Biofouling-proof nylon copper composite material and preparation method thereof

A composite material and nylon technology, which is applied in the field of anti-biofouling nylon-copper composite material and its preparation, can solve the problems of difficult material processing, difficulty in reaching a critical exudation rate, increased material cost, etc., and achieves easy operation and composition. Simple, low material cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

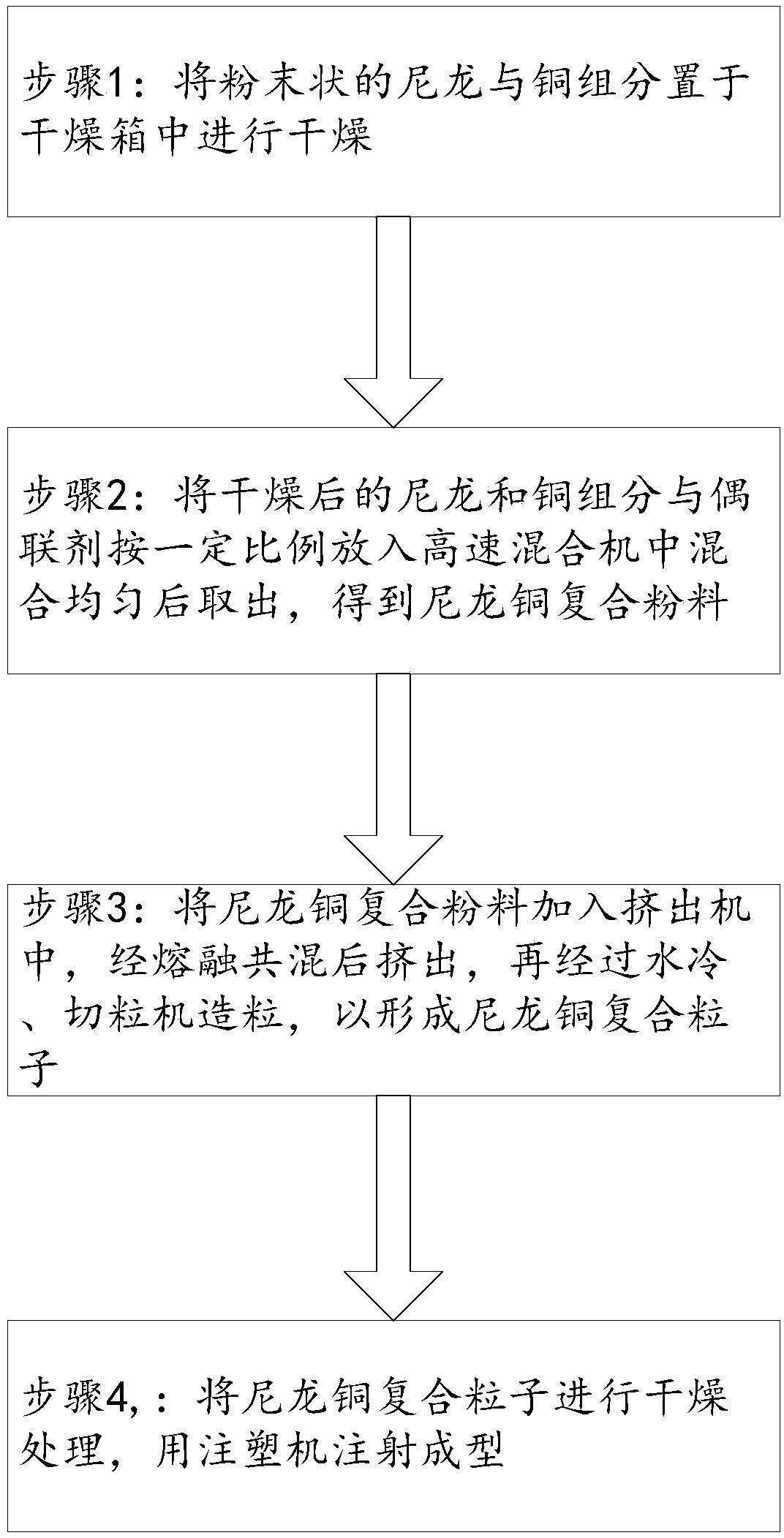

[0029] In addition, if figure 1 As shown, the present invention also proposes a preparation method of an anti-biofouling nylon-copper composite material, which is used to prepare the above-mentioned anti-biofouling nylon-copper composite material, comprising the following steps:

[0030] Step 1: Place the powdered nylon and copper components in a drying oven for drying;

[0031] Step 2: Put the dried nylon and copper components and the coupling agent in the mass proportion: 0.5%-10% copper component, 0.1-1% coupling agent and 89%-99.4% nylon Take out after mixing evenly in a high-speed mixer to obtain nylon-copper composite powder;

[0032] Step 3: adding nylon-copper composite powder into the extruder, extruding after melt blending, and then passing through water cooling and pelletizing to form nylon-copper composite particles;

[0033] Step 4: Drying the nylon-copper composite particles and injecting them with an injection molding machine.

[0034] In this embodiment, the...

Embodiment 1

[0041] A nylon-copper composite material comprises the following components: copper oxide, with a mass fraction of 10%; a silane coupling agent, with a mass fraction of 1%; and the balance of nylon 6. Copper oxide is added in powder form with an average particle size of 100 mesh. The ingredients in the formula are dried, mixed uniformly, then extruded with a twin-screw extruder, granulated and then injection-molded to obtain a nylon-copper composite material. The strength of the prepared nylon-copper composite material is 65MPa, and it has been used in seawater for 2 years without marine biofouling.

Embodiment 2

[0043] A nylon-copper composite material is composed of: cuprous oxide, with a mass fraction of 10%; a silane coupling agent, with a mass fraction of 1%; and the balance of nylon 6. Cuprous oxide is added in powder form, and the average particle size of the powder is 100 mesh sieve. The ingredients in the formula are dried, mixed uniformly, then extruded with a twin-screw extruder, granulated and then injection-molded to obtain a nylon-copper composite material. The strength of the prepared nylon-copper composite material is 65MPa, and it has been used in seawater for 2 years without marine biofouling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com