Improved type porous granular ammonium nitrate fuel oil explosive and preparing method thereof

An ammonium oil explosive, an improved technology, applied in the direction of explosives, etc., can solve the problems of easy volatility, poor storage stability, and rising raw material prices, and achieve the effects of reducing toxic gas content, reducing production costs, and high combustion utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments.

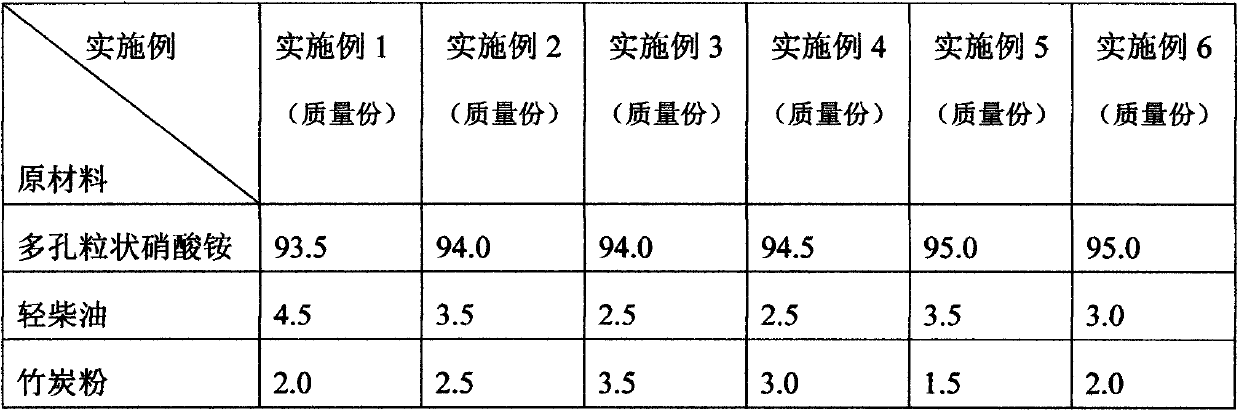

[0035] Each embodiment of table 2 makes proportioning table

[0036]

[0037] The manufacturing method of above 6 embodiments is identical, and concrete steps are as follows:

[0038] The first step, take a certain amount of porous granular ammonium nitrate (white, granular), light diesel oil (No. 0) and bamboo charcoal powder (particle diameter: 0.5mm~1.0mm) according to each embodiment component distribution ratio in table 2, and Pour into each batching tank respectively.

[0039] Among them, the bamboo charcoal powder is obtained by carbonizing and pulverizing bamboo materials under the condition that the carbonization end temperature is 700°C to 800°C.

[0040] In the second step, add all the weighed porous granular ammonium nitrate into the dispersing mixer, turn on the dispersing mixer for low-speed stirring, and control the stirring speed at 60 rpm to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com