Gas washing method and washing tower

A gas scrubbing and gas technology, which is applied in the fields of process equipment, environmental protection, and gas-liquid two-phase separation, can solve problems such as corrosion, aggravating haze, blockage, etc., and achieve the effect of improving cleaning effect and improving contact uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

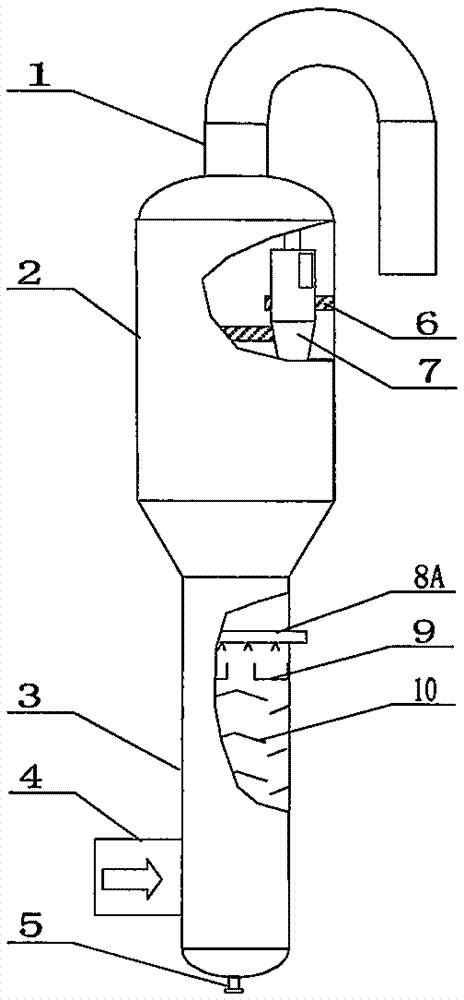

[0017] See figure 1 , The washing section 3 adopts a single-tube structure, and a distribution pipe 8A, a distributor 9, and a baffle 10 are arranged inside, the lower part is connected to the gas inlet 4, and the upper end is connected to the settling section 2. The settling section 2 adopts an enlarged diameter structure, and a wire mesh 6 and a centrifugal separator 7 are arranged inside, the lower end is connected with the washing section 3 , and the upper end is connected with the gas outlet pipe 1 . The cross-sectional area ratio of the settling section 2 and the washing section 3 is 1.5-4.

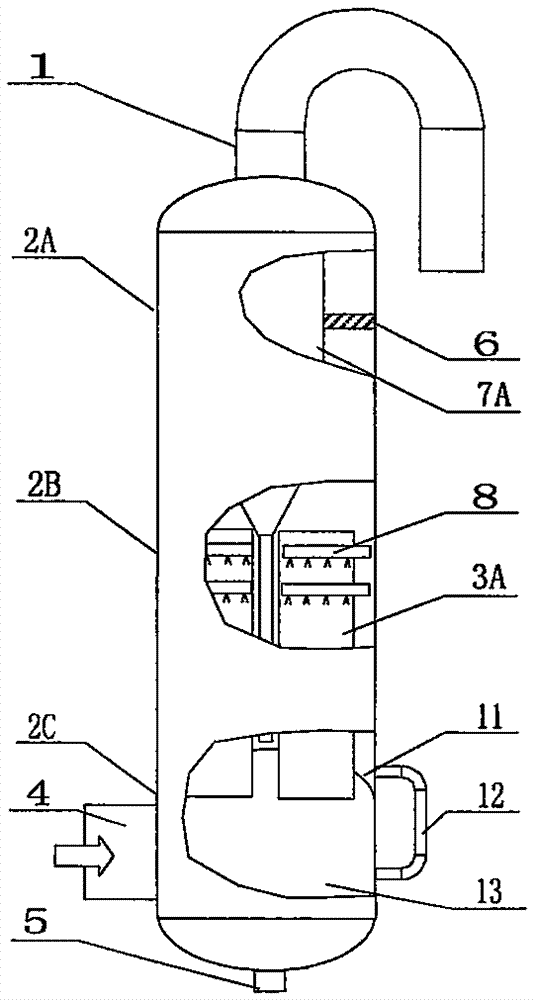

[0018] See figure 2 , The equipment from top to bottom is the gas outlet pipe 1, the upper casing 2A (the interior is the settling section), the middle casing 2B (the interior is the washing section), and the lower casing 2C (the interior is the air intake section 13). The lower part of the multi-tubular washing section 3A is connected to the lower casing 2C through the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com