Method for manufacturing electrode assembly

一种电极组件、制造方法的技术,应用在电极制造、二次电池制造、电池组零部件等方向,能够解决作业时间变长、生产率降低、电极未整齐排列等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

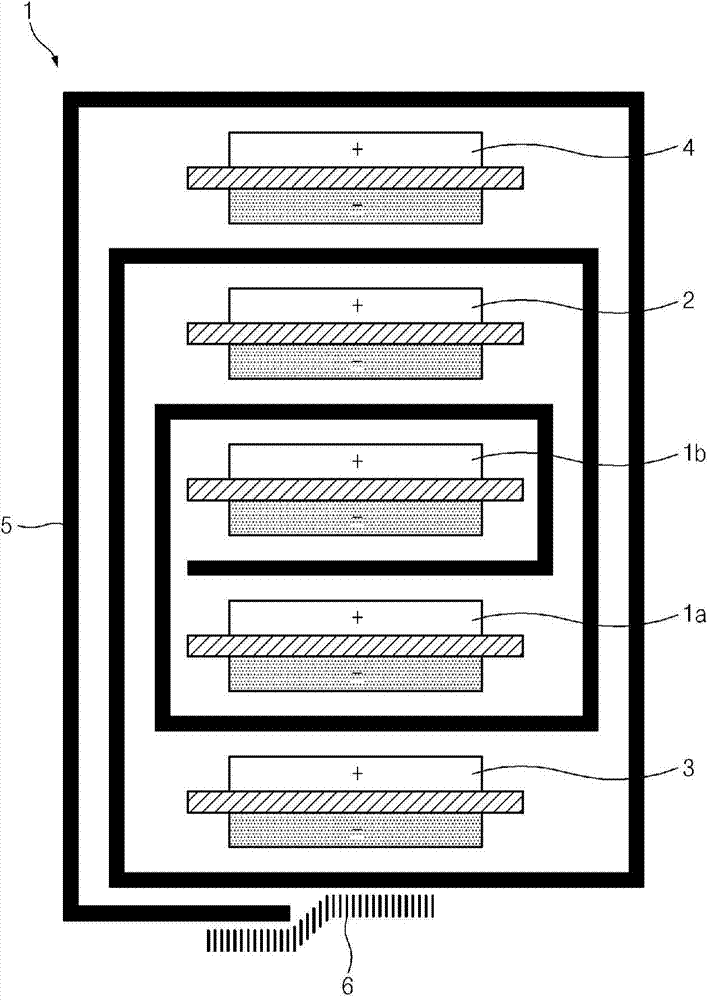

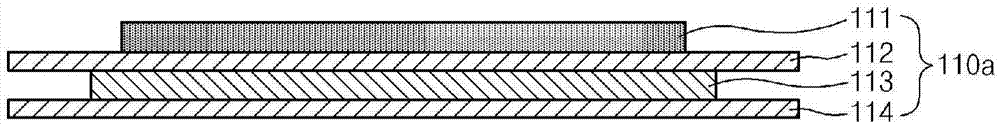

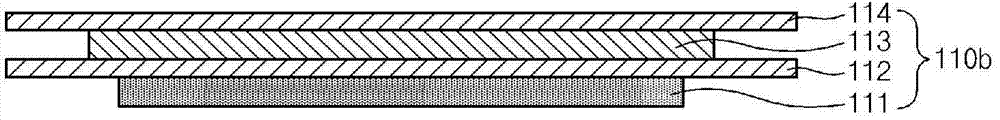

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited or limited to the following examples.

[0040] The terms or words used in this specification and the scope of claims should not be interpreted as ordinary or dictionary meanings, but should be based on the concept that the inventor can properly define the terms in order to explain his invention in the best way. Principles are interpreted as meanings and concepts consistent with the technical idea of the present invention.

[0041] For the convenience and clarity of description, the size of each structural element or a specific part constituting the structural element in the drawings is shown in an exaggerated, omitted or schematic manner. Therefore, the size of each structural element does not utterly reflect an actual size. In cases where it is judged that a detailed description of a relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com