Chemical mechanical polishing pad and chemical mechanical polishing method

A chemical mechanical and polishing pad technology, applied in the field of polishing, can solve problems such as uneven distribution of polishing pressure, local high-stress scratch damage, local stress peeling, etc., to reduce scratch damage and stress peeling, and reduce scratch damage defects , The effect of reducing the possibility of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

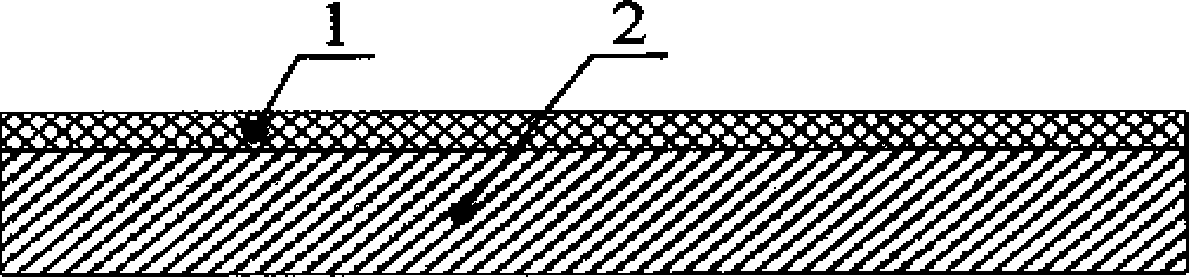

[0031] figure 1 For a specific embodiment of the chemical mechanical polishing pad of the present invention, select commonly used filter paper as the substrate layer 2, adopt the electrospinning method in the prior art to make a layer of nanofiber layer 1 on the surface of the substrate layer 2, the present embodiment The material of the nanofiber layer is polyvinylidene fluoride (PVDF), the thickness of the nanofiber layer is 4 μm, the average fiber diameter is 100 nm, and the fiber length is 20 cm. The polishing pad in Example 1 of the present invention is constituted by the nanofiber layer 1 and the substrate layer 2 .

Embodiment 2

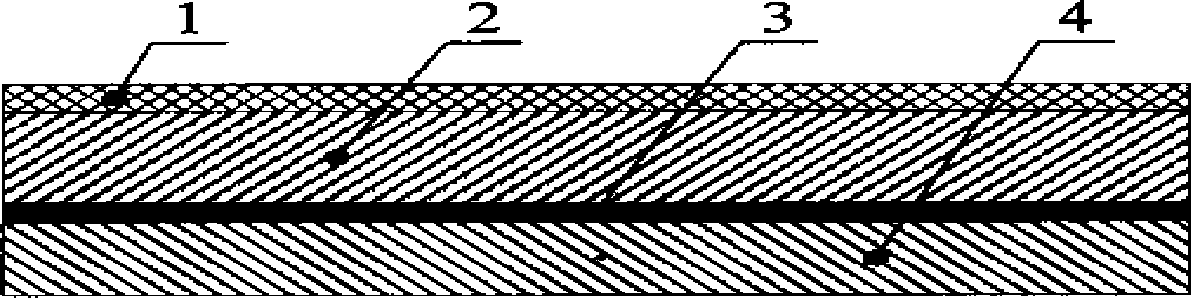

[0033] figure 2 For another specific embodiment of the chemical mechanical polishing pad of the present invention, select the IC1000 polishing pad of Rohm & Haas (Rohm & Haas, the U.S.) as the subpad 4, use the double-sided pressure-sensitive adhesive tape 3 of 3M (3M, the U.S.) The polishing pad in Example 1 of the present invention (consisting of nanofiber layer 1 and substrate layer 2 ) and the sub-pad 4 are connected together to form the polishing pad in Example 2 of the present invention.

Embodiment 3

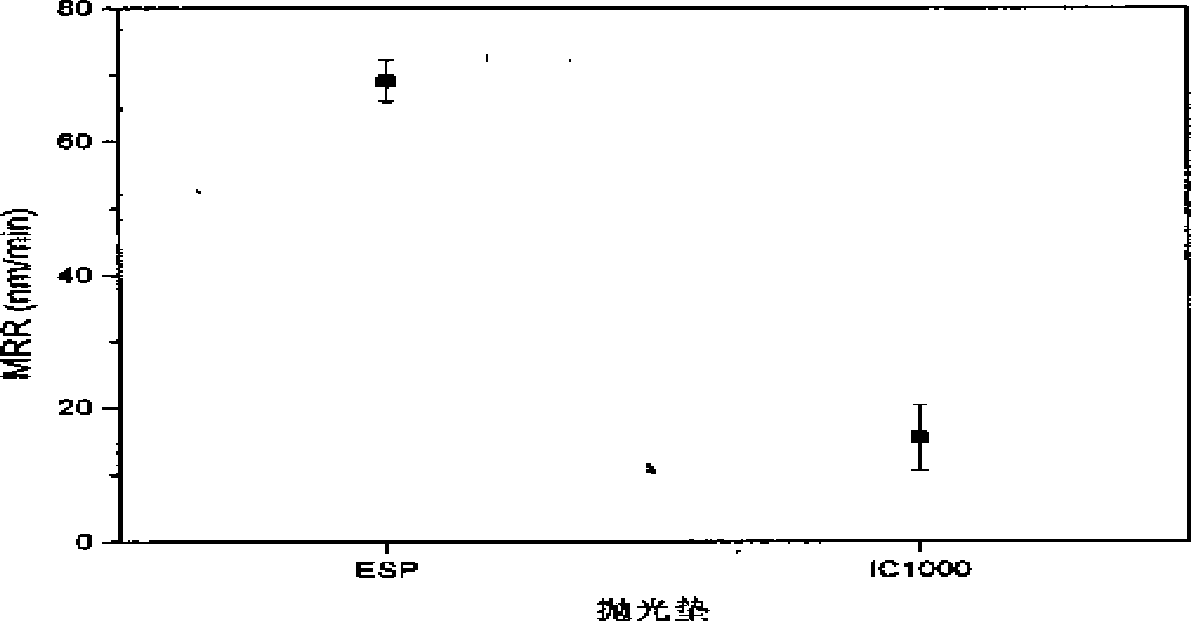

[0035]A kind of specific embodiment of the polishing pad using method of the present invention, use the polishing pad (ESP polishing pad) prepared in the embodiment of the present invention 2, utilize the chemical mechanical polishing equipment that Tsinghua University State Key Laboratory of Tribology makes, cooperate Fujimi 7105 ( Fujimi 7105, Japan) polishing liquid for copper, the pure copper sheet of diameter 12.5mm is polished, and process parameter is as follows:

[0036] Speed (head / plate): 300 / 50RPM

[0037] Eccentric distance: 9mm

[0038] Pressure: 0.5psi

[0039] Polishing fluid dilution ratio: 1:9

[0040] Polishing liquid flow rate: 60mL / min

[0041] Polishing time: 5min

[0042] The performance of the polishing pad prepared in Example 2 of the present invention was evaluated by the material removal rate MRR of the copper sheet being polished and the change in roughness value Ra before and after polishing. Use a Sartorius (Germany) ME235S electronic balanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com