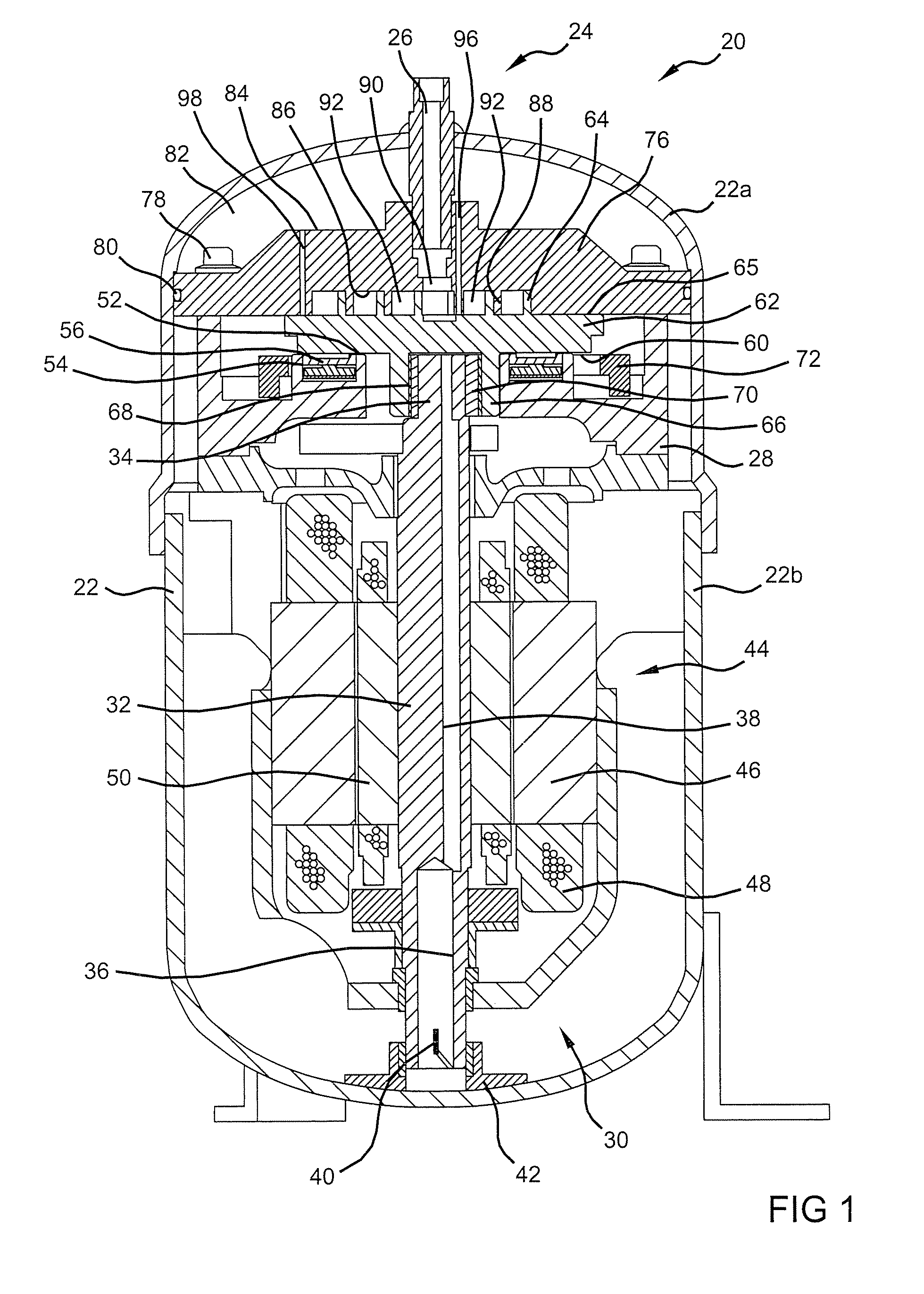

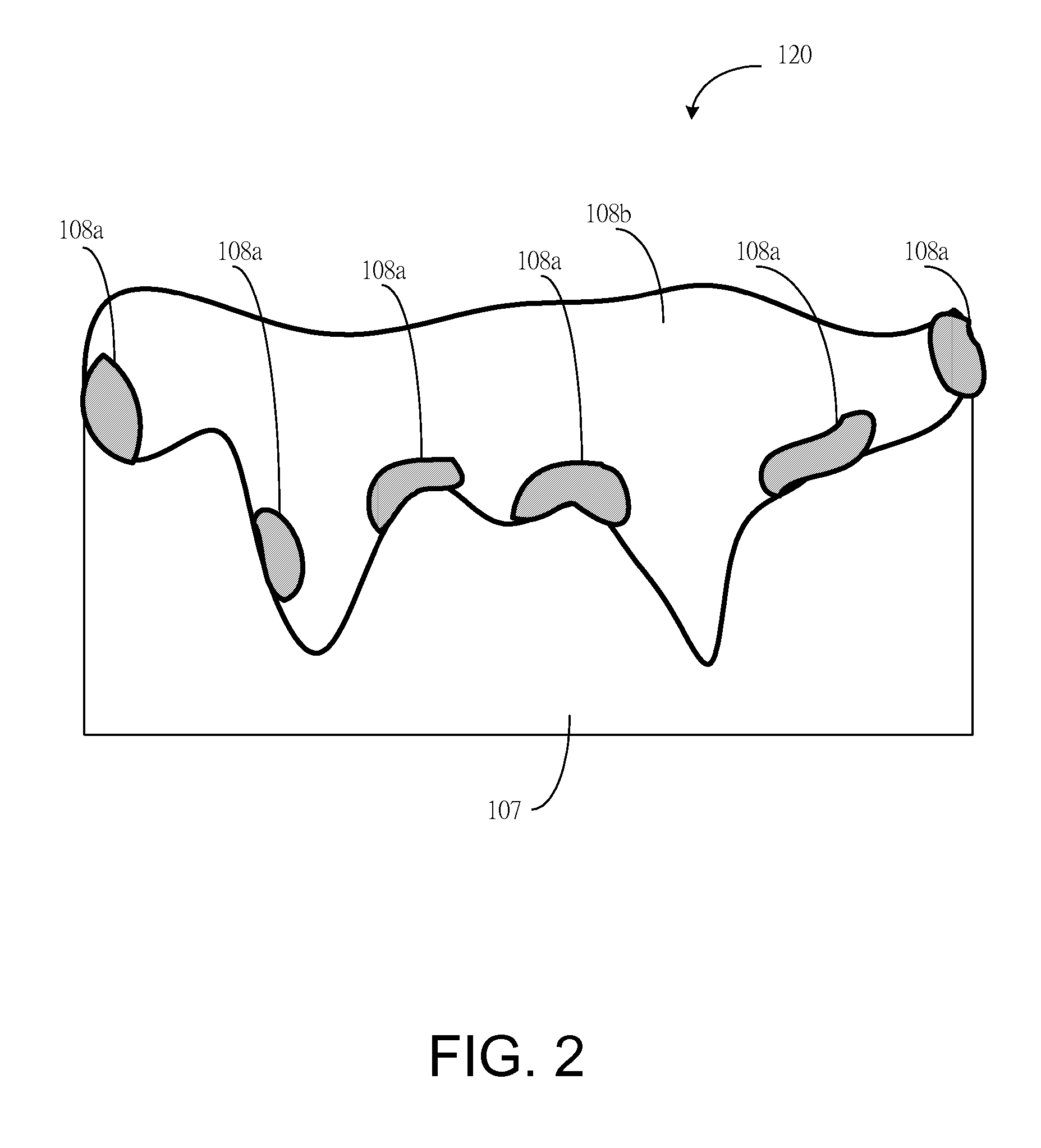

Scroll compressor with scroll deflection compensation

ActiveUS20090098000A1Improve efficiencyImprove contact uniformityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

A scroll compressor may incorporate controlled bending of a scroll member to compensate for axial deformations that can occur between the scroll members. The controlled bending may be through the use of fluid pressure in a sealed chamber that communicates with a surface of the scroll member opposite the intermeshing wraps. Fluid passageways can extend through the scroll member between the sealed chamber and the intermeshing wraps. The controlled bending can increase the uniformity of the contact between the scroll members and improve the efficiency of the compressing operation.

Owner:EMERSON CLIMATE TECH INC

Modified ammonium nitrate fuel explosive negatively pressurized static continuous production method

InactiveCN101139236ARaw material formula is simpleGood explosive performanceExplosive working-up apparatusWaxChemistry

The present invention discloses a negative-pressure, static and continual manufacturing method for a modified ammonium oil detonator. The steps include: (1) each raw material is matched according to the weight ratio: 80-92 percent of oxidant, 3-12 percent of water, 4-10 percent of ignitable composite cere; (2) the oxidant and the water are mixed in 100-140 DEG C to resolute into a hydrofacies material. (3) The composite cere is melted into an oil phase material in 90-120 DEG C; (4) The oil phase material and the hydrofacies material are mixed to become even suspending liquid after being mixed in the static mixing device; the mixing temperature is 95-140 DEG C; (5) the suspending liquid obtained in step (4) is pumped into a vacuum milling device and then is to milled into powder after being dehydrated in vacuum state; the vacuum drying pressure is 0.01-0.03 MPa; the temperature in the milling device is 60-100 DEG C. The blasting performance of the modified ammonium oil detonator prepared by the present invention is much better without agglomeration; besides, the present invention is with safe production and low cost. The energy consumption can be decreased 20 percent.

Owner:唐秋明

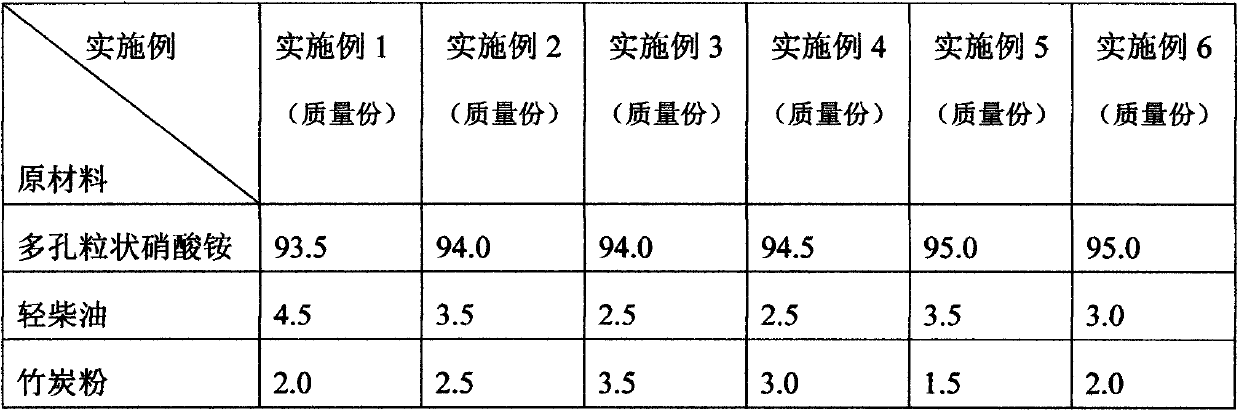

Improved type porous granular ammonium nitrate fuel oil explosive and preparing method thereof

The invention discloses an improved type porous granular ammonium nitrate fuel oil explosive and a preparing method thereof. The improved type porous granular ammonium nitrate fuel oil explosive is prepared by mixing the following three raw materials in percentage by weight: 93%-95% of porous granular ammonium nitrate, 2.5%-5.0% of light diesel oil and 1.5%-4.0% of bamboo charcoal powder. The preparing method comprises the following steps of adding the porous granular ammonium nitrate to a dispersator according to quantity, then slowly adding sufficient light diesel oil, sufficiently stirring for 5 minutes, and then stopping stirring; standing for 5 minutes, starting the dispersator again, slowly adding the residual bamboo charcoal powder, continuously stirring till color and luster are uniform, wherein the black bamboo charcoal powder is uniformly absorbed on the surface of the porous granular ammonium nitrate; finally filling and sealing to obtain the finished improved type porous granular ammonium nitrate fuel oil explosive product which has the advantages of uniform stirring, excellent property, low moisture absorption and agglomeration ratio, stability in storage, safety, environmental protection, energy conservation, low consumption and low cost.

Owner:ZHEJIANG ZHENKAI CHEM IND +1

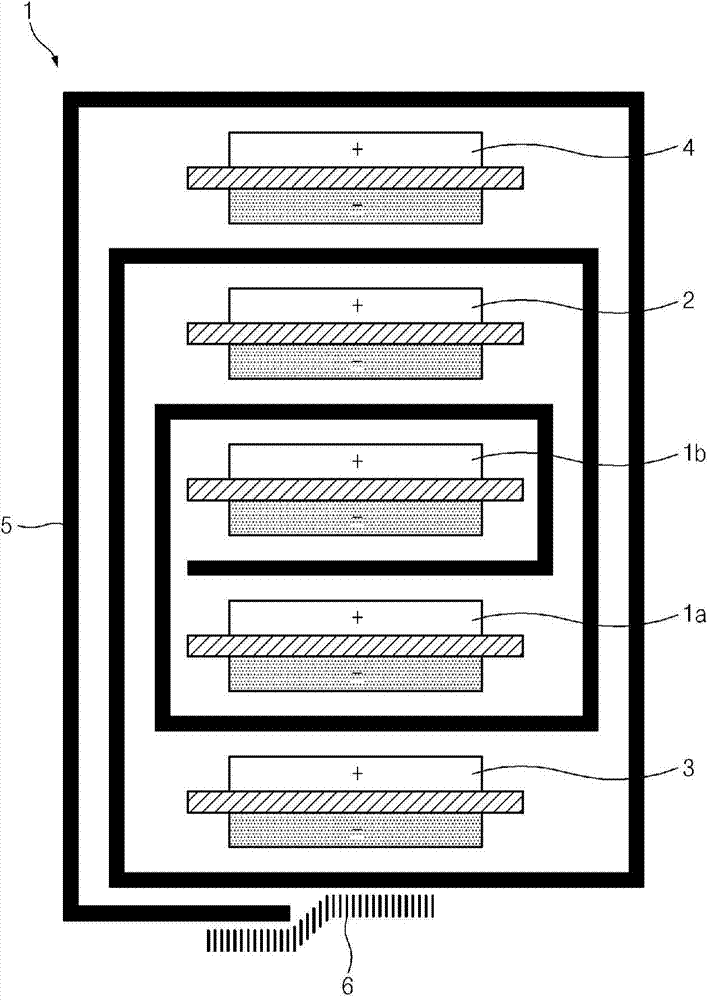

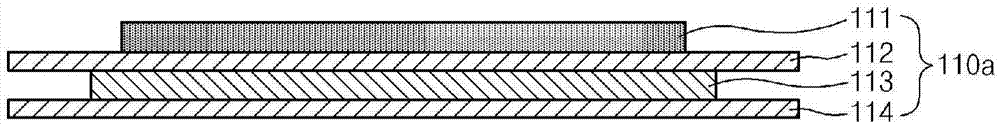

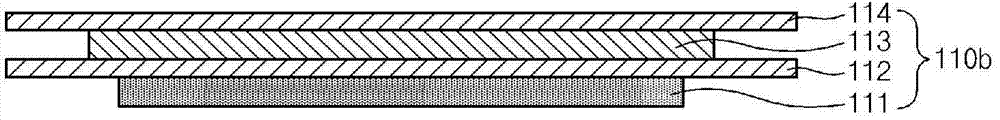

Method for manufacturing electrode assembly

ActiveCN104718656ASimple processLow costElectrode rolling/calenderingLarge-sized flat cells/batteriesEngineeringUnit structure

The present invention relates to a method for manufacturing an electrode assembly by a third process which is neither a stack folding process or a stack process. The method for manufacturing an electrode assembly in accordance with a preferred embodiment of the present invention comprises: a step (S10) of forming a unit structure comprising a structure stacked in the order of a first electrode, a first separation membrane, a second electrode, and a second separation membrane, or comprising a structure in which the structure is repeated multiple times; a step (S20) of forming an electrode assembly by stacking the unit structure in multiple layers; and a step (S30) of discharging a gas interposed between respective layers by pressurizing the electrode assembly.

Owner:LG ENERGY SOLUTION LTD

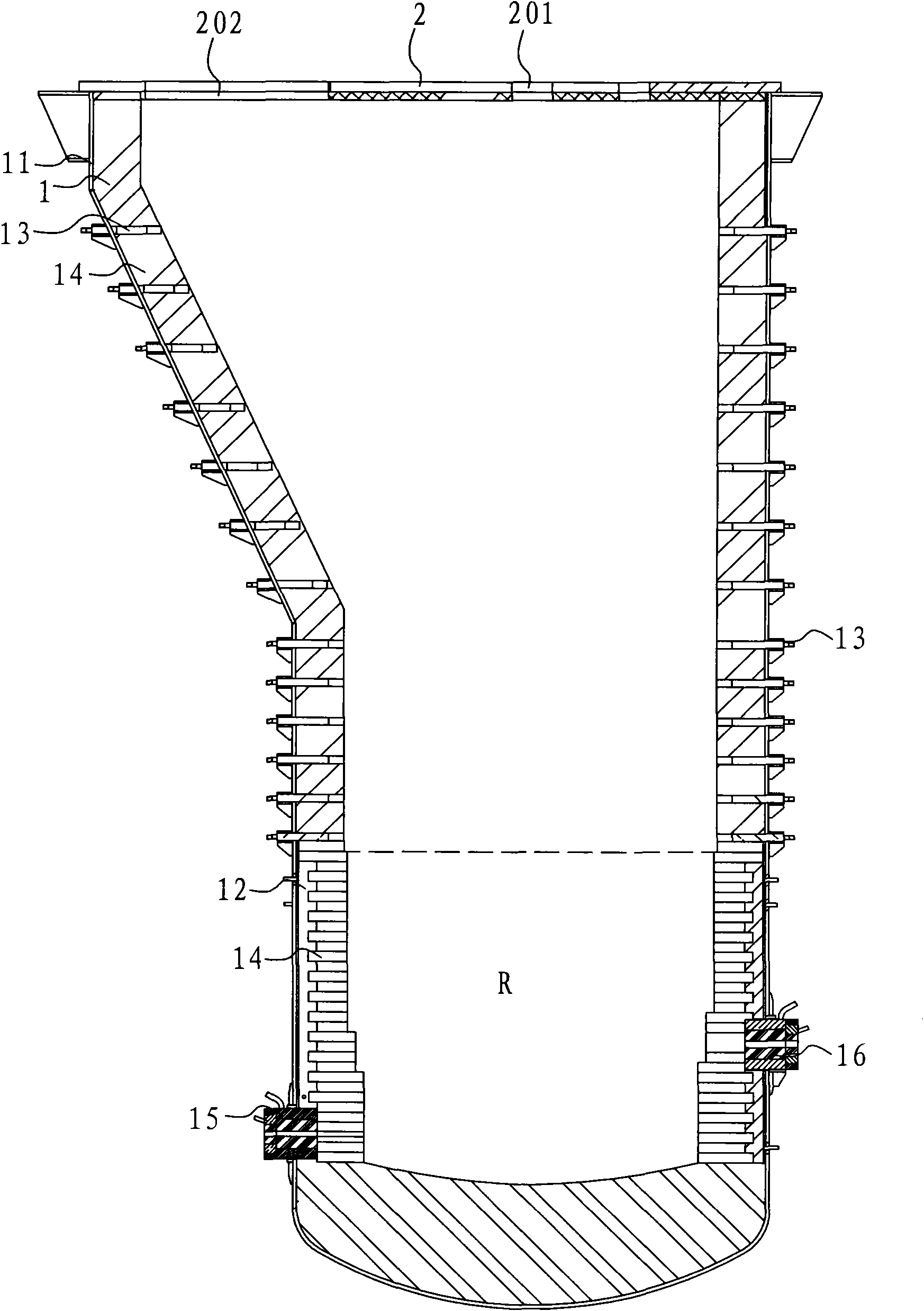

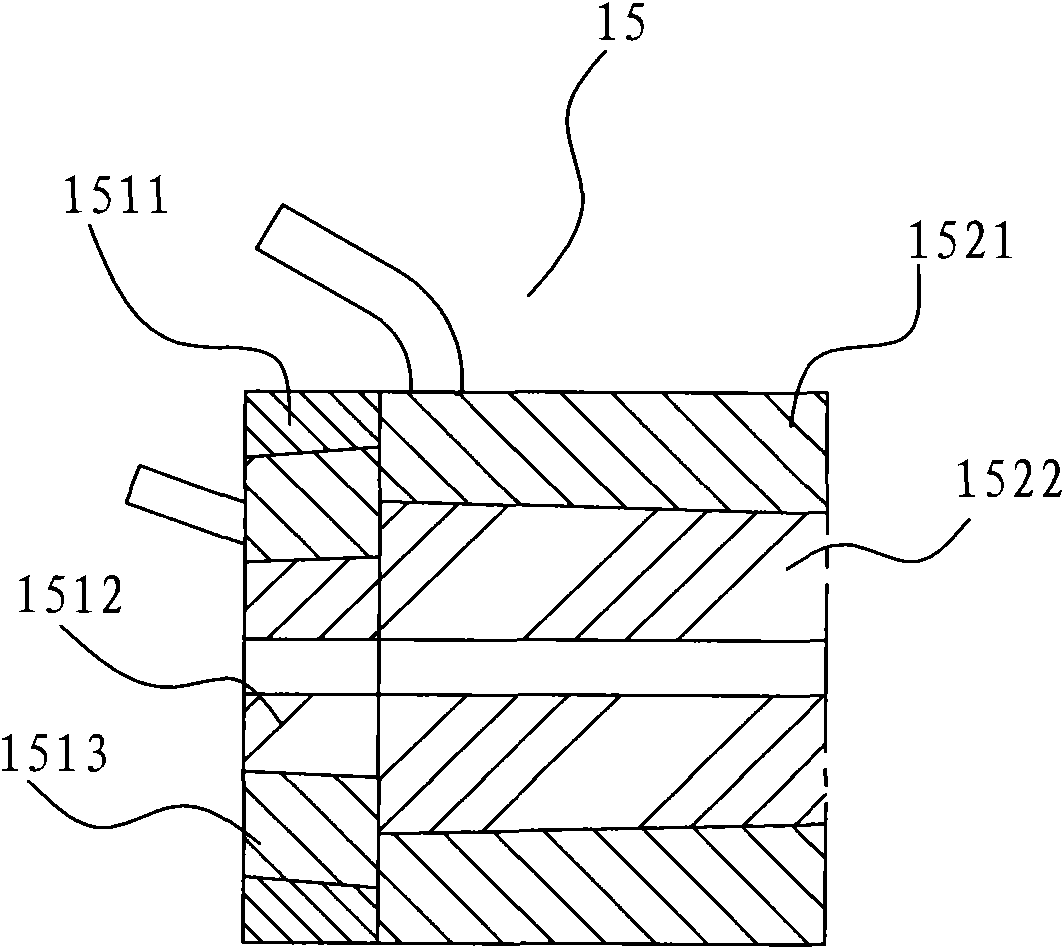

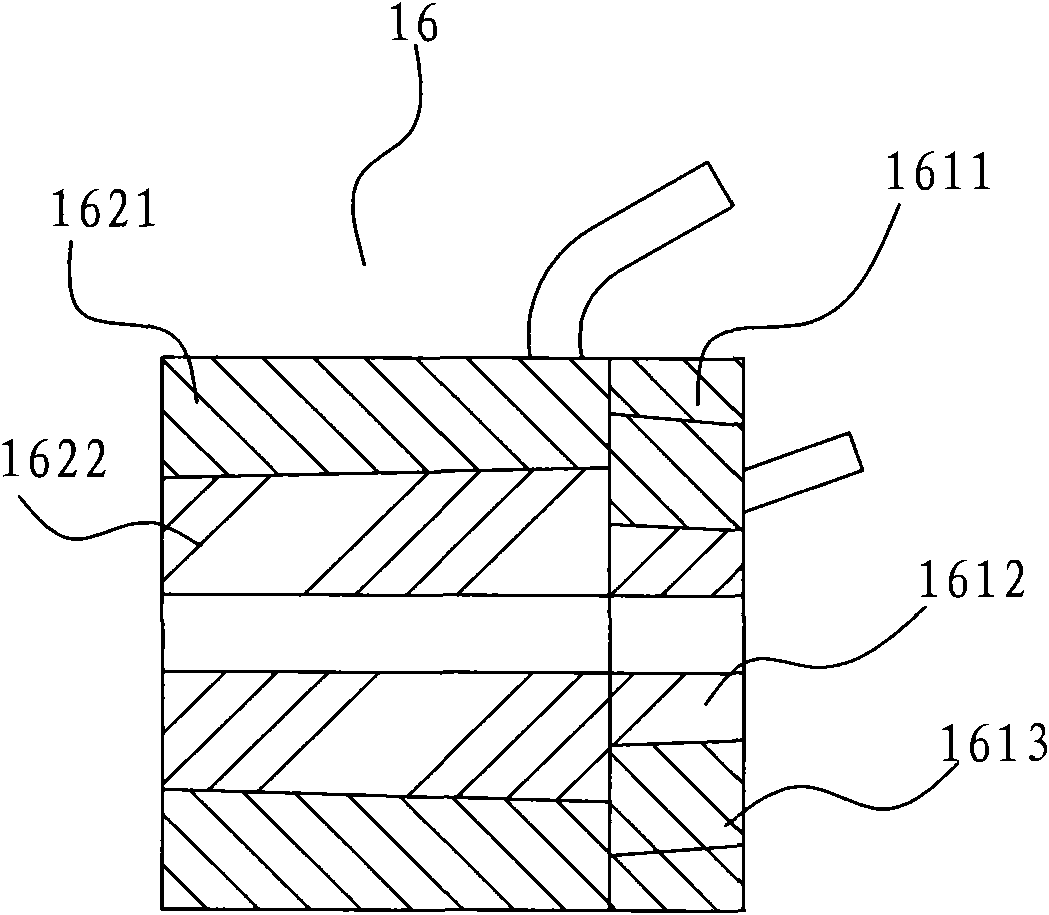

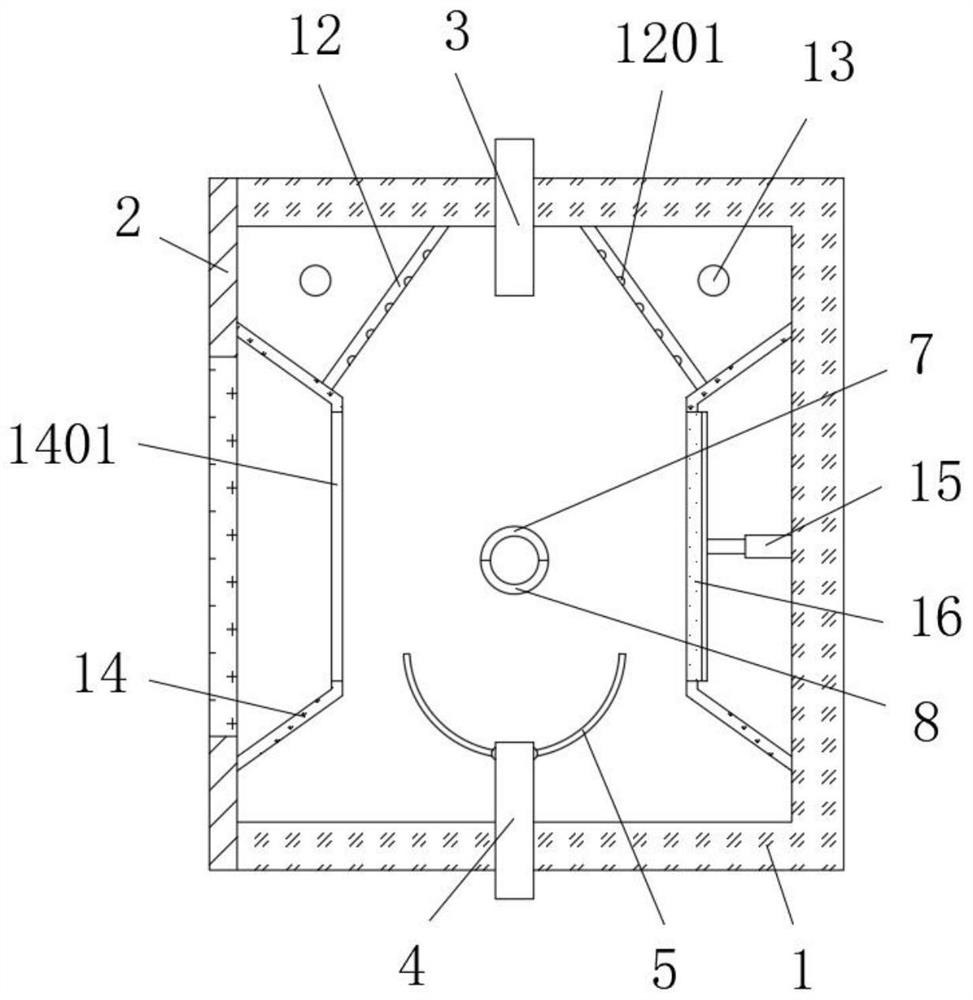

Self-heating smelting furnace

ActiveCN101839640AImprove cooling effectImprove bindingCharge manipulationCrucible furnacesBrickCooling effect

The invention discloses a self-heating smelting furnace, which comprises a furnace body, a furnace cover and a dentiform water jacket. The furnace body comprises a furnace shell and refractory brick layers arranged in the furnace shell; the furnace cover is used for sealing an opening at the top end of the furnace body; the dentiform water jacket is arranged in the furnace body and comprises a jacket body and a cooling medium channel; the cooling medium channel is formed in the jacket body and is provided with a cooling medium inlet for supplying cooling media and a cooling medium outlet for discharging the cooling media; and the surface of the inner side of the jacket body is a dentiform surface. According to the self-heating smelting furnace, the surface of the inner side of the dentiform water jacket is the dentiform surface, so refractory bricks of the smelting furnace can be matched in a groove so as to improve the combination performance of the dentiform water jacket and the refractory bricks and reduce gaps between the dentiform water jacket and the refractory bricks; and in addition, due to large contact area and good contact uniformity, the self-heating smelting furnace has excellent cooling effect.

Owner:CHINA ENFI ENGINEERING CORPORATION

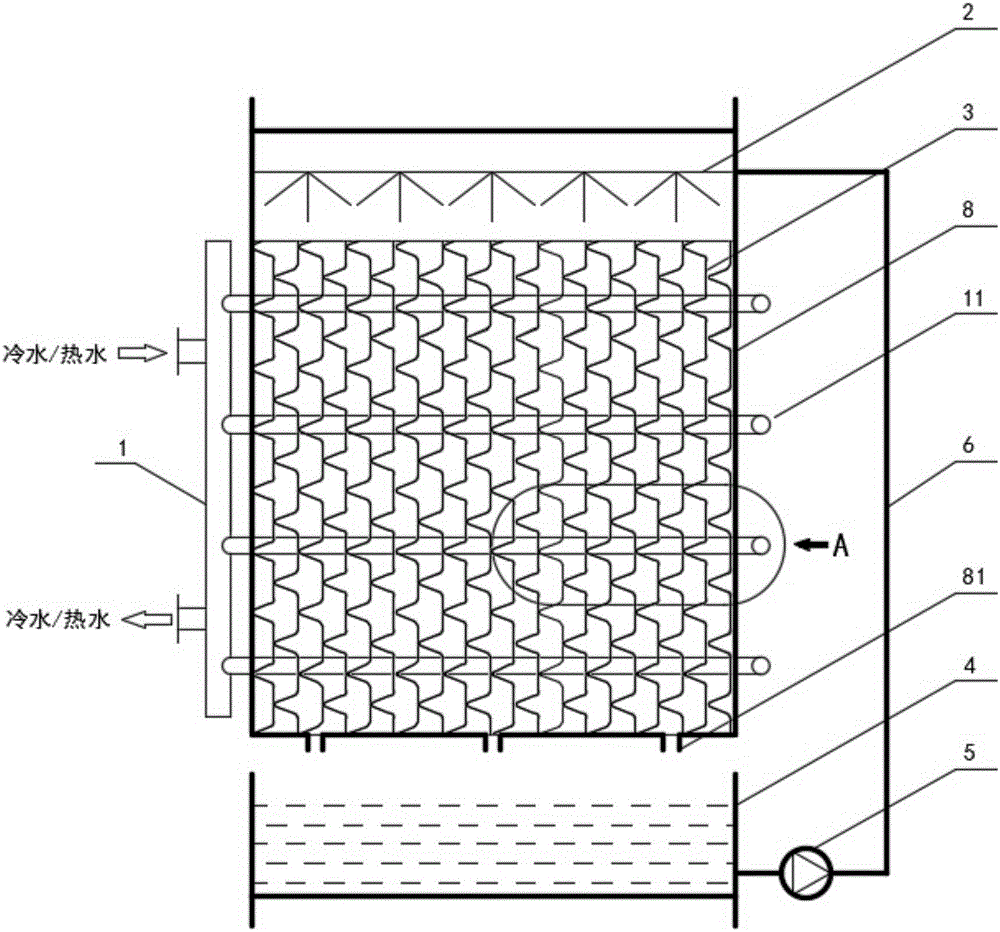

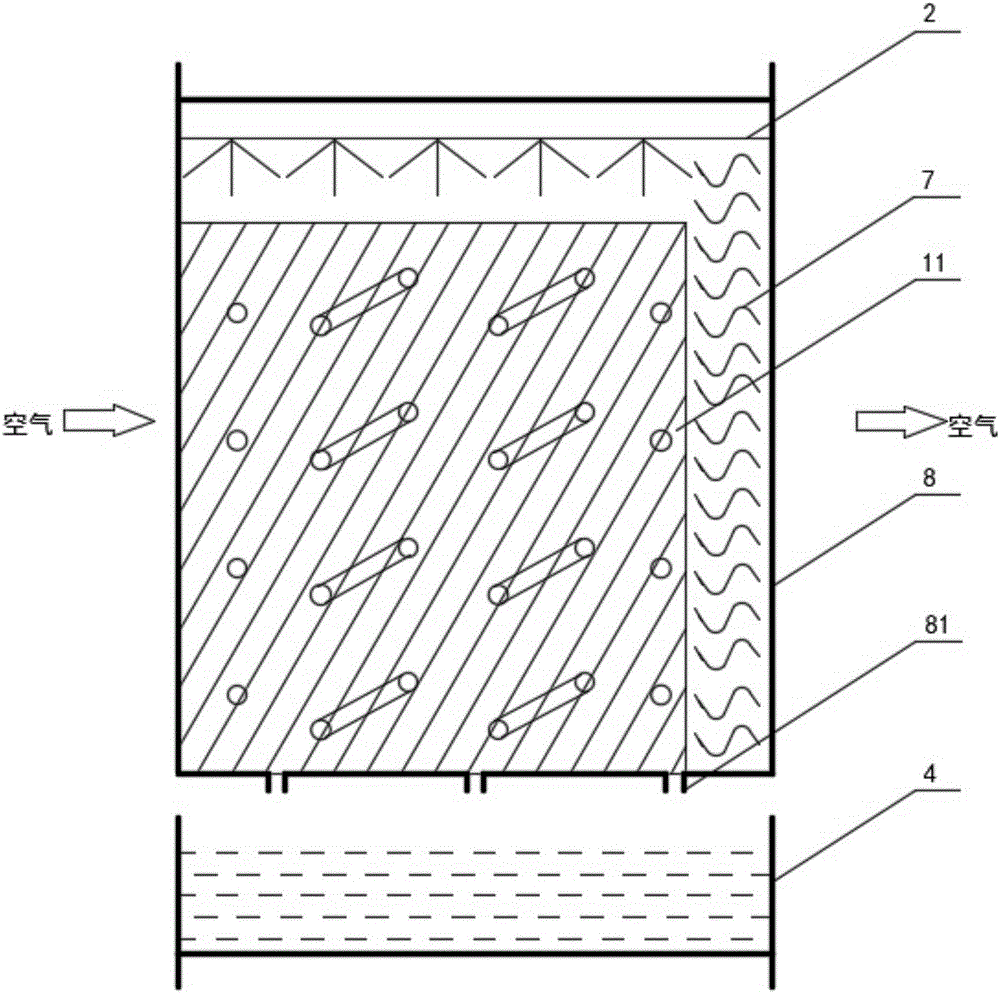

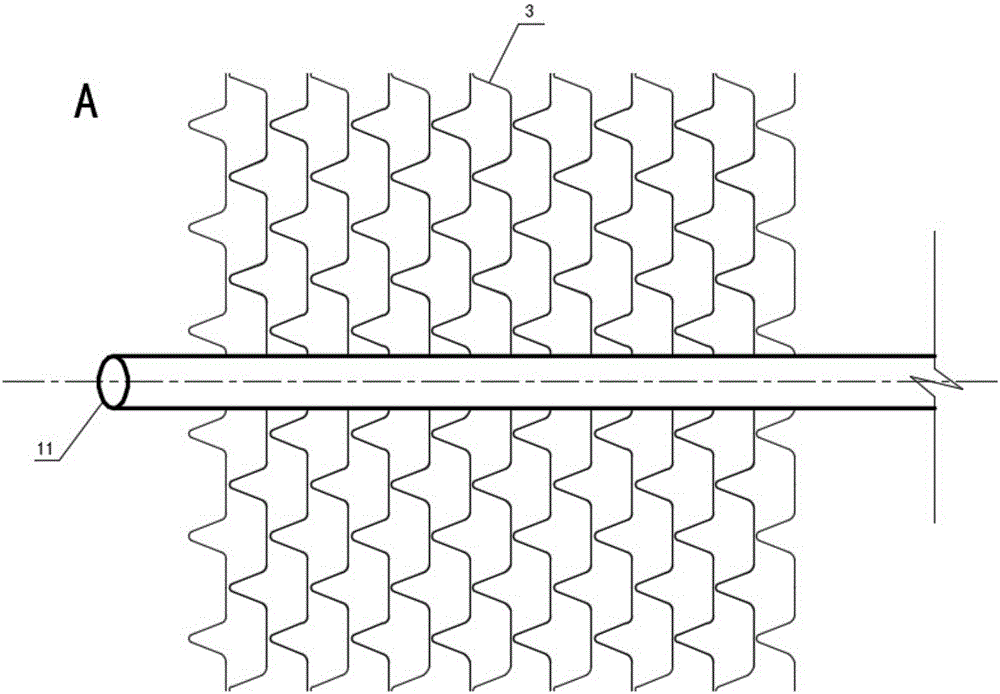

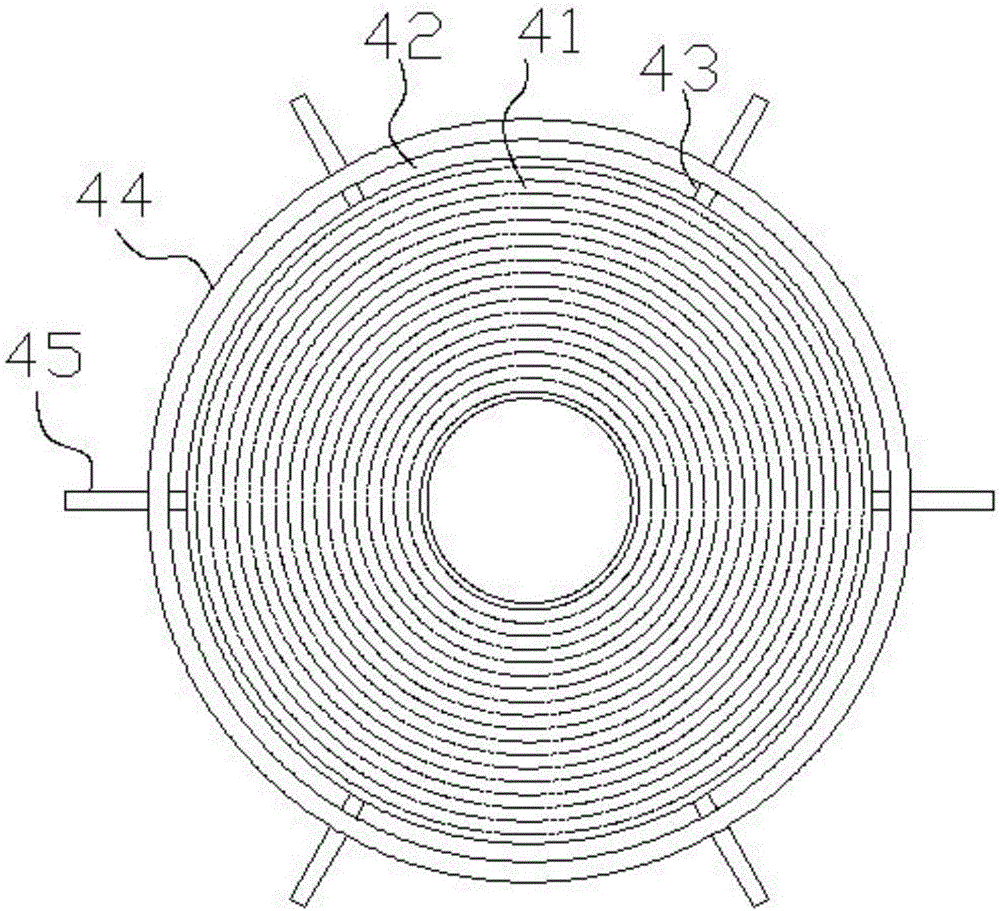

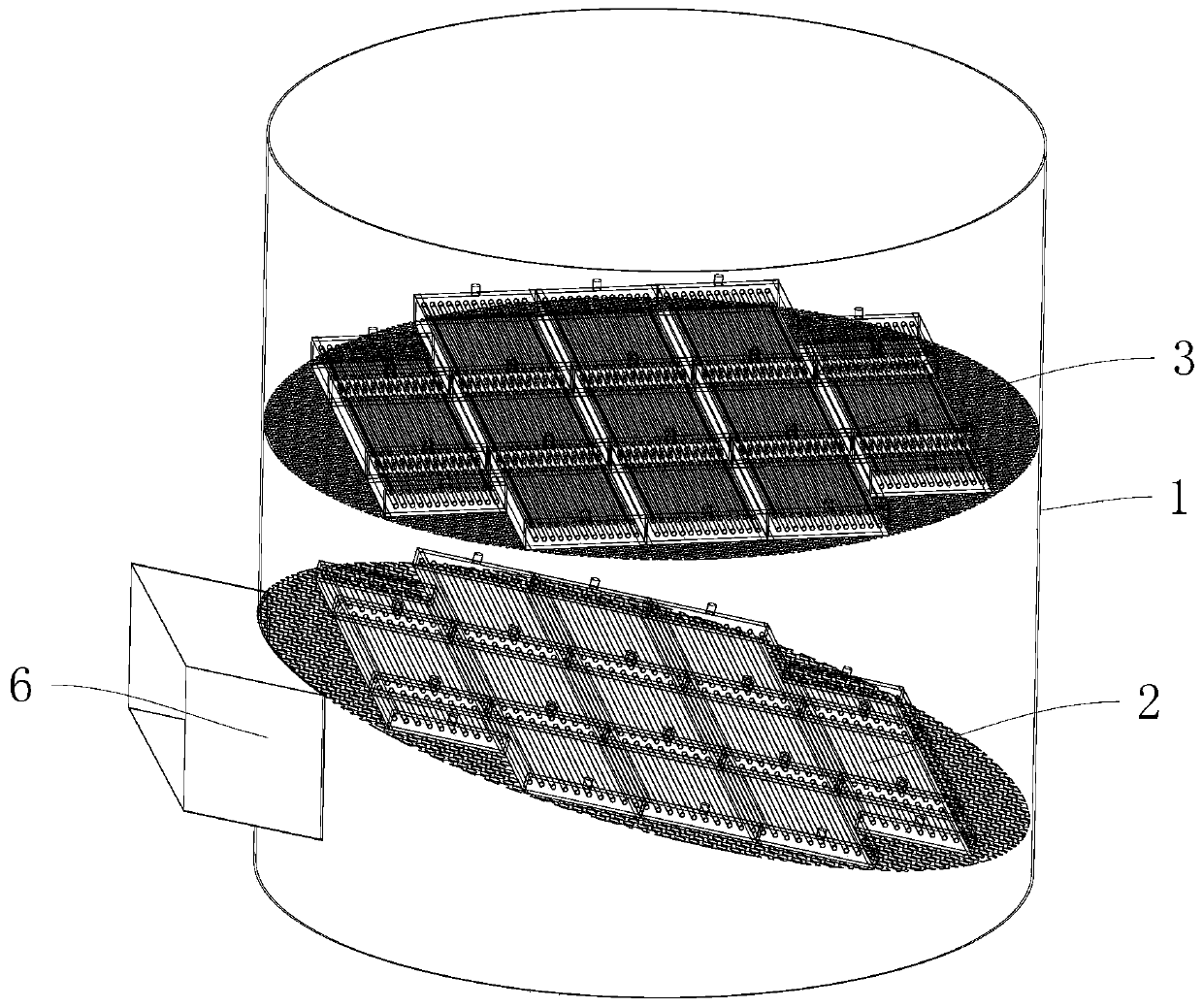

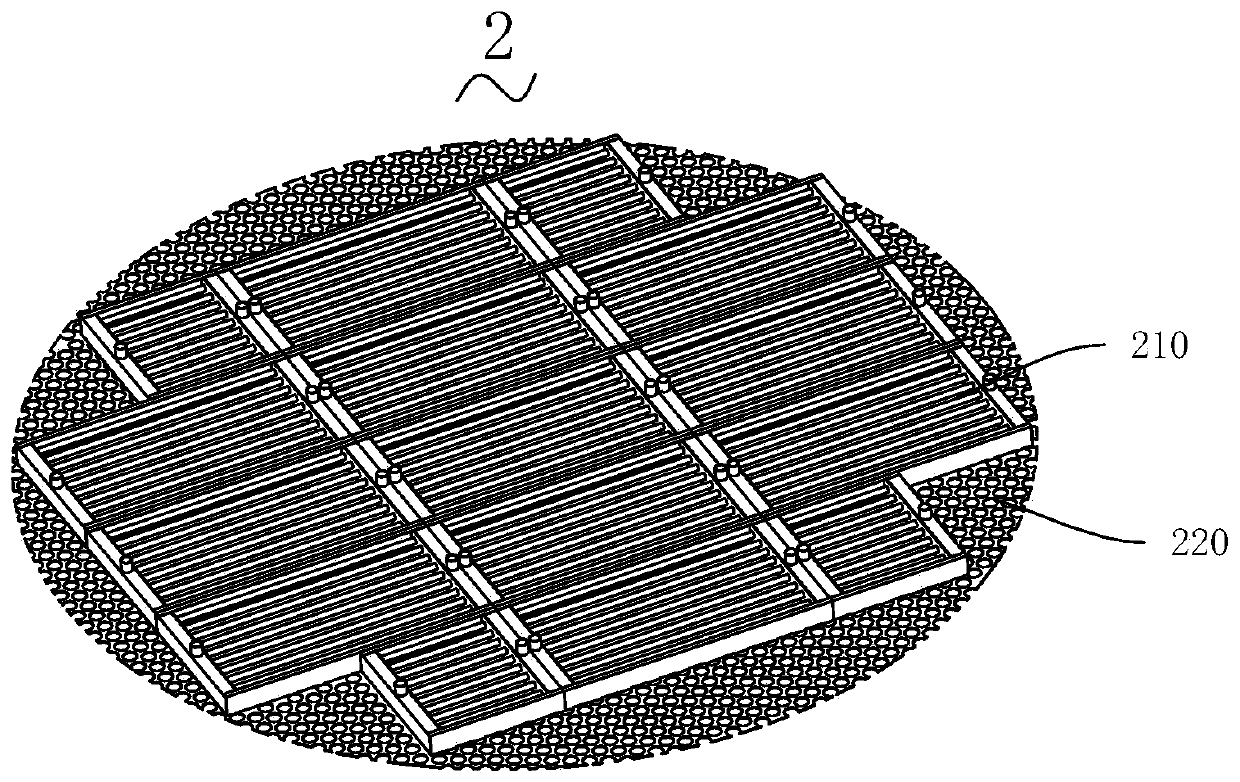

Gas-liquid whole-heat exchange device with built-in cold and heat source based on metal fiberfill

ActiveCN105890147AIncrease contact areaExtension of timeSpace heating and ventilation detailsTrickle coolersMetal fiberHeat mass transfer

The invention discloses a gas-liquid whole-heat exchange device with a built-in cold and heat source based on a metal fiberfill. The gas-liquid whole-heat exchange device comprises a heat exchange coil, a sprayer, a metal fiberfill, a solution tank, a solution pump, a solution circulating pipeline and a tank body, wherein the solution tank is located under the tank body; the sprayer is arranged above the metal fiberfill; the solution tank is communicated with the sprayer through the solution circulating pipeline; the solution pump is arranged on the solution circulating pipeline; the heat exchange coil and the metal fiberfill are arranged in the tank body; the metal fiberfill is formed by overlapping and assembling the inclined ripple metal fiber mats at two angles; the surfaces of the metal fiber mats are preferably treated through hydrophilic nano coating; the heat exchange coil comprises a metal heat exchange tube which penetrates through the metal fiber mats along the overlapped direction of the metal fiber mats; a solution flowing channel and an air-guide channel are formed between the two adjacent metal fiber mats. According to the device, can effectively increase the contact area between the solution and air can be effectively increased, the contact time of the solution and air can be effectively prolonged, the heat mass transfer coefficient can be increased and the device can be served as a dehumidifying or regenerating unit of a solution humidity-adjusting air-conditioning system.

Owner:BEIJING KANGFU TECH

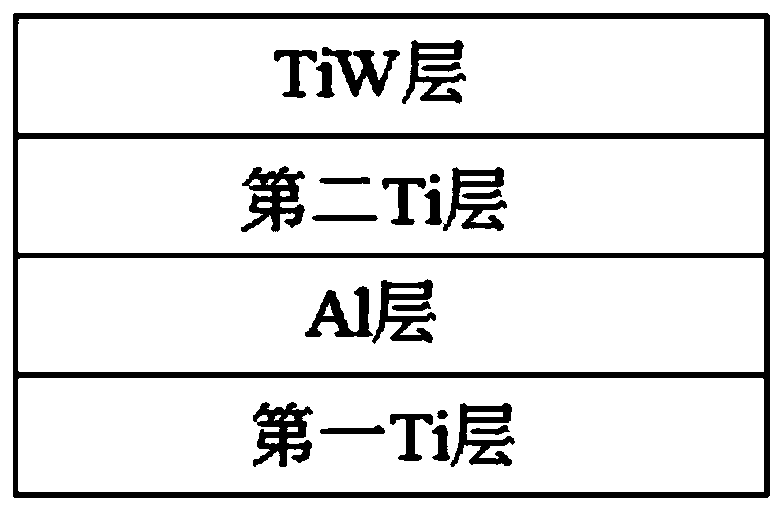

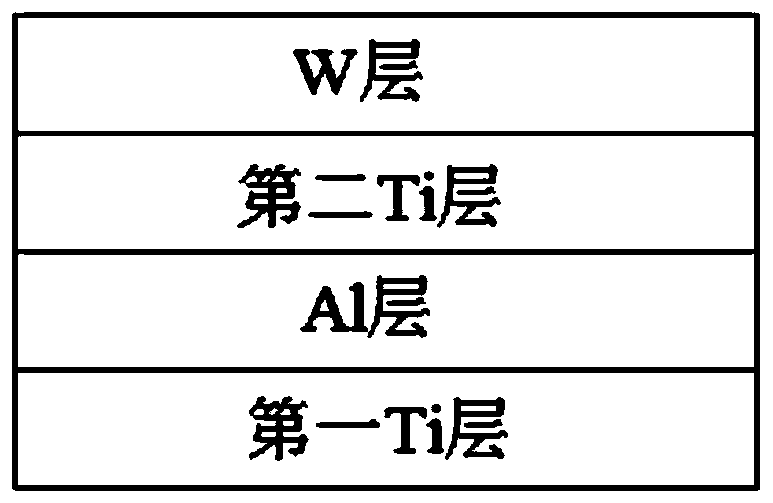

Ohmic contact electrode, HEMT device and preparation method

InactiveCN109712877AImprove contact uniformityReduce the formation temperatureSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactOptoelectronics

The invention provides an ohmic contact electrode, an HEMT device and a preparation method, and the preparation method comprises the following steps: S1, defining a source-drain ohmic contact window by photoetching; S2, etching an ohmic contact area of AlGaN to a certain thickness; S3, sequentially depositing metal layers in the source-drain region; S4, carrying out alloy annealing treatment by adopting a microwave radiation process after degumming and stripping to form the ohmic contact electrode provided by the invention. According to the preparation method of the ohmic contact electrode, the deposited metal layer is processed in a microwave annealing mode, the formation temperature of the GaN ohmic contact resistor can be reduced, the ohmic contact uniformity is improved, and the electrical parameters and the working reliability of a GaN power device are improved.

Owner:ZHANGJIAGANG EVER POWER SEMICON

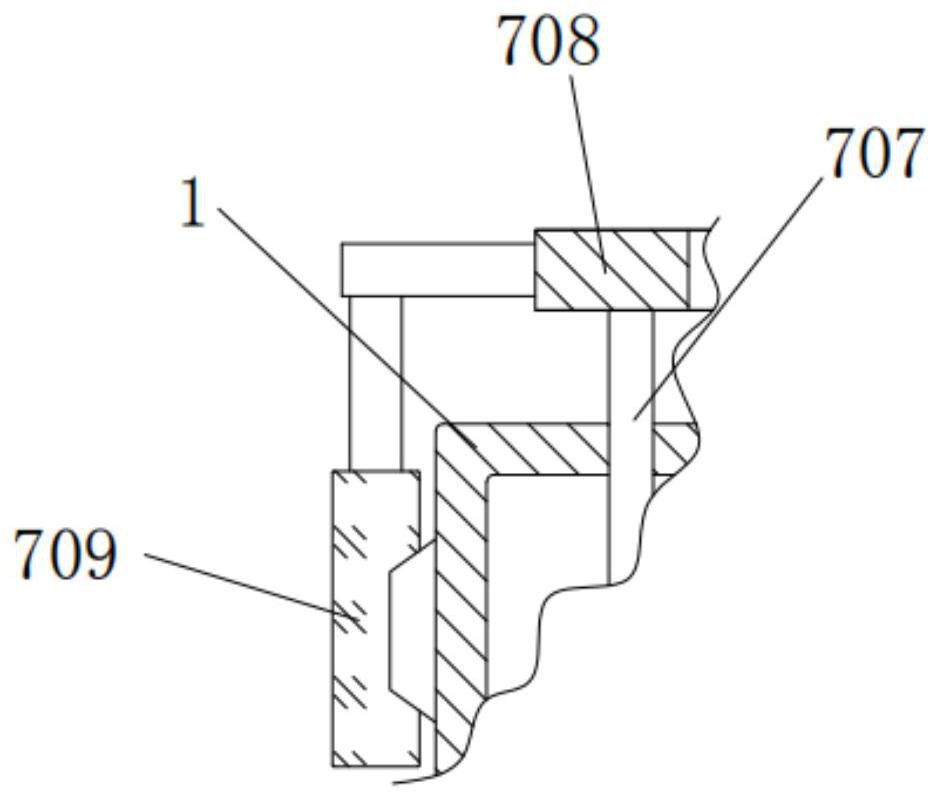

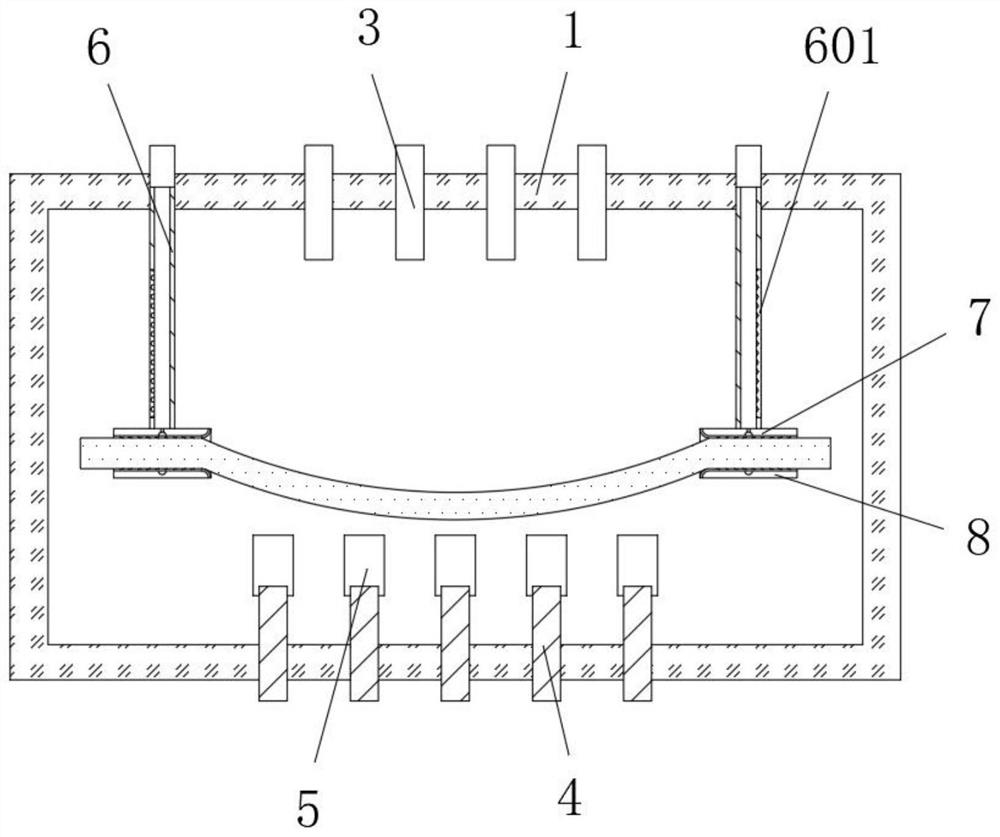

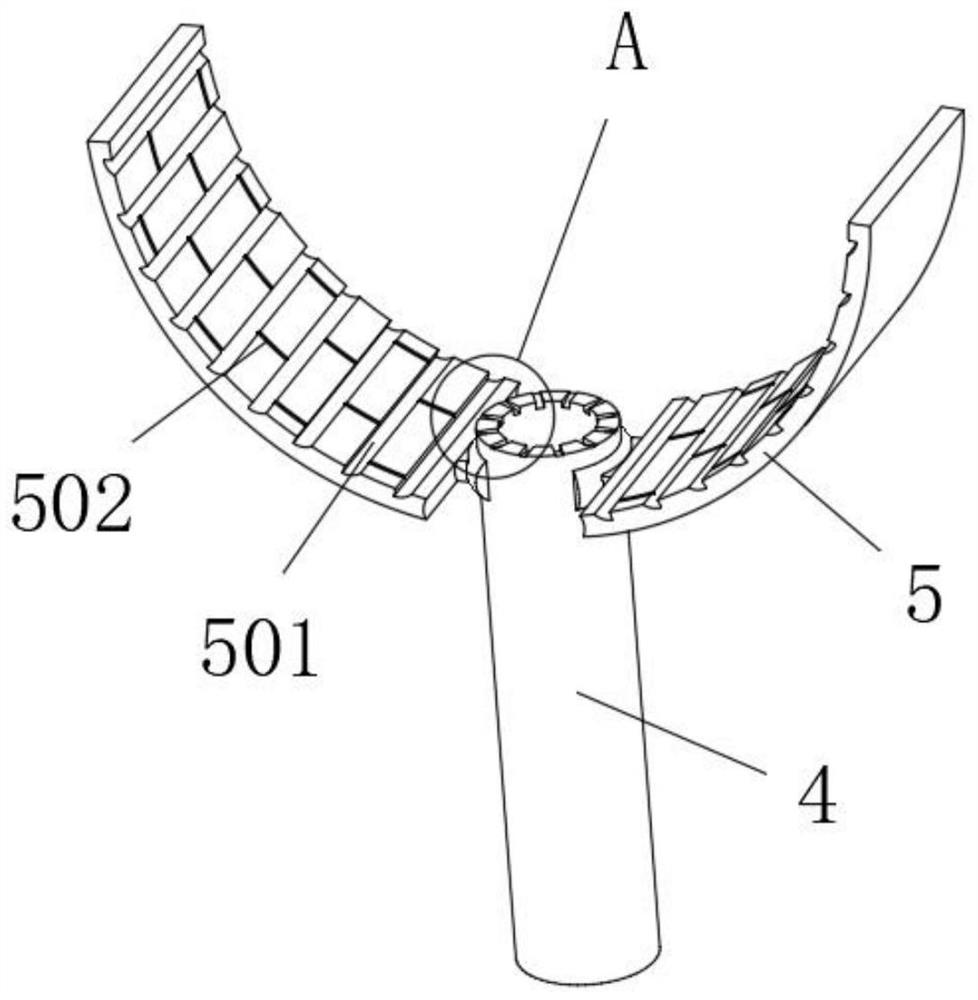

Thin-wall special-shaped curved surface polishing device and method based on static pressure principle polishing tool

PendingCN110238730ASame loadImprove uniformityOptical surface grinding machinesLensEngineeringSurface loading

The invention discloses a thin-wall special-shaped curved surface polishing device and method based on a static pressure principle polishing tool. The thin-wall special-shaped curved surface polishing device comprises a nozzle, wherein the nozzle is used for spraying polishing liquid; the device is further comprises a fluid cylinder, wherein a plurality of pistons are connected to the fluid cylinder, and the output directions of the pistons face a polished curved surface, polishing grinding tools is arranged at the output ends of the pistons, and the polishing grinding tools are matched with the polished curved surface. The invention aims to provide the thin-wall special-shaped curved surface polishing device and method based on the static pressure principle polishing tool so as to solve the problems that a polishing method for the thin-wall special-shaped curved surface in the prior art is low in machining efficiency and poor in uniformity and that the initial surface shape is easy to be damaged and the high-precision surface is difficult to obtain, so that the uniform application of the thin-wall special-shaped curved surface loading is realized, the uniformity of removal is ensured, and meanwhile, the edge effect is greatly reduced.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

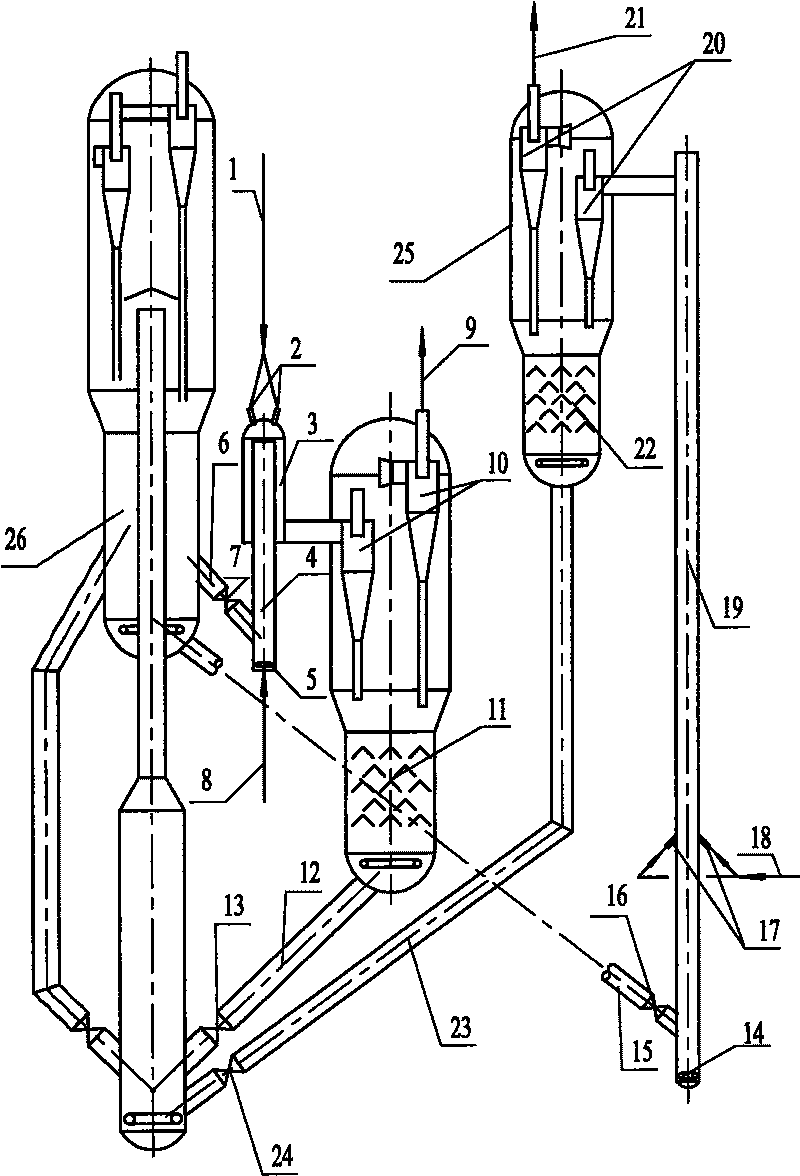

Combined catforming of high-production low carbon alkene

ActiveCN101045667BReduce backmixingHigh selectivityChemical recyclingBulk chemical productionAlkeneCracking reaction

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon depositedcatalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest ofsaid product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water jacket

The invention discloses a water jacket which comprises a jacket body and a cooling medium channel, wherein the cooling medium channel is arranged in the jacket body and is provided with a cooling medium inlet used for supplying cooling media and a cooling medium outlet for discharging the cooling media, and the interior surface of the jacket body is a serrated surface. In the invention, the water jacket is provided with the serrated surface at the inner side of the jacket body (the surface facing the inner side of a smelting furnace when the water jacket is installed in the smelting furnace), i.e. bulges and recesses are arranged on the interior surface of the jacket body, therefore, firebricks in the smelting furnace can be matched in the recesses, thereby improving the binding ability of the water jacket and the firebricks, reducing gaps between the water jacket and the firebricks and achieving large contact area, good contact uniformity and favorable cooling effect.

Owner:CHINA ENFI ENGINEERING CORPORATION

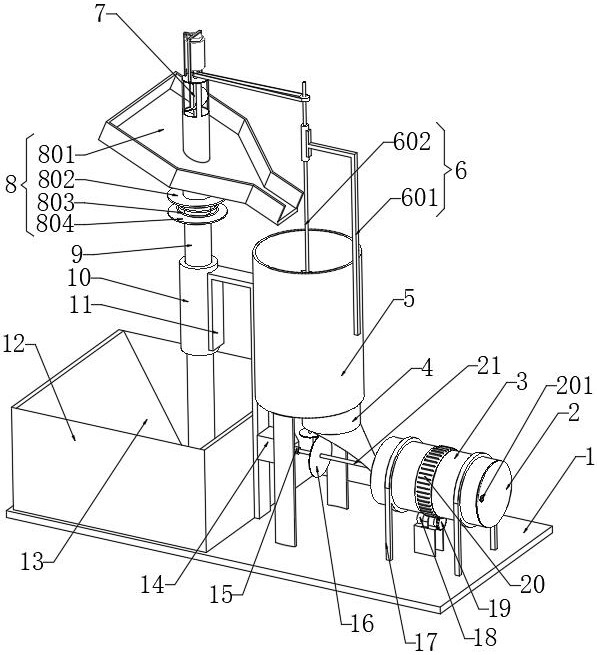

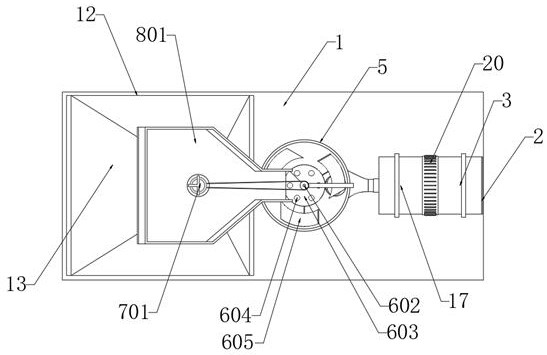

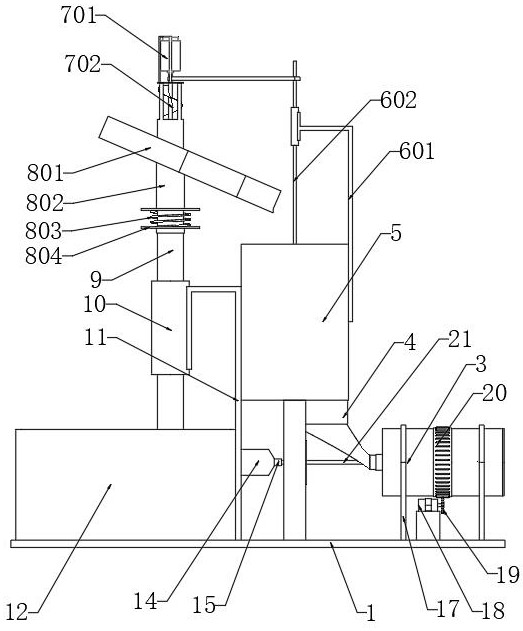

Distiller's yeast drying device for distiller's yeast processing

ActiveCN114294937AImprove drying qualityEfficient crushingDrying gas arrangementsDrying chambers/containersBiotechnologyEngineering

The invention discloses a distiller's yeast drying device for distiller's yeast processing, and relates to the technical field of distiller's yeast processing, the distiller's yeast drying device comprises a mounting plate, a raw material box, a material drying tank and a drying tank are mounted on the mounting plate, a lifting assembly is mounted on the raw material box, a material overturning assembly is mounted on the material drying tank, and the drying tank is connected with a material overturning and drying mechanism. A supporting vertical frame is fixedly mounted on the outer wall of one side of the raw material box; according to the distiller's yeast drying device, the arranged lifting assembly is matched with the material barrel, distiller's yeast to be dried can fall into the material drying tank through the guiding effect of the vibration material guiding assembly after being lifted from the raw material box at a constant speed, in the process, a heating wire is started, the material barrel and the material drying tank have the high temperature, and the distiller's yeast can be heated and dried when passing through the surface walls of the material barrel and the material drying tank; and finally, the distiller's yeast is fed into the drying tank through the material receiving assembly, multi-stage and efficient drying treatment of the distiller's yeast is achieved, the drying quality of the distiller's yeast is improved, and the uniformity and dryness are well guaranteed.

Owner:济南趵突泉酿酒有限责任公司

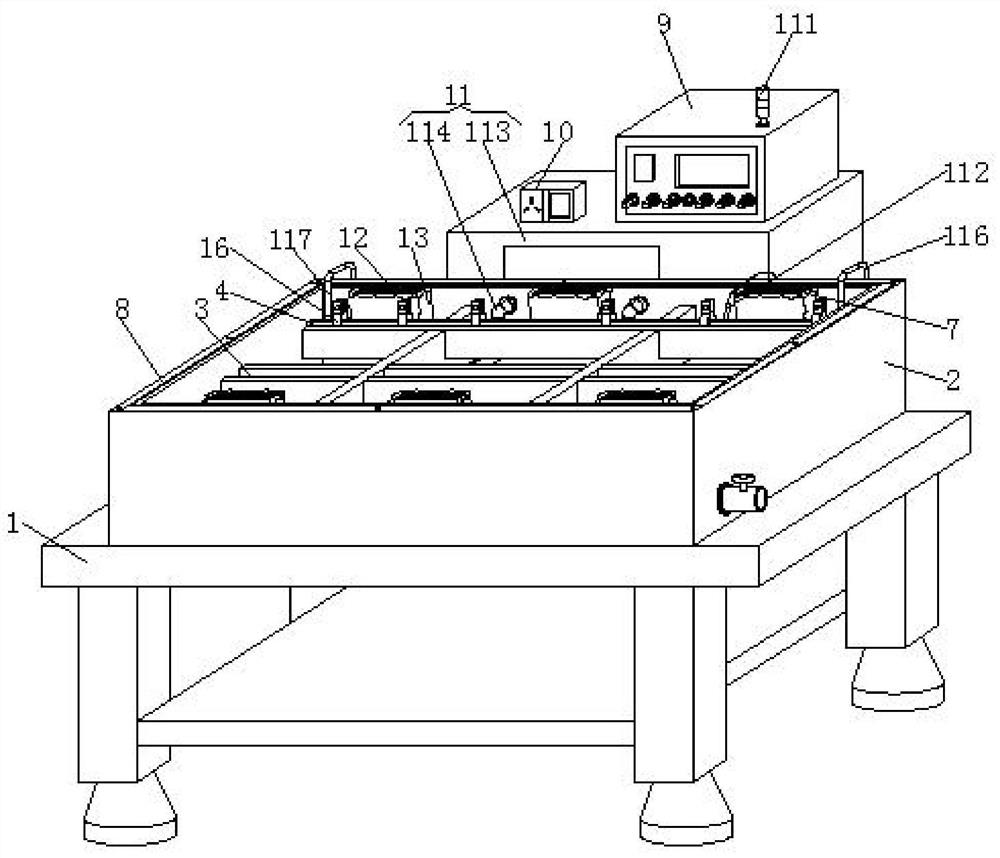

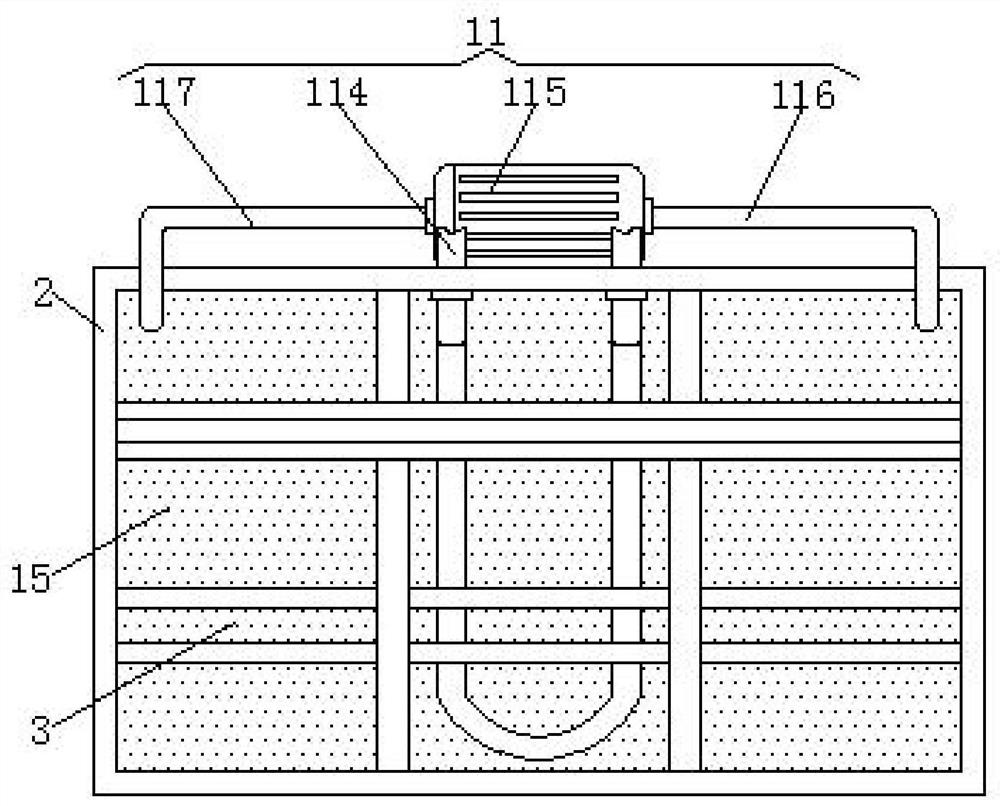

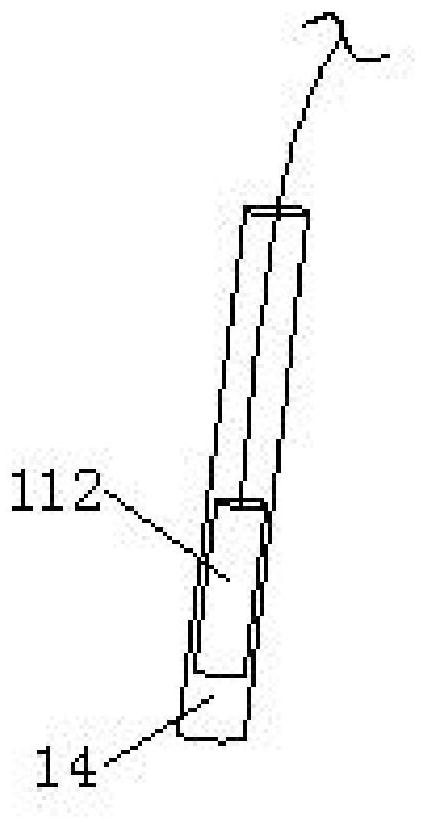

Diamond bur electroplating device with good electroplating effect and electroplating process for diamond bur electroplating device

InactiveCN112575363AIncrease contact areaImprove contact uniformityCellsElectrolytic coatingsCopper wireThermal treatment

The invention provides a diamond bur electroplating device with a good electroplating effect and an electroplating process for the diamond bur electroplating device. The diamond bur electroplating device comprises a workbench, an electroplating pool is connected to the top of the workbench in a bolted manner, electroplating tanks are arranged on the periphery of an inner cavity of the electroplating pool, sand attaching frames are embedded in inner cavities of the electroplating tanks, bur bodies are sequentially embedded in the inner cavities of the sand attaching frames from left to right, copper wires are wound on the sides, away from the sand attaching frames, of the bur bodies, and anode titanium baskets are hung on the periphery of the inner cavity of the electroplating pool. According to the diamond bur electroplating device with the good electroplating effect and the electroplating process for the diamond bur electroplating device, by means of cooperation of an alarm, a temperature control probe, a heater and a titanium heating pipe, an electrolyte in the electroplating pool can be uniformly heated, the electrolyte in each area in the electroplating pool is uniformly heated, and uniform electroplating operations are performed on the bur bodies; and by means of the cooperation of a circulating pump, a circulating pipe and a return pipe, the electrolyte in the electroplating pool can circularly flow, the contact area between the electrolyte and the titanium heating pipe is enlarged, and the contact uniformity of the electrolyte and the titanium heating pipe is improved.

Owner:浙江常山仓谷防护用品有限责任公司

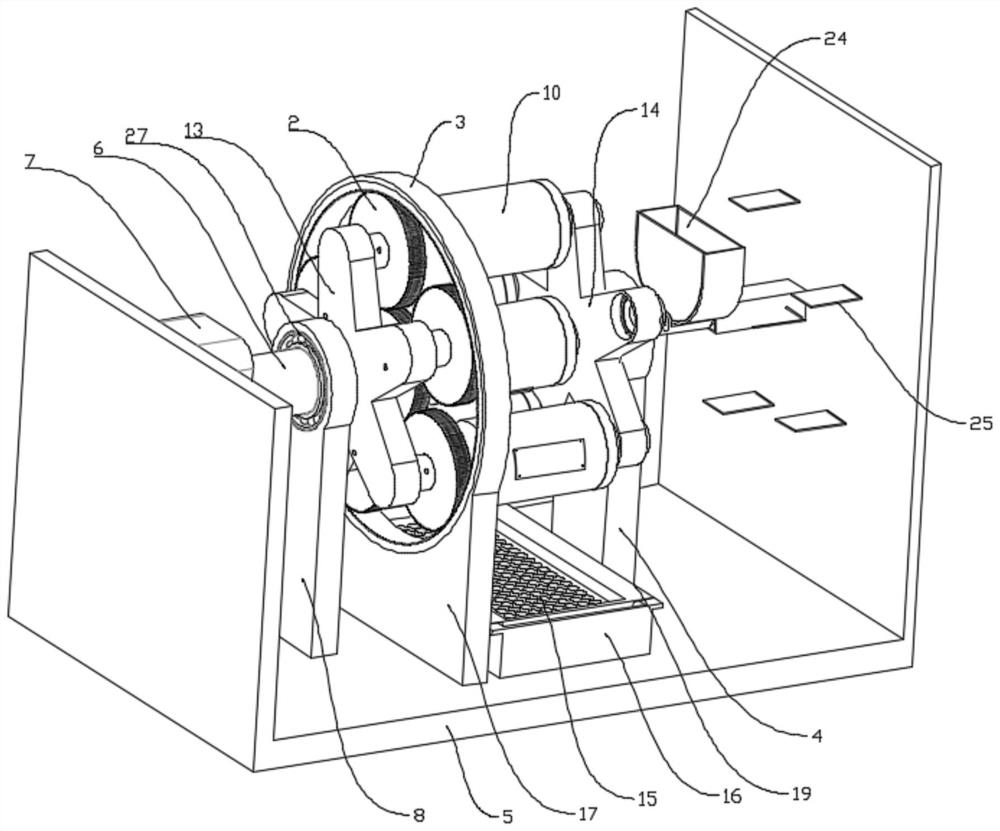

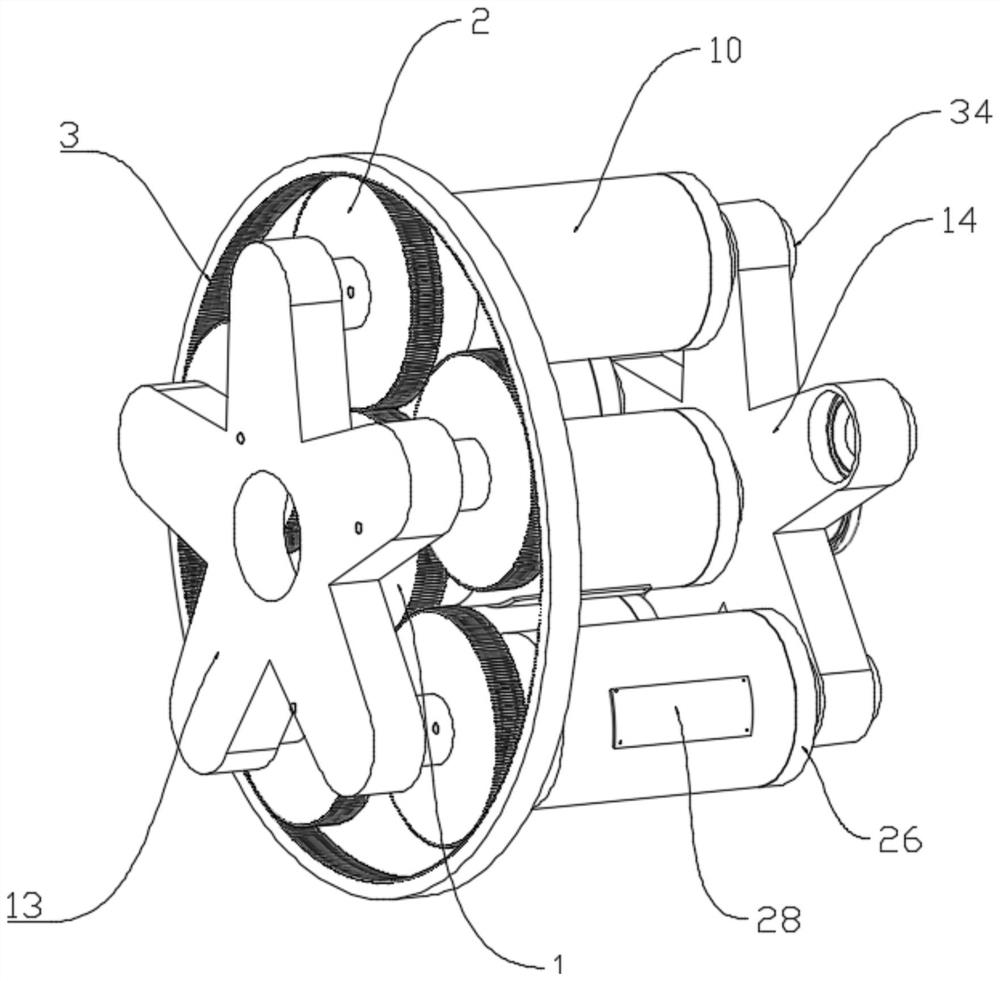

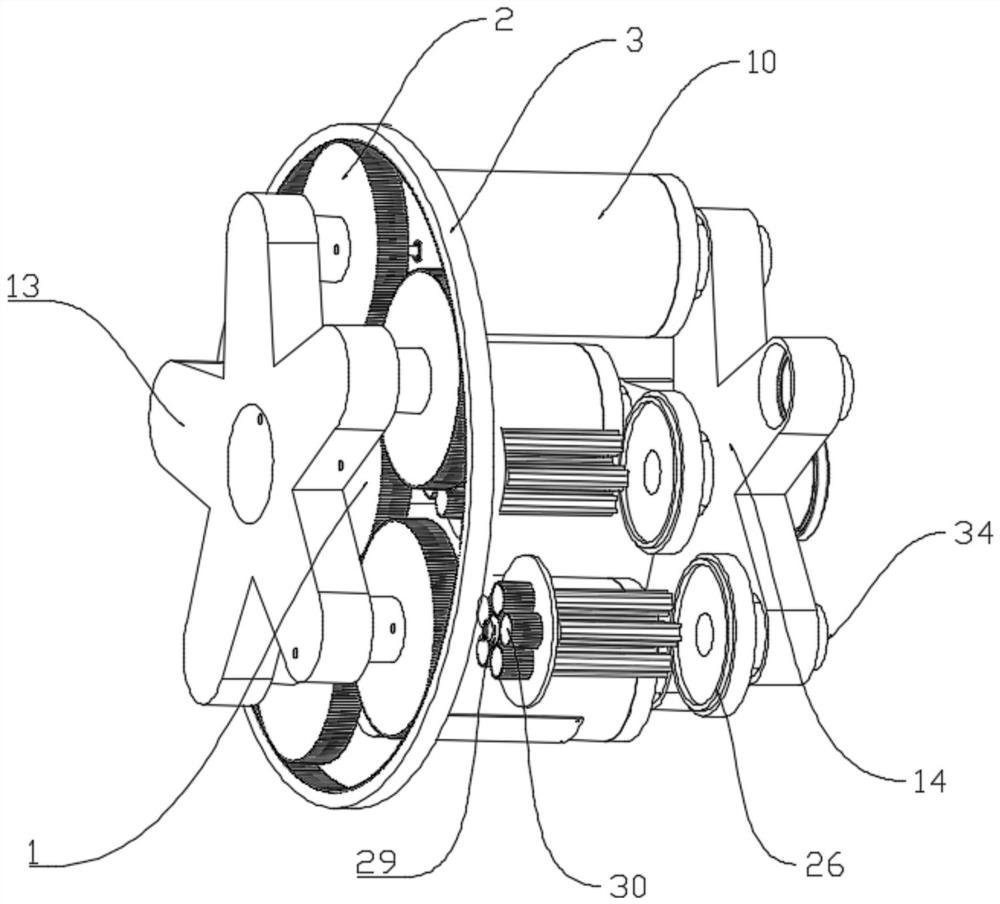

Centrifugal swing type strengthened grinding machining device

ActiveCN114473833AImprove contact uniformityImprove processing qualityEdge grinding machinesPolishing machinesDrive shaftGear wheel

The invention provides a centrifugal swing type strengthened grinding machining device which comprises a planetary gear train mechanism. The planetary gear train mechanism comprises a sun gear, a plurality of planetary gears and a plurality of gear sleeves on the outer sides of the planetary gears. The planet wheel type grinding mechanism comprises a plurality of grinding units connected with the sun gear or the planet gear, each grinding unit comprises a grinding roller, a grinding stirring rod is arranged in each grinding roller, and a sealing cover is arranged on the side wall of each grinding roller; the middle of the first planet carrier is rotationally connected with a driving shaft of the sun gear, the middle of the second planet carrier is rotationally connected with the grinding roller located in the center, the first planet carrier is rotationally connected with the planet gears, and the second planet carrier is rotationally connected with the grinding rollers located on the edges. The contact uniformity of a grinding body and a to-be-ground body can be improved, the grinding effect is improved through rotation and revolution of the grinding roller, and the machining quality of the to-be-ground body can be improved.

Owner:GUANGZHOU UNIVERSITY

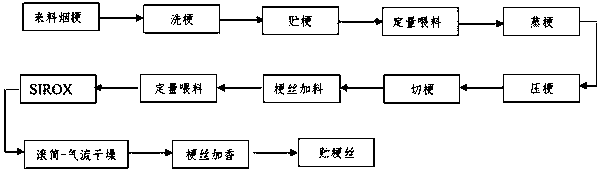

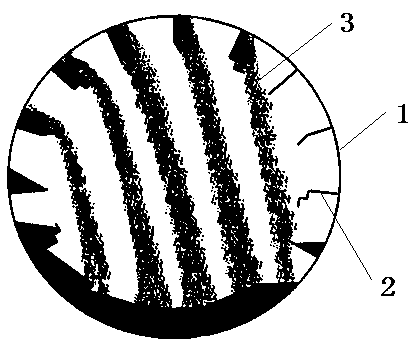

Cut stem drying method by using roller-air flow

InactiveCN109674079AImprove sensory qualityImprove contact uniformityTobacco preparationPulp and paper industryWater content

The invention relates to a cut stem drying method by using roller-air flow and belongs to the field of cigarette processing. The cut stem drying method comprises the following steps: screening; washing the cut stems; storing the cut stems; steaming the cut stems; pressing the cut stems; slicing the cut stems; charging the cut stems; expanding the cut stems; and drying and winnowing to flavor. In adrying process, the cut stems are dried by using a roller-air flow drier, the cut stems are in uniform contact with hot air containing steam in the roller-air flow drier, so that the cut stem is uniform in water content, caking of the cut stems is avoided, the wooden gas of the cut stems is reduced, and the sensory quality of the cut stems is improved.

Owner:HONGTA TOBACCO GRP

Scroll compressor with scroll deflection compensation

InactiveUS7997883B2Improve efficiencyImprove contact uniformityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringScroll compressor

Owner:EMERSON CLIMATE TECH INC

A distiller's yeast drying device for distiller's yeast processing

ActiveCN114294937BImprove drying qualityEfficient crushingDrying gas arrangementsDrying chambers/containersThermodynamicsProcess engineering

The invention discloses a distiller's yeast drying device for distiller's yeast processing, which relates to the technical field of distiller's yeast processing, and comprises a mounting plate, on which a raw material box, a drying tank and a drying tank are installed, and a lifting assembly is installed on the raw material box. In addition, a material turning assembly is installed on the drying tank, and the drying tank is connected with a turning drying mechanism, and a support stand is fixedly installed on one side of the outer wall of the raw material box; the present invention utilizes the provided lifting assembly to cooperate with the material cylinder, and can The koji to be dried is lifted from the raw material box at a uniform speed, and then falls into the drying tank through the guidance of the vibrating material guide assembly. During this process, the heating wire is turned on, so that the material cylinder and the drying tank have a higher temperature. The distiller's yeast can be heated and dried when it passes through its surface wall, and finally sent into the drying tank through the material receiving component to realize multi-stage and efficient drying treatment of the distiller's yeast, which is conducive to improving the drying quality of the distiller's yeast, in terms of uniformity and dryness All are well guaranteed.

Owner:济南趵突泉酿酒有限责任公司

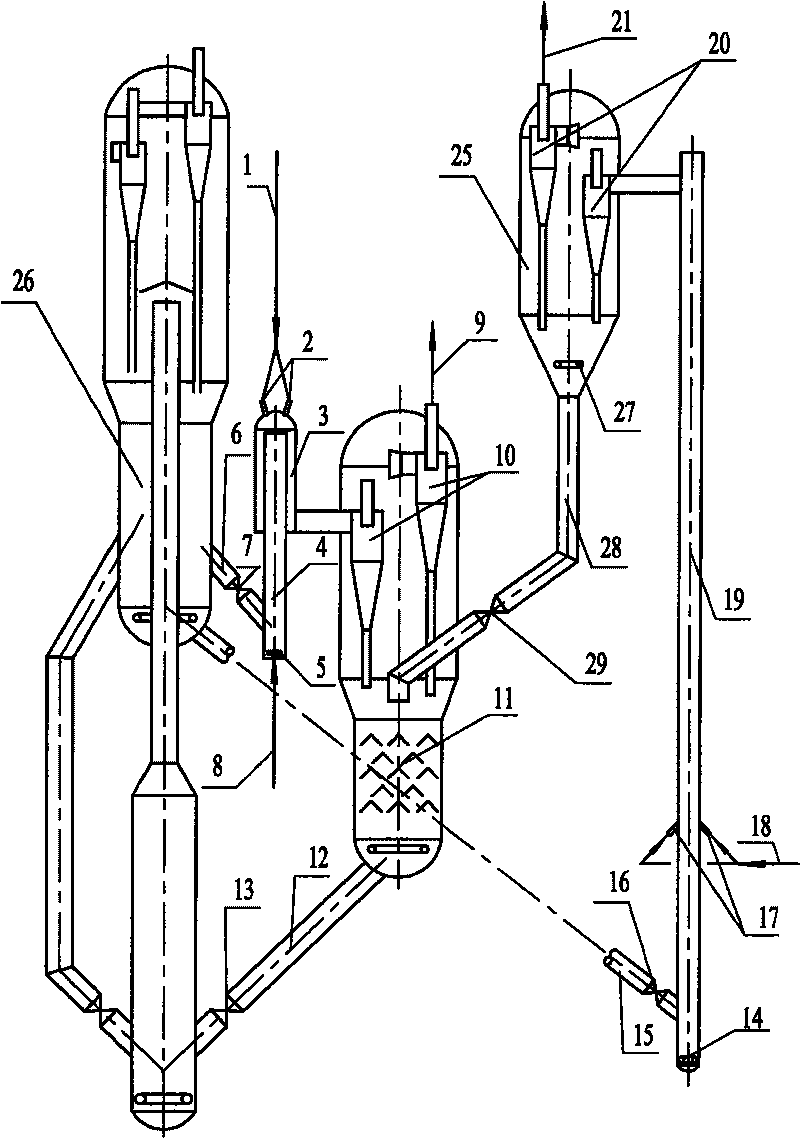

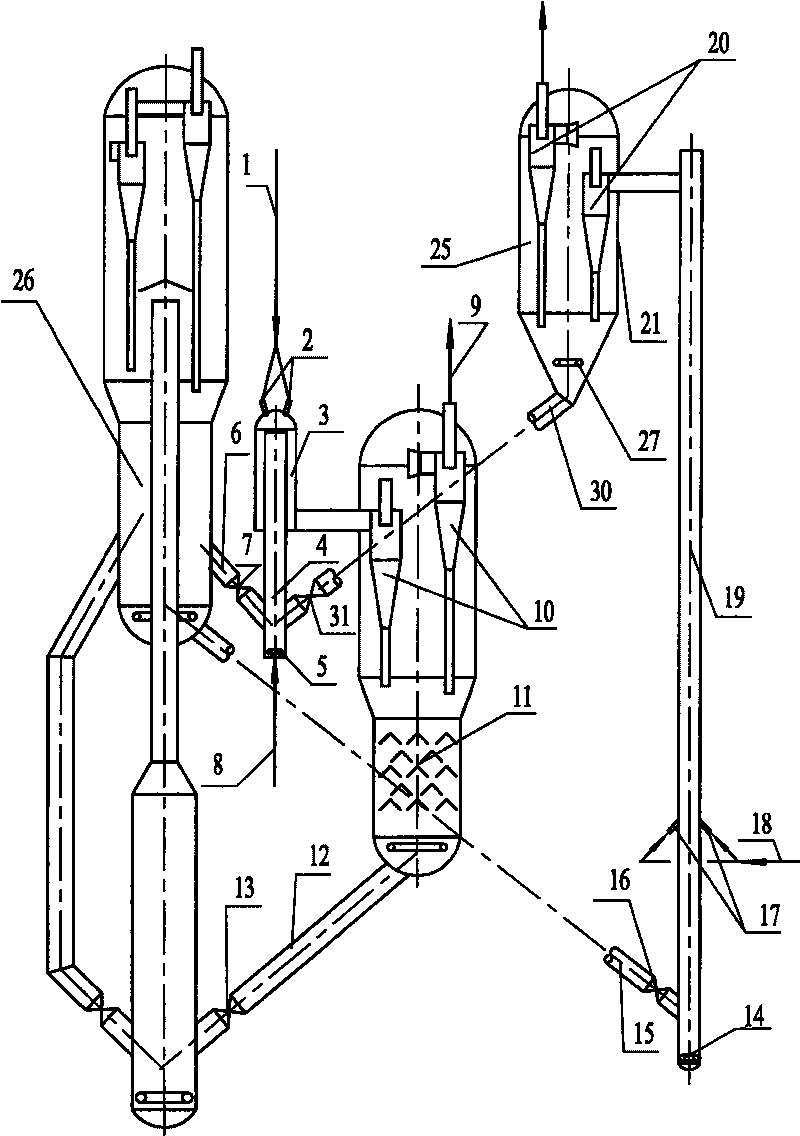

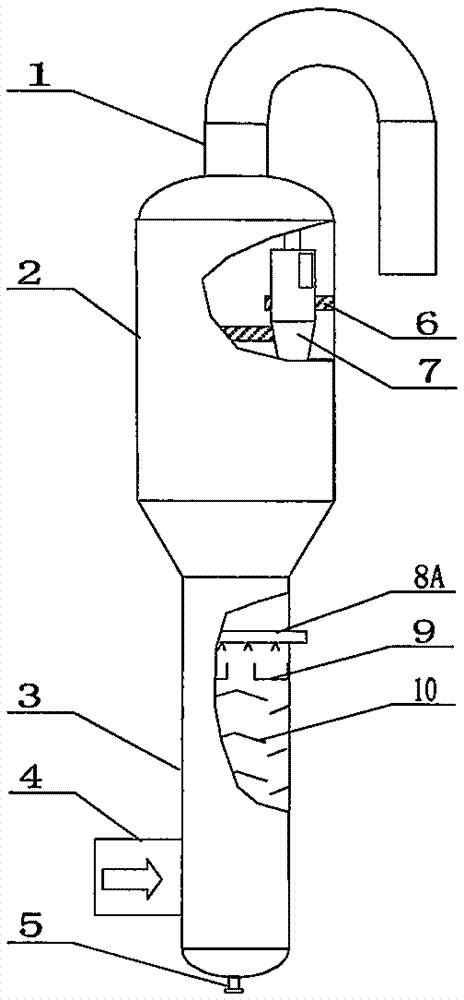

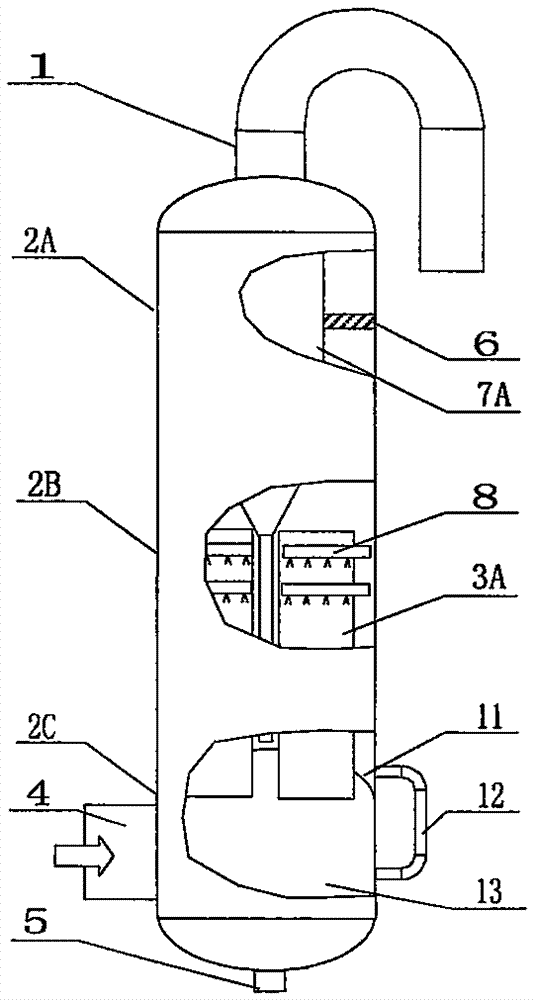

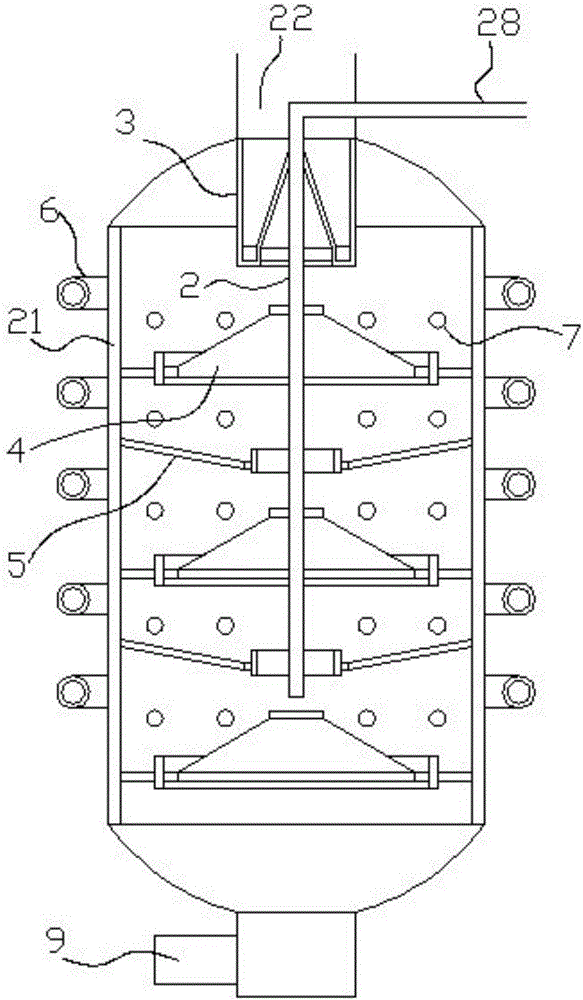

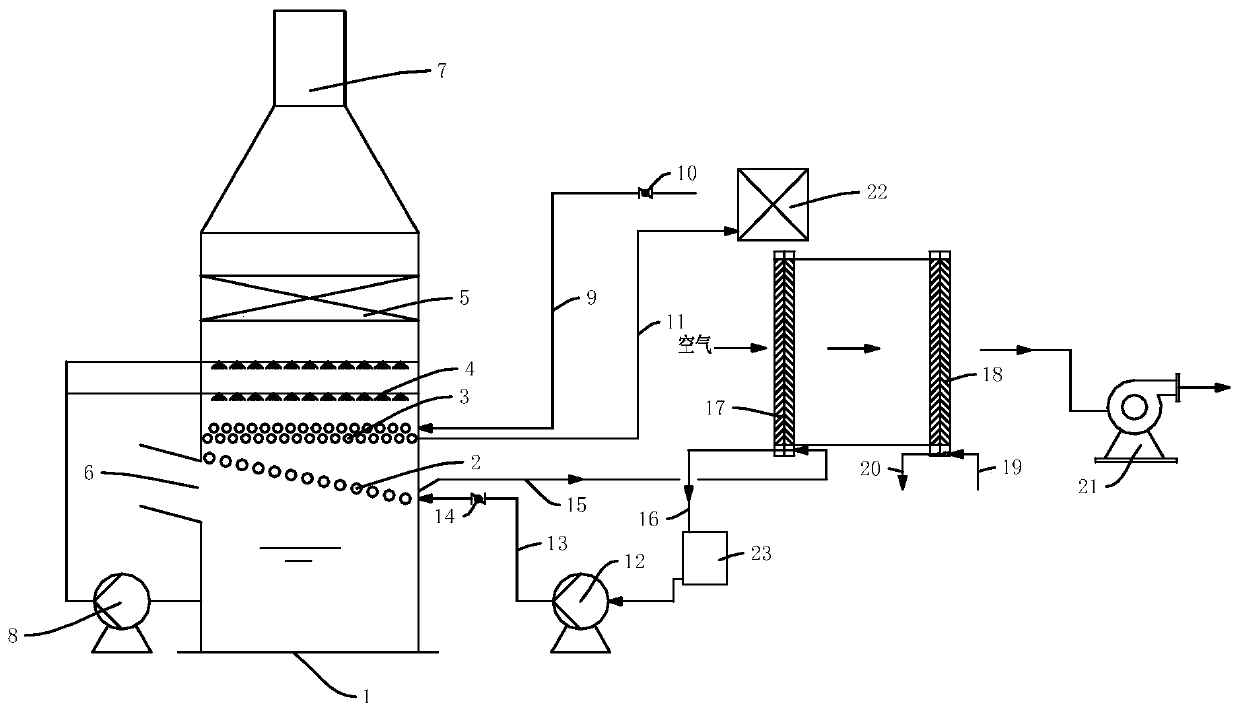

Gas washing method and washing tower

InactiveCN106955549AAchieve purificationImprove contact uniformityCombination devicesProcess equipmentFlue gas

The invention relates to a gas washing method and belongs to the technical fields of gas-liquid two-phase separation, environmental protection and process equipment. The method is used for solving the problems of high volume of liquid carried by gas and large negative effect. The method comprises the steps of feeding the gas, discharging the gas, feeding a washing solution and draining the washing solution. The method is characterized in that the two processes of gas washing and gas-liquid separation are designed, the gas washing and the inter-phase transferring are performed and completed under the turbulence state of higher gas flow rate, and then the settling, coalescence gas-liquid separation or additional centrifugal gas-liquid separation are performed at a lower flow rate. The invention also provides a turbulence type washing section, a settling section, a silk screen and a centrifugal separator used for realizing the method. The method is applied to the processes of dust cleaning and desulfuration of flue gas, cleaning and purification of exhaust gas, technical gas purification, and the like.

Owner:刘英聚

A centrifugal pump mechanical seal flushing device

ActiveCN106122108BMonitor pressure changes at any timeReduced pipeline flowPump componentsPumpsVena contracta diameterCooling effect

The invention discloses a flushing device for a mechanical seal of a centrifugal pump, and belongs to the technical field of centrifugal pumps. The flushing device comprises a flushing pipe connected to the centrifugal pump; the liquid feeding end of the flushing pipe is connected with the outlet end of the centrifugal pump; the liquid discharging end of the flushing pipe is connected with the mechanical seal of the centrifugal pump; the flushing device is characterized in that the flushing pipe is connected with a tubular filter, a pressure gauge and a throttling orifice plate; the tubular filter is close to the outlet end of the centrifugal pump; the throttling orifice plate is close to the mechanical seal of the centrifugal pump; a first stop valve and a second stop valve are arranged on the flushing pipe; the first stop valve is positioned between the outlet end of the centrifugal pump and the tubular filter; and the second stop valve is positioned between the pressure gauge and the throttling orifice plate. The flushing device can both achieve a good cooling effect on the mechanical seal and prevent particle impurities from being deposited on the sealing surfaces of movable and fixed rings, thus effectively protecting the sealing surfaces of the movable and fixed rings, relieving wear and enhancing the sealing effect; and therefore, normal and stable operation of the centrifugal pump is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

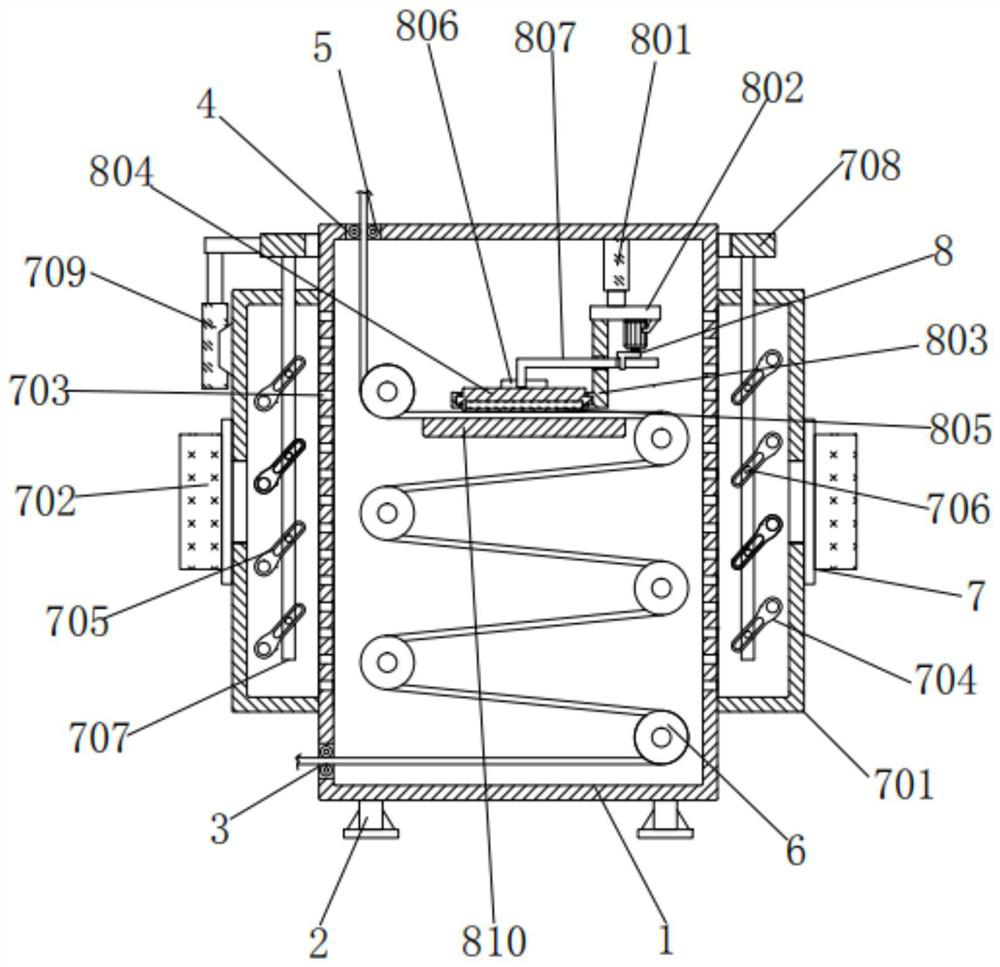

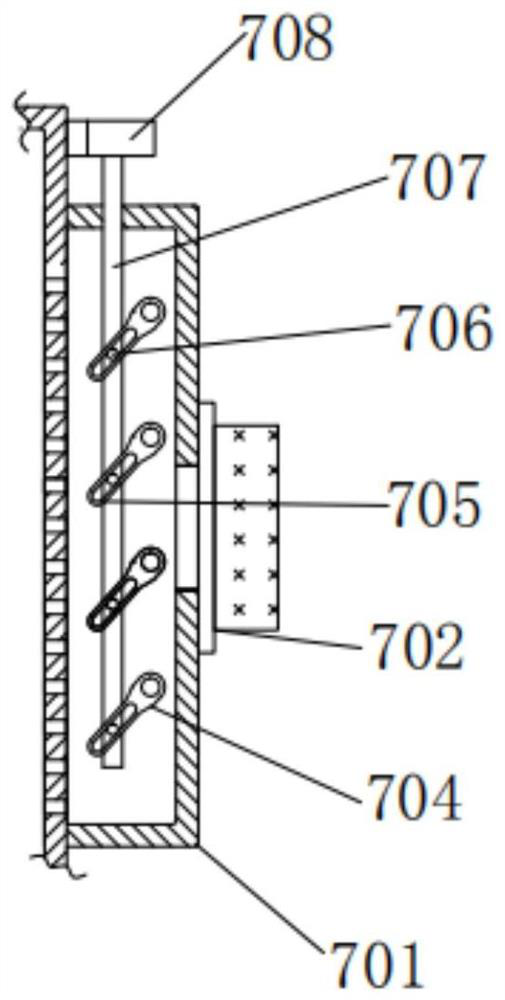

Drying device for textile printing and dyeing

InactiveCN112195597AExtended stayIncrease contact areaLiquid/gas/vapor removalTextile treatment carriersManufacturing engineeringTextile printer

The invention discloses a drying device for textile printing and dyeing. The device comprises a box body, supporting legs are fixedly connected to the bottom of the box body, round rollers are rotatably connected with the inner wall of the box body, and drying assemblies are arranged at the left side and the right side of the box body. According to the drying device for textile printing and dyeing, through the arrangement of the multiple round rollers, when cloth is wound around the round rollers and walks at a low speed, the retention time of the cloth can be prolonged, the contact area of the cloth and hot air is greatly increased, and then the drying efficiency is improved; and through clearance fit of a through groove and a sliding rod and reverse arrangement of driving levers at the two sides, the driving levers at the two sides can swing reversely in a reciprocating manner at the same time when an air cylinder stretches out and draws back, so that the hot air is distributed, thecontact uniformity of the hot air and the cloth is improved, the drying efficiency is further improved, the working time is saved, and wrinkles of the cloth can be directly removed by arranging an electric heating plate and abutting against the cloth through a sliding plate and a bottom plate; and therefore, the cloth quality is improved, multiple purposes are achieved by one device, and the practicability is better.

Owner:绍兴嘉越纺织机械有限公司

Special single dyeing process for polyester knitted fabrics

InactiveCN107653718AEasy to dyeHigh color fastnessDry-cleaning apparatus for textilesGrip property fibresPolyesterAcetic acid

The invention discloses a special single dyeing process for polyester knitted fabrics. The process includes steps: subjecting the polyester knitted fabrics to uniform beating by a group of fabric beating devices, sending into a dying tank, and adding acetic acid and dyeing additives; adding dyes into a system; heating the system to 90-100 DEG C, then heating to 115-120 DEG C, then heating to 130-135 DEG C, performing heat preservation, and cooling to 75-80 DEG C; adding soda solution in batches; adding a bleaching combined agent; subjecting the fabrics to cleaning, softening and re-cleaning. By adoption of the dyeing scheme, great dyeing of polyester is realized; by strict step control of parameters of temperature and the like in different time periods, dyeing effects and dyeing quality stability are improved, dye fastness of the fabrics is improved, and the problem of fading can be reduced or even avoided.

Owner:盐城福汇纺织有限公司

Quick cotton dyeing technology for cotton-terylene blended knitted fabric after washing and dyeing

InactiveCN107574692AShorten the timeImprove contact uniformityTextile treatment machine arrangementsDyeing processCotton fibrePolyester

The invention belongs to the technical field of knitted fabric dyeing and discloses a quick cotton dyeing technology for a cotton-terylene blended knitted fabric after washing and dyeing. The technology particularly comprises the following steps of adding acetic acid and dyeing assistant into a dye tank for dyeing a polyester fiber, regulating a pH (potential of hydrogen) of a system, after regulation, raising the temperature of the system to 75-80 DEG C, performing heat preservation and stirring, adding a dye into the system at a constant speed, performing heat preservation and stirring, raising the temperature to 98-102 DEG C, then raising the temperature to 130-133 DEG C, performing heat preservation and then cooling, conveying the dyed blended knitted fabric to a washing tank via a group of conveying tension rollers for alternate washing, and drying the dyed knitted fabric at last. According to the dyeing scheme, a cotton fiber dyeing process is performed immediately after polyester fiber dyeing for the cotton-terylene blended knitted fabric; the time of a fabric dyeing technology is greatly shortened; the dyeing operation efficiency is improved; the dyeing uniformity is improved; and the conveying tension rollers and a washing technology arranged at the late course of the technology improve a washing effect of the fabric after the dyeing.

Owner:盐城福汇纺织有限公司

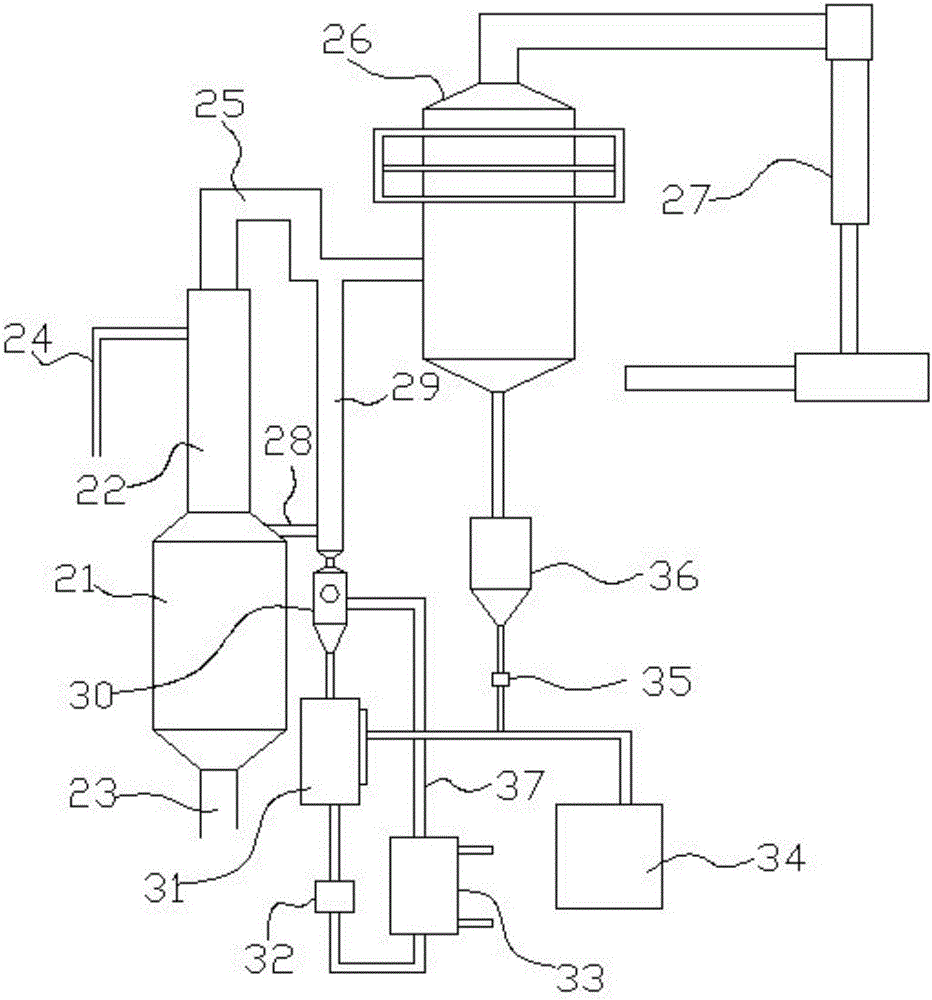

Fast automatic deodorization system in vegetable oil refining

PendingCN106753783AGuaranteed deodorization efficiencyImprove processing qualityFatty-oils/fats refiningEdible oils/fatsAgricultural engineeringOil and grease

The invention discloses a fast automatic deodorization system in vegetable oil refining. An oil inlet pipe is arranged at the top end of a deodorization tower; an oil delivery pipe is arranged at the side of the oil inlet pipe; the upper end of the oil inlet pipe is connected with an air return pipe; the air return pipe is connected with a vacuum storage tank; steam nozzles are uniformly arranged on the inner wall of the deodorization tower; a center pipe is arranged at the center of the deodorization tower and connected with an exhaust pipe; the exhaust pipe is connected with a vacuum supply pipe; the upper end of the vacuum supply pipe is connected with the vacuum storage tank and the lower end is connected with a fatty acid capture tank; the lower end of the fatty acid capture tank is connected with a primary storage tank; the primary storage tank is connected with the fatty acid capture tank through a circulating pipe; the circulating pipe is provided with a circulating pump and a heat exchanger; the side wall of the upper end of the primary storage tank is connected with a secondary storage tank through a pipe; the upper end of the vacuum storage tank is connected with a vacuum pump system through a pipe and the lower end is connected with an accumulation tank; the accumulation tank is connected with the secondary storage tank through a pipe; and a valve is arranged on the pipe between the accumulation tank and the secondary storage tank. The uniform vacuum deodorizing treatment of oil can be achieved, the deodorizing speed is high and the effect is good.

Owner:岳阳长康绿态福海油脂有限公司

Energy-saving boiler tail gas purification system and method

PendingCN111589290AReduce operating energy consumptionReduce coal consumptionCombustion processDispersed particle separationAir preheaterFlue gas

The invention discloses an energy-saving boiler tail gas purification system and method. The system comprises a washing tower, a washing pump, a pure water pipeline, an energy-saving pump, an energy-saving water pipeline, an air preheater, a steam pipeline and an air reheater; a flue gas inlet is formed in the side surface of the washing tower, a flue gas outlet is formed in the top of the washingtower, a flow equalizing layer, a venturi tube grid layer, a washing spraying layer and a demisting layer are sequentially arranged between the flue gas inlet and the flue gas outlet in the washing tower from bottom to top, and a washing liquid circulating pool is arranged below the flue gas inlet; the washing pump is used for communicating the washing liquid circulating pool with the washing spraying layer to form a circulating loop; the flow equalizing layer and the air preheater are connected into a circulation loop by the energy-saving pump; and the venturi tube grid layer is connected with a pure water pipeline. Low-grade waste heat in low-industrial tail gas can be effectively recycled, the recycled waste heat is used for boiler air preheating and boiler deaerator water supplementing, and boiler operation energy consumption is reduced.

Owner:新疆天富环保科技有限公司 +3

A method for testing optical fiber aging performance

ActiveCN113063724BImprove the diffusion effectAvoid damageWeather/light/corrosion resistanceTesting fibre optics/optical waveguide devicesEngineeringTest chamber

The invention discloses a method for testing optical fiber aging performance. The device comprises a test box, a box door is arranged at one end of the test box, and a visible window is arranged at the middle position of the box door, and both sides of the inside of the test box are provided with There is a fixing mechanism, and the optical fiber cable to be tested is detachably connected between the two fixing mechanisms, the length of the middle position of the optical fiber cable to be tested is greater than the distance between the two fixing mechanisms, and the test box is equipped with a temperature control mechanism The method includes the following steps: open the box door and place the optical fiber cable to be tested between the fixed plate and the positioning plate at both sides, and make the two ends of the optical fiber cable clamped and fixed by the silica gel pad by fastening the fixed plate and the positioning plate , close the door and start the temperature control mechanism. The present invention keeps the overall stability of the test box by interval spraying and blowing air to reduce the loss error, calculates and infers the anti-aging performance of the cable through the breaking time, and improves the convenience and effectiveness of the actual test.

Owner:深圳鸿恩高科新能源有限公司

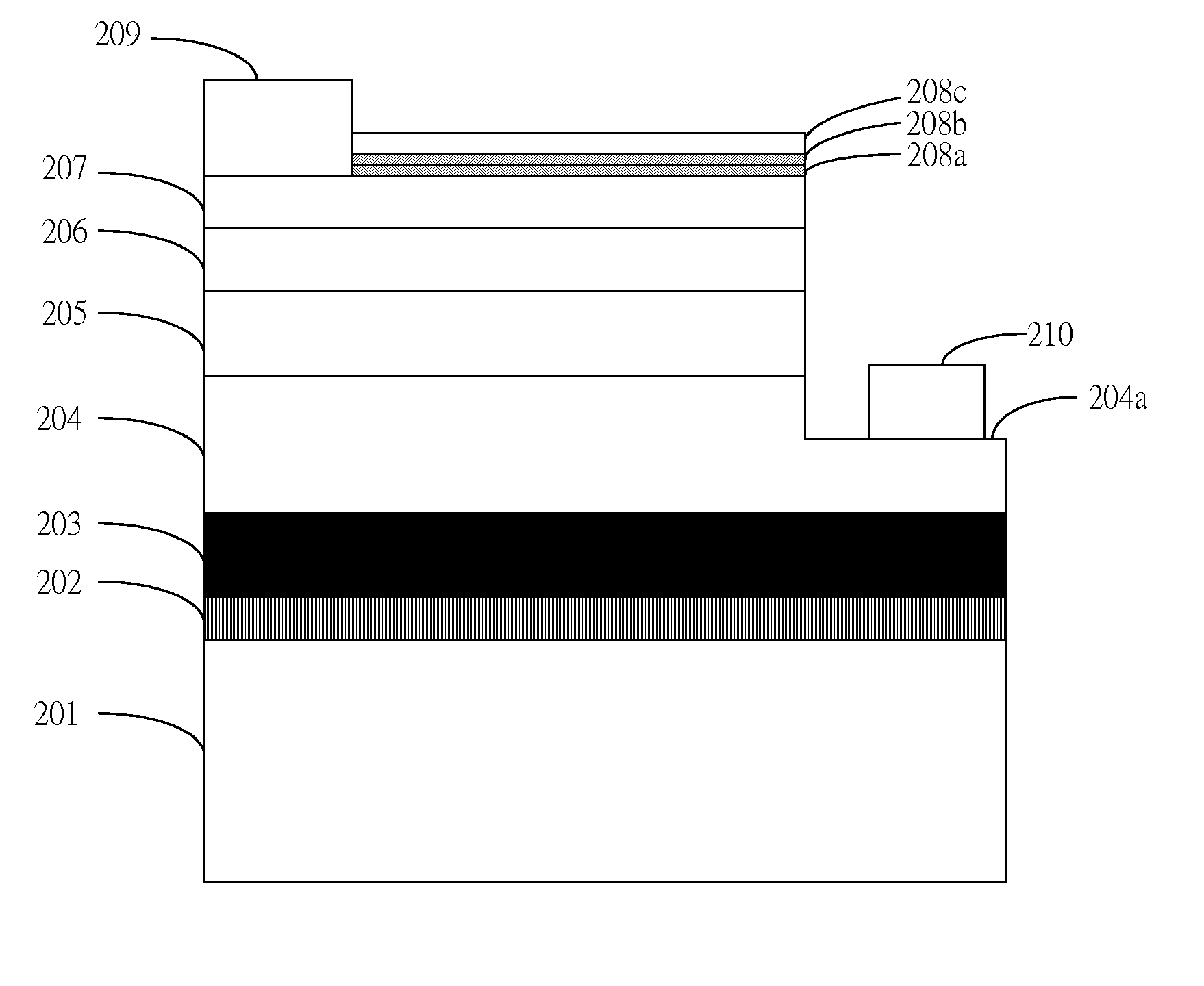

Gallium-nitride based light emitting diode structure and fabrication thereof

InactiveUS20060244017A1Improve conductivityImprove contact uniformityTransistorSolid-state devicesQuantum efficiencyMetallic electrode

A method for fabricating GaN-based LED is provided. The method first forms a first contact spreading metallic layer on top of the texturing surface of the p-type ohmic contact layer. The method then forms a second and a third contact spreading metallic layers on top of the first contact spreading layer. The p-type transparent metallic conductive layer composed of the three contact spreading metallic layers, after undergoing an alloying process within an oxygenic or nitrogenous environment under a high temperature, would have a superior conductivity. The p-type transparent metallic conductive layer could enhance the lateral contact uniformity between the p-type metallic electrode and the p-type ohmic contact layer, so as to avoid the localized light emission resulted from the uneven distribution of the second contact spreading metallic layer within the third contact spreading metallic layer. The GaN-based LED's working voltage and external quantum efficiency are also significantly improved.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

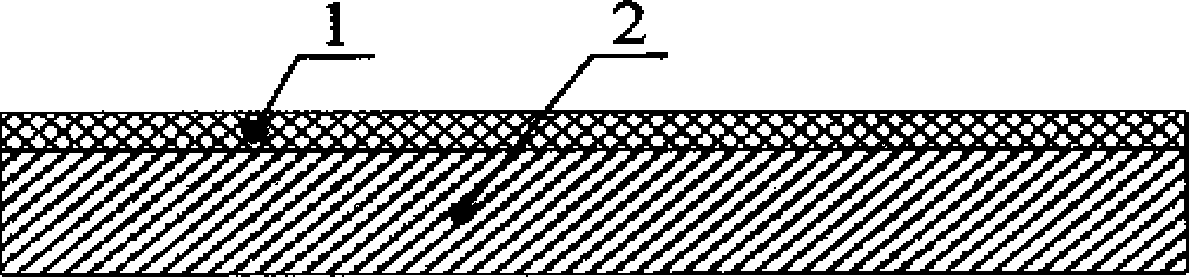

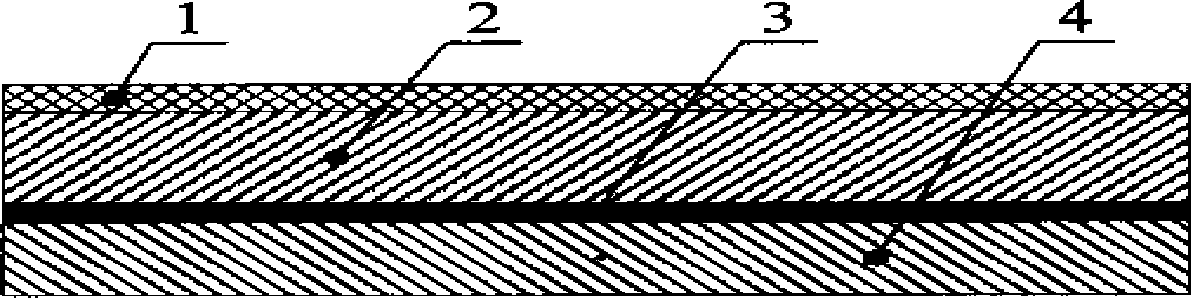

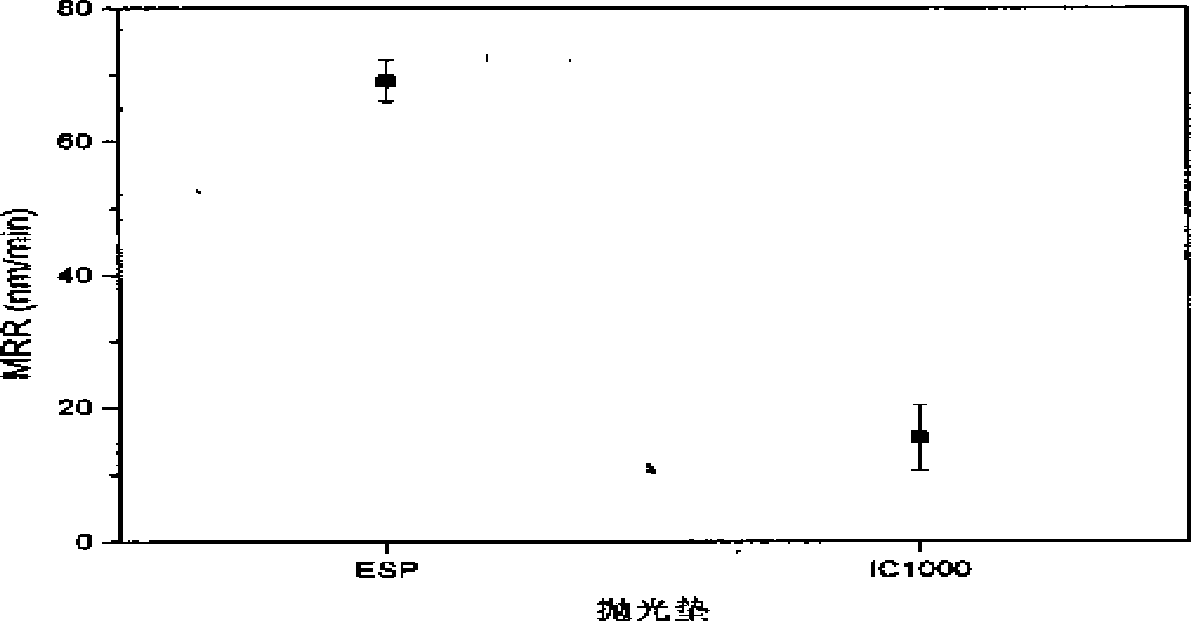

Chemical mechanical polishing pad and chemical mechanical polishing method

Owner:TSINGHUA UNIV

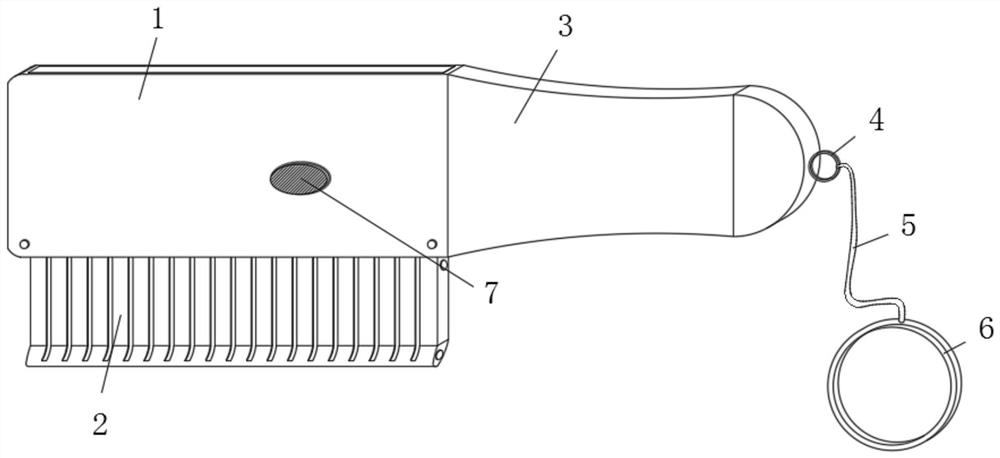

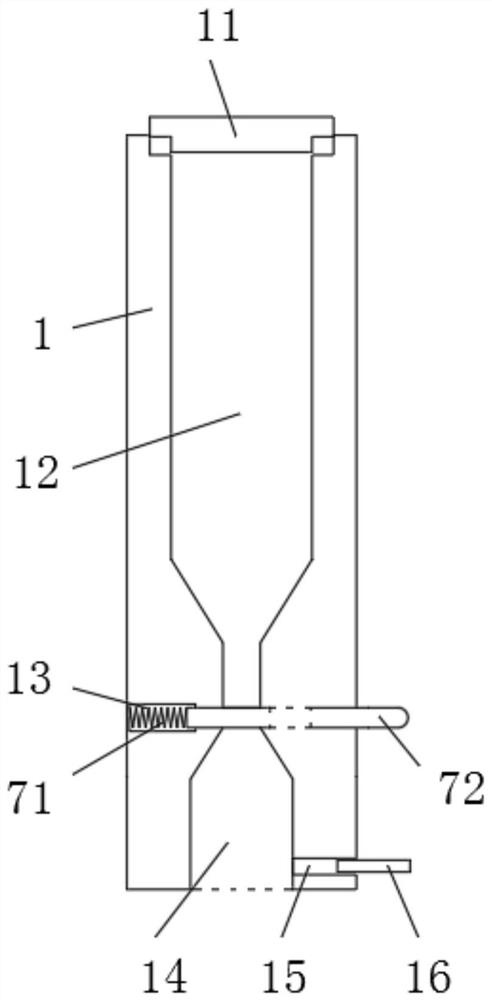

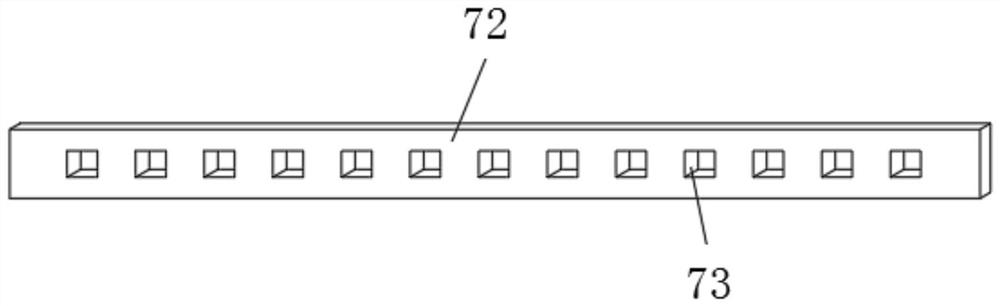

Scraping device for traditional Chinese medicine acupuncture and massage

InactiveCN114081808AAvoid damageAvoid the phenomenon of local aggregationMedical applicatorsSuction-kneading massageAcupunctureMassage

The invention discloses a scraping device for traditional Chinese medicine acupuncture and massage. The scraping device comprises a fixing plate, an oil storage bin is arranged on the fixing plate, a scraping assembly communicated with the oil storage bin is arranged on the fixing plate in the length direction of the fixing plate, and a pressing assembly for controlling opening and closing of a connecting channel of the oil storage bin and the scraping assembly is arranged on the fixing plate. The scraping assembly is provided with a plurality of oil flowing channels connected with an oil outlet of the oil storage bin. According to the scraping device, the combined structural design is utilized, essential oil and a scraping a plate are effectively combined into a whole, the essential oil for assisting the scraping therapy can be guided out and uniformly and comprehensively flows between the scraping plate and a scraping part during scraping therapy, the scraping plate can be prevented from injuring the skin of the scraping part, meanwhile, the phenomenon that the essential oil is locally gathered when flowing out is avoided, the contact uniformity of the essential oil and the skin of the scraping part is improved, and then the subsequent safe and efficient scraping therapy operation is facilitated.

Owner:怀化市第一人民医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com